Magnesium oxychloride cement coating for exterior walls and preparation method of coating

A technology for magnesium oxychloride cement and exterior wall coatings, applied in the field of coatings, can solve the problems of wasting manpower, material and financial resources, difficult construction, peeling off into pieces, etc., and achieves the effects of convenient construction and operation, good fire resistance and good cold resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

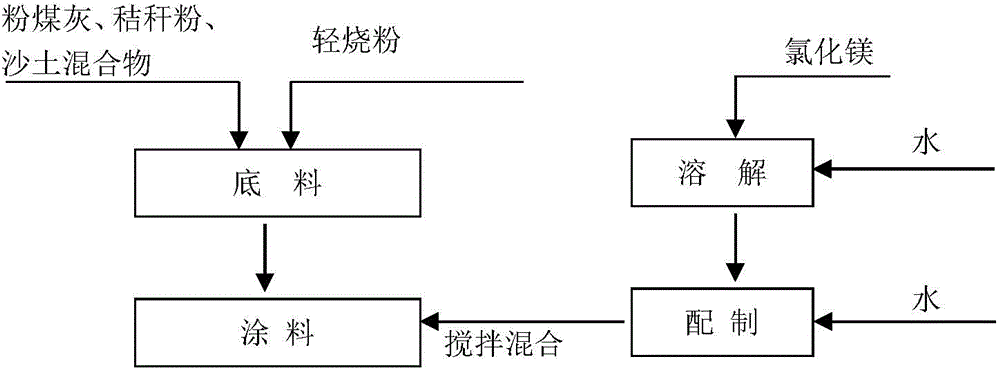

[0020] The magnesium oxychloride cement exterior wall coating of the present embodiment comprises multiple components, and every kind of component adds and mixes according to mass ratio, and the step of this magnesium oxychloride cement exterior wall coating comprises the steps:

[0021] A. combined figure 1 As shown, 100 parts of lightly burnt powder, 8 parts of fly ash, 60 parts of straw, and 55 parts of sand and soil mixture are stirred and mixed to form a base material. Wherein, the length of the straw is crushed to less than 0.5 cm; the sand-soil mixture is formed by mixing sand and soil at a mass ratio of 4.5:1.

[0022] B. Add 180 parts of magnesium chloride aqueous solution with a mass fraction of 23 to the base material, and stir again to form a coating on the outer wall.

[0023] Apply the coating obtained in this example to the surface of the exterior wall with a coating thickness of 5 mm. After curing for a period of time and after the water evaporates and dries u...

Embodiment 2

[0025] The difference between this embodiment and embodiment 1 is the proportional relationship between the components,

[0026] In this embodiment, 100 parts of lightly burned powder, 18 parts of fly ash, 30 parts of straw, and 70 parts of sand and soil mixture are mixed to form a base material, and then 130 parts of magnesium chloride aqueous solution with a mass fraction of 20 are added and mixed evenly again. Get paint. Other steps are described with reference to embodiment 1.

[0027] Wherein, the sand-soil mixture is formed by mixing sand and soil at a mass ratio of 2:5; of course, in other embodiments, the straw can also be replaced by sawdust, and the fly ash can also be replaced by silica fume. It is better to control the mass ratio of the lightly burnt powder, fly ash or silica fume, straw or sawdust, sandy soil mixture, and magnesium chloride aqueous solution within the range of 100:8-18:30-60:55-70:130-180.

[0028] Apply the paint obtained in this example to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com