Preparation method of Y-shaped hot-pressed three-way pipe fitting

A technology of tee and mold pressing, which is used in mechanical equipment, branch pipelines, pipes, etc., can solve the problems of difficulty in making special molds, high production costs, complex processing processes, etc. Low, reasonable channel streamline effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

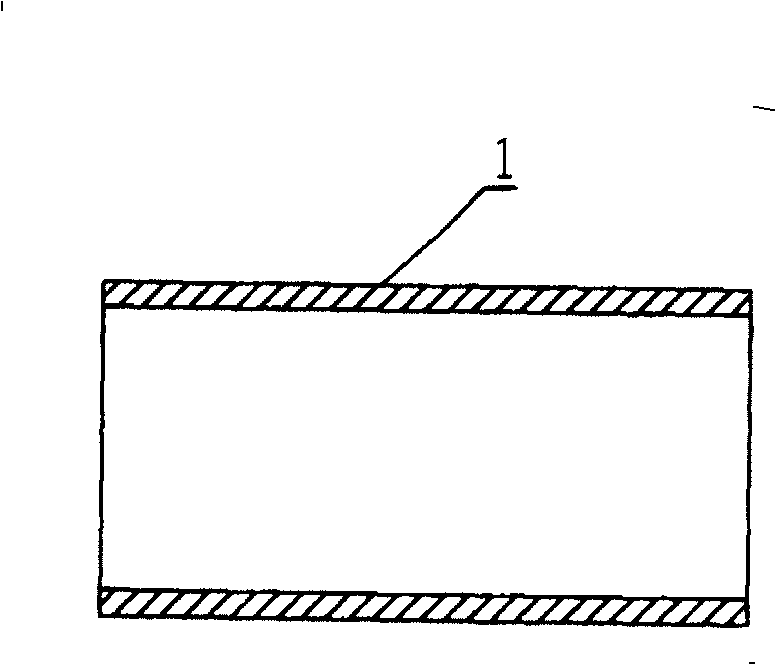

[0025] a. Billet selection: seamless steel pipe material: No. 20 steel; specification: Dn100mm, wall thickness is 10mm;

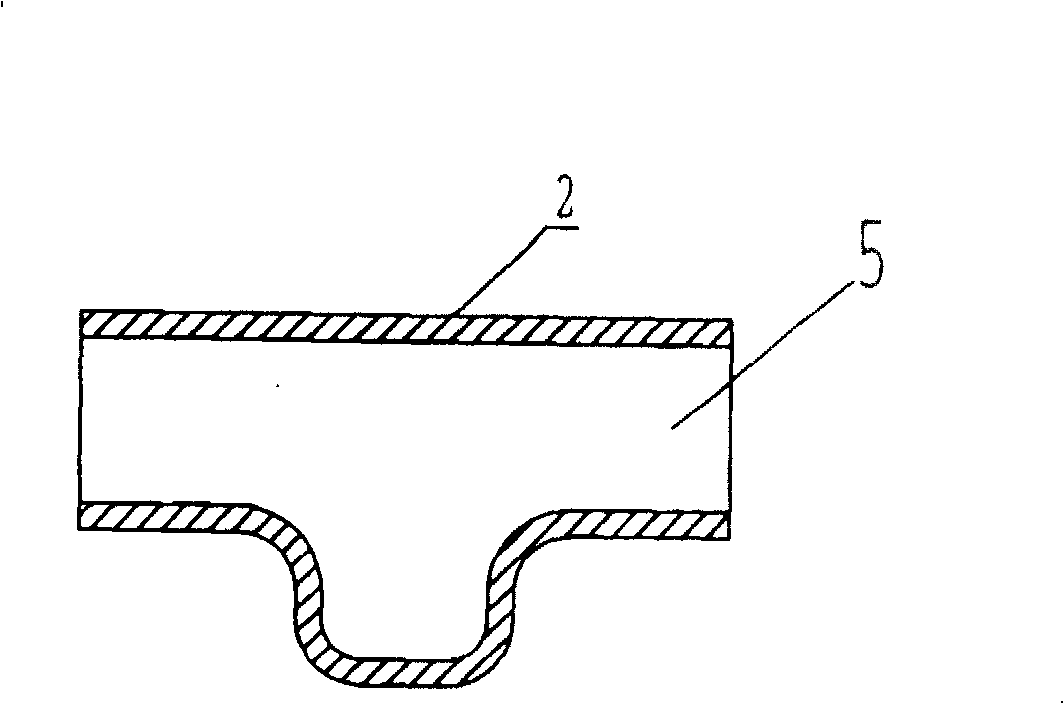

[0026] b. Hot pressing: heat the billet to 980-1050°C, and press it into a T-shaped tee-shaped billet in a T-shaped tee mold;

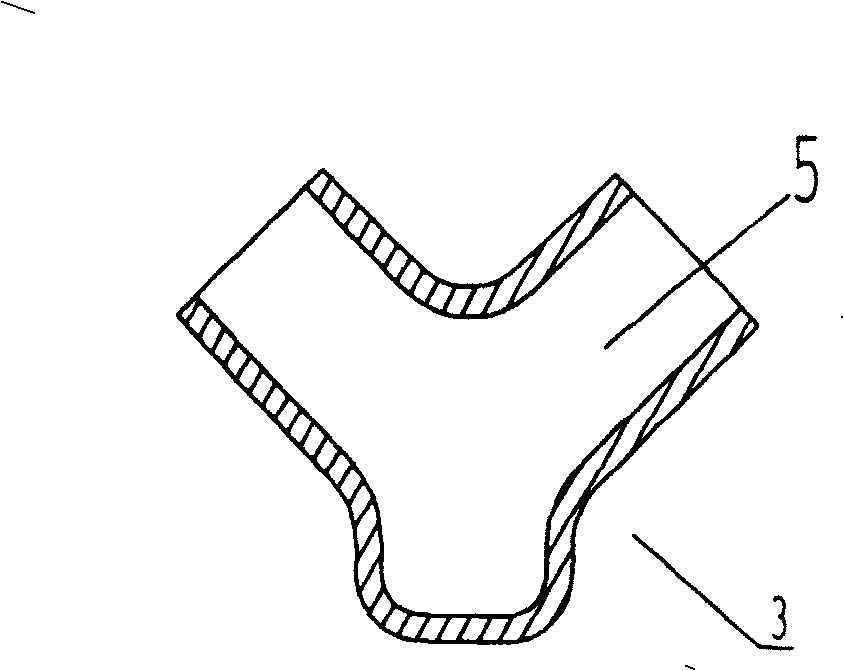

[0027] c. Curved shape: heat the hot-pressed T-shaped tee-shaped blank to 950-1050°C, and bend the main pipe on the short-radius elbow mold to make a 90°Y-shaped tee-shaped blank;

[0028] d. Machining: remove the margin at each end of the Y-shaped tee shape blank, and perform groove machining on the port.

Embodiment 2

[0030] a. Billet selection: seamless steel pipe material: 12Cr1MoV steel; specification: Dn1000mm, wall thickness 80mm

[0031] b. Hot pressing: heat the billet to 1000-1100°C, and press it into a T-shaped tee-shaped billet on a T-shaped tee mold;

[0032] c. Curved shape: reheat the hot-pressed T-shaped tee-shaped blank to 1000-1100°C, bend the main pipe on the short-radius elbow mold, and make it into a Y-shaped tee-shaped blank;

[0033] d. Machining: remove the margin at each end of the Y-shaped tee shape blank, and perform groove machining on the port.

Embodiment 3

[0035] a. Billet selection: seamless steel pipe material: 0Cr18Ni9 steel; specification: Dn300mm, wall thickness 30mm;

[0036] b. Hot pressing: heat the billet to 1000-1200°C, and press it into a T-shaped tee-shaped billet in a T-shaped tee mold;

[0037] c. Curved shape: reheat the hot-pressed T-shaped tee-shaped blank to 1100-1200°C, bend the main pipe on a short-radius elbow mold, and make it into a Y-shaped tee-shaped blank;

[0038] d. Machining: remove the margin at each end of the Y-shaped tee shape blank, and perform groove machining on the port.

[0039] The finished Y-shaped tee still needs to undergo various corresponding tests on mechanical properties and metallurgy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com