Composite middle layer and method for brazing boron carbide composite ceramic and titanium alloy through composite middle layer

A technology of composite intermediate layer and composite ceramics, used in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of large residual stress of joints, difficult welding of ceramic materials, cracking, etc., and achieve excellent bending strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

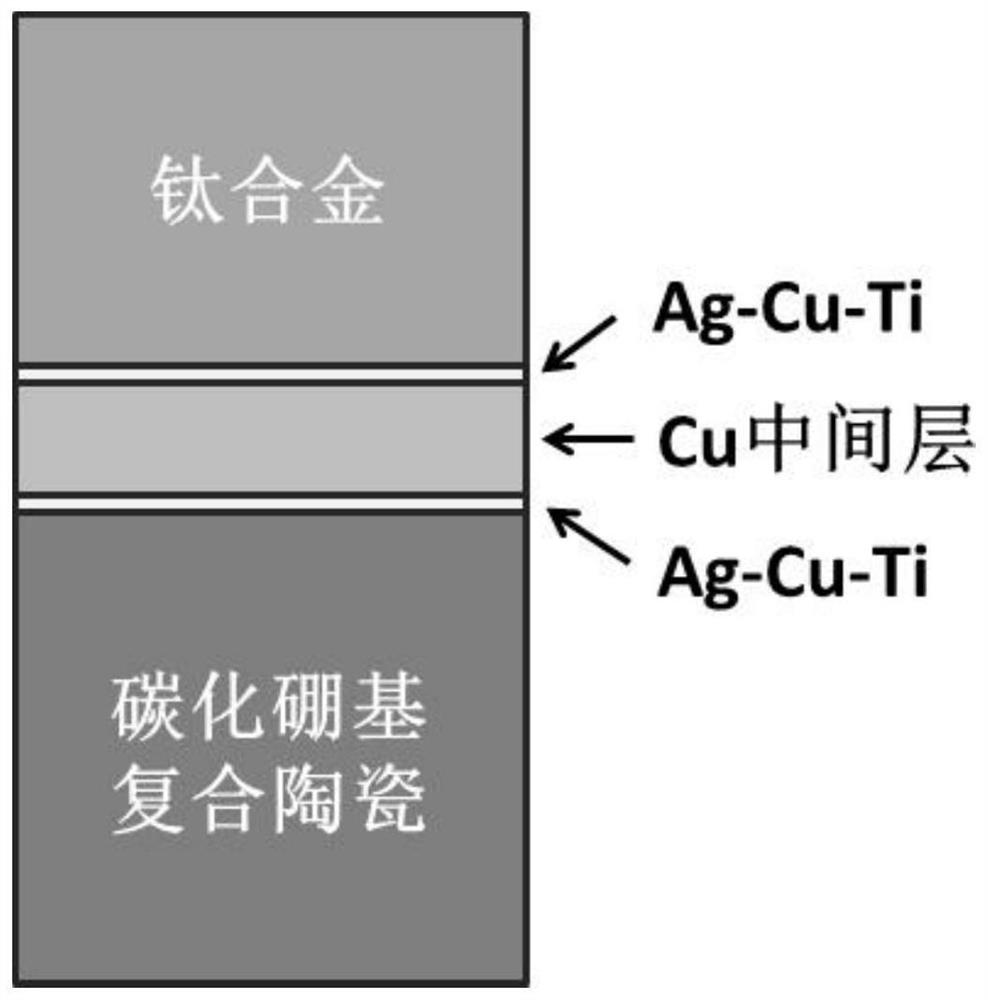

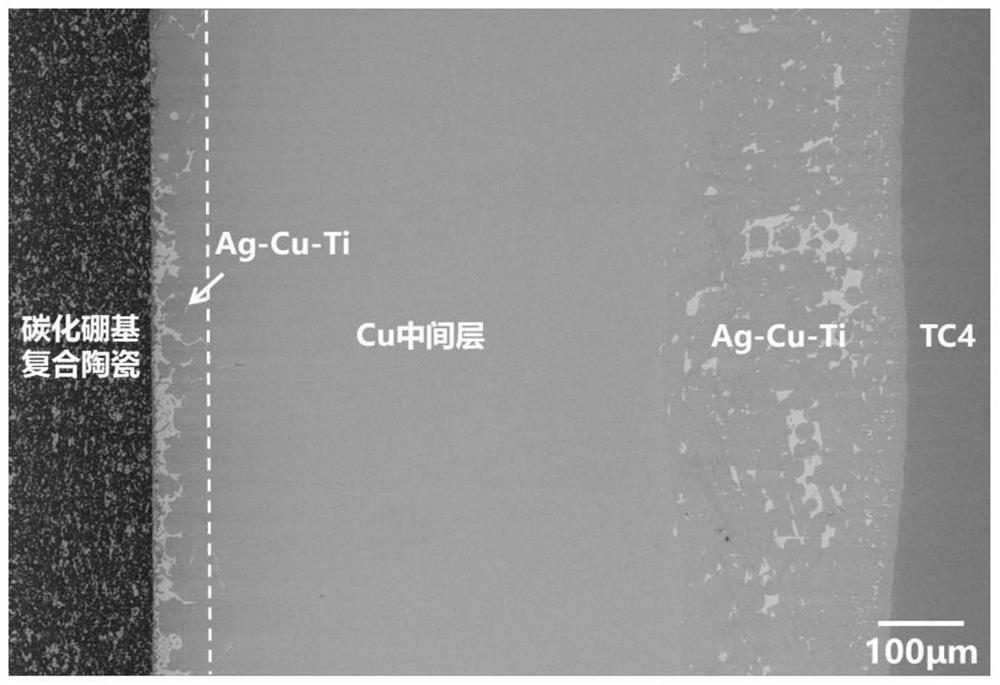

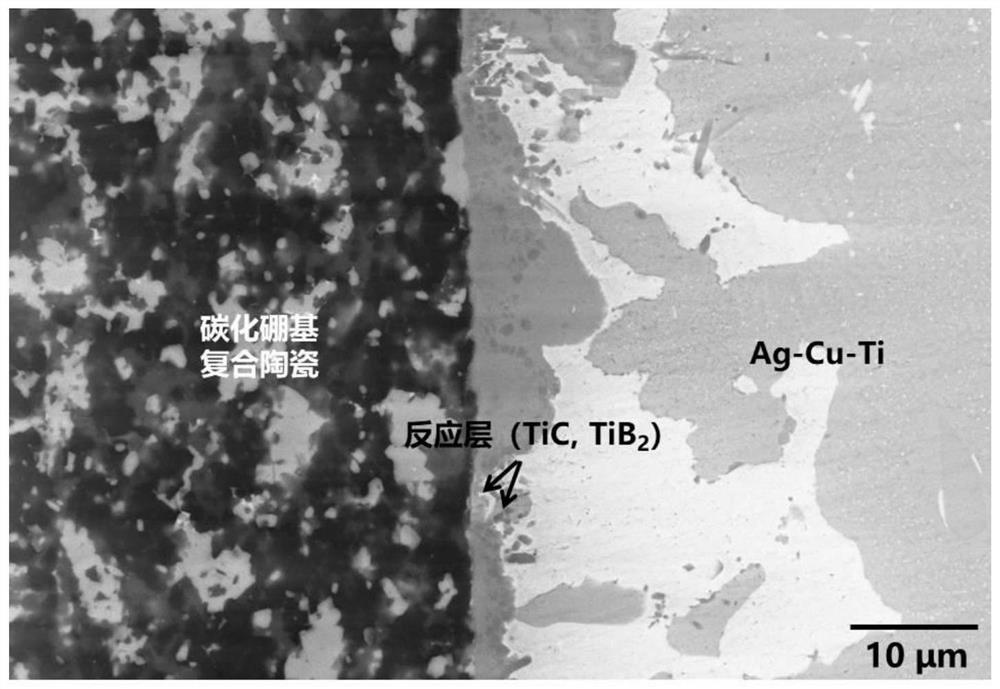

[0028] A composite middle layer is composed of an upper solder layer, a middle metal layer and a lower solder layer; both the upper and lower solder layers are made of Ag-Cu-Ti solder, and the material of the middle metal layer is copper. The composite intermediate layer in the present invention is represented by "Ag-Cu-Ti / Cu / Ag-Cu-Ti".

[0029] Among them, the Ag-Cu-Ti solder is a solder foil, the mass fractions of Ag, Cu, and Ti in the Ag-Cu-Ti solder are 68.8%, 26.7%, and 4.5%, respectively, and the size is 8mm×8mm×0.07mm ;Copper is copper foil, the purity of copper is 99.95%, the size is 8mm×8mm×0.8mm;

[0030] A method for brazing boron carbide composite ceramics and titanium alloys using the composite intermediate layer, specifically comprising the following steps:

[0031] 1) Polish the surface to be welded of boron carbide composite ceramics, titanium alloy, Ag-Cu-Ti solder and copper with SiC sandpaper, so that the surface roughness of the material is Ra≤5 μm;

[00...

Embodiment 2

[0039] This embodiment is the same as Embodiment 1, the only difference lies in step 4, the brazing temperature during brazing is 810°C.

[0040] After testing, the three-point bending strength of the brazed joint obtained in this embodiment is 69 MPa.

Embodiment 3

[0042] This embodiment is the same as Embodiment 1, the only difference lies in step 4, the brazing temperature during brazing is 830°C.

[0043] After testing, the three-point bending strength of the brazed joint obtained in this embodiment is 74 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com