Method for preparing bimetal composite plate by stirring friction braze welding

A friction stir and metal plate technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large free shrinkage of aluminum, poor flexibility, slow heating/cooling speed, etc., and achieve good interface uniformity, Avoid direct contact and avoid the effect of remaining keyholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

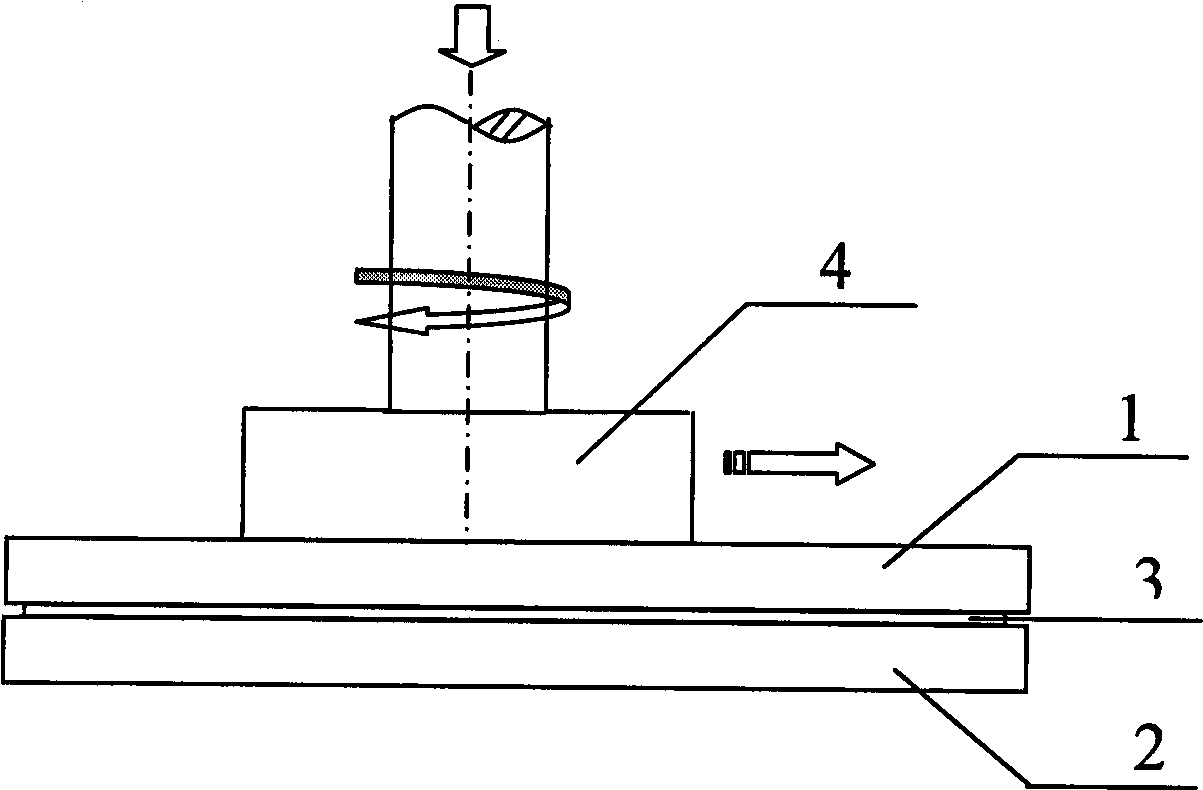

[0068] see figure 1 , a method for preparing a bimetal composite plate by friction stir brazing, the cladding metal plate 1 and the base metal plate 2 are horizontally fixed on the work table in the form of overlapping; between the cladding metal plate 1 and the base metal plate 2 The solder 3 that can undergo eutectic reaction with one of the two plates is preset; the friction tool 4 arranged on the upper surface of the cladding metal plate 1 is a needle-free cylindrical friction tool, and the distance between the needle-free cylindrical friction tool 4 and the normal line of the two plates is The angle of inclination is 1-5°; the needle-free cylindrical friction tool 4 is rotated and slowly pressed until the end of the needle-free cylindrical friction tool 4 is in contact with the upper surface of the cladding metal plate 1; then the needle-free cylindrical friction tool 4. Friction on the upper surface of the cladding metal plate 1 in situ or moving along the welding direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com