Al-Ti alloy dissimilar metal welding method

A technology of dissimilar metals and welding methods, which is applied in the field of invention related to excitation, can solve problems such as welding difficulties and reduce the service life of welded parts, and achieve the effects of avoiding the formation of Al-Ti brittle phases, solving difficulties in welding, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The Al alloy powder used in Example 1 is A6061-T6 aluminum alloy powder, and the Ti alloy powder is TC4 titanium alloy powder. Example 1 uses a direct welding method of A6061-T6 aluminum alloy and TC4 titanium alloy dissimilar metals. The specific steps are as follows:

[0023] (1) Polish the welding surface of the metal to be welded until the oxide film on the surface is removed.

[0024] (2) Use laser welding to directly weld A6061-T6 aluminum alloy and TC4 titanium alloy. The welding process parameters are laser power 350W, laser control current 50A, pulse width 15ns, and pulse frequency 8Hz.

[0025] (3) Test the tensile properties of the dissimilar metal weldments directly welded by A6061-T6 aluminum alloy and TC4 titanium alloy as comparative group 1.

Embodiment 2

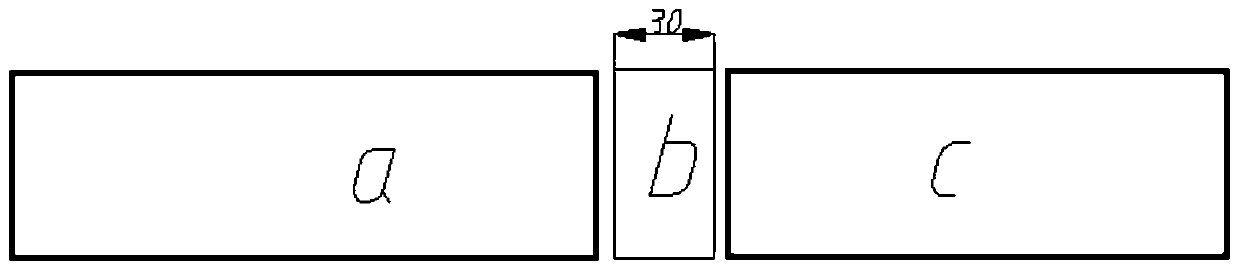

[0027] The Al alloy powder used in Example 2 is A6061-T6 aluminum alloy powder, and the Ti alloy powder is TC4 titanium alloy powder. This example uses the method described in this method for welding Al-Ti alloy dissimilar metals with gradient changes in transition metal composition , The length of the transition metal is 30mm, the number of layers is N=600, the specific dimensions of the substrate and the transition metal plate are as follows figure 2 Shown.

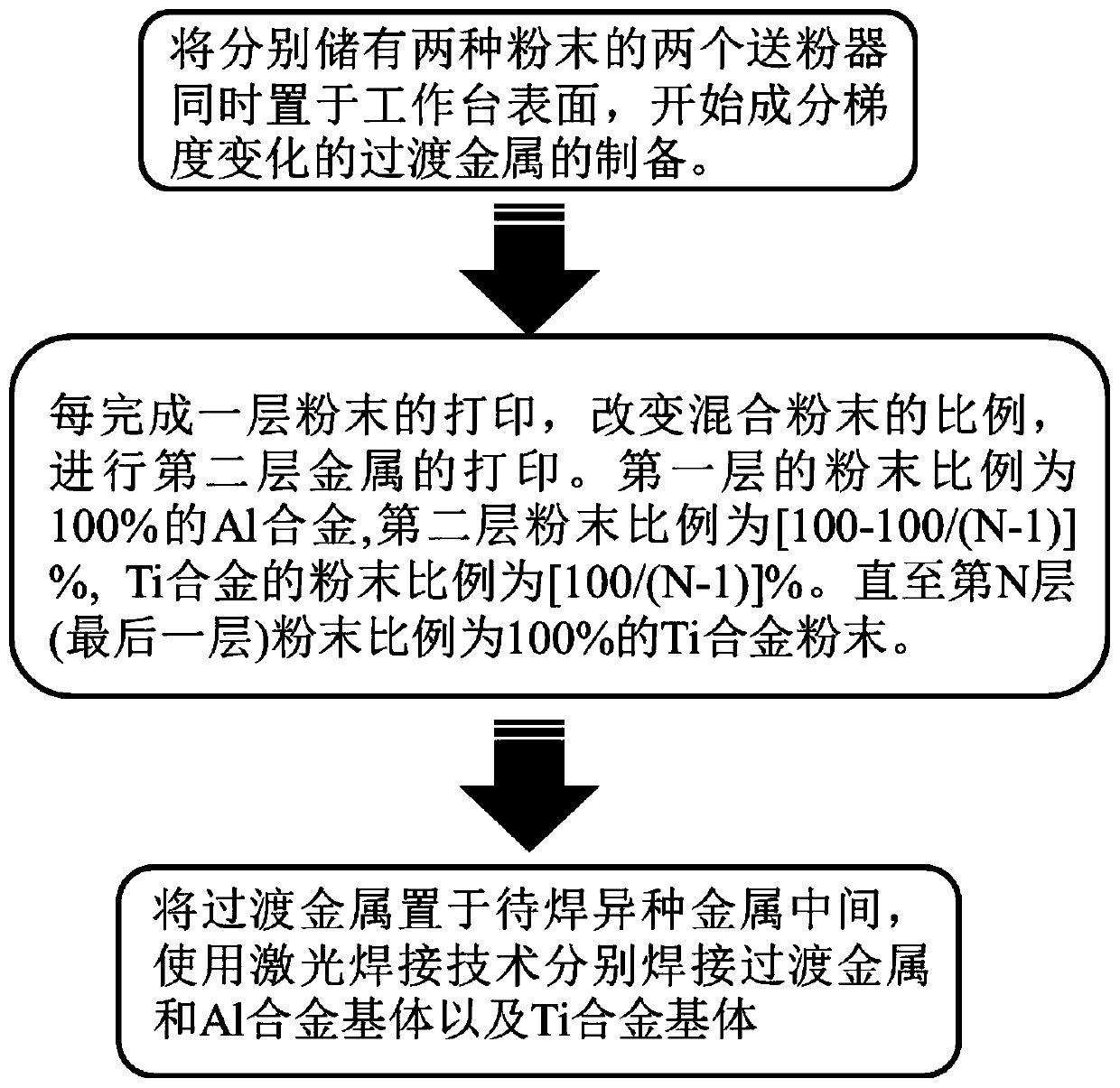

[0028] An example of an Al-Ti alloy dissimilar metal welding method with a gradient change of transition metal composition, the steps are:

[0029] (1) Two powder feeders respectively storing two powders are placed on the surface of the worktable at the same time, and the preparation of the transition metal plate with a gradient of composition is started. The parameters of laser additive manufacturing are: laser power 300W, spot diameter is 0.12mm, and each layer of additive is 0.05mm.

[0030] (2) Each time the printing of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com