Treatment method for aluminium-alloy synergistic fluoropolymer coating with high-temperature viscosity resistance

A fluoropolymer, coating treatment technology, applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of affecting the use of aluminum alloy, affecting the production efficiency of bag making, strong high temperature viscosity, etc., to improve production Efficiency, high hardness, good light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

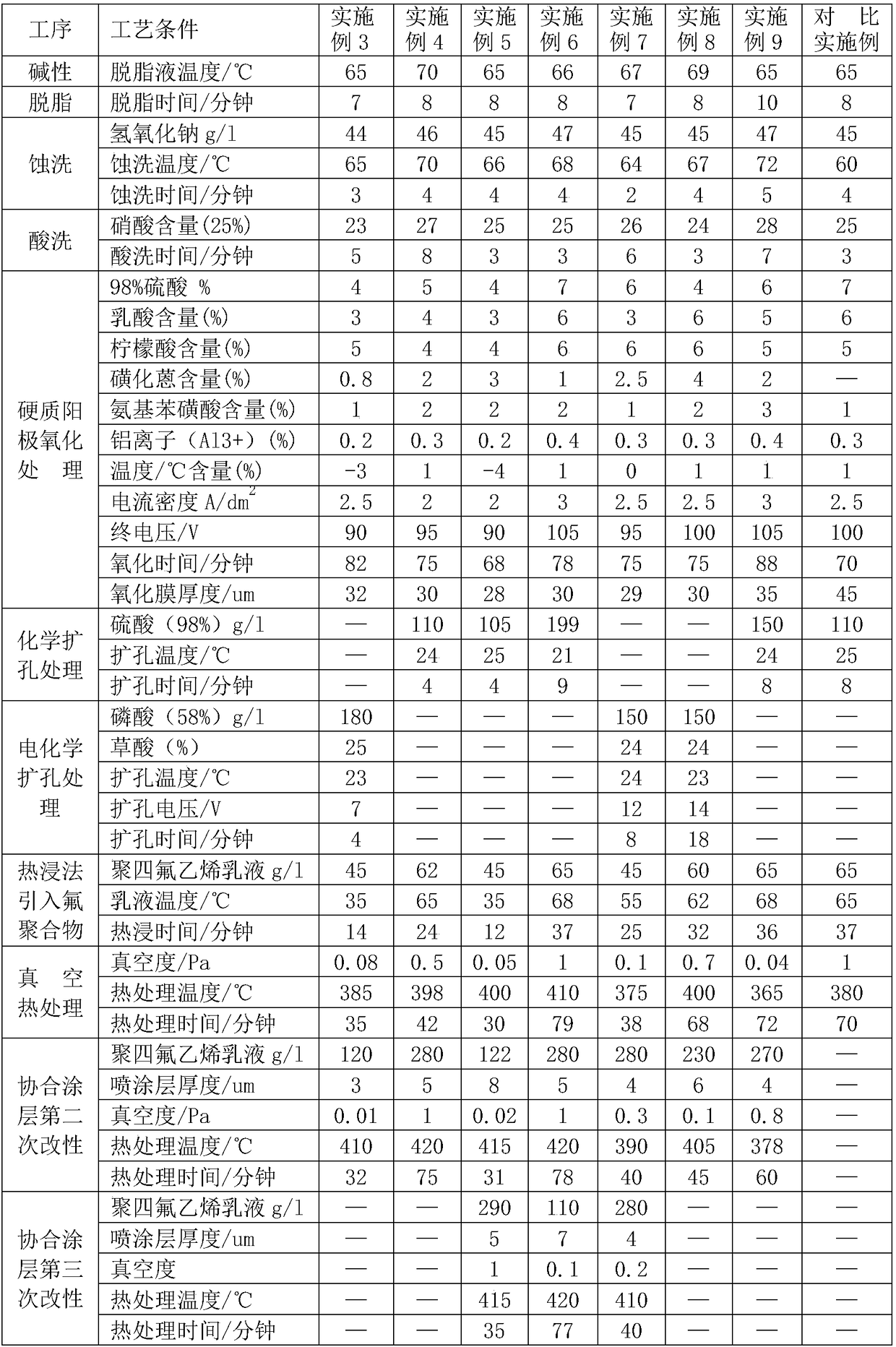

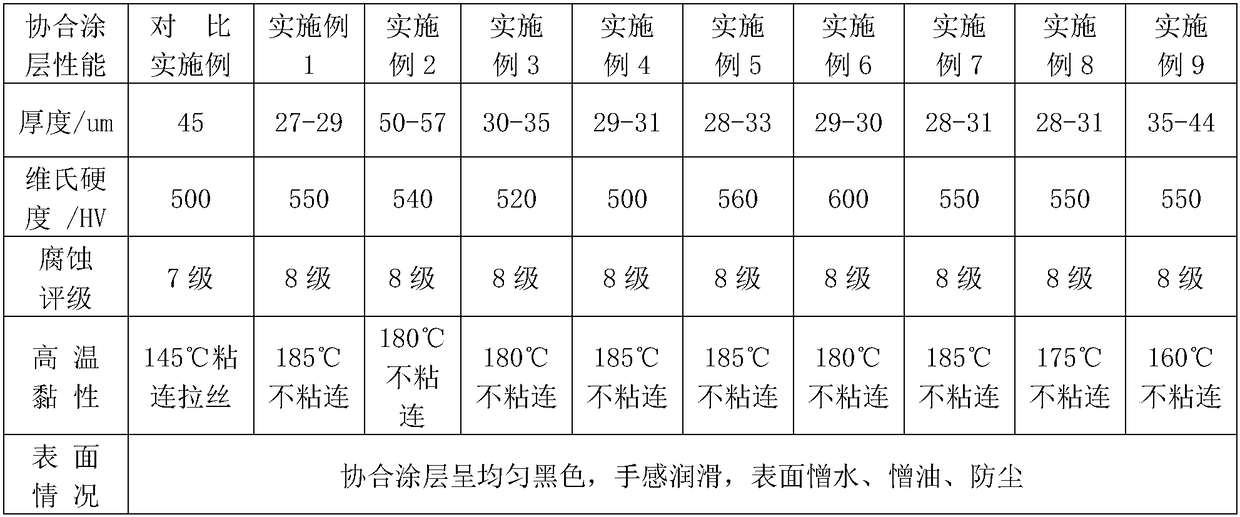

[0024] Take a 7075 aluminum alloy (Al-Zn-Mg-Cu super duralumin) mold sample for non-PVC bags, degrease it with an alkaline degreasing solution at 61°C for 8 minutes, wash it with water, and place it in 42g / l hydrogen peroxide Etch and wash at 62°C for 3 minutes in sodium solution to remove the oxide film on the surface of the aluminum alloy, and obtain the aluminum alloy mold sample after etching; put the above-mentioned etched aluminum alloy mold sample in 21% nitric acid solution for pickling Light treatment for 3 minutes, remove the hanging ash and residues produced by pickling, and obtain the aluminum alloy mold sample after pickling;

[0025]The aforementioned aluminum alloy mold sample after pickling was placed in a mixed acid solution for hard anodic oxidation treatment, and after washing with water, an aluminum alloy hard anodized film was obtained (the inventor observed that the aluminum alloy hard anodized film was very uniform); Among them, the content of sulfuric a...

Embodiment 2

[0030] Take 7A04T6 (Al-Zn-Mg-Cu super duralumin) aluminum alloy mold sample, degrease with alkaline degreasing solution at 74°C for 9 minutes, wash with water and place in 49g / l sodium hydroxide solution at 73°C Etching and washing for 5 minutes to remove the oxide film on the surface of the aluminum alloy to obtain an aluminum alloy mold sample after etching and washing; placing the aforementioned aluminum alloy mold sample after etching and washing in 29% nitric acid solution for pickling and light treatment for 9 minutes, Remove the hanging ash and residues produced by pickling, and obtain the aluminum alloy mold sample after pickling;

[0031] The aforementioned aluminum alloy mold sample after pickling was placed in a mixed acid solution for hard anodic oxidation treatment, and after washing with water, an aluminum alloy hard anodized film was obtained (the inventor observed that the aluminum alloy hard anodized film was very uniform); Among them, the content of sulfuric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com