Hulling separation method for rapeseeds and special separation device

A separation method and separation device technology, applied in solid separation, chemical instruments and methods, fat oil/fat production, etc., can solve the problems of low shelling rate, prone to seed leakage, and different grain sizes, and achieve the goal of kernel shell High separation efficiency, no kernel shell adhesion, good peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

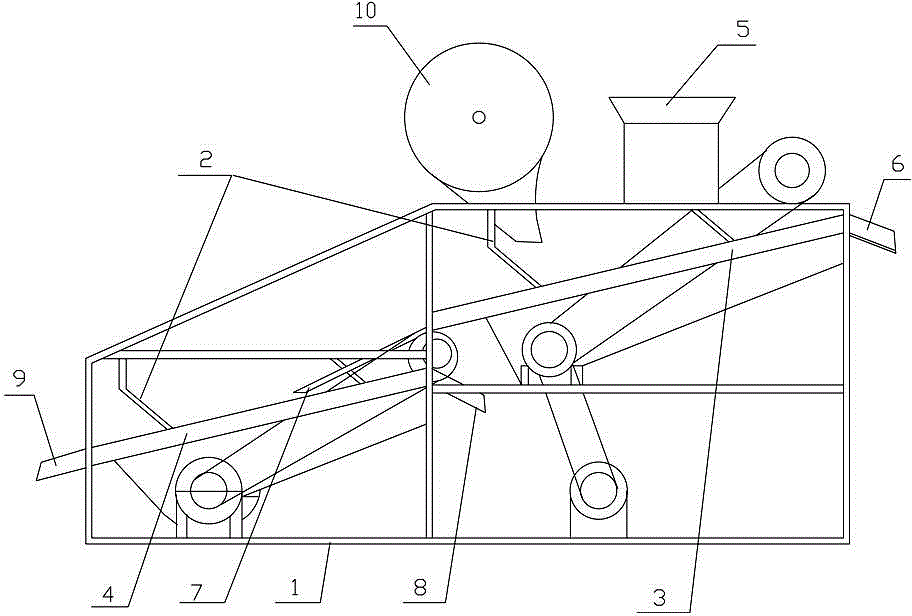

Image

Examples

Embodiment Construction

[0020] The peeling separation method of rapeseed of the present invention, it comprises the following steps:

[0021] The first step is to clean the raw materials of rapeseed, remove sand and vegetation impurities, and make the impurity rate ≤ 2%;

[0022] The second step is to dry the rapeseed after the impurity removal, the drying temperature is 160°C, and the moisture content of the dried rapeseed is 5-8%;

[0023] The third step is to cool the dried rapeseed oil to normal temperature, and remove metal impurities by magnetic separation;

[0024] The fourth step is to send the qualified rapeseed into the rapeseed shelling machine for shearing, crushing, and extruding into a shell-kernel mixture;

[0025] The fifth step is to send the mixture of shells and kernels to the separation screen in the special separation device. Under the joint action of the vibrating screen and the fan, the shells with low density in the upper layer are removed by the fan, and the seeds with high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com