Anti-counterfeit printing device and method

A technology of anti-counterfeiting printing and printing table, applied in printing, printing machine, printing process and other directions, can solve the problems of affecting the quality of printing, unable to print continuously, low work efficiency, etc., to improve drying speed, improve printing quality, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method of anti-counterfeiting printing. The ink used in the printing machine is ultraviolet-induced color-changing anti-counterfeiting ink, and its components include: 35 parts of epoxy resin, 10 parts of phenolic resin, 12 parts of ultraviolet fluorescent powder, 6 parts of dispersant, and 4 parts of defoaming agent , 8 parts of calcium carbonate, 13 parts of ethyl acetate, 12 parts of Virahol; The preparation method of anti-counterfeiting printing ink comprises the following steps: a) weighing, the proportioning weighing material of each composition described in claim 2 is standby; b ) stirring, stirring epoxy resin, phenolic resin, ethyl acetate and isopropanol evenly, stirring at 500r / min for 40min; c) tempering, adding ultraviolet fluorescent powder, dispersant, defoamer, calcium carbonate b) Stir the obtained material for 50 min at 1000 r / min to obtain the finished ink.

Embodiment 2

[0029] Method step is the same as embodiment 1, and different processing parameters are as follows:

[0030] 40 parts of epoxy resin, 15 parts of phenolic resin, 15 parts of ultraviolet fluorescent powder, 8 parts of dispersant, 5 parts of defoamer, 10 parts of calcium carbonate, 15 parts of ethyl acetate, 15 parts of isopropanol;

Embodiment 3

[0032] Method step is the same as embodiment 1, and different processing parameters are as follows:

[0033] 30 parts of epoxy resin, 5 parts of phenolic resin, 8 parts of ultraviolet fluorescent powder, 3 parts of dispersant, 2 parts of defoamer, 4 parts of calcium carbonate, 10 parts of ethyl acetate, 8 parts of isopropanol;

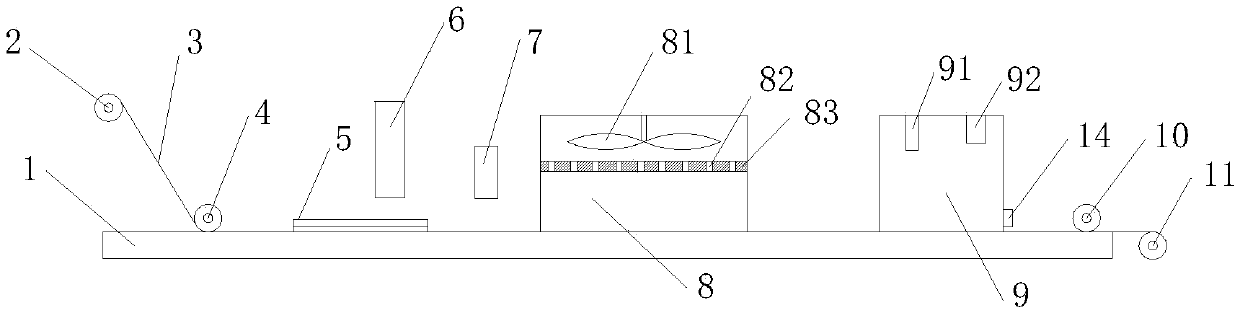

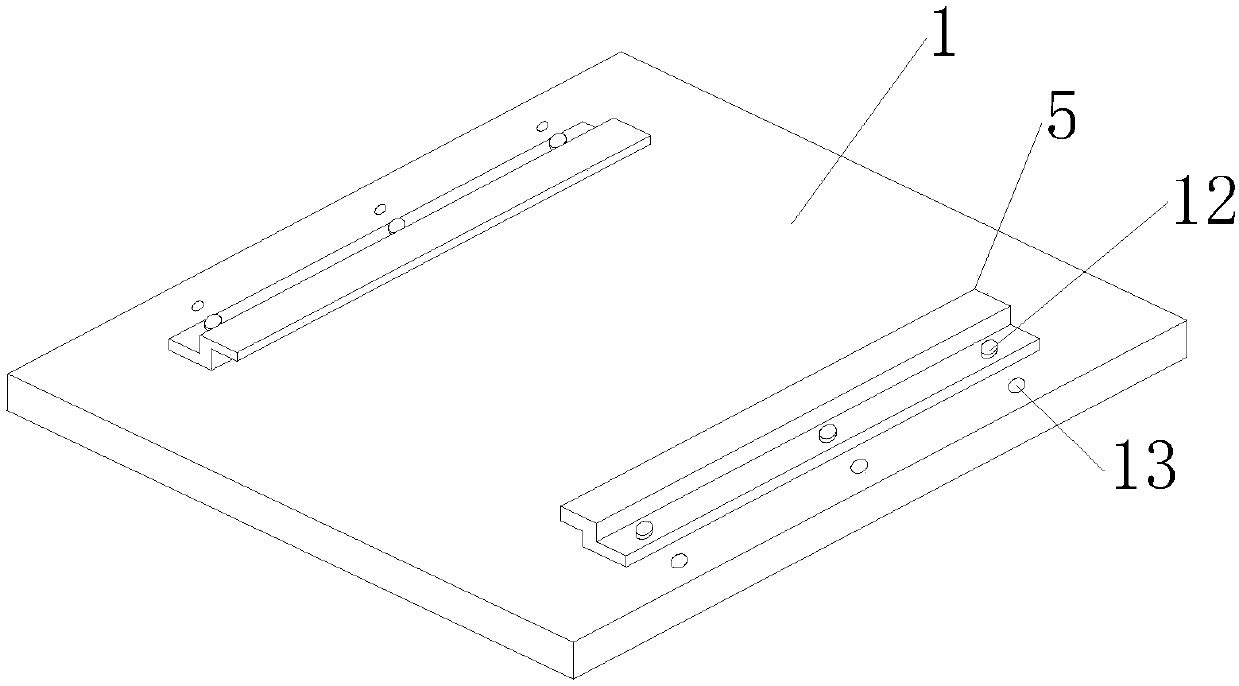

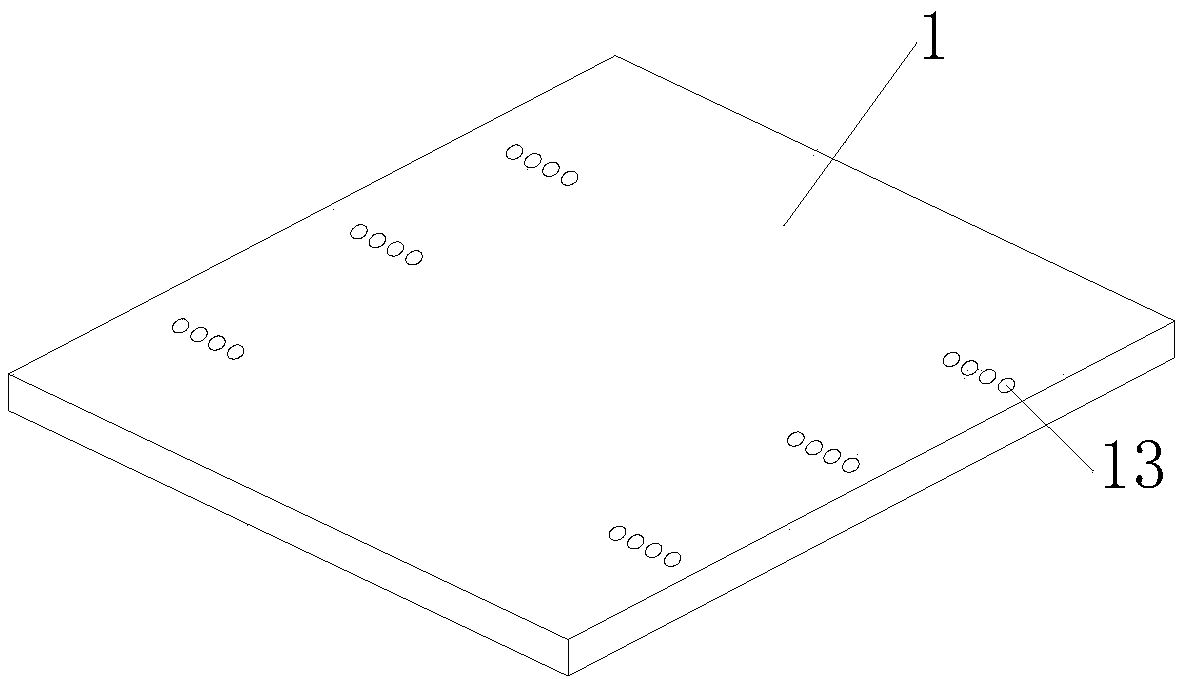

[0034]The printing table 1 is provided with a positioning block 5, which fixes the position of the printing paper 3 and improves the printing accuracy of the printing machine. At the same time, the fixing block 5 cooperates with the first pressure roller 4 to make the printing paper 3 more flat without curling , to improve the printing quality; the right side of the printing machine 6 is provided with a photoelectric sensor 7, which can effectively obtain the transmission speed of the printing paper 3, and then by adjusting the speed of the driving motor connected to the paper feed roller 2 and the roll roller 11, it can avoid the The excessive speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com