Patents

Literature

52results about How to "No curling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

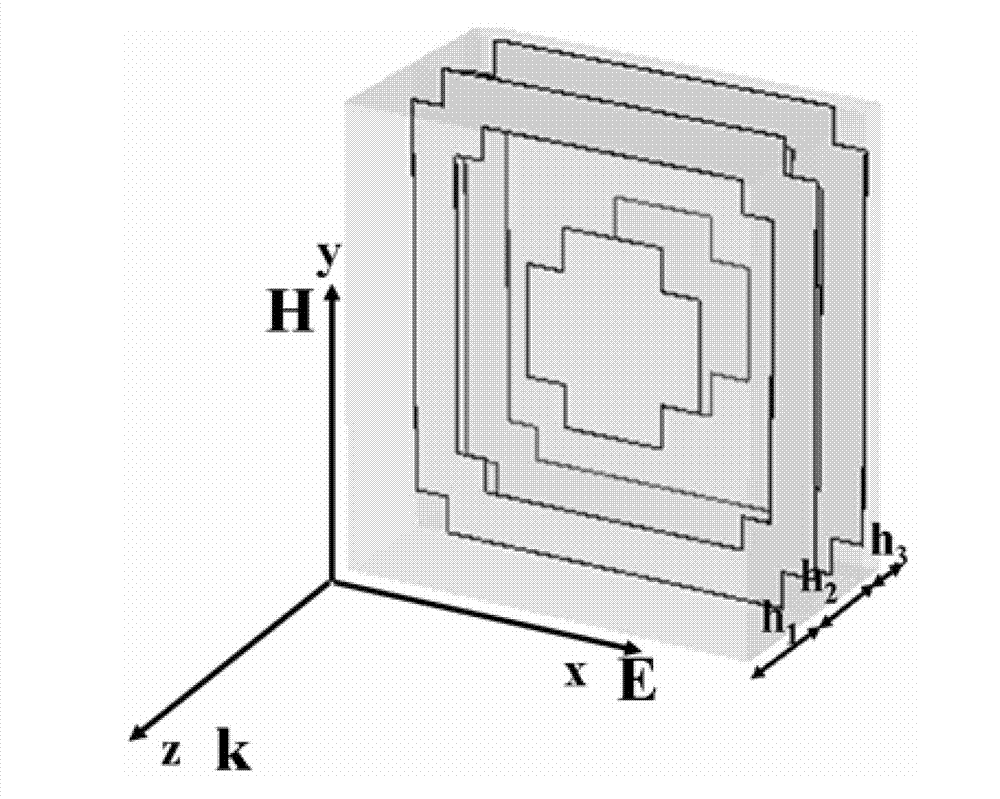

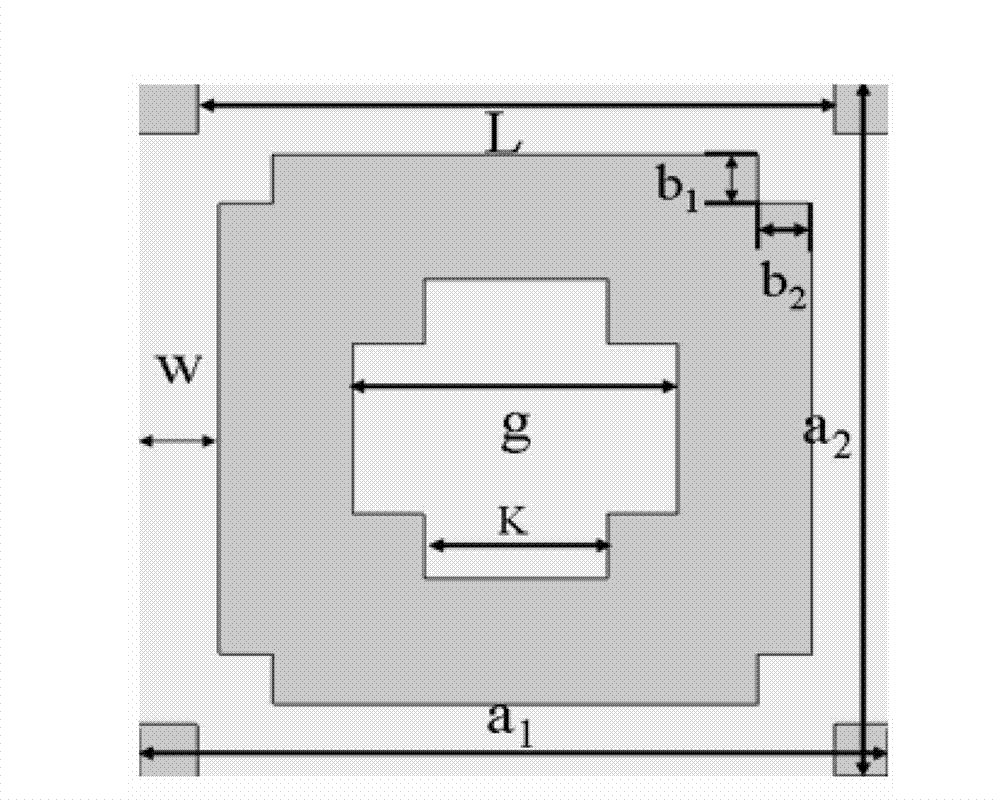

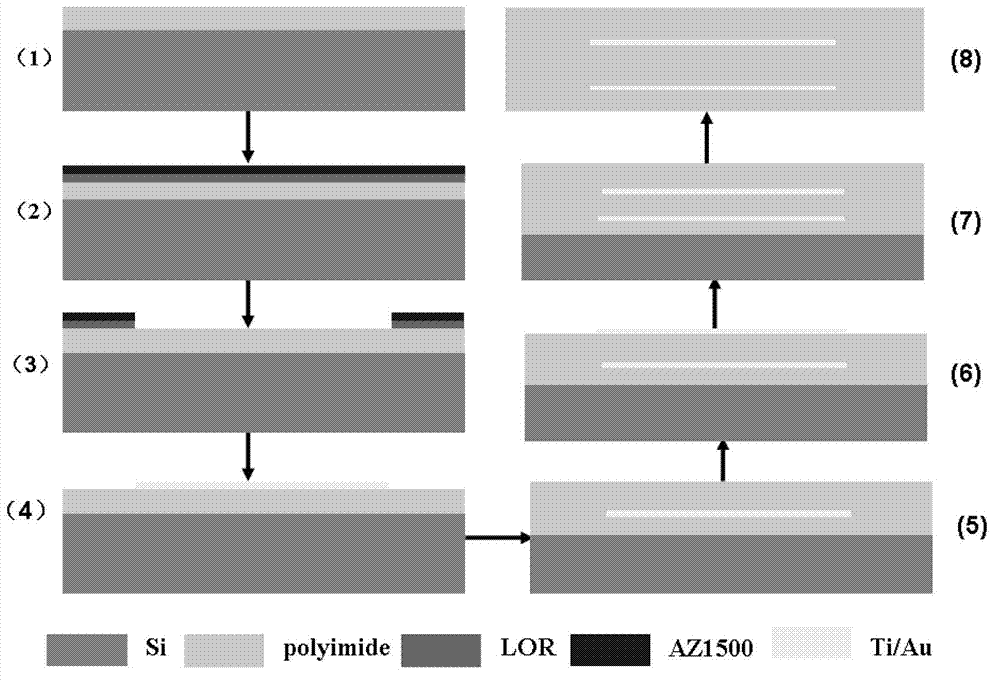

Method for manufacturing novel terahertz ultra-wide pass band filter

The invention discloses a method for manufacturing a novel terahertz ultra-wide pass band filter. The method includes cleaning a substrate, coating a polyimide film on the substrate, coating a photoresist lift off resist (LOR) on the polyimide film and drying, coating a photoresist AZ1500 on the photoresist LOR and drying, exposing the photoresist, subjecting the exposed photoresist to development and drying, vaporizing a first layer of metal on the photoresist AZ1500 and the exposed polyimide film, soaking the substrate which is subjected to vaporizing the first layer of metal in an acetone solution for lift-off, coating the polyimide film on the substrate and curing, vaporizing a second layer of metal on the photoresist AZ1500 and the exposed polyimide film, soaking the substrate which is subjected to vaporizing the second layer of metal in the acetone solution for lift-off, coating the polyimide film on the substrate and curing, removing the substrate, and lifting off the substrate and the polyimide film. The method for manufacturing the novel terahertz ultra-wide pass band filter has the advantage that the expansion of frequency bands is achieved.

Owner:NANJING UNIV

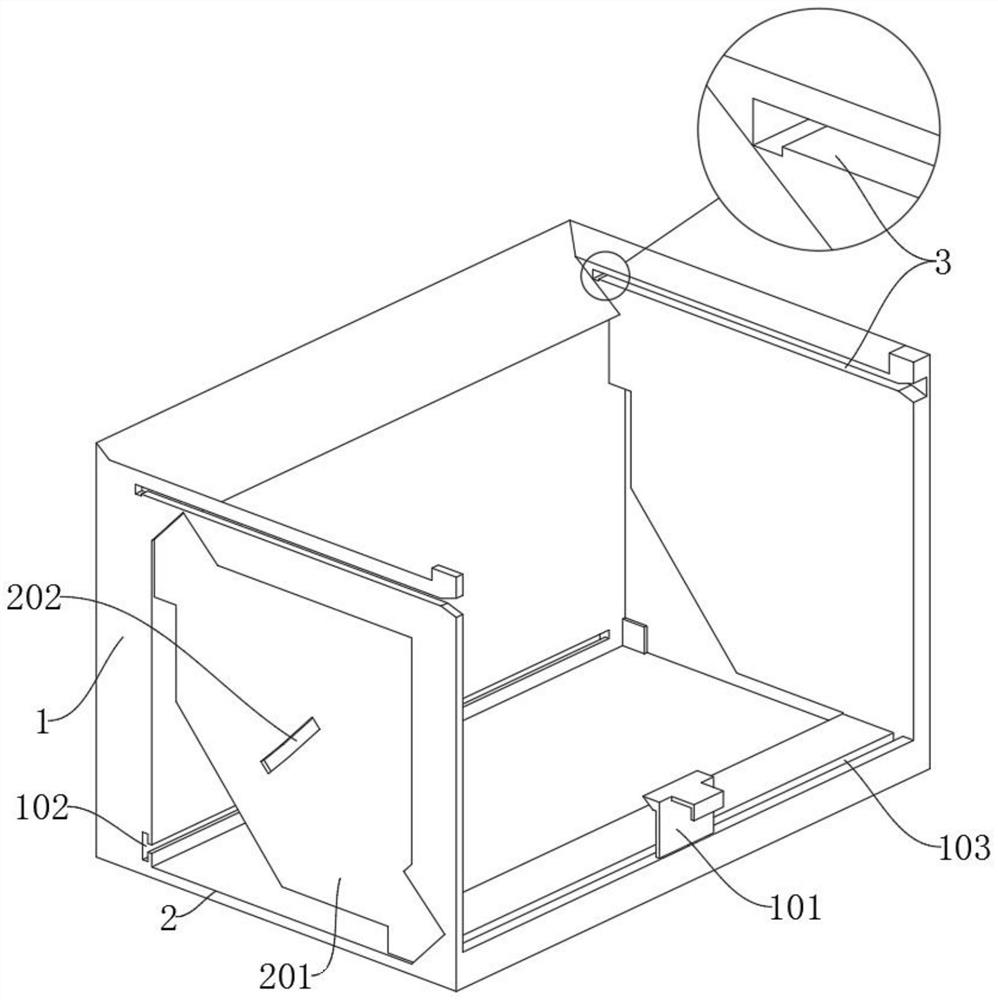

Tension-free cloth storing frame

Owner:JIANGSU HONGYE MACHINERY

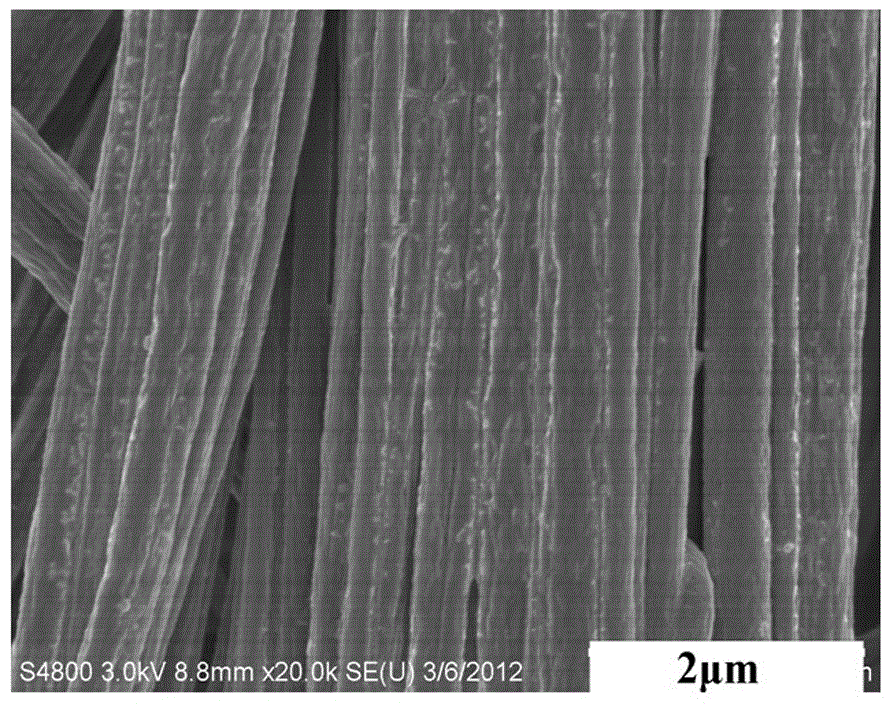

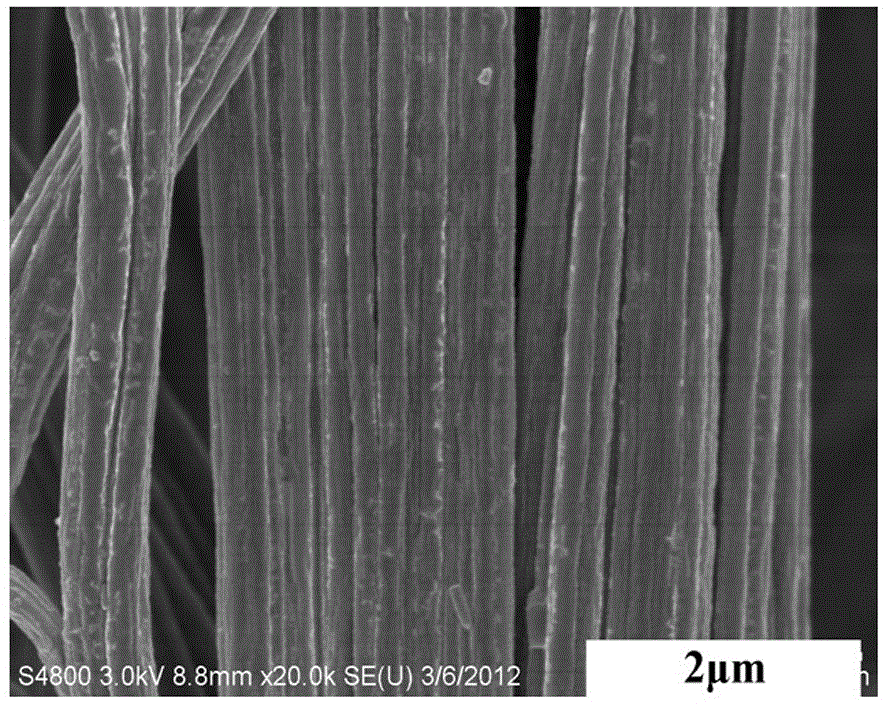

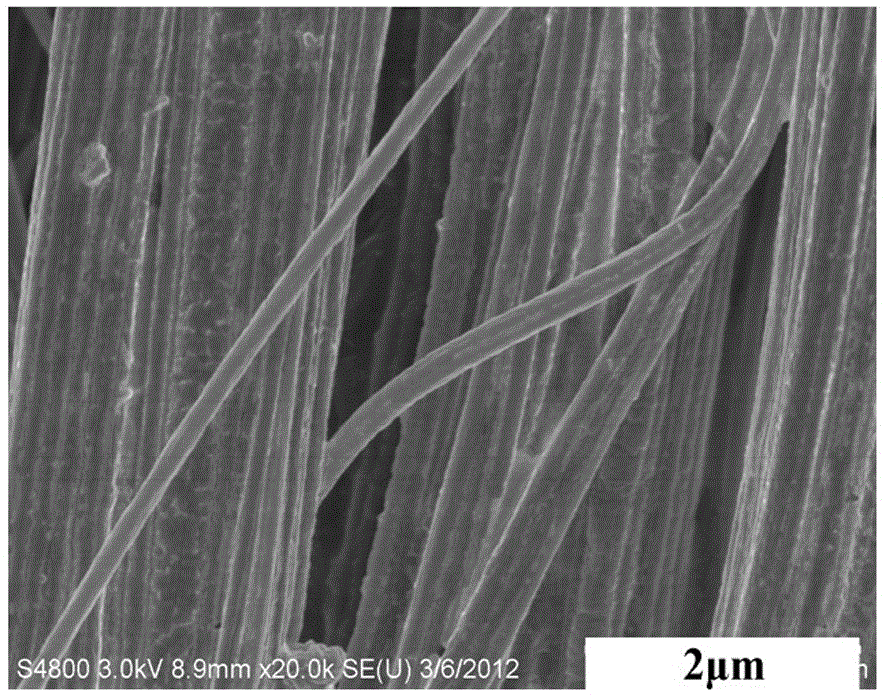

Aramid 1313/MWCNT (Multi-Walled Carbon Nanotube) nano fibers and preparation method thereof

InactiveCN102877152APlay a reinforcing roleAvoid reunionFilament/thread formingStretchingSpinningElectrospinning

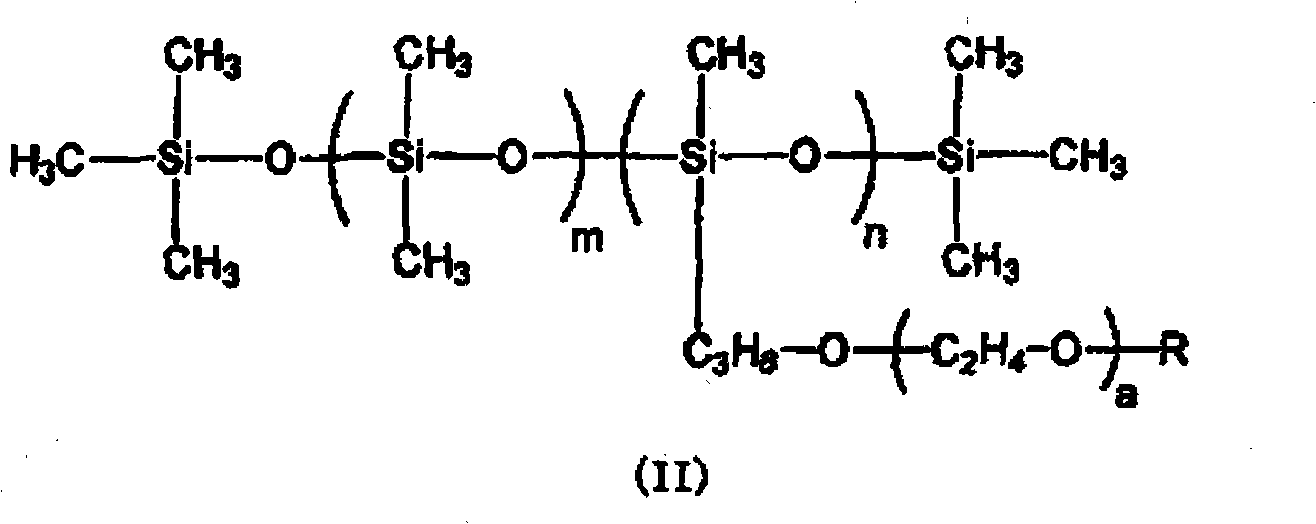

The invention discloses aramid 1313 / MWCNT (Multi-Walled Carbon Nanotube) nano fibers and a preparation method thereof. The preparation method comprises the following steps of: obtaining MWCNTs grafted with octyl phenoxy poly ethoxy; uniformly dispersing the grafted MWCNTs into a solvent by ultrasonic treatment so as to obtain a solution containing the MWCNTs; obtaining a dissolution system containing halide, adding aramid 1313 fibers into the dissolution system and stirring to dissolve the aramid 1313 fibers so as to obtain a solution containing the aramid 1313 fibers; mixing the two solutions to obtain a spinning solution; by adopting an electrostatic spinning method, obtaining a nano fiber felt of which the fibers are directionally arranged; and obtaining the strengthened nano fiber felt by adopting thermal stretching treatment. According to the invention, the aramid 1313 / MWCNT nano fibers are obtained; the orientation degree of the aramid 1313 is improved; and the tensile breaking strength and the initial modulus of the fiber felt are improved.

Owner:SUZHOU UNIV

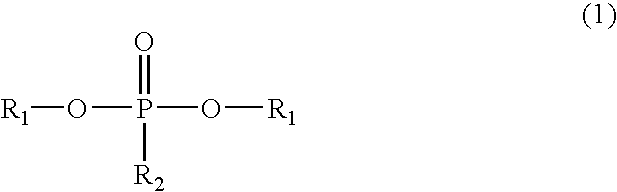

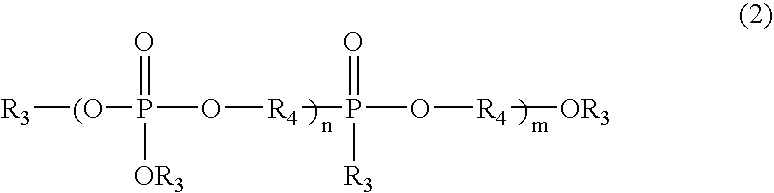

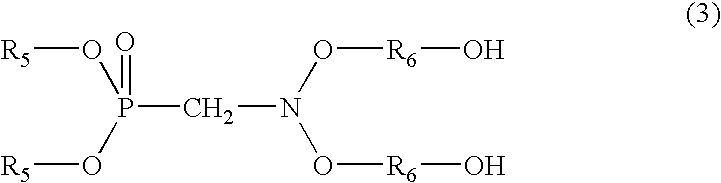

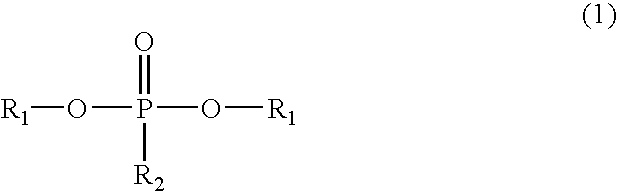

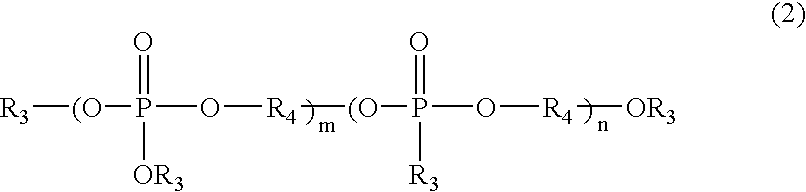

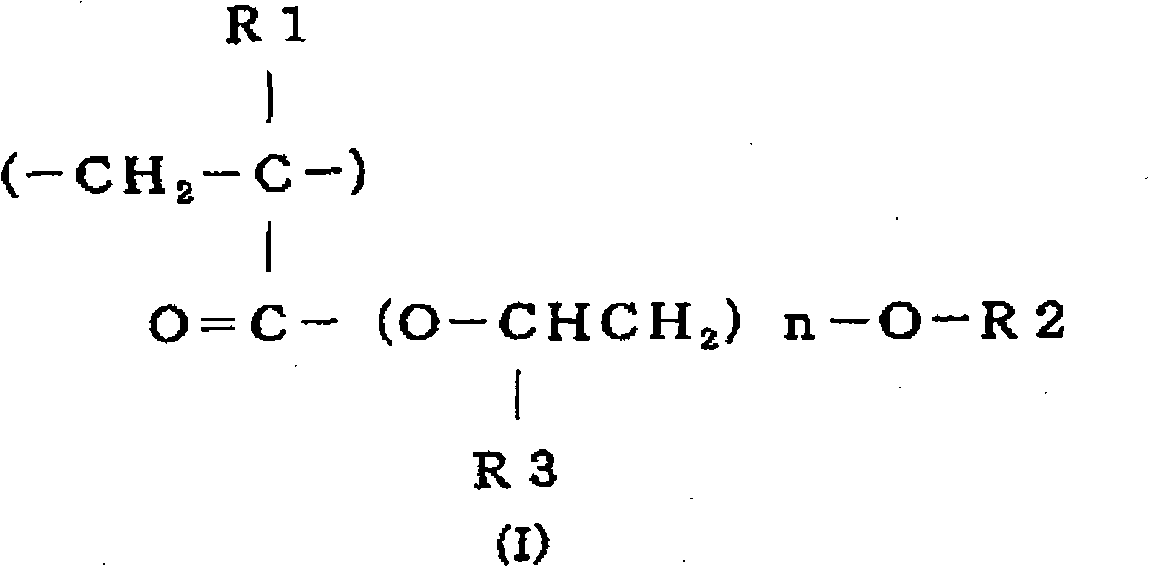

Phosphorus-containing urethane(meth)acrylate compounds and photosensitive compositions

InactiveUS20050107556A1Improve flame retardant performanceDevelopment capabilityOrganic chemistryPolyurea/polyurethane coatingsMethacrylatePolyol

A phosphorus-containing urethane (meth)acrylate compound obtained by reacting (A) a polyol compound comprising (A1) a phosphorus-containing polyol having a phosphorus atom, with (B) a bifunctional or greater polyisocyanate and (C) a hydroxyl group-containing (meth)acrylate.

Owner:SHOWA DENKO KK

Method for finishing cotton-nylon elastic woven fabrics

InactiveCN101845735AImprove color vibrancyWrinkle freeTextile storage in superimposed formFibre treatmentEngineeringAmmonia

The invention provides a method for finishing cotton-nylon elastic woven fabrics, and the process flow comprises singeing, desizing, mercerizing, dry setting and preshrinking, which is characterized in that a step of cold batching yarding is added between the steps of singeing and desizing, and the steps of liquefying ammonia and pre-tendering are added between the steps of mercerizing and dry setting, therefore the whole process flow is as follows: singeing, cold batching yarding, desizing, mercerizing, liquefying ammonia, pre-tendering, dry forming and preshrinking. The invention has scientific and easily-operated process, compared with conventional cotton-nylon elastic woven fabrics, the cotton-nylon elastic woven fabrics obtained by the invention has better gloss, greatly improved fabric color brightness, no fold and turned edge on surface fabric, uniform fabric width, good tendering and setting effects, favorable elasticity up to 20-30% and the first-rate product rate above 99%, can further perfect the stability of product quality and satisfies high quality requirement on top grade fabrics.

Owner:LUTAI TEXTILE

Ammonia-smoking method and flame-proof treatment method for pure cotton knitted fabric

InactiveCN101775721ALittle tensionNo deformationHeating/cooling textile fabricsTextile treatment carriersEngineeringAmmonia

The invention provides an ammonia-smoking method and a flame-proof treatment method for pure cotton knitted fabric. The flame-proof treatment method comprises the following steps: padding the pure cotton knitted fabric into a flame-proof treatment solution with a fire retardant by a setting machine, and performing pre-drying on the pure cotton knitted fabric at the temperature of 100-120 DEG C; leading the pure cotton knitted fabric to be in a natural suspension state to pass through an ammonia-smoking crosslinking chamber fully filled with ammonia, so that the ammonia can be fully crosslinked with the fire retardant on the knitted fabric evenly; and then performing oxidizing, washing and parching. In the invention, the pure cotton knitted fabric is in a natural loose suspension state to pass through the ammonia-smoking crosslinking chamber, thus the strain suffered by the pure cotton knitted fabric is small and can not cause the deformation and turned edges of the knitted fabric, the anti-flaming effects of the two sides of the shell fabric and the middle part of knitted fabric are the same, and the defect of colored spots can not appear.

Owner:江苏华瑞时尚集团有限公司

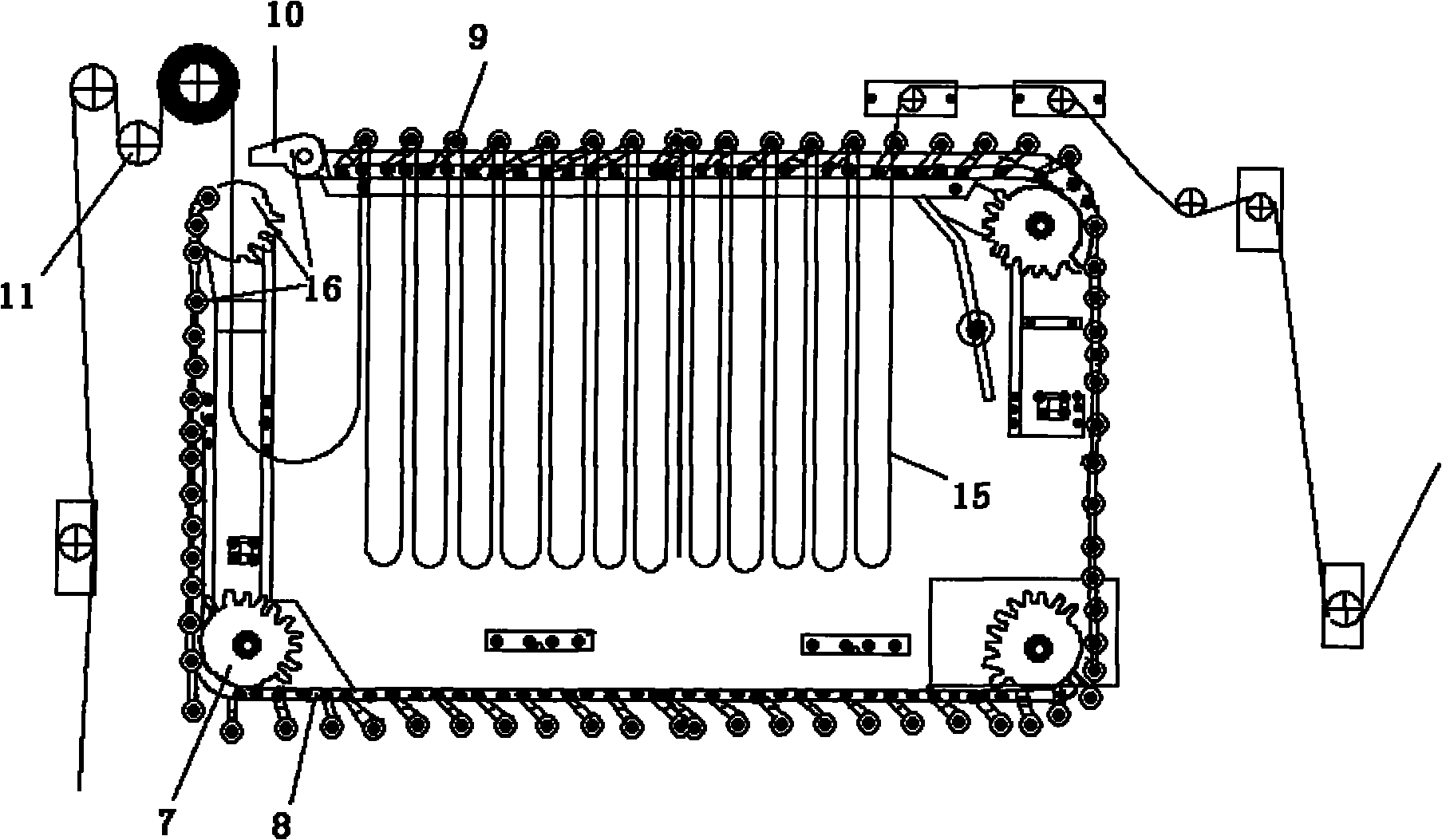

Porous polypropylene resin film, cell separator, and cell

ActiveCN102782027AImprove slipExcellent pin sheddingLi-accumulatorsCell component detailsStatic friction coefficientStatic friction

Owner:MITSUBISHI CHEM CORP

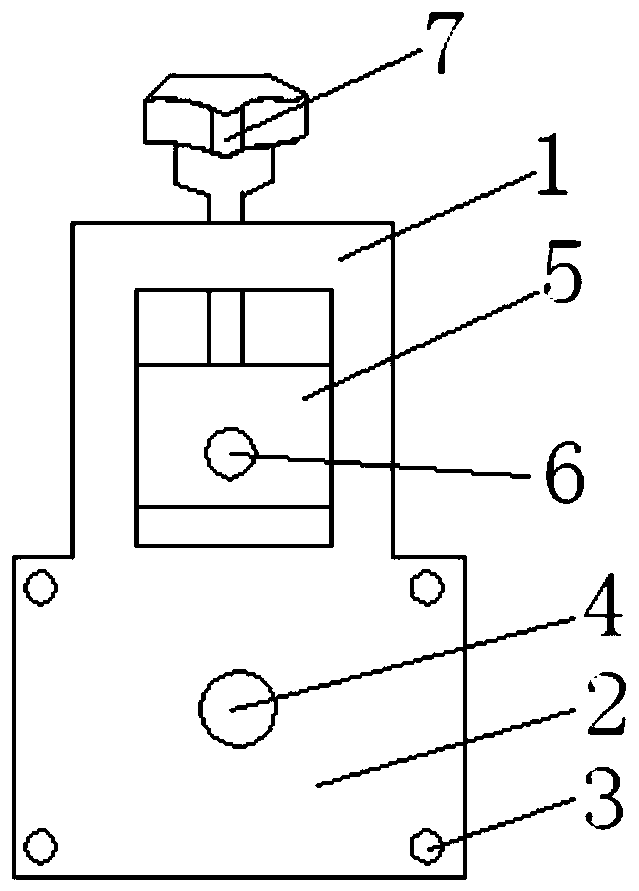

Anti-counterfeit printing device and method

InactiveCN107554060AImprove accuracyImprove printing qualityPattern printingInksAgricultural engineeringPrinting press

The invention discloses an anti-counterfeiting printing device, comprising a printing table, a paper feed roller is connected to the entrance of the printing table, a first pressure roller is arranged at the entrance of the printing table, and a positioning block is arranged on the right side of the first pressure roller , the positioning block is provided with screws, the printing table is provided with screw holes corresponding to the screws, a printing machine is provided above the positioning block, a photoelectric sensor is provided on the right side of the positioning block, and the photoelectric sensor There is a drying chamber on the right side of the drying chamber, a fan is provided on the top of the drying chamber, a partition is provided at the lower end of the fan, a through hole is provided on the partition, and a proofreading room is provided on the right side of the drying chamber. , the interior of the pair of chambers is provided with an ultraviolet lamp and a high-speed camera, the right side of the proofreading room is provided with a punching device, the right side of the punching device is provided with a second pressure roller, and the exit of the printing table is connected with a roll roll. The invention can improve the printing efficiency of bills, and conveniently remove problematic bills.

Owner:合肥汇融文印有限责任公司

Phosphorus-containing urethane(meth)acrylate compounds and photosensitive compositions

InactiveUS7232876B2Good flexibilityExcellent pressure cooker resistanceOrganic chemistryPolyurea/polyurethane coatingsPolyolMeth-

A phosphorus-containing urethane (meth)acrylate compound obtained by reacting (A) a polyol compound comprising (A1) a phosphorus-containing polyol having a phosphorus atom, with (B) a bifunctional or greater polyisocyanate and (C) a hydroxyl group-containing (meth)acrylate.

Owner:SHOWA DENKO KK

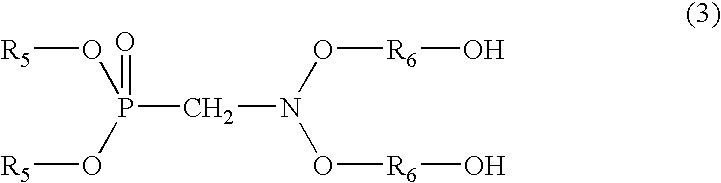

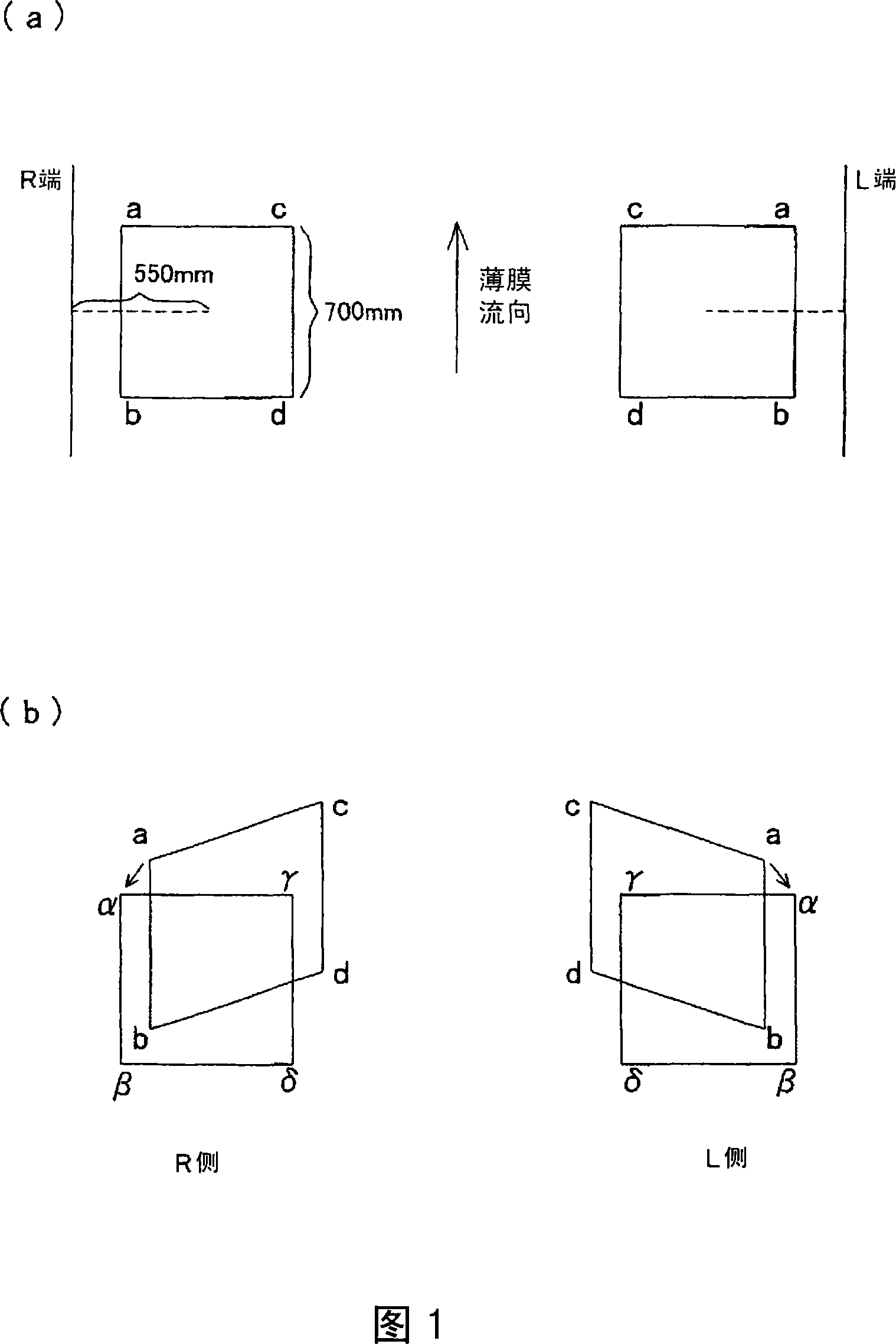

Biaxially orientated polyamide-based resin film and its manufacturing method

Owner:TOYOBO CO LTD

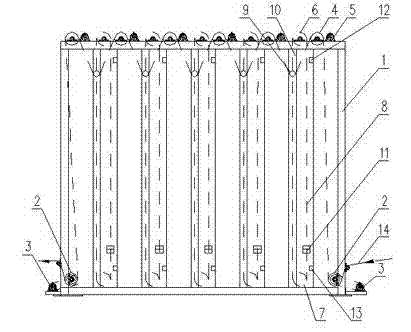

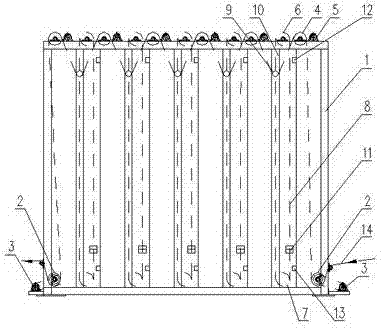

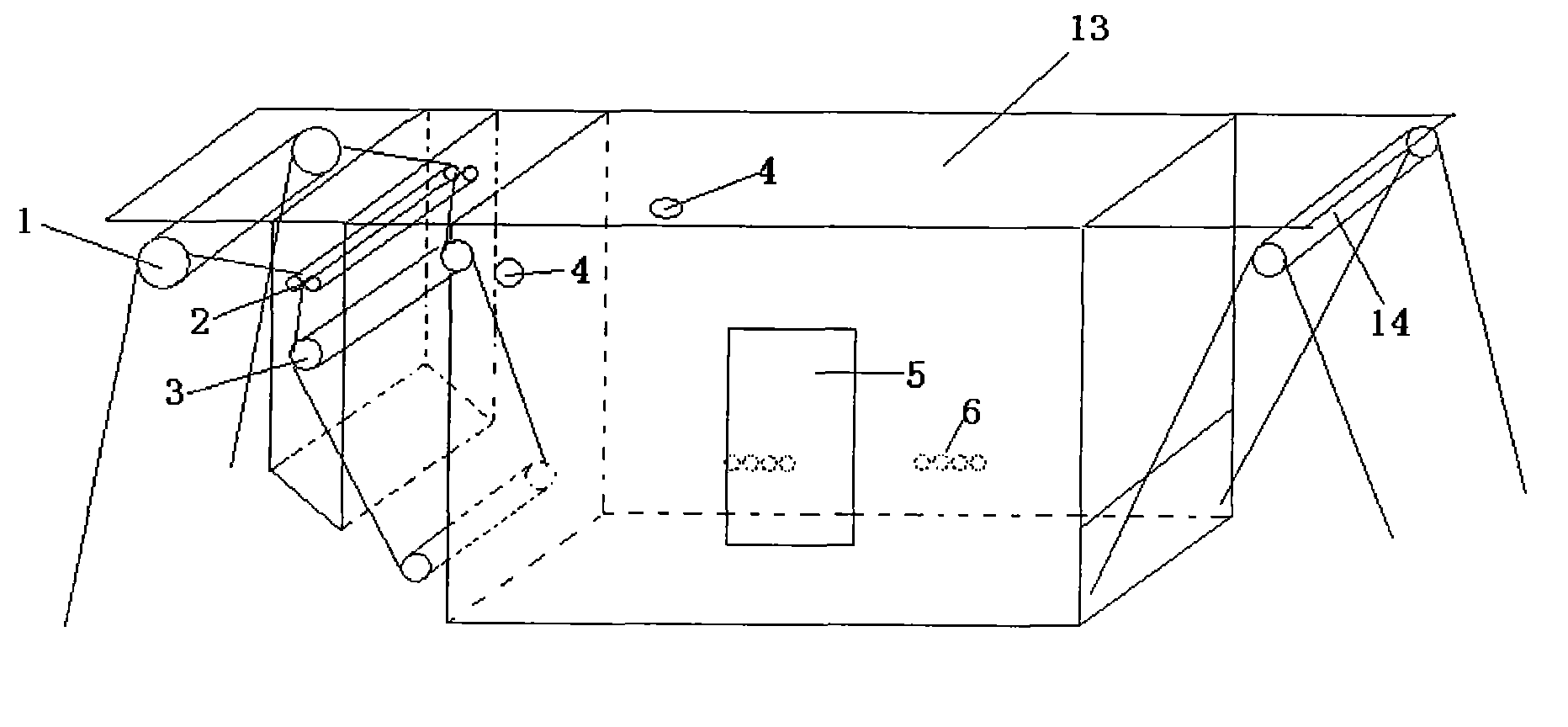

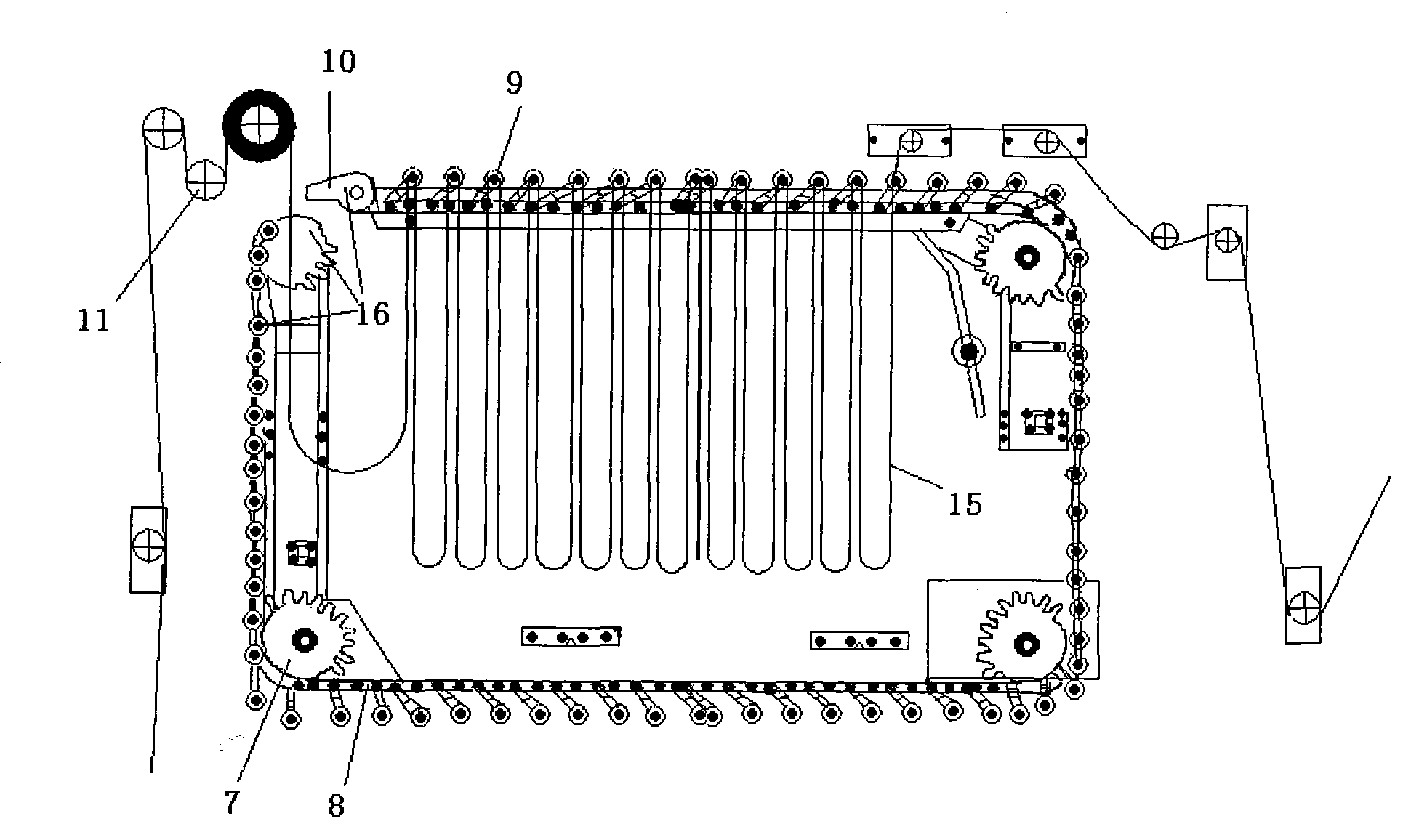

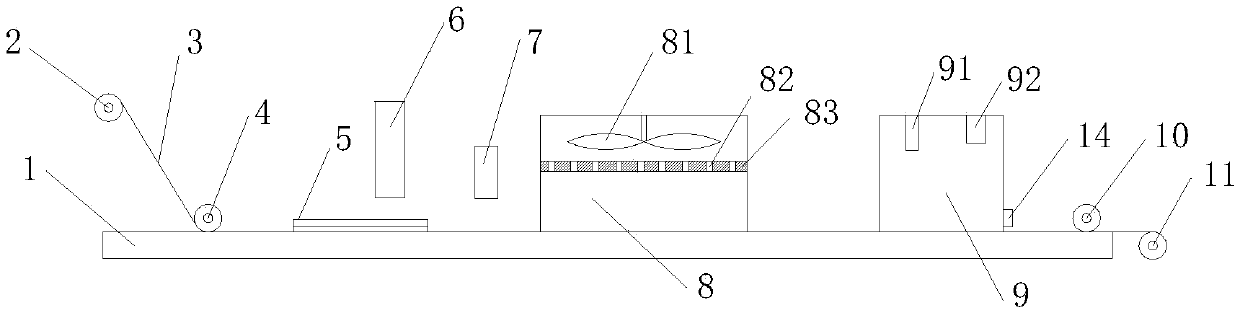

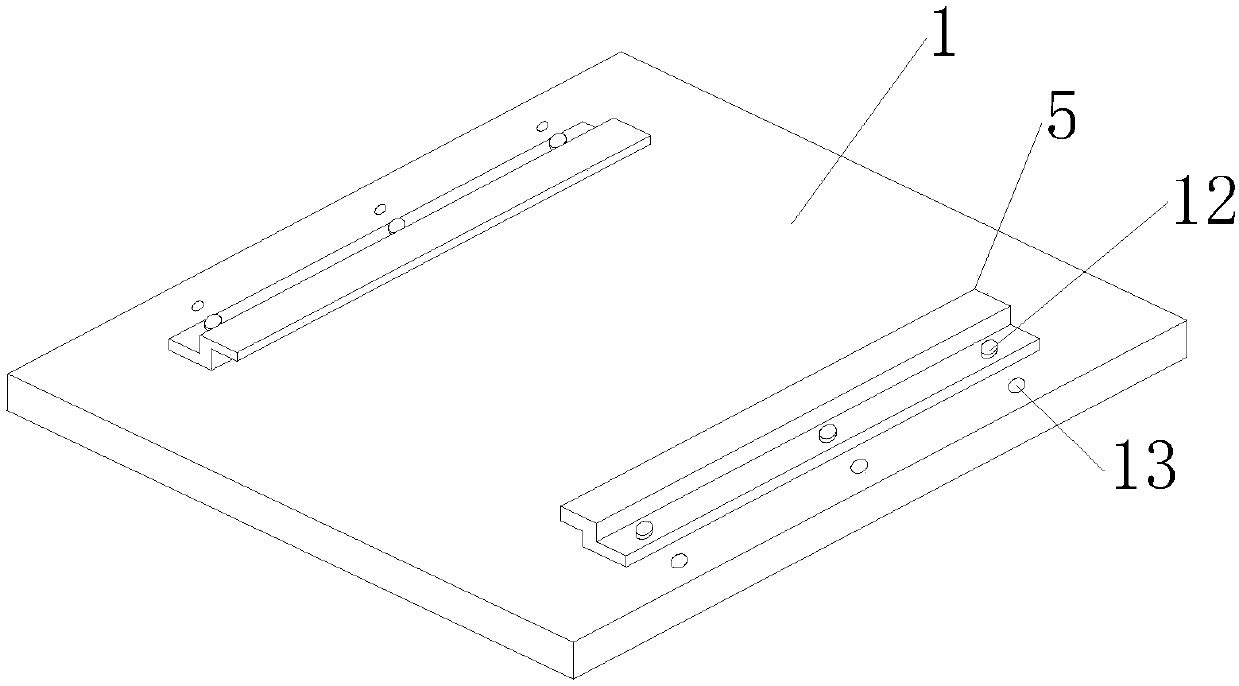

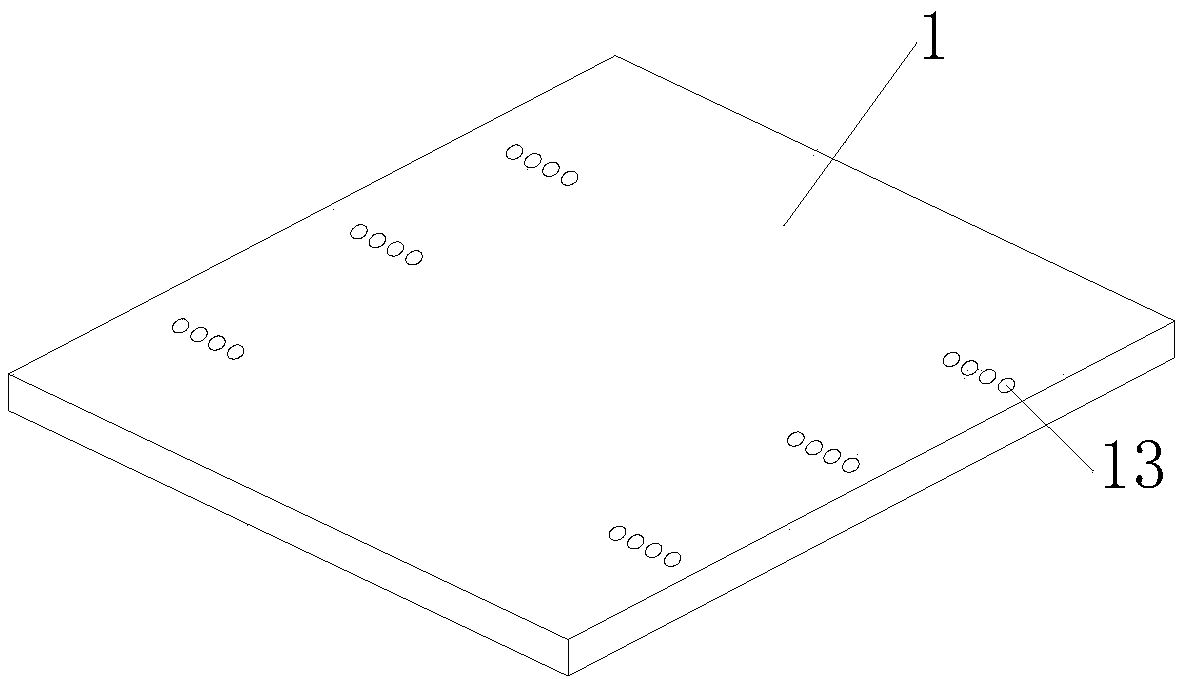

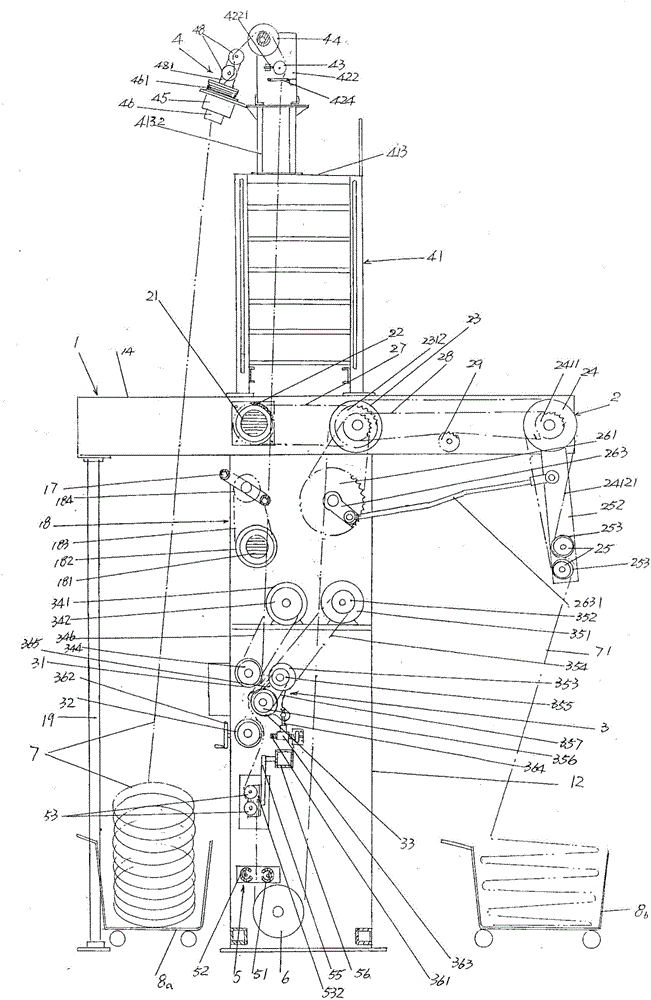

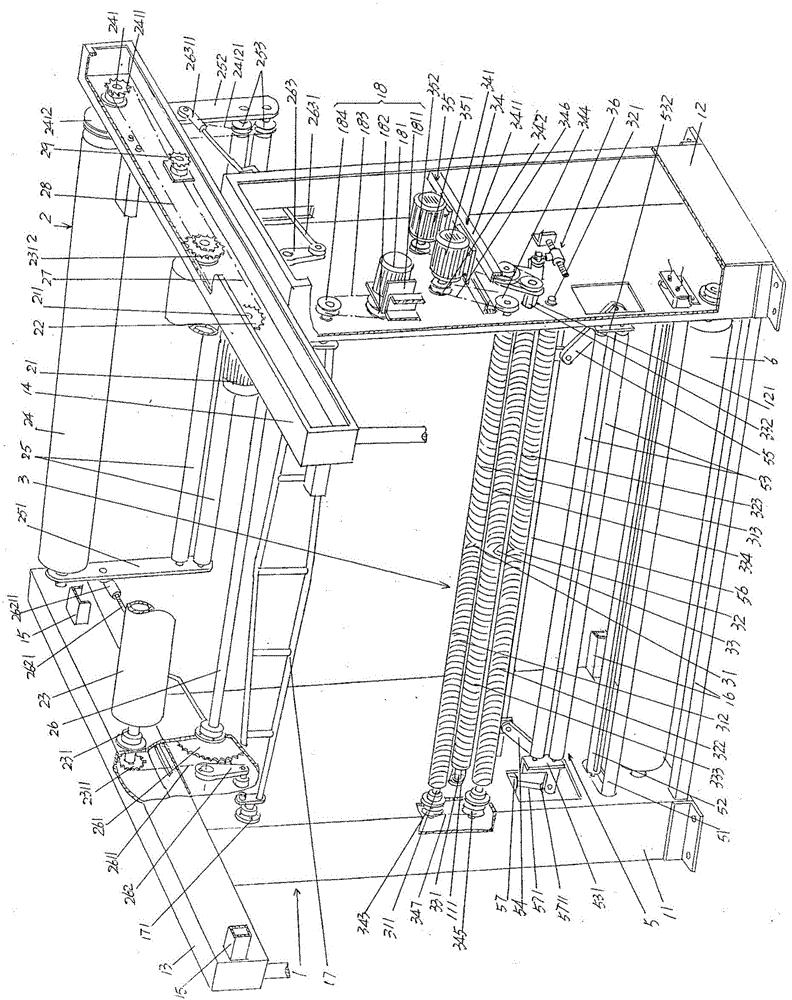

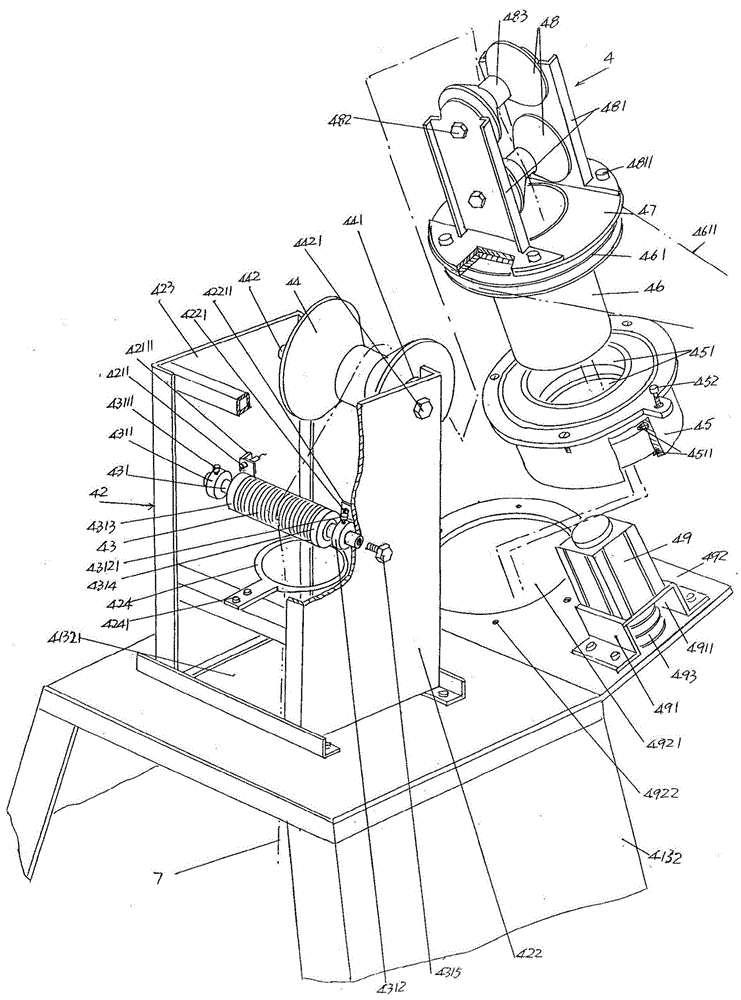

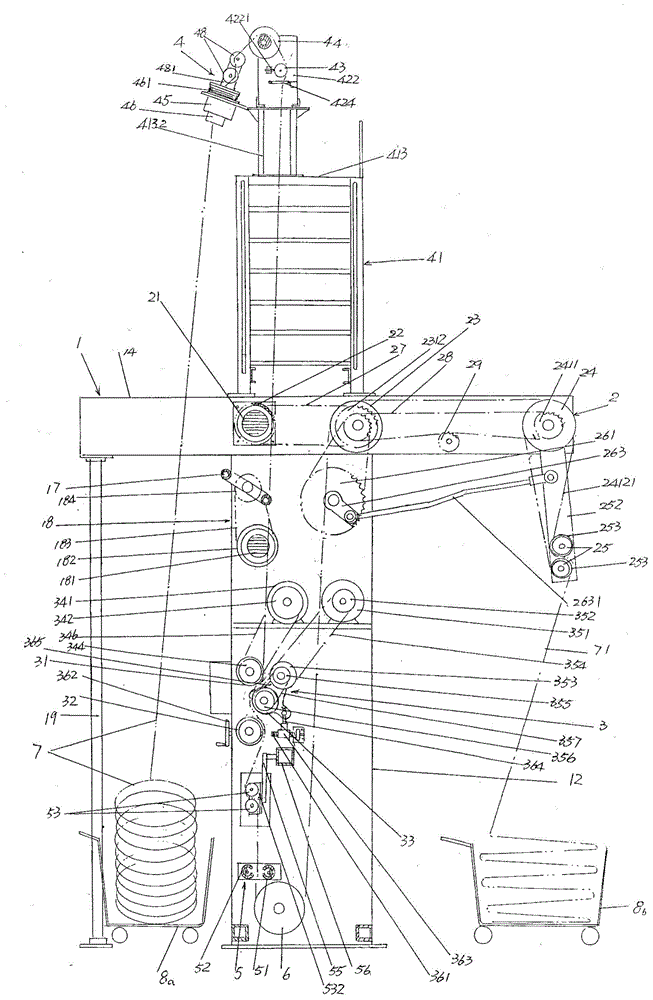

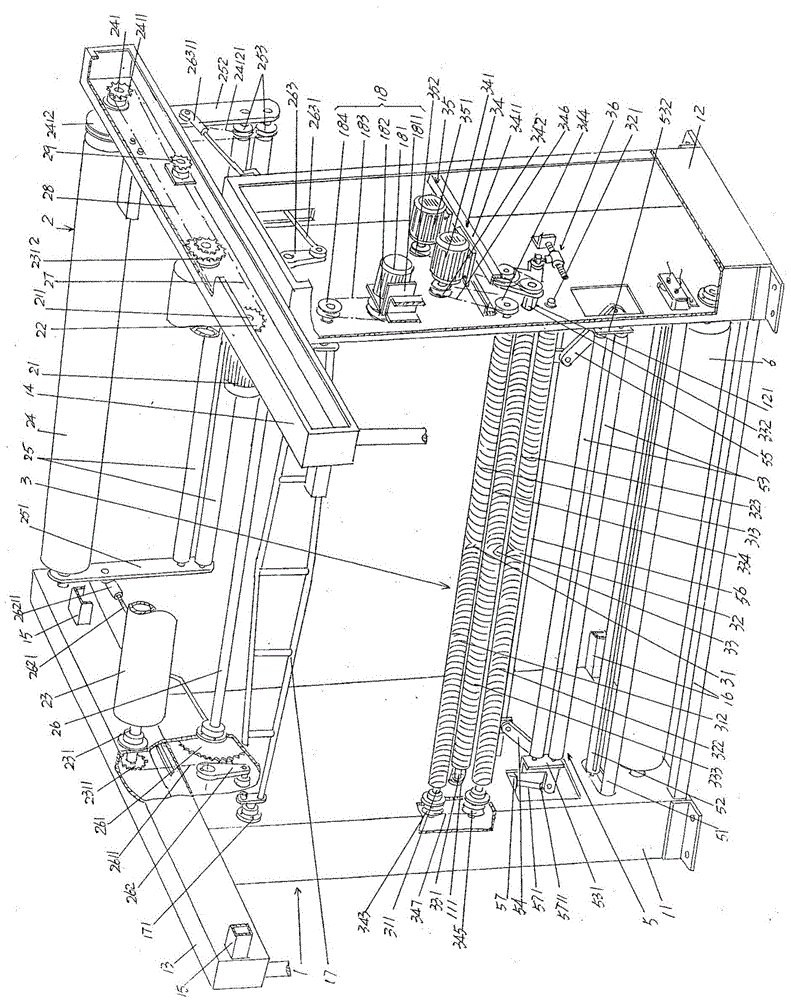

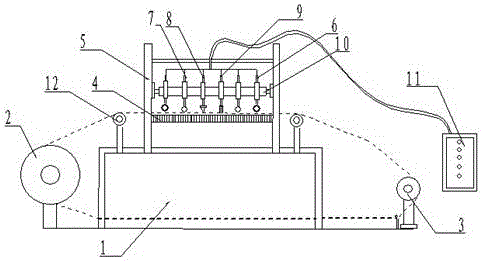

Fabric spreading machine

InactiveCN104528454AReduce operating intensitySimple structureUnfolding thin materialsWebs handlingTextile printerFrame based

The invention relates to a fabric spreading machine and belongs to the technical field of textile printing and dyeing machinery. The fabric spreading machine comprises a machine frame, a fabric guide mechanism, a fabric spreading mechanism, an untwisting device, an automatic deflection detection and correction device and a guide-out roller. The fabric spreading machine is characterized in that the untwisting device comprises an untwisting frame base, an untwisting frame, a detection roller, an untwisting fabric guide wheel, a rotary cylinder bearing block, a rotary cylinder, a rotary disk, a pair of untwisting transition wheels and an untwisting servo motor, the untwisting frame base is composed of a first ladder, a second ladder and a platform, one side of a left wallboard of the untwisting frame is provided with a first signal collector, one side of a right wallboard of the untwisting frame is provided with a second signal collector, a first signal trigger coil is fixed to the left end of the detection roller, and a second signal trigger coil is fixed to the right end of the detection roller; the fabric spreading mechanism comprises a first fabric stretching roller, a second fabric stretching roller, a tension roller, a fabric stretching roller driving device, a tension roller driving device and a pair of tension roller manual adjustment devices. The structure is simplified, the response speed of the first signal collector and the response speed of the second signal collector are increased, and reliability of the first signal collector and the second signal collector is improved; deflected fabric is corrected automatically, and strength is relieved; selvages will not curl.

Owner:常熟市龙略机电有限公司

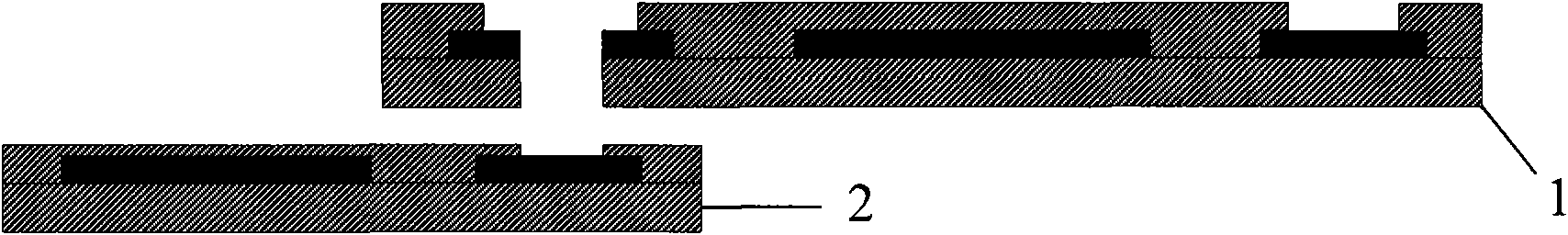

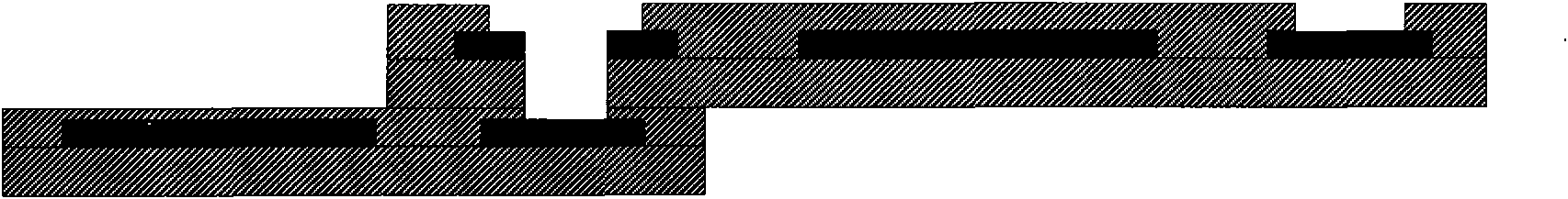

Interconnecting method for flexible device and used flexible connector

InactiveCN101599609AInterconnectionNo curlingLine/current collector detailsElectrically conductive adhesive connectionsAdhesiveMicroelectrode

The invention relates to an interconnecting method for a flexible device and a used flexible connector. The interconnecting method for the flexible device is characterized by comprising the following steps: a) manufacturing the flexible connector with a through hole characteristic welding locus according to the size of the flexible device; b) aligning and fitting the through hole characteristic welding locus of the flexible connector and a welding locus of the flexible device to be connected, and coating conductive adhesive at the welding loci to realize connection and communication; and c) coating or depositing a polymer at the welding loci to insulate and encapsulate a connected part. The flexible connector is an elongated membrane, and has a three-layer structure of polymer, metal and polymer; two ends of the flexible connector are the welding loci or connecting loci exposed by the metal layer; and the middle of the flexible connector is an embedded metal connecting line. The provided microelectrode connector based on a flexible polymer material has the characteristics of compatibility with the prior micro-electromechanical processing technology and standardized mass manufacture. The flexible connector ensures the effective connection and signal transmission between the flexible device and an equipment or between the flexible devices, and solves the problem of connection reliability of the flexible device.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

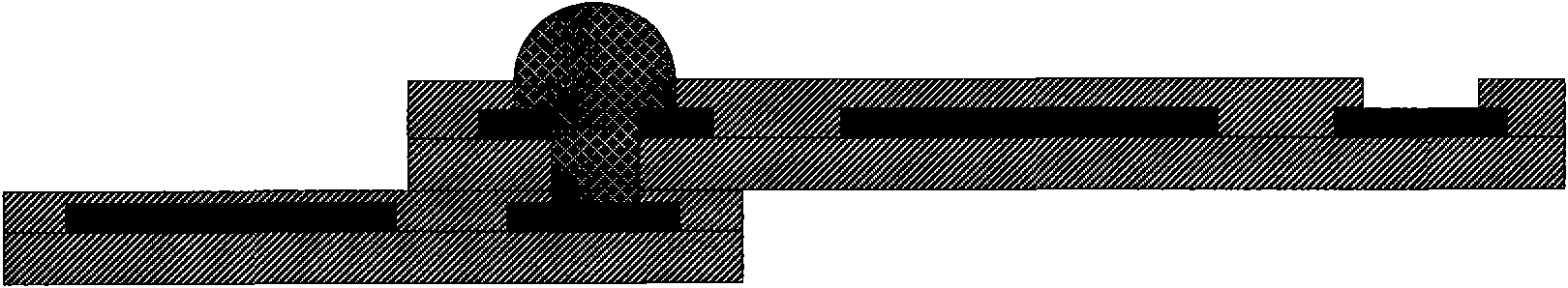

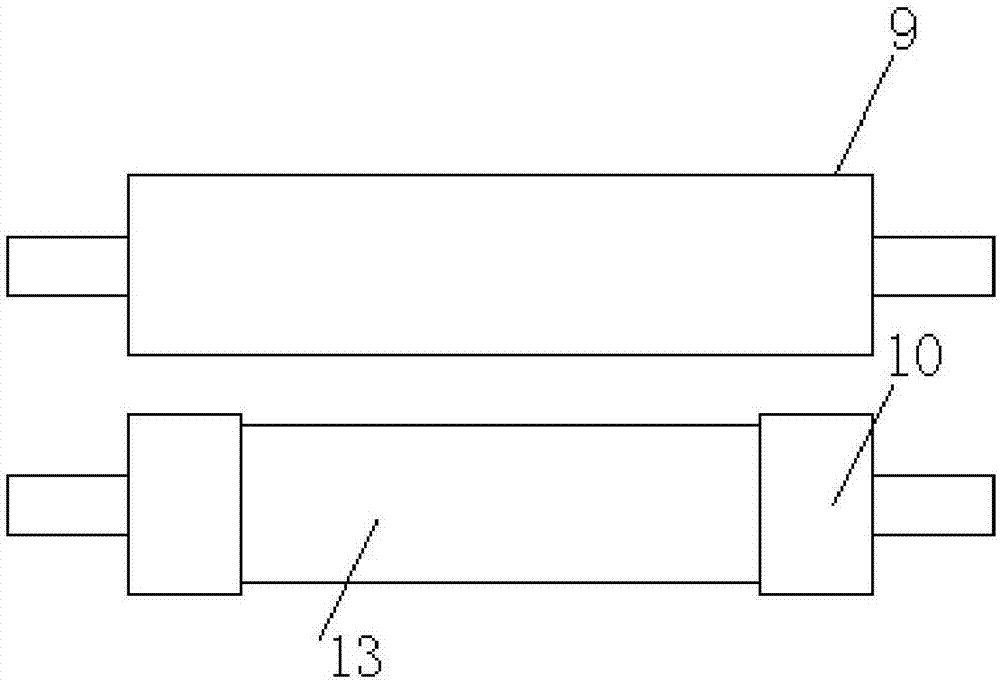

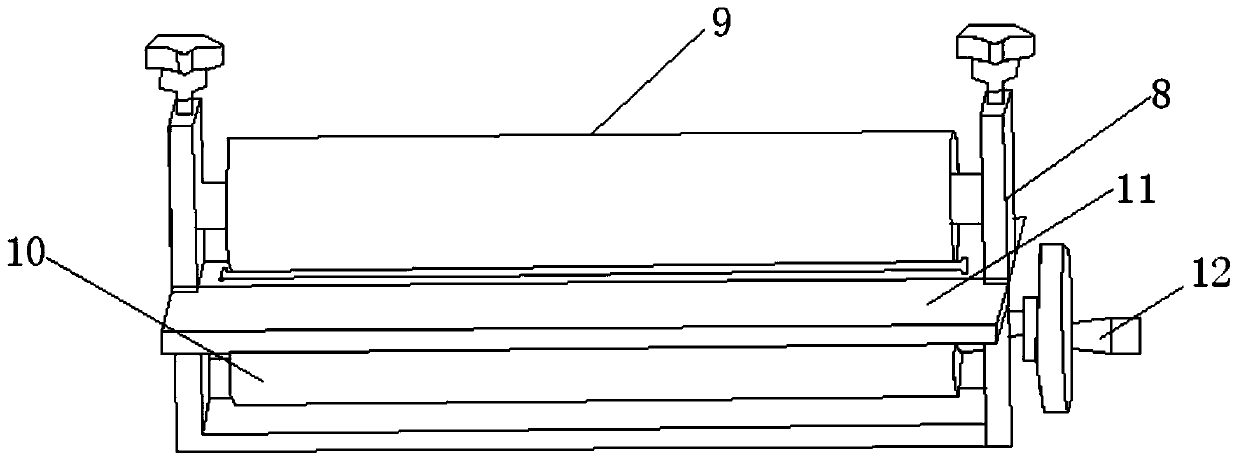

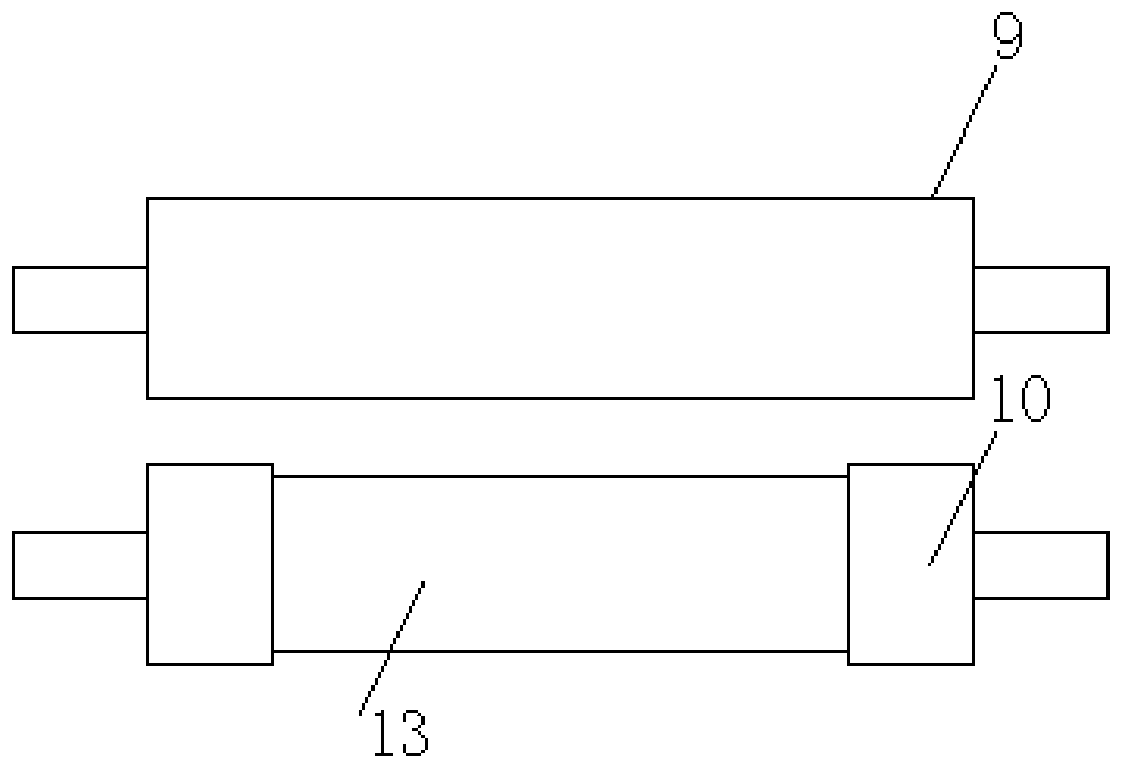

Cold lamination machine used for laminating film on advertisement picture

The invention discloses a cold lamination machine used for a laminating film on an advertisement picture. The cold lamination machine includes two wall boards and two film pressing rollers, wherein the two wall boards are symmetrically arranged respectively on the left and right sides of the cold lamination machine. The two film pressing rollers respectively are an upper pressing roller and a lower pressing roller, wherein the upper pressing roller is connected between first connection portions of the wall boards through rotation bearings, and the lower pressing roller is connected between second connection positions of the wall boards through rotation bearings. An anti-stick plate is disposed between the upper pressing roller and the lower pressing roller, wherein the two sides of the anti-stick plate are connected to threaded holes in the second connection portions through bolts. A rotating crank is connected to the rotation bearing, at one of the wall board, of the lower pressing roller.

Owner:江苏剑山包装科技有限公司

Spreader

InactiveCN104528454BReduce operating intensitySimple structureUnfolding thin materialsWebs handlingTextile printerEngineering

The invention relates to a fabric spreading machine and belongs to the technical field of textile printing and dyeing machinery. The fabric spreading machine comprises a machine frame, a fabric guide mechanism, a fabric spreading mechanism, an untwisting device, an automatic deflection detection and correction device and a guide-out roller. The fabric spreading machine is characterized in that the untwisting device comprises an untwisting frame base, an untwisting frame, a detection roller, an untwisting fabric guide wheel, a rotary cylinder bearing block, a rotary cylinder, a rotary disk, a pair of untwisting transition wheels and an untwisting servo motor, the untwisting frame base is composed of a first ladder, a second ladder and a platform, one side of a left wallboard of the untwisting frame is provided with a first signal collector, one side of a right wallboard of the untwisting frame is provided with a second signal collector, a first signal trigger coil is fixed to the left end of the detection roller, and a second signal trigger coil is fixed to the right end of the detection roller; the fabric spreading mechanism comprises a first fabric stretching roller, a second fabric stretching roller, a tension roller, a fabric stretching roller driving device, a tension roller driving device and a pair of tension roller manual adjustment devices. The structure is simplified, the response speed of the first signal collector and the response speed of the second signal collector are increased, and reliability of the first signal collector and the second signal collector is improved; deflected fabric is corrected automatically, and strength is relieved; selvages will not curl.

Owner:常熟市龙略机电有限公司

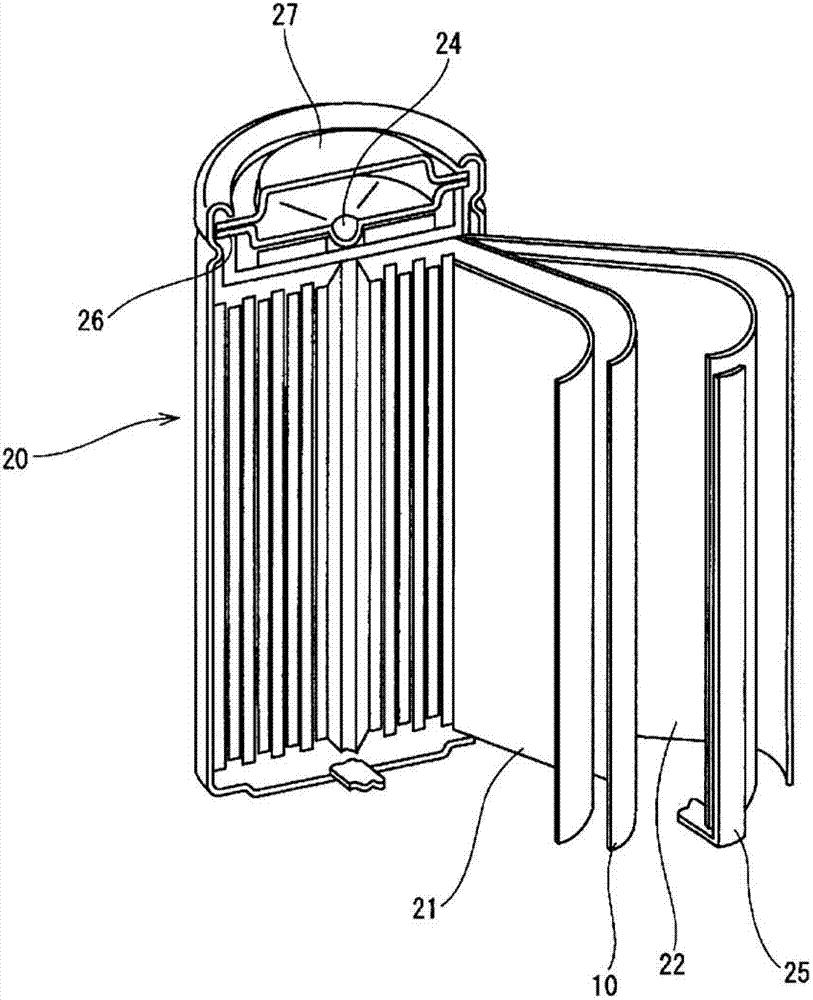

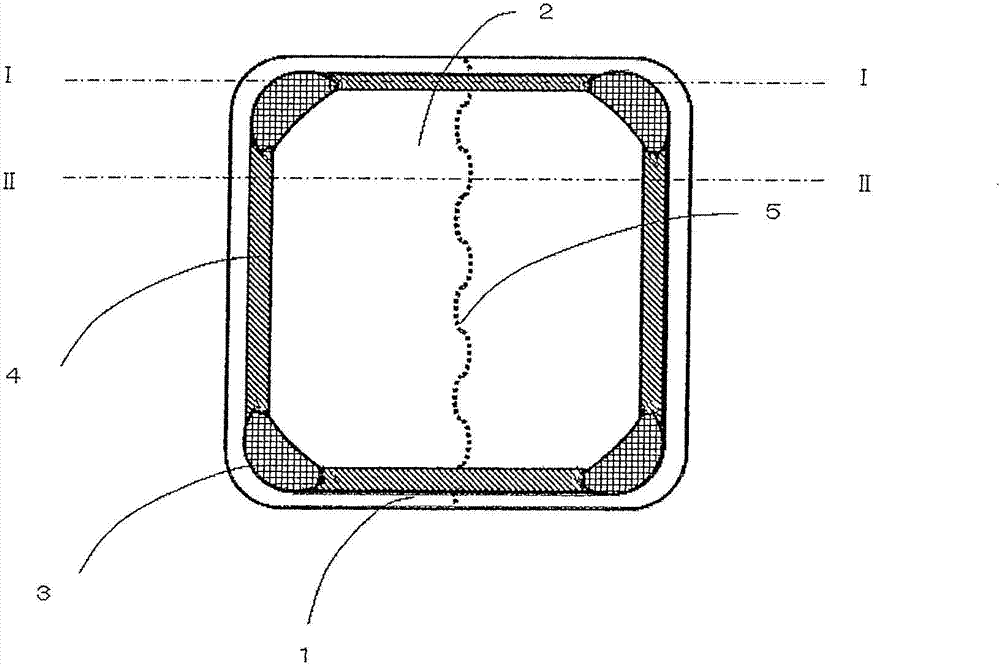

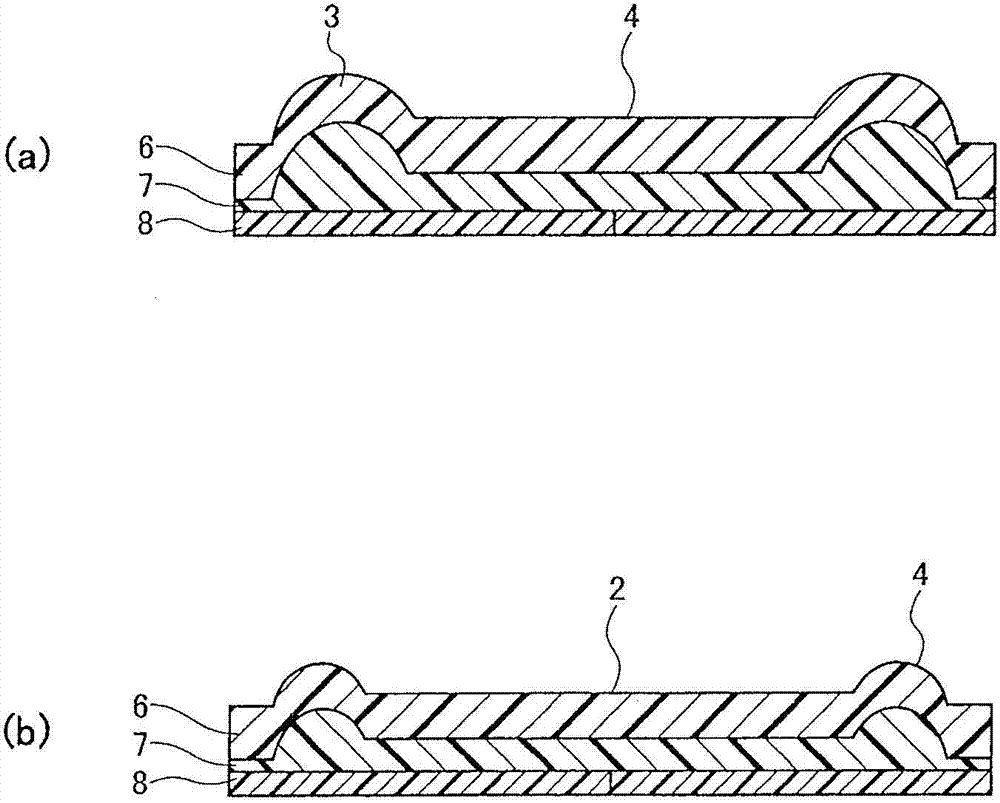

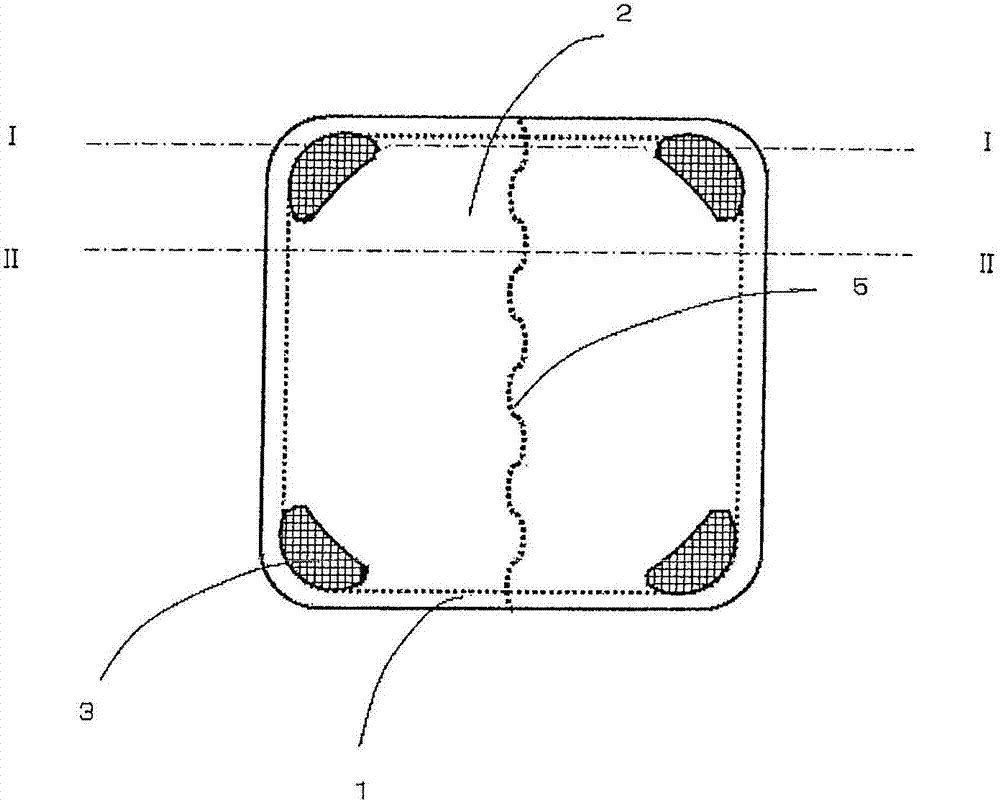

Adhesive patch containing bisoprolol

InactiveCN102770130AInhibition of attachmentEasy to take outOrganic active ingredientsPlastersDrug contentBisoprolol

Disclosed is an adhesive patch which effectively inhibits the occurrence of oozing or squeezing out of the adhesive layer component from the exposed area of the adhesive layer of the adhesive patch during storage, and also inhibits the occurrence of oozing of bisoprolol or salts of same from the adhesive layer thereby preventing reduction of drug content. A backing material, a release liner and an adhesive layer respectively, along with the entire adhesive patch, are shaped into a planar rectangle wherein the corners of the adhesive patch are formed into convex shapes on the rear surface on the backing material side. Further, the adhesive patch has a central part and edges wherein the corners of the rectangular shape of the central part can also be formed into convex shapes, and furthermore it can be provided with built-up articulated sections between two or more adjacent convex parts wherein the thickness of the adhesive patch is thinner than the thickness of the adhesive layer at each convex part. If the release liner is provided with a split at the back, the split should not traverse the convex parts.

Owner:NITTO DENKO CORP +1

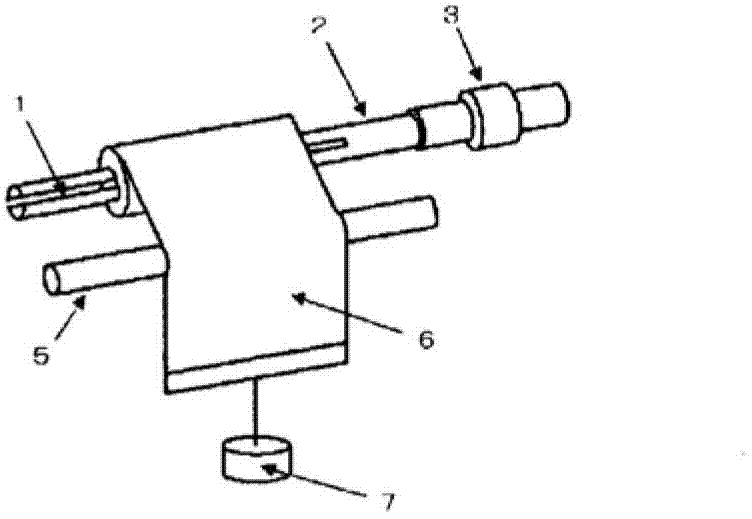

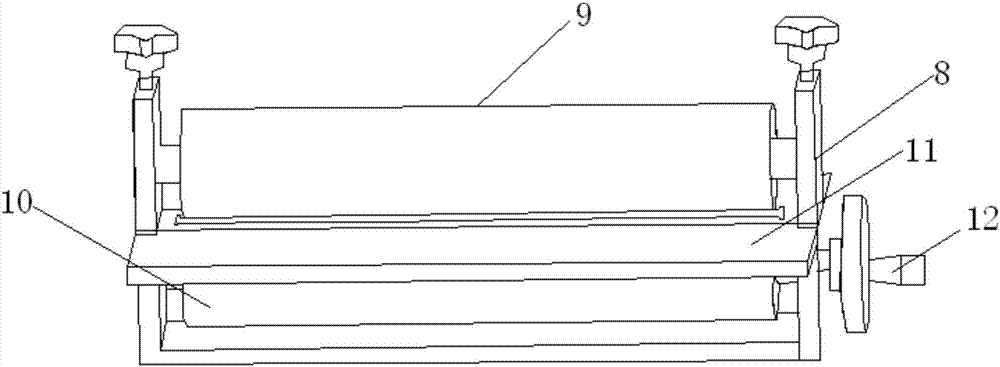

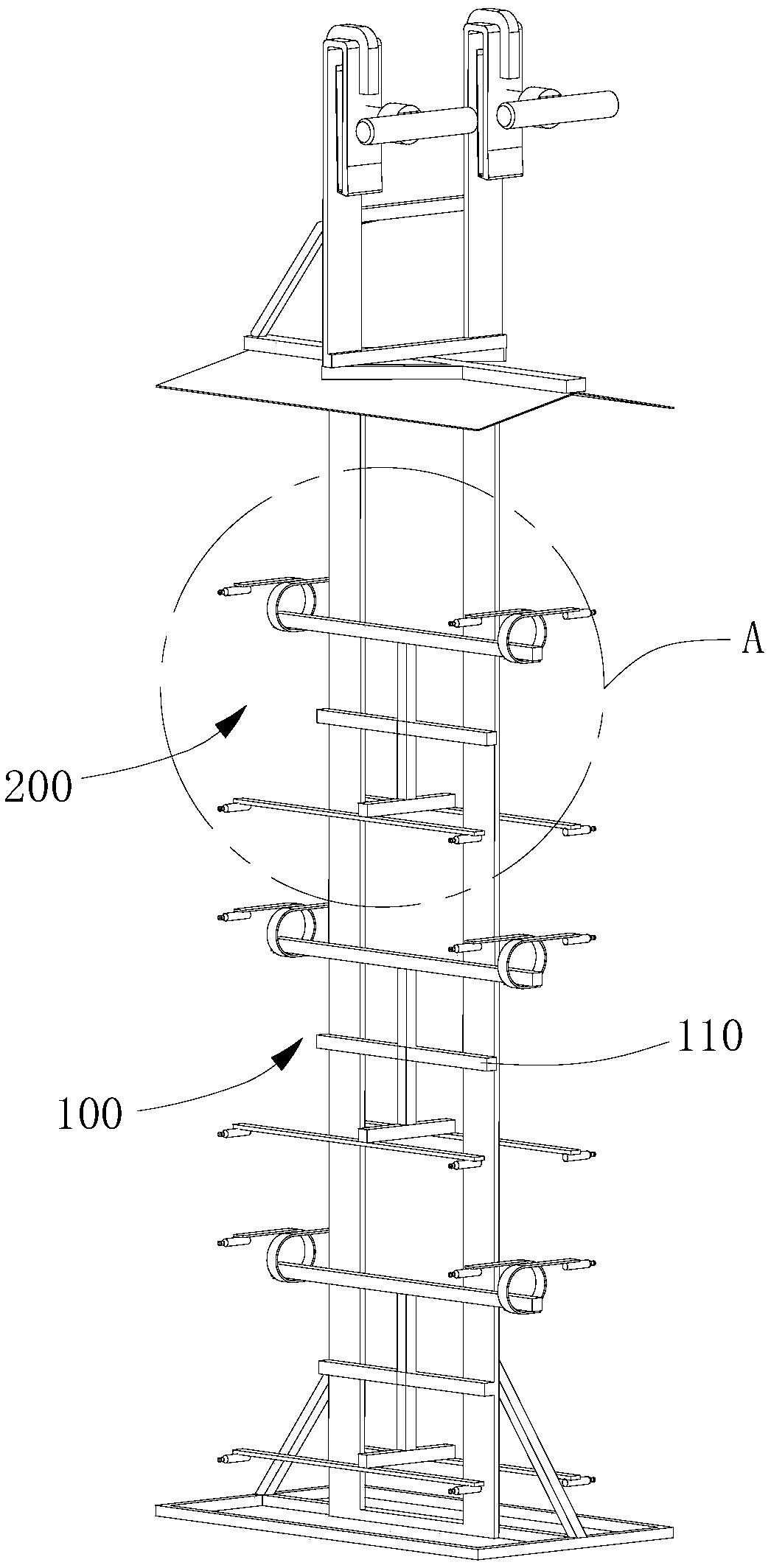

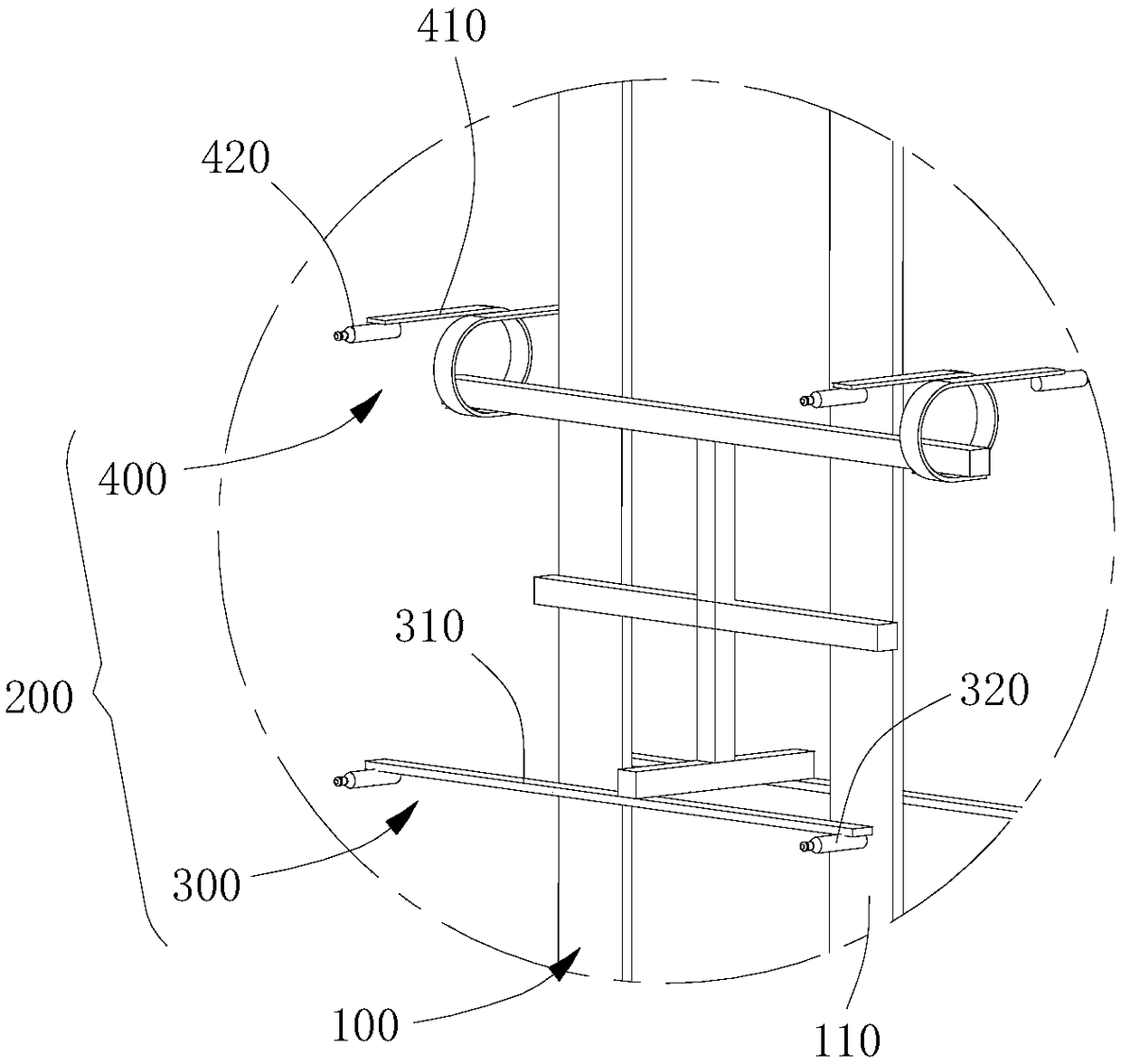

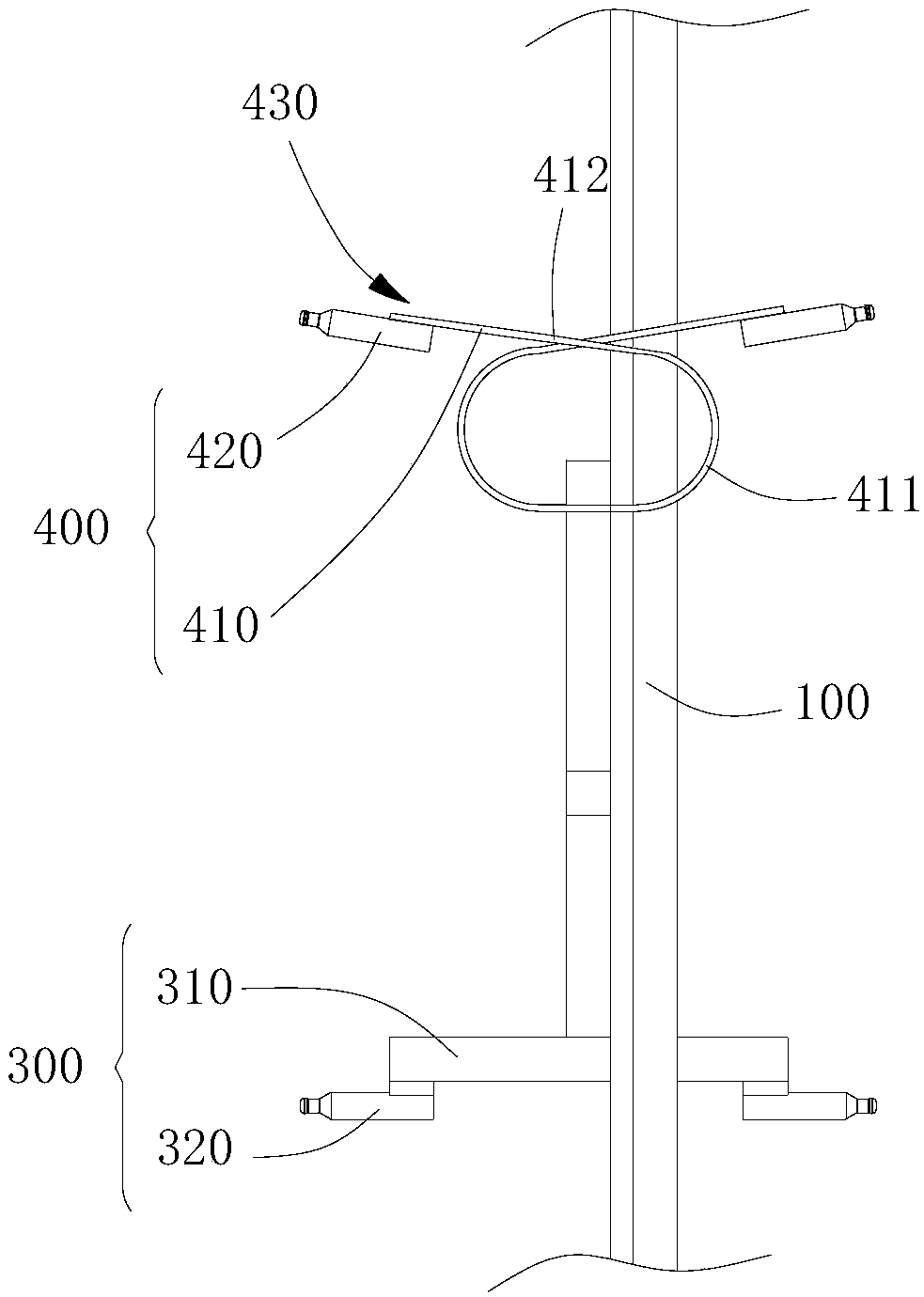

Anode oxidization process conductive hanger

ActiveCN109234777ANo curlingImprove the forceAnodisationElectrolysis componentsElectrical and Electronics engineeringAnode

The invention relates to an anode oxidization process conductive hanger which is used for suspending a product with a connecting hole. The anode oxidization process conductive hanger comprises a rackand a hanger unit which are fixed with each other and are in conductive communication, wherein the hanger unit comprises a positioning hanging part and a fastening hanging part, which are matched withthe connecting hole; the fastening hanging part is used for providing elastic force away from the positioning hanging part to the product, so that the product is hung on the hanger unit; the positioning hanging part and the fastening hanging part are arranged in a vertical direction; when the product is not hung, the fastening hanging part tilts in a direction away from the positioning hanging part; and after the product is hung, the fastening hanging part generates elastic deformation in a direction close to the positioning hanging part. The anode oxidization process conductive hanger has the advantage of relieving stress at the product connecting hole, so that the connecting hole does not have a turned edge.

Owner:DONGGUAN CHANGYING PRECISION TECH CO LTD

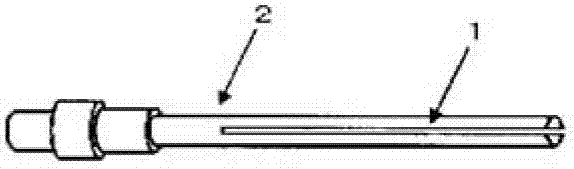

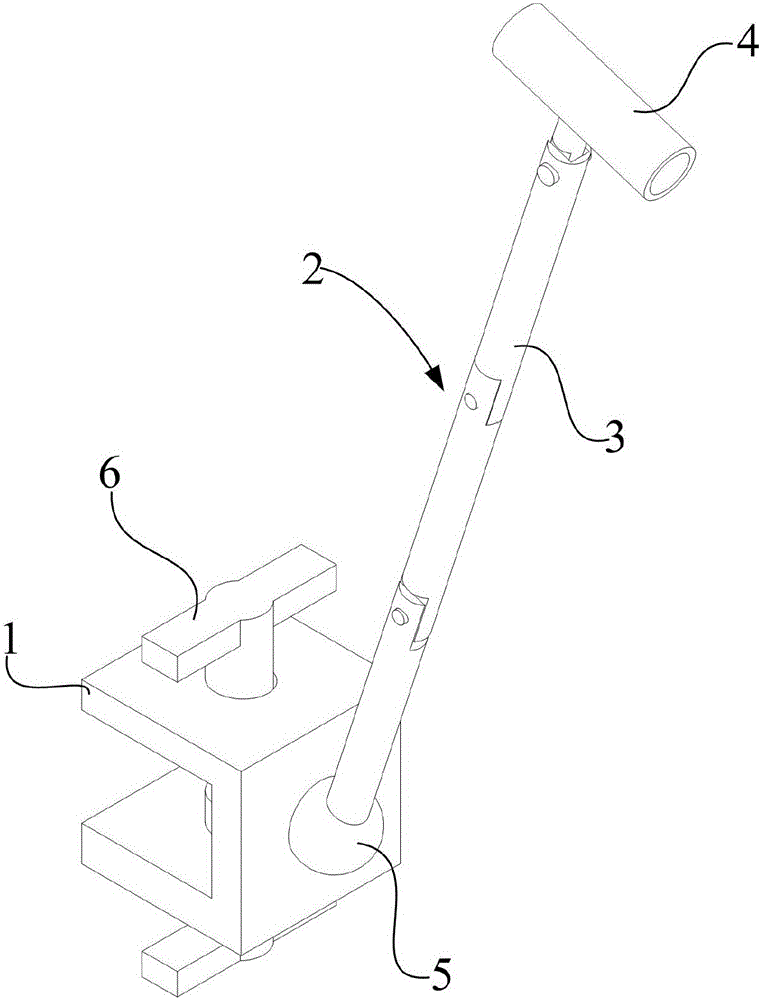

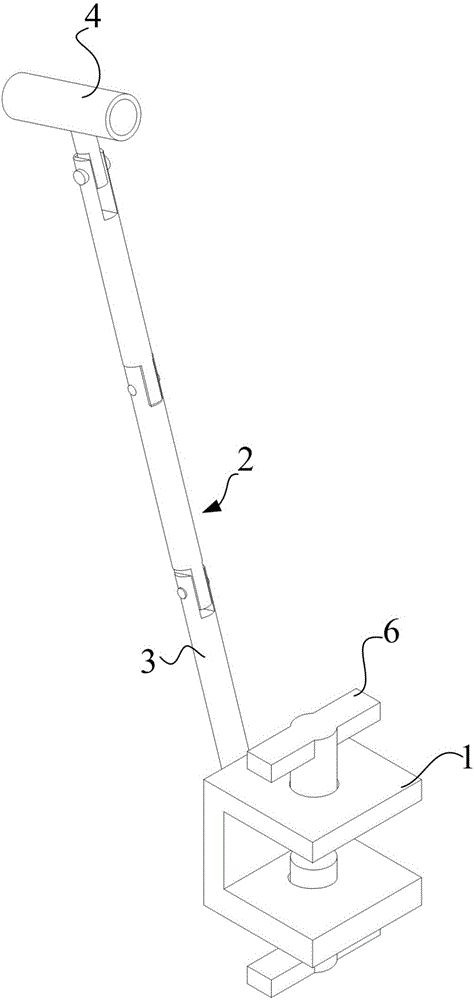

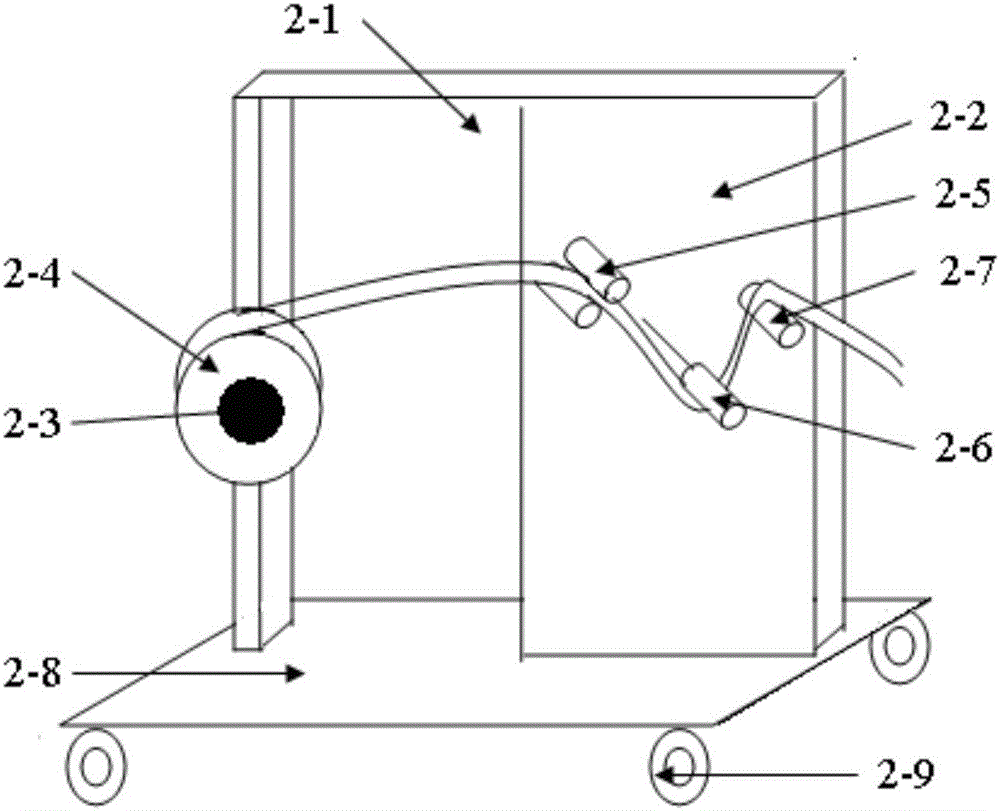

Portable cable conductor paying off device

The invention belongs to the field of electric power auxiliary equipment and relates to cables, in particular to a portable cable pay-off device. It includes a fixing base for fixing the whole device and a guide rod movably connected with the fixing base. The end of the guide rod away from the fixing base is provided with a guide cylinder. The guide rod includes at least three adjacent sections pivotally connected together. rod, and the guide cylinder is pivotally connected with the guide rod. Compared with the prior art, the advantages and positive effects of the present invention are that, by providing a portable cable pay-off device, the present invention uses the guide cylinder to guide the cable regularly from the coil, so that it does not Rolling occurs, and at the same time, the structure of the device provided by the invention is a foldable structure, which is easy to carry and can be applied to various complex environments.

Owner:GAOTANG COUNTRY POWER SUPPLY BUREAU OF STATE GRID SHANDONG ELECTRIC POWER CO

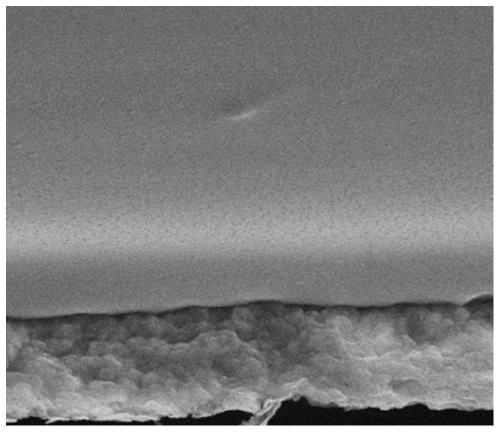

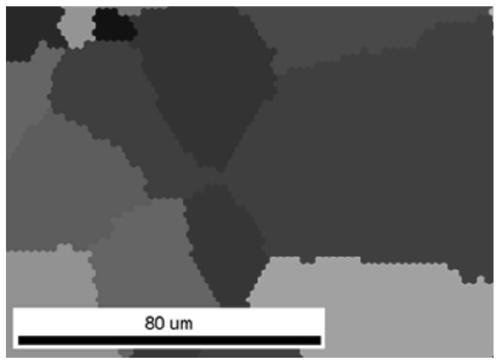

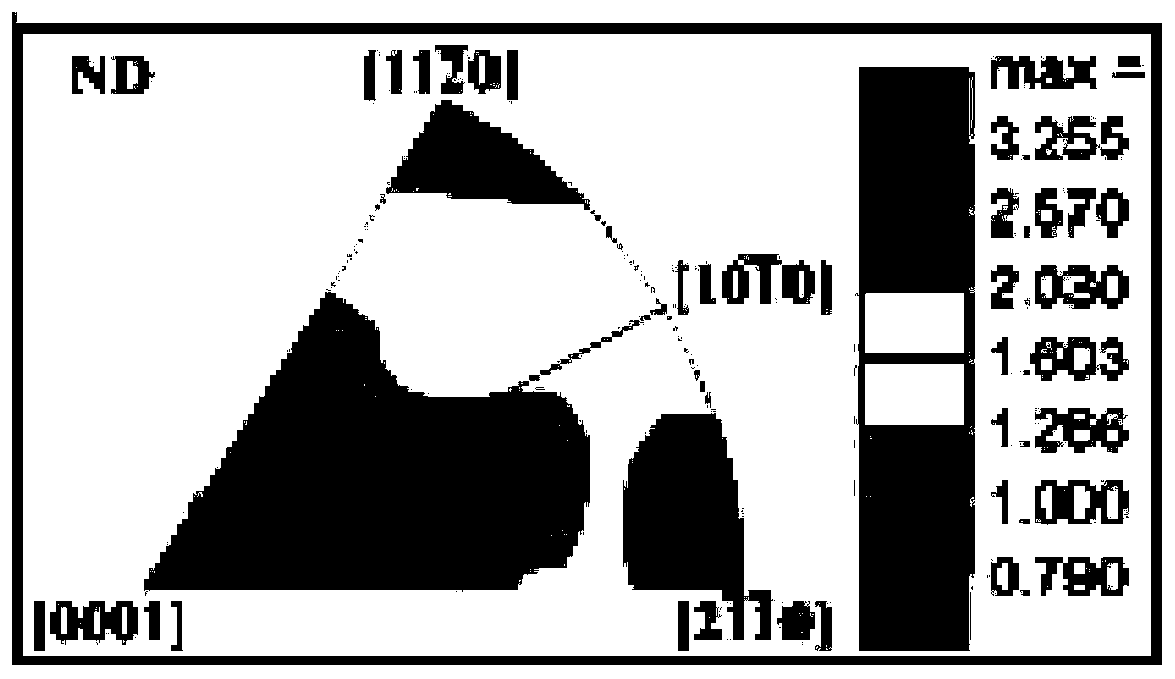

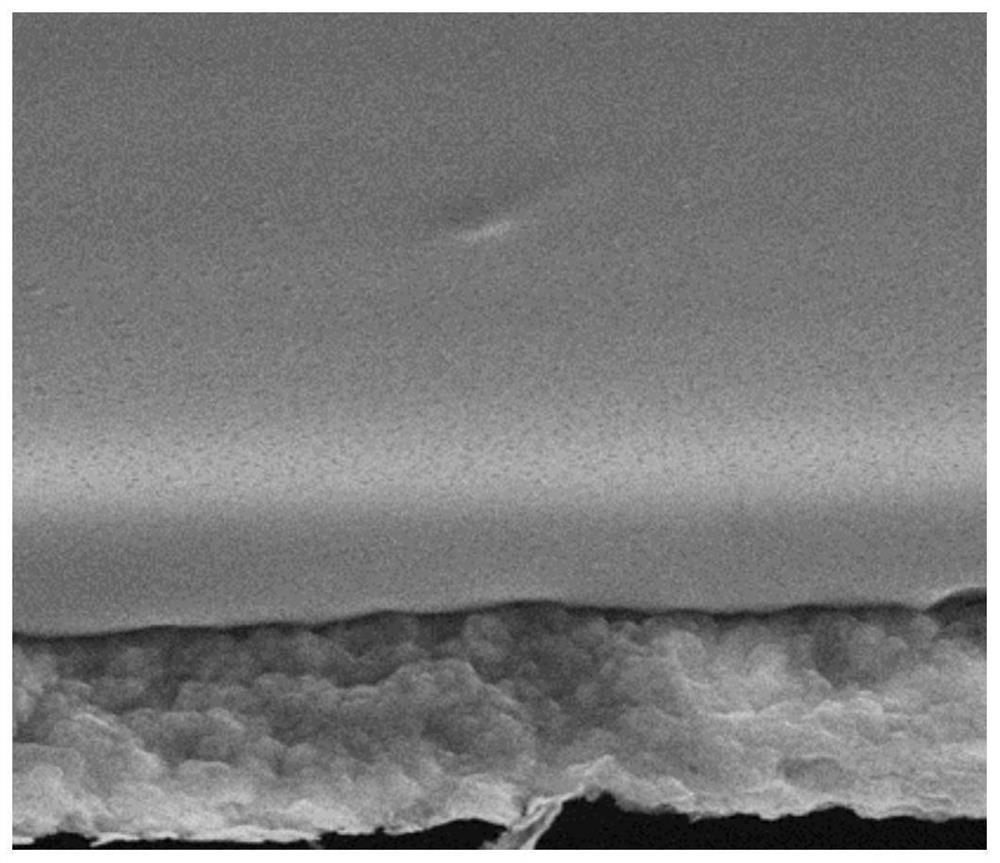

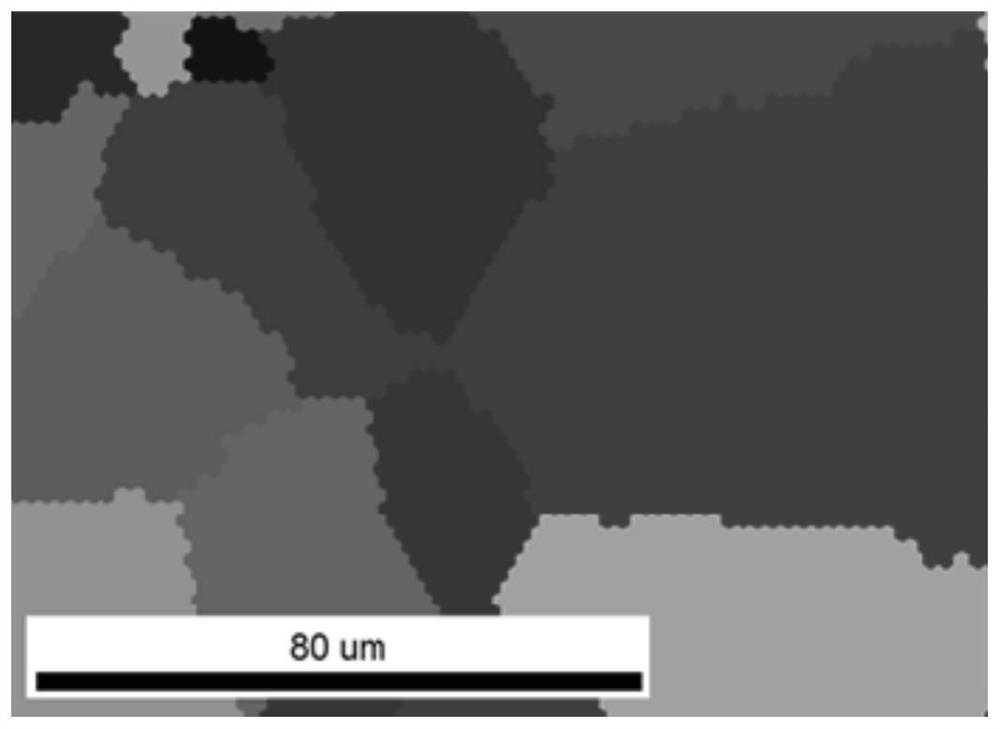

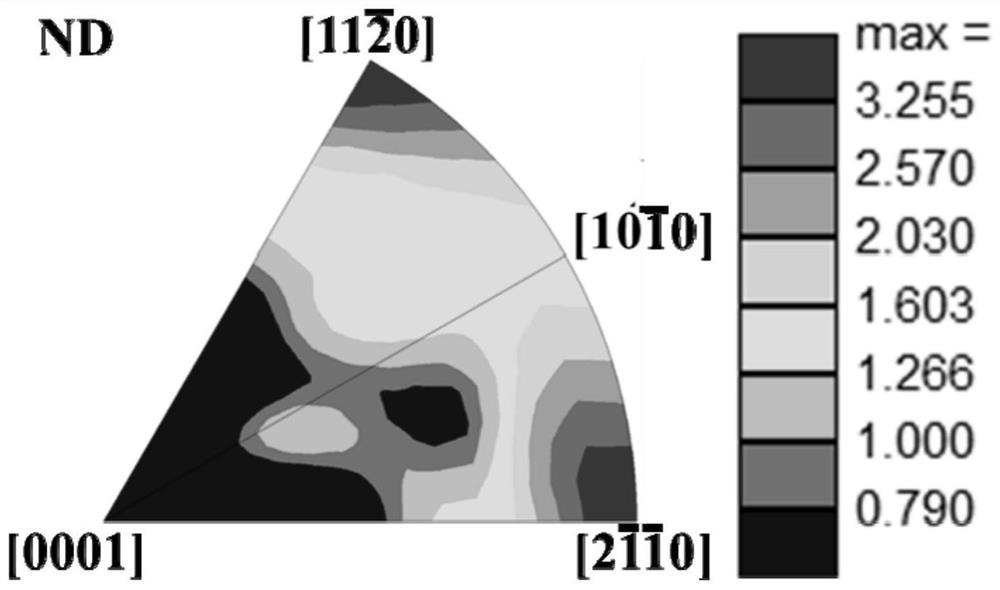

Method for processing metal-based hard coating transmission electron microscope in-situ mechanical sample by using focused ion beam

ActiveCN111044543AQuality improvementGuaranteed stabilityMaterial analysis using wave/particle radiationPreparing sample for investigationIon beam processingScanning electron microscope

The invention discloses a method for processing a metal-based hard coating transmission electron microscope in-situ mechanical sample by a focused ion beam, and relates to a manufacturing method of atransmission electron microscope in-situ mechanical sample. The objective of the invention is to solve problems that an existing common transmission electron microscope in-situ mechanical test systemcannot realize optimal diffraction analysis conditions and cannot obtain an optimal diffraction result; and a common transmission electron microscope sample manufacturing technology cannot accuratelyanalyze deformation and fracture problems of a metal-based hard coating material in an in-situ mechanical test process in a transmission electron microscope in-situ mechanical test system. The methodcomprises the steps of 1, pretreatment; 2, electrochemical polishing treatment; 3, scanning electron microscope observation; 4, focused ion beam processing; and 5, copper bracket processing. And the method for processing the metal-based hard coating transmission electron microscope in-situ mechanical sample by using the focused ion beam is completed.

Owner:HARBIN INST OF TECH

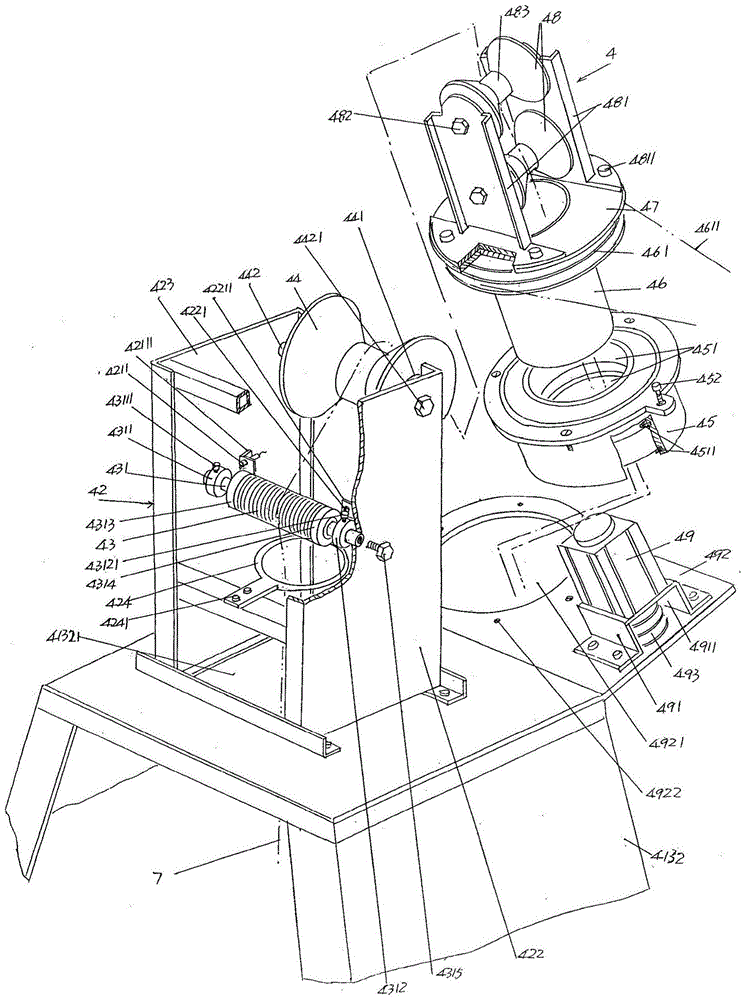

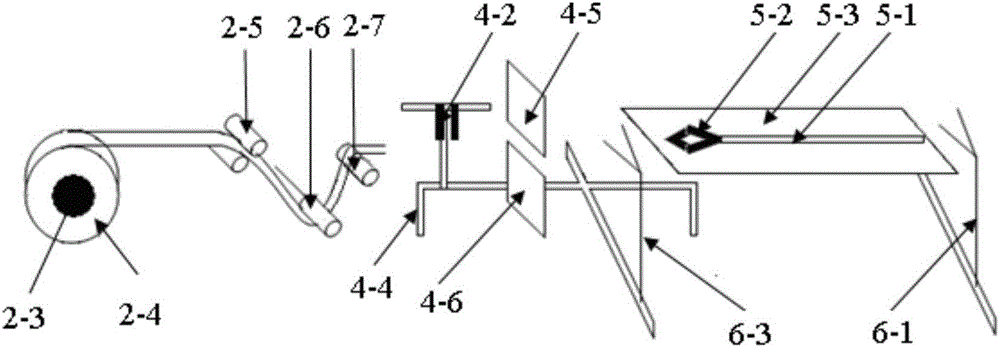

Zero-twist feeding system for flattened wefts of weaving

The invention provides a zero-twist feeding system for flattened wefts of weaving of weaving. The zero-twist feeding system comprises a picking back device, a weft insertion device, a weft receiving device and beating-up devices, wherein the picking back device is arranged at the front end of the weft insertion device, the weft receiving device is arranged at the rear end of the weft insertion device, and the beating-up devices are arranged at the inlet end and the outlet end of the weft receiving device. The motion of the zero-twist feeding system is controlled and sensed by combining pneumatic-electric drive with the light-sensing laser technology, the tension, thickness and width of the flattened wefts can be set and monitored according to needs so as to conveniently regulate the tension, thickness and width timely, the flattened wefts are fed into the cloth-fell of fabric without twist, bending, friction fluffing, edge curling and gaps during weaving, the requirements such as flatness, even yarn width, even thickness and low gap rate of the flattened fabric are satisfied while the shortest waste edge is achieved, and raw material loss and cost can be lowered to the maximum extent.

Owner:SHANGHAI CEDAR COMPOSITES TECH CO LTD +1

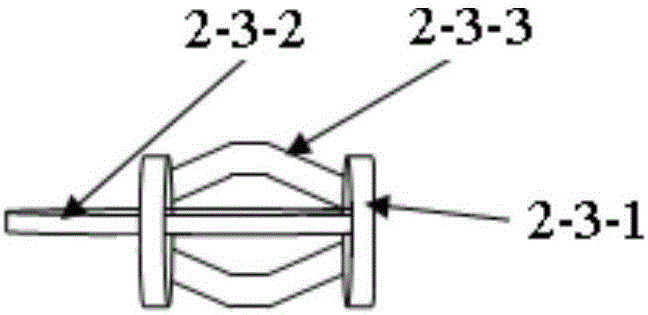

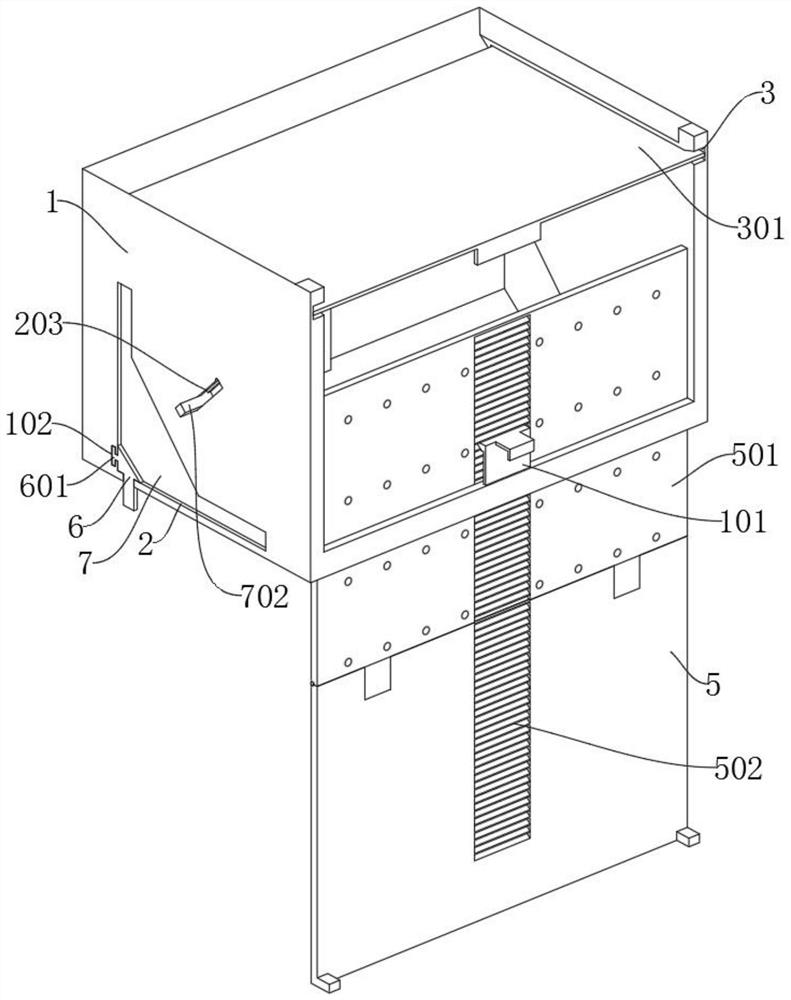

Novel fly and mosquito killer adopting trapping, sticky catching and killing mode

InactiveCN111771839AEasy to fixEasy to installInsect catchers and killersAgainst vector-borne diseasesTrappingFishery

The invention provides a novel fly and mosquito killer adopting a trapping, sticky catching and killing mode, relates to the technical field of fly and mosquito killers, and aims to solve the problemsthat when an existing fly and mosquito killer is in use, a common fly and mosquito killing sticky plate cannot be conveniently replaced, and when the fly and mosquito killing sticky plate is in use,no supporting and fixing structure is arranged, so that the sticky plate is easy to be stuck with other parts when being put in. The device comprises a main body, mounting grooves and top grooves, wherein the main body is of a rectangular structure, and a trapping lamp tube is mounted at the top end in the main body; the mounting grooves are formed in the bottoms of two sides of the main body andlocated in the front ends of the fixing grooves; the top grooves are formed in the two sides of the top end of the main body, and rectangular blocks provided with inserting plates are embedded in thebottom ends in the top grooves. The fixing part is used for being directly connected with the fly and mosquito eradication sticky plate, so that the fixing part can drive the fly and mosquito eradication sticky plate to be inserted into the main body, and thus flies and mosquitoes can fall on the fly and mosquito eradication sticky plate to be stuck and caught when the trapping lamp tube of the device is used for trapping the flies and mosquitoes.

Owner:程鹏

Tape slitting and rewinding all-in-one machine

InactiveCN105752735AStable jobReasonable design layoutArticle deliveryWebs handlingEngineeringMechanical engineering

The invention discloses a tape slitting and rewinding all-in-one machine comprising a slitting base. Two base columns in the vertical direction are arranged at the upper end of the slitting base, a tape supporting baseplate is arranged between the base columns, an unwinding drum and a winding drum are respectively arranged on two sides of the slitting base, a support is arranged at the lower end of each of the unwinding drum and the winding drum, the unwinding drum is used for realizing unwinding of a bale of tape, and the winding drum is used for realizing winding of a wisp of tape. The tape slitting and rewinding all-in-one machine is stable in operation, reasonable in overall design and layout and convenient to operate, and curling of cloth can be prevented.

Owner:TAICANG ZHONGHOU MECHANICS CO LTD

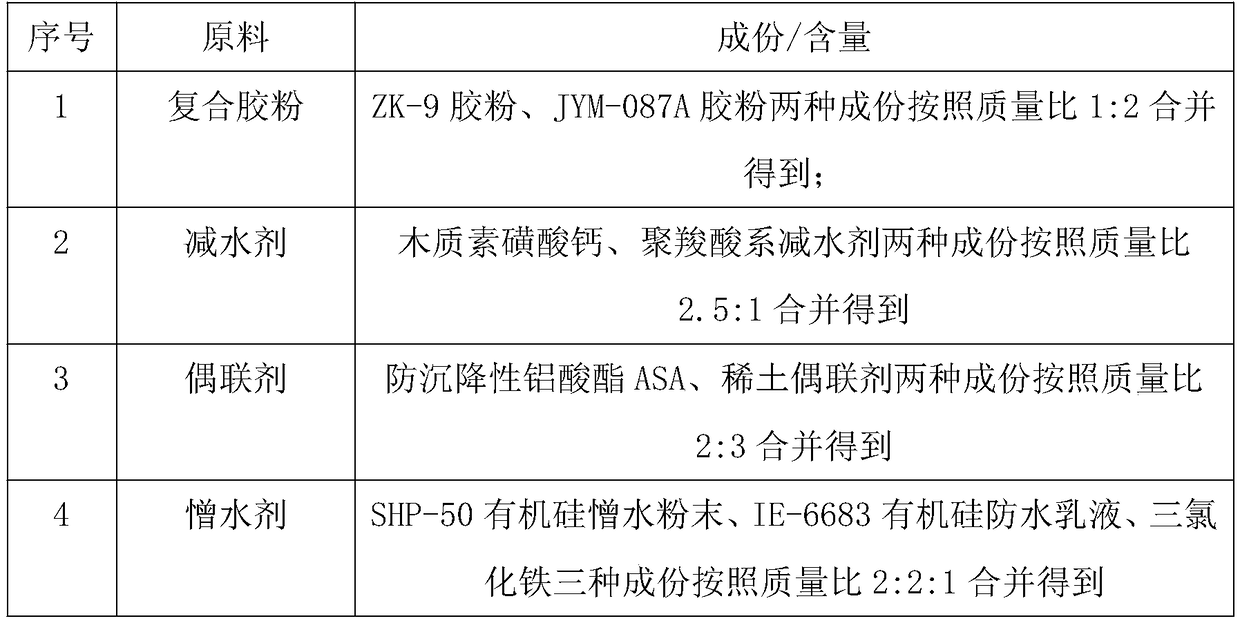

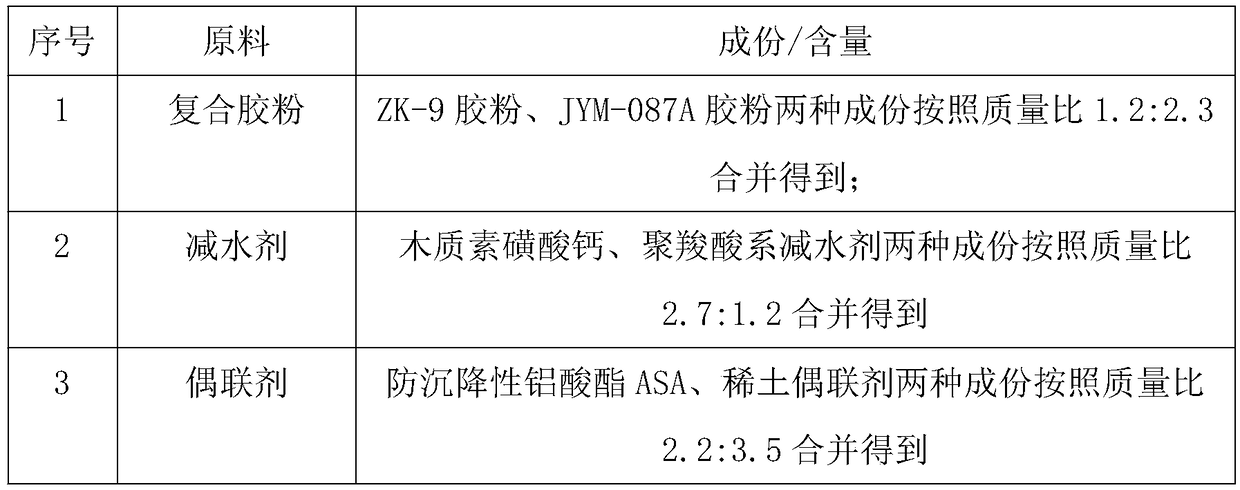

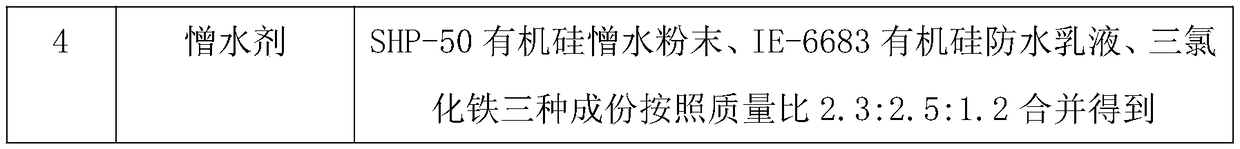

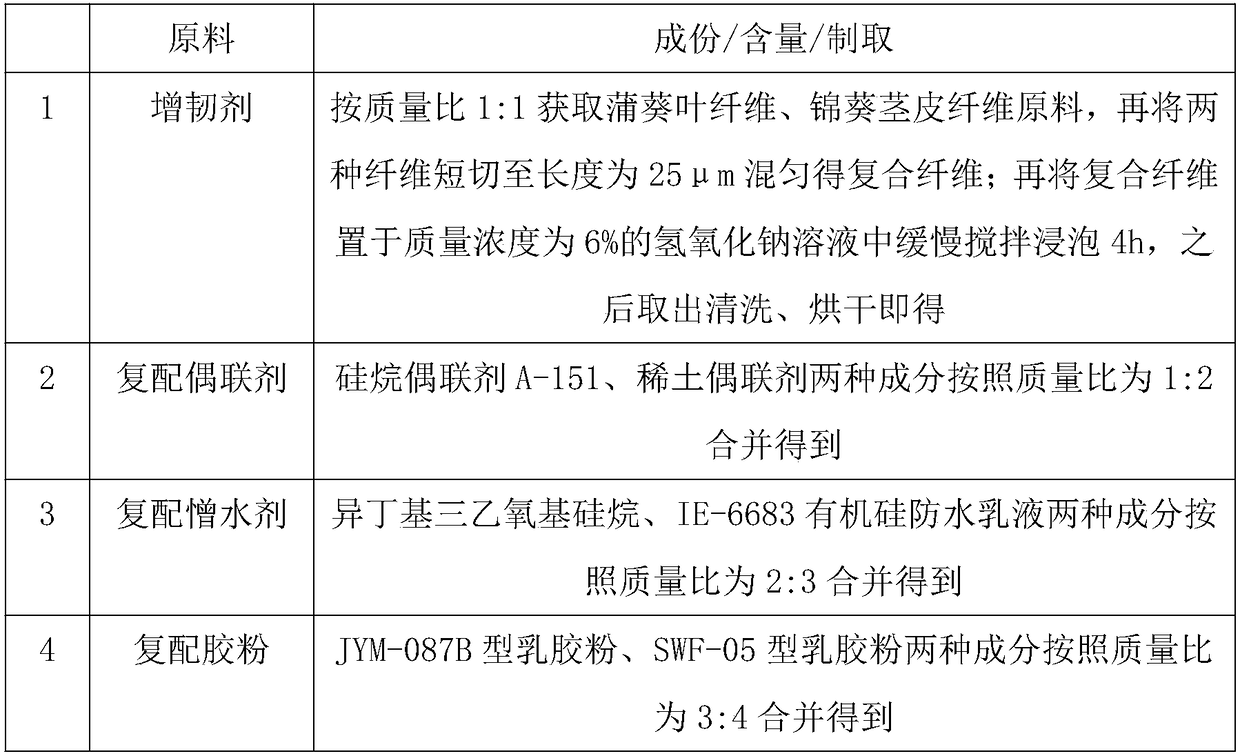

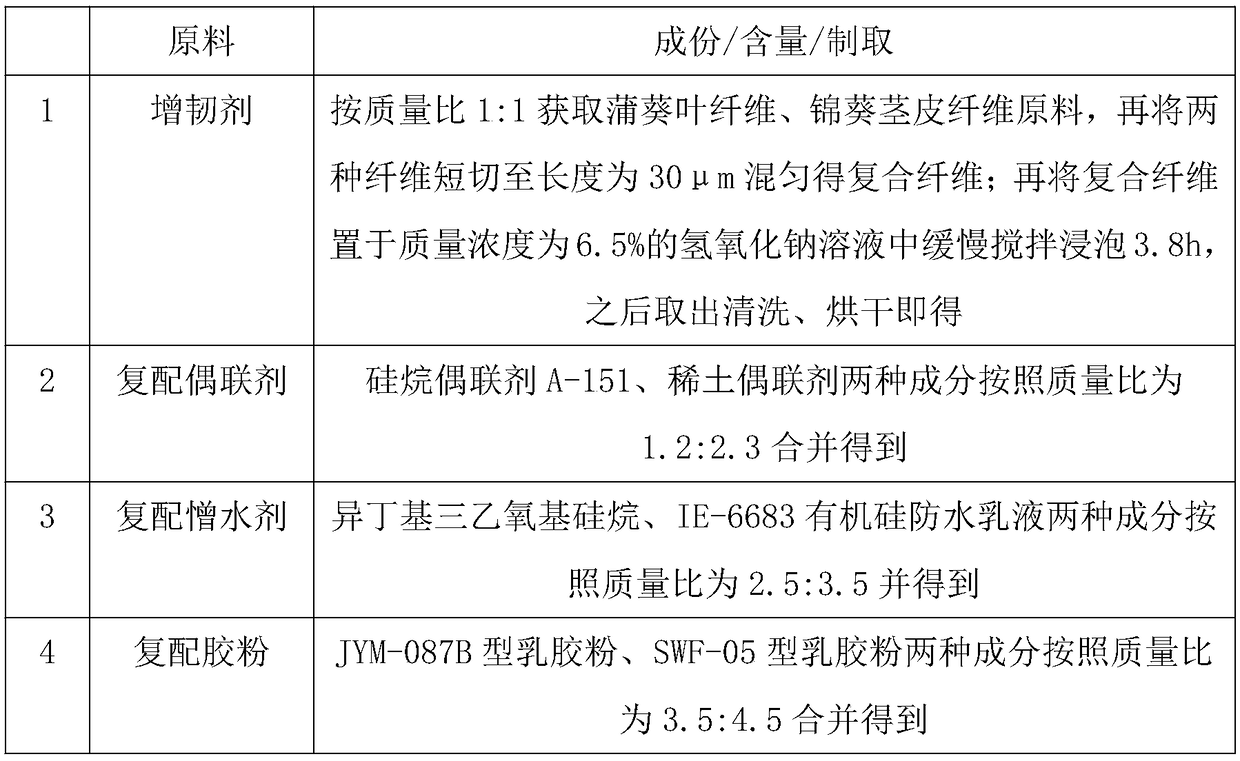

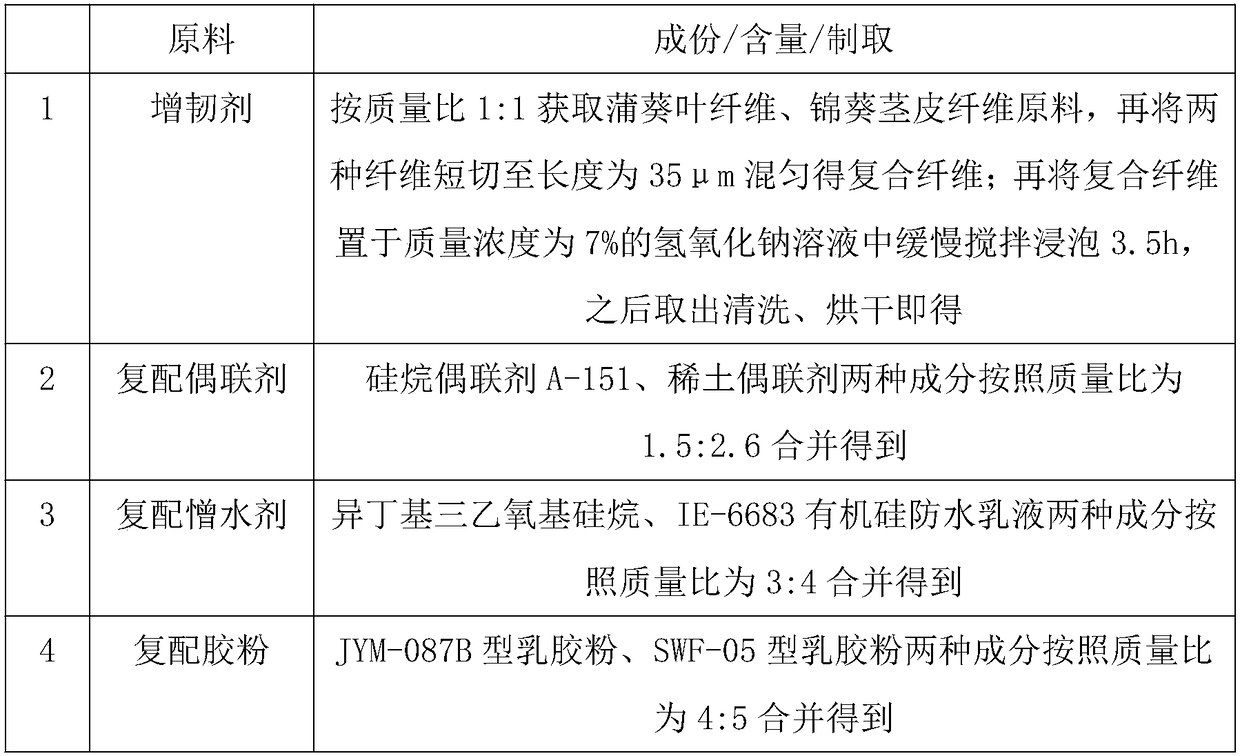

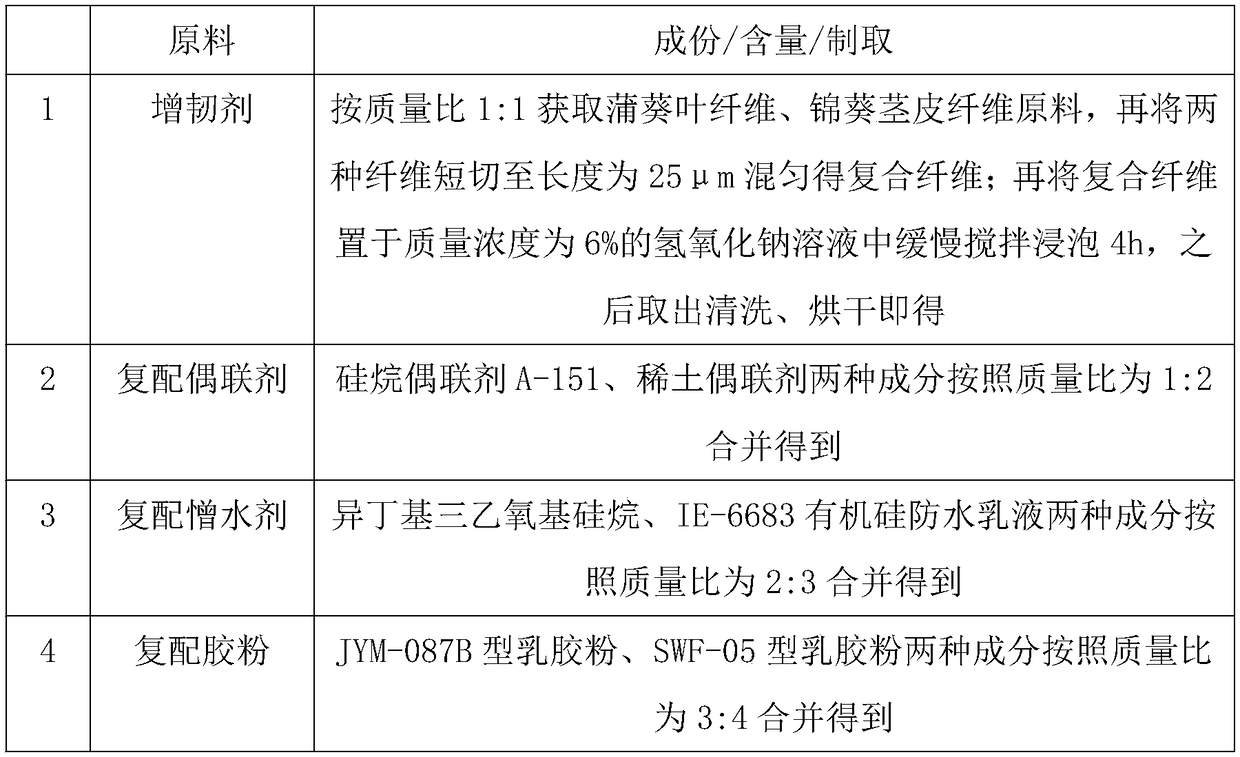

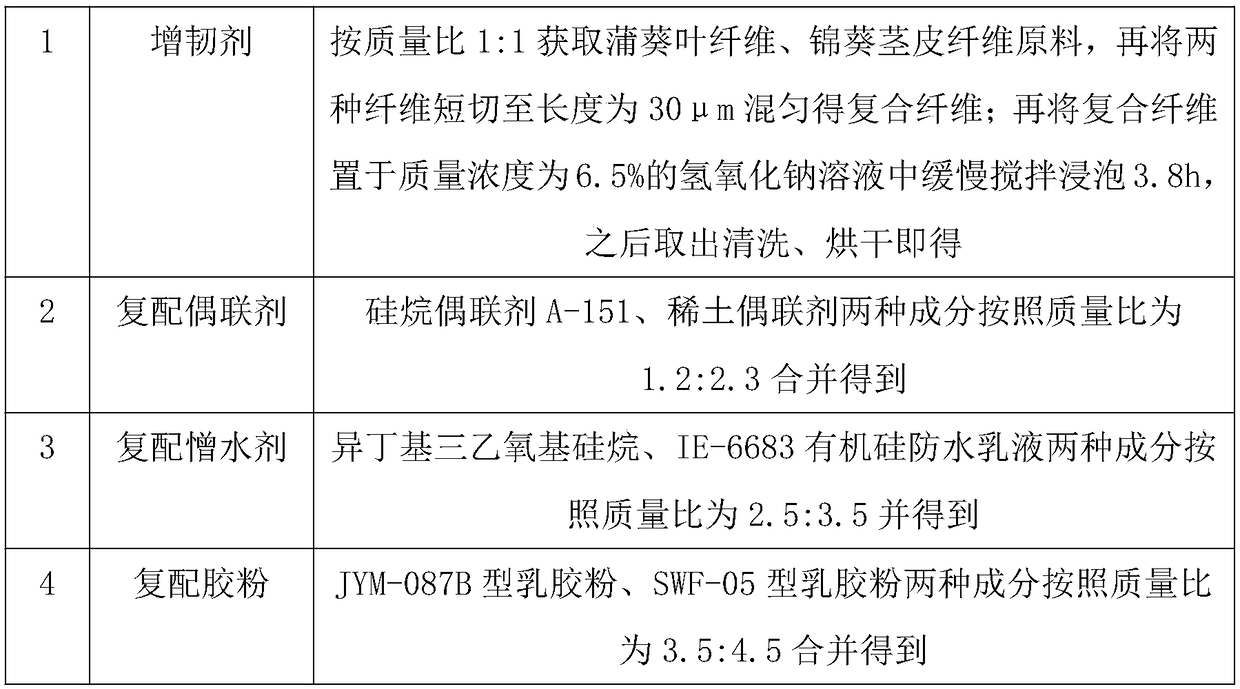

Waterproof alkali-resistant outer wall putty powder

The invention discloses waterproof alkali-resistant outer wall putty powder, and relates to the technical field of a putty powder building material. The waterproof alkali-resistant outer wall putty powder is prepared from the following raw materials: asbestos flotation tailings, bauxite, brucite velvet, bismuth vanadate, portland-pozzolana cement 32.5R, HPMC with 100,000 viscosity, a dispersing agent FT-78, composite glue powder, a water reducing agent, a coupling agent, a water repellent and magnetized water. The putty powder disclosed by the invention is comprehensively and remarkably improved in terms of physical property, water resistance, alkali resistance, flexibility, shielding property, mould resistance and the like; compared with the prior art, the putty powder is obviously improved and has good applicability and long service life.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

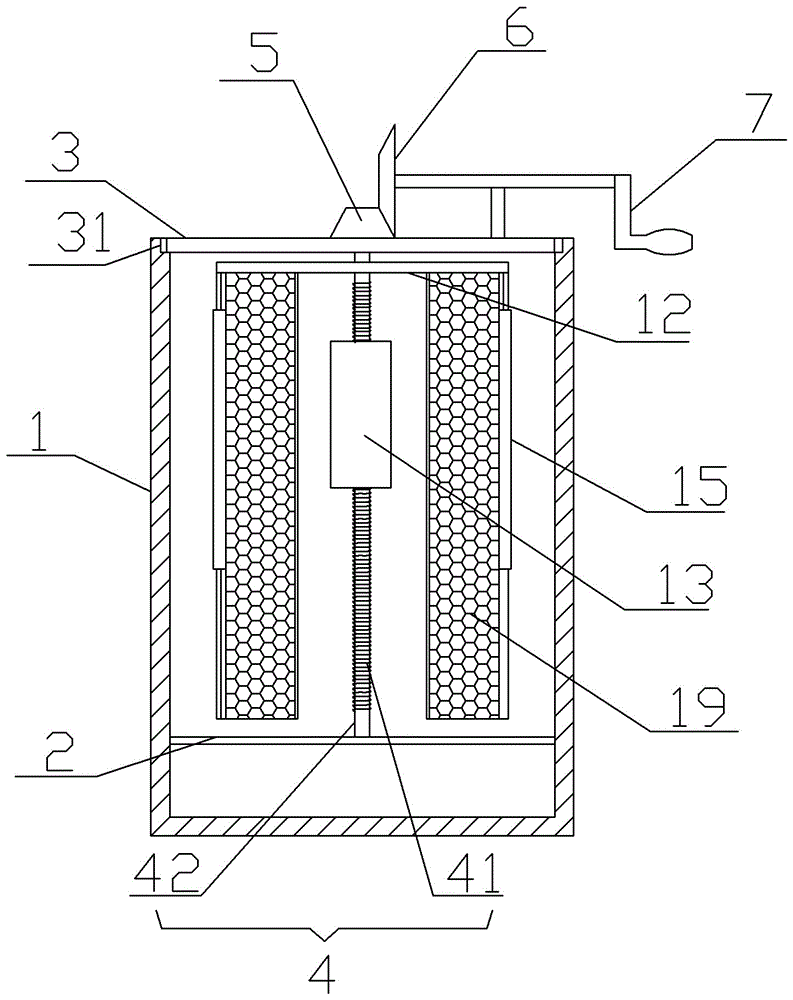

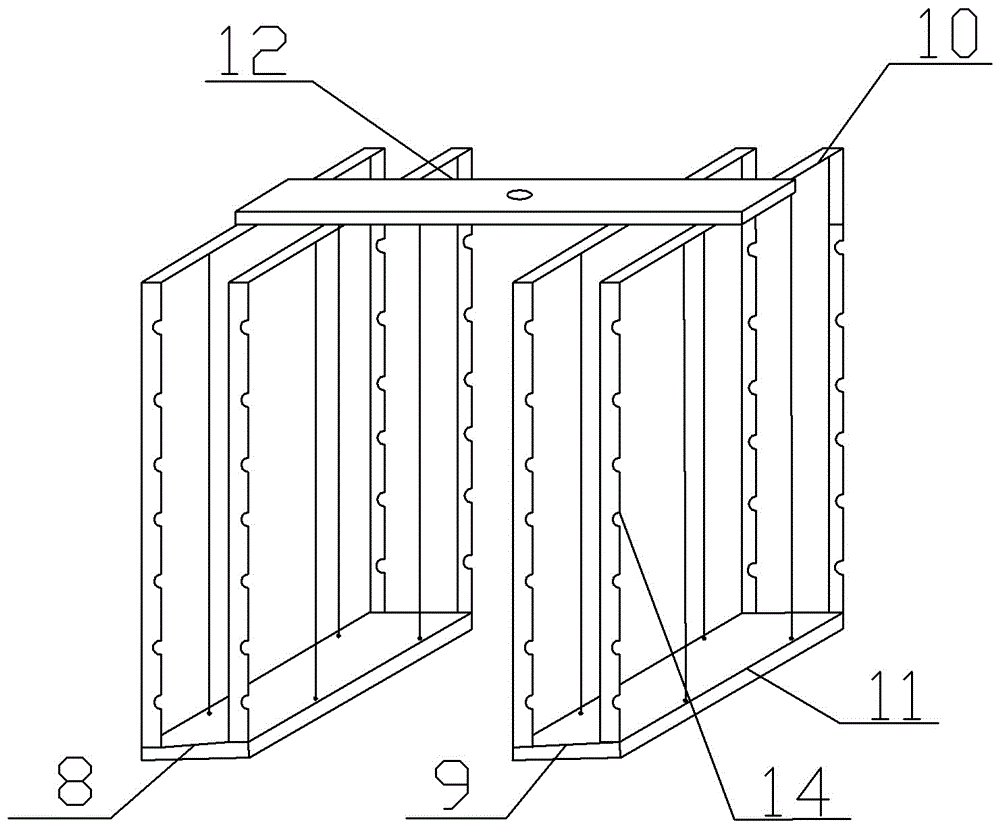

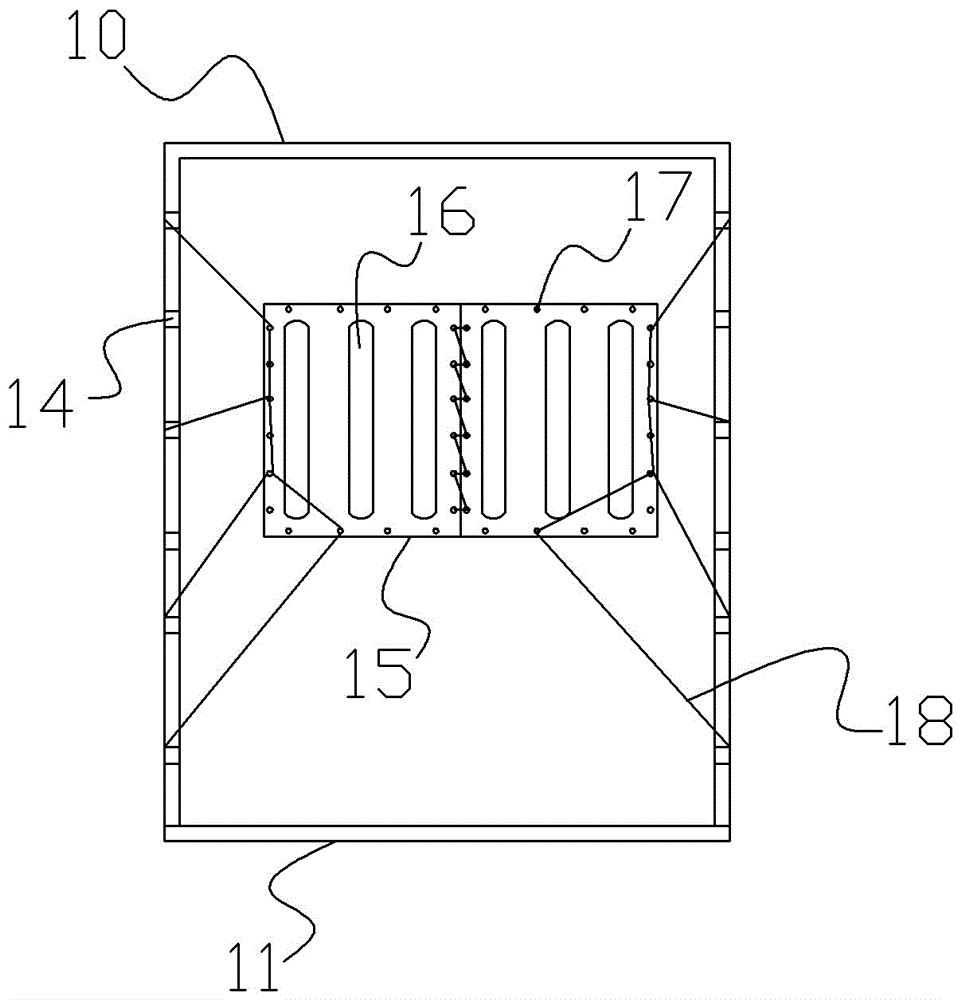

Honey extracting device

The invention belongs to A01K 59 / 00: honey extracting technique. A honey extracting device includes a rocking barrel; a lower transverse beam is arranged on an inner wall of the rocking barrel; an upper transverse beam is arranged on a barrel opening of the rocking barrel; the upper end of a drive shaft passes through the upper transverse beam and is connected to a power structure, and the lower end of the drive shaft is rotatably connected to the lower transverse beam; a connection plate is fixed on the drive shaft; a left rocking frame and right rocking frame are fixed at two ends of the connection plate respectively; an anti-throwing sheet is provided, the anti-throwing sheet is formed by binding an inner layer and an outer layer, the outer layer projects at an equal distance to form cavities, iron powder is filled in the cavities, and suture holes are formed in edges of the anti-throwing sheet; binding grooves are formed in vertical portions of a U-shaped sheet frame at an equal distance; a silk thread passes through the suture holes of the anti-throwing sheet, and the silk thread is bound in the binding grooves; and a magnetic member is connected to the drive shaft. Through the anti-throwing sheet the attachment position of which can be changed, the situation that larva in a brood comb apiary is thrown away and dies can be prevented, and pollution to honey can be avoided.

Owner:正安县正江蜜蜂养殖场

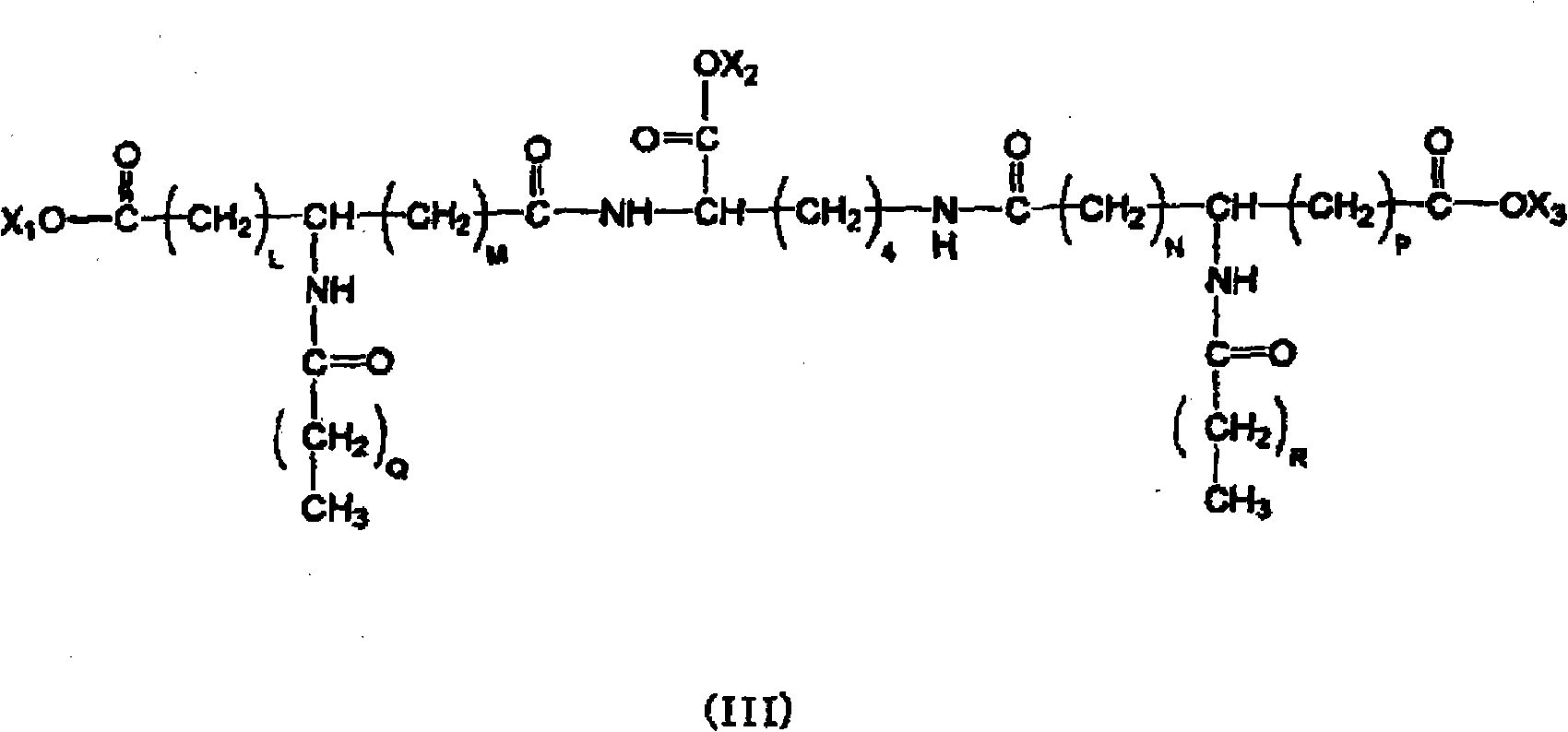

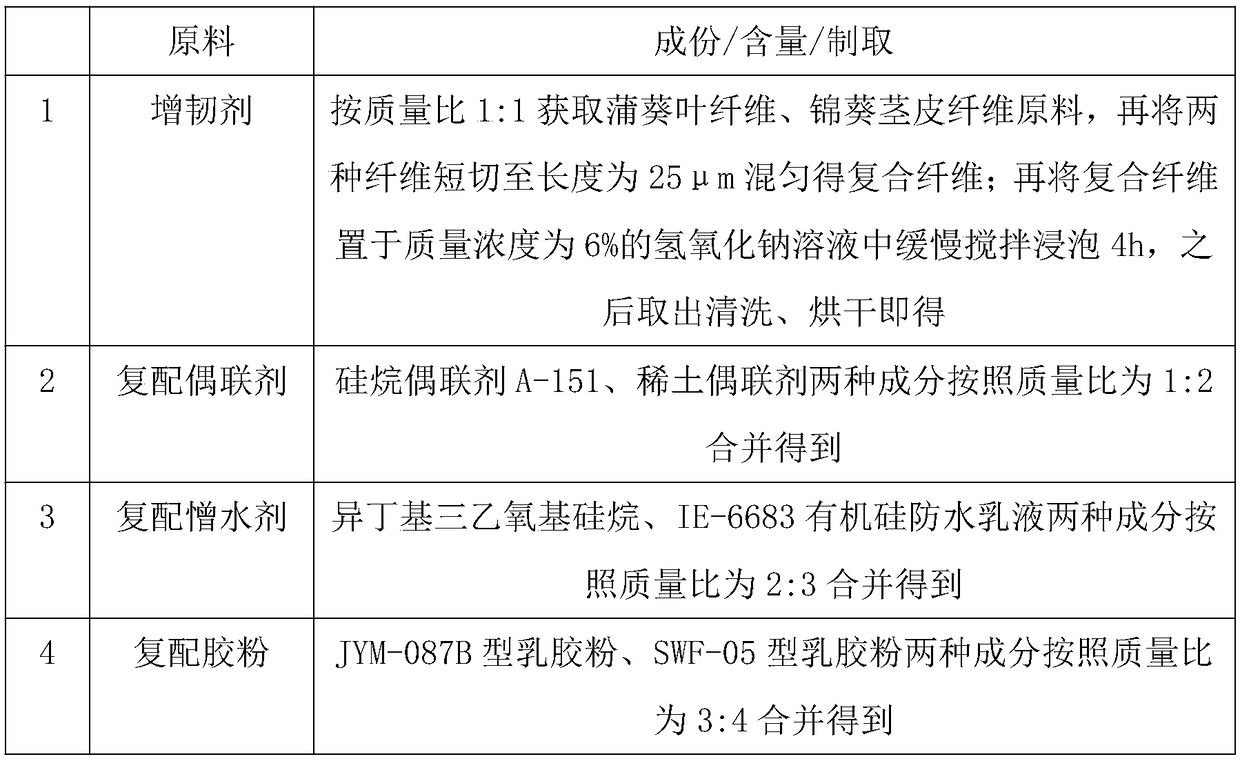

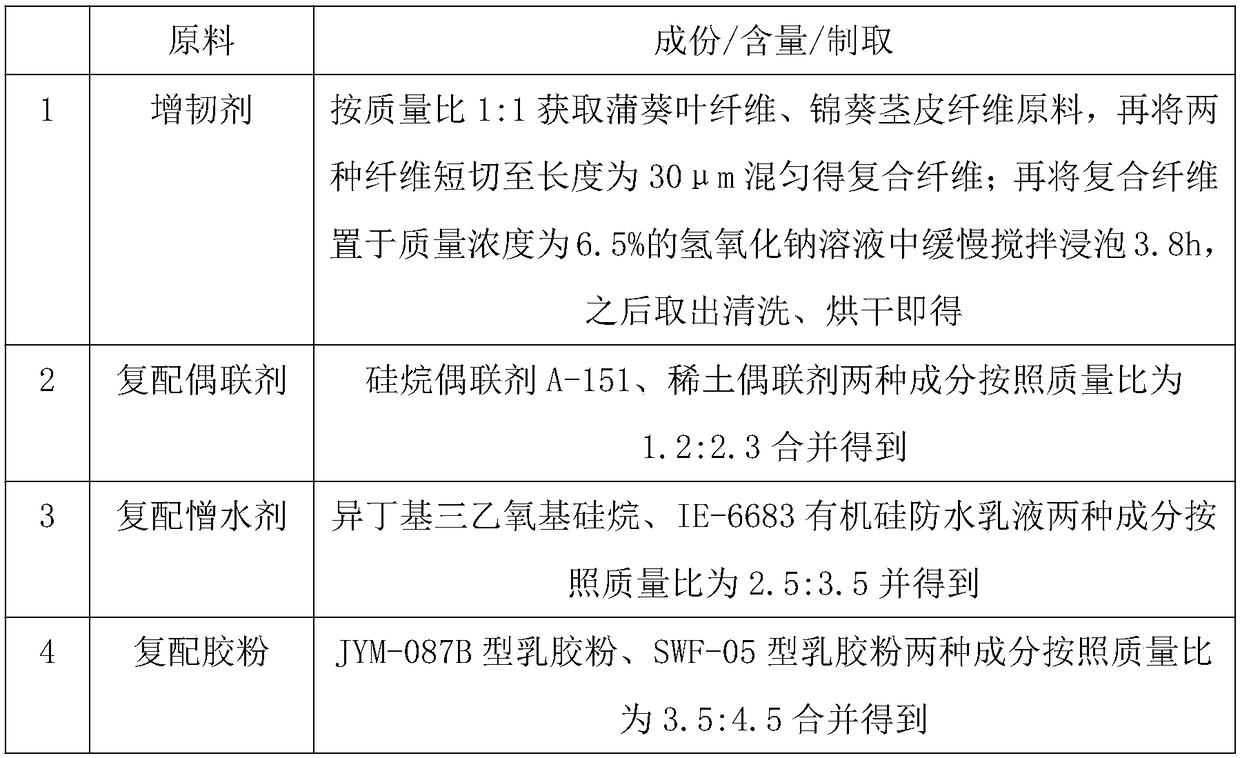

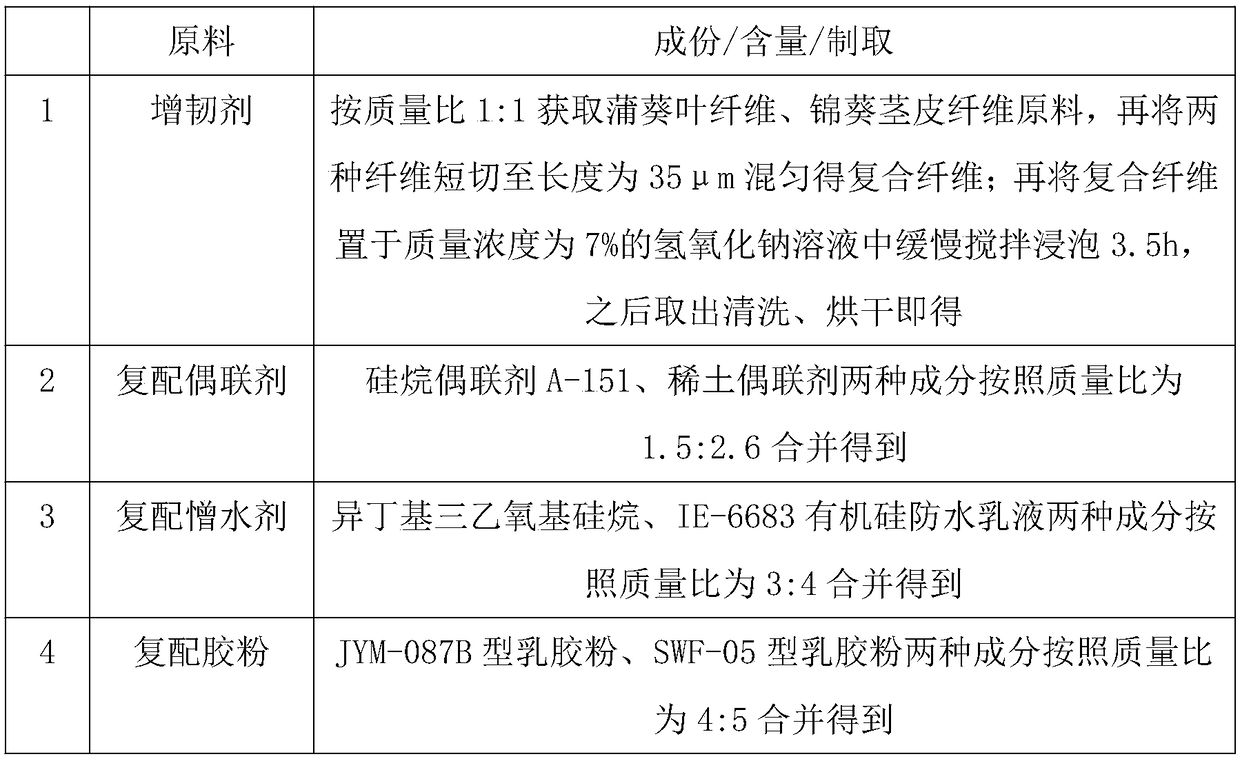

Flexible anti-cracking putty composition and application thereof

InactiveCN108892992ACreative improvementGood compatibilityFilling pastesElectromagnetic radiation4-Methylimidazole

The invention discloses a flexible anti-cracking putty composition and application thereof, and relates to the technical field of putty materials. The flexible anti-cracking putty composition comprises white cement with the label of 325, coumarone resin, perovskite tailing powder, bismuth alum acid powder, bryozoatum powder, mordenite powder, banana juice, 2-ethyl-4-methylimidazole, tri-butoxyl ethyl phosphate ester, toughening agents, complex coupling agents, complex water repellents, complex gum powder and magnetized water. The flexible anti-cracking putty composition and the application have the advantages that interior wall putty of the flexible anti-cracking putty composition is obviously enhanced in the aspects of mechanical strength, hydrophobicity, flexibility, purification and humidification capacity, antibacterial property, heat insulation, electromagnetic radiation absorbing ability and the like, accordingly, the flexible anti-cracking putty composition is excellent in integral performance and good in applicability, and the service life can be effectively guaranteed.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

Ink composition for ink jet recording

InactiveCN102070955AImprove qualityHigh glossDuplicating/marking methodsInksAlcohol sugarsWater soluble

The invention provides an ink composition, which can realize images advantaged by no bleeding or edge curling, high quality, and high gloss, under the circumstance that the ink composition uses printing paper such as coated paper and even under the circumstance that printing with particularly small drain time difference is performed, even when the ink composition is placed in a high-temperature low-humidity open environment and in a high-temperature common-humidity closed environment, blocking revering performance is good. The ink composition for ink jet recording at least includes a coloring material, water, a sparingly water-soluble alkanediol, a crystalline sugar alcohol solid below 20 DEG C., and a (poly)alkylene glycol.

Owner:SEIKO EPSON CORP

Antibacterial waterproof inner wall putty

InactiveCN108864798ACreative improvementImprove the humidity environmentFilling pastesElectromagnetic radiationMechanical property

The invention discloses an antibacterial waterproof inner wall putty, and relates to the technical field of putty materials. The antibacterial waterproof inner wall putty is prepared from the following raw materials of 325 white cement, coumarone resin, perovskite tailing powder, bismuth vandate powder, bryozoatum powder, mererized zeolite powder, plantain juice, 2-ethyl-4-methyl imidazole, tributoxy ethyl phosphate, a toughening agent, a compound coupling agent, a compound hydrophobic agent, a compound rubber powder and magnetized water. The antibacterial waterproof inner wall putty has the advantages that the mechanical property, hydrophobicity, flexibility, purification and humidity control ability, antibacterial property, heat-insulation property, electromagnetic radiation absorption property and the like are obviously improved; the whole property is more excellent, the application property is better, and the service life is guaranteed.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Finishing method of copper ammonia hemp interweaved fabric

ActiveCN110685105AThe cloth surface is smooth and beautifulLittle power lossFabric breaking/softeningSingeingTextile technologyPleat

The invention belongs to the technical field of textiles, and particularly relates to a finishing method of a copper ammonia hemp interweaved fabric. The method includes the steps: singeing; desizing;softening; tentering; preshrinking. According to a softening process, a fabric is woven when the content of the humidity is 50%, the air amount of a main fan is 70-90%, the air amount of a lower fanis 50-70%, the air amount of an exhaust fan is 40-60%, drying temperature is 110-130 DEG C, inner width is 110-120cm, reverse executing time is 3-8 seconds, and the speed is 8-20m / min. The finishing method of the copper ammonia hemp interweaved fabric is scientific in process and easy to operate. Compared with a conventional copper ammonia or hemp fabric, the interweaved fabric has more luster andsofter in hand feeling, wrinkles and turned edges of fabric surface are avoided, fabric width is uniform, the first-grade rate of the copper ammonia hemp fabric reaches 99% or more, stability of product quality is further improved, and high-quality requirements of high-end fabrics are met.

Owner:LUTAI TEXTILE

A cold laminating machine for advertising screen lamination

ActiveCN107962853BAvoid stickingNo curlingLaminationLamination apparatusEngineeringMechanical engineering

Owner:江苏剑山包装科技有限公司

Preparation method of multifunctional inner-wall environment-friendly putty

InactiveCN108707361ACreative improvementWide variety of sourcesFilling pastesPhosphateElectromagnetic radiation

The invention discloses a preparation method of multifunctional inner-wall environment-friendly putty, relating to the technical field of putty materials. The preparation method comprises the following steps: weighing the following raw materials: tab-325 white cement, coumarone resin, calcium-titanium tailing powder, barium strontium silicate powder, bryozoatum powder, mordenite powder, banana juice, 2-ethyl-4-methylimidazole, tributyloxyethyl phosphate, a toughening agent, a compound coupling agent, a compound water repellent, compound rubber powder and magnetized water; and adequately mixingand stirring the raw materials in batches. The inner-wall putty is easy to prepare and environment-friendly, the mechanical strength, hydrophobicity, flexibility, purification and humidifying capacities, antibacterial property, heat retaining property, electromagnetic radiation absorptivity and the like of the inner-wall putty are remarkably improved, the inner-wall putty has relatively excellentintegral performance and relatively good application property, and the service life is relatively guaranteed.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

A method for processing metal-based hard coating transmission electron microscopy in-situ mechanical specimens

ActiveCN111044543BQuality improvementGuaranteed stabilityMaterial analysis using wave/particle radiationPreparing sample for investigationIon beam processingElectron microscope

The invention discloses a method for processing a metal-based hard coating transmission electron microscope in-situ mechanical sample by a focused ion beam, and relates to a manufacturing method of atransmission electron microscope in-situ mechanical sample. The objective of the invention is to solve problems that an existing common transmission electron microscope in-situ mechanical test systemcannot realize optimal diffraction analysis conditions and cannot obtain an optimal diffraction result; and a common transmission electron microscope sample manufacturing technology cannot accuratelyanalyze deformation and fracture problems of a metal-based hard coating material in an in-situ mechanical test process in a transmission electron microscope in-situ mechanical test system. The methodcomprises the steps of 1, pretreatment; 2, electrochemical polishing treatment; 3, scanning electron microscope observation; 4, focused ion beam processing; and 5, copper bracket processing. And the method for processing the metal-based hard coating transmission electron microscope in-situ mechanical sample by using the focused ion beam is completed.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com