Waterproof alkali-resistant outer wall putty powder

An exterior wall putty and alkali-resistant technology, applied in filling slurry and other directions, can solve the problems of poor weather resistance, application limitation, poor waterproofness, etc., and achieve the effects of long service life, high bonding strength and excellent weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment relates to a waterproof and alkali-resistant exterior wall putty powder and a preparation method thereof. The putty powder is composed of the following raw materials in parts by weight:

[0057] 45 parts of asbestos flotation tailings;

[0058] 10 parts of bauxite;

[0059] 2 parts of brucite wool;

[0060] 4 parts of bismuth vanate;

[0061] Pozzolanic Portland cement 32.5R 20 parts;

[0062] 5 parts of 100,000 viscosity HPMC;

[0063] Dispersant FT-78 1.5 parts:

[0064] 6 parts of compound rubber powder;

[0065] 2 parts of water reducing agent;

[0066] 1 part of coupling agent;

[0067] 2 parts of water repellent;

[0068] 18 parts of magnetized water.

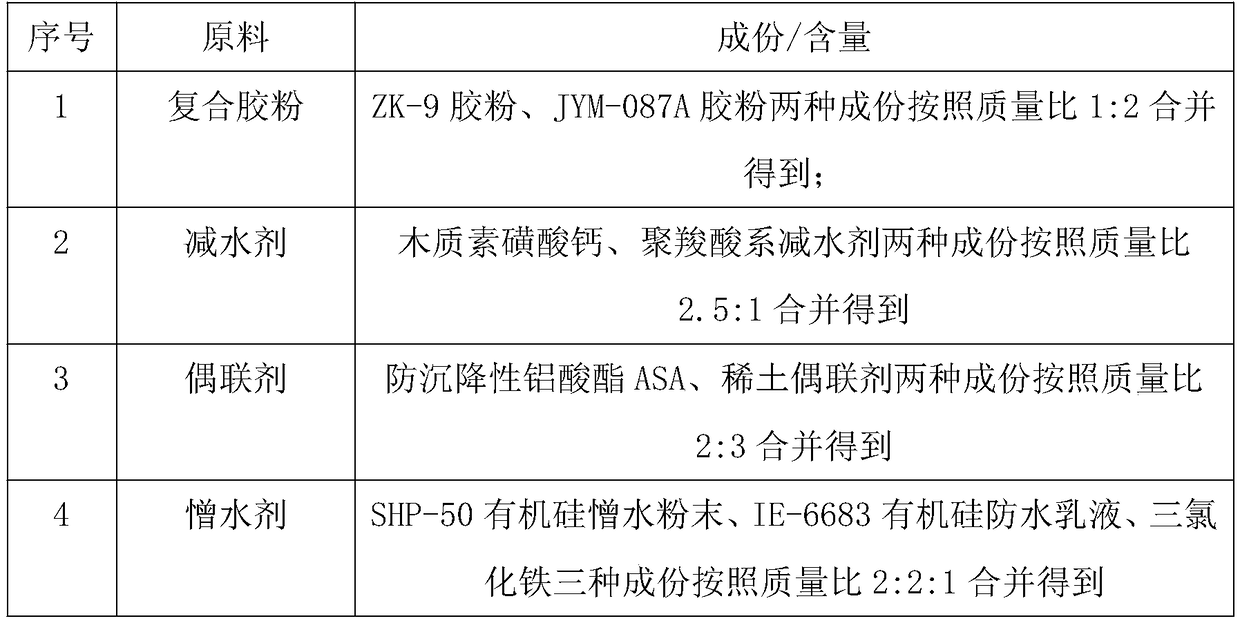

[0069] The selection of composite rubber powder, water reducer, coupling agent and water repellent in the above raw materials is shown in Table 1 below:

[0070] Table 1

[0071]

[0072] Among the above, the polycarboxylate water reducer is generally prepared by the following formula an...

Embodiment 2

[0079] This embodiment relates to a waterproof and alkali-resistant exterior wall putty powder and a preparation method thereof. The putty powder is composed of the following raw materials in parts by weight:

[0080] 47 parts of asbestos flotation tailings;

[0081] 12 parts of bauxite;

[0082] 2.5 parts of brucite wool;

[0083] 4.5 parts of bismuth vanate;

[0084] Pozzolanic Portland cement 32.5R 22 parts;

[0085] 5.5 parts of 100,000 viscosity HPMC;

[0086] Dispersant FT-78 1.8 parts:

[0087] 6.5 parts of composite rubber powder;

[0088] 2.3 parts of water reducing agent;

[0089] 1.4 parts of coupling agent;

[0090] 2.2 parts of water repellent;

[0091] 20 parts of magnetized water.

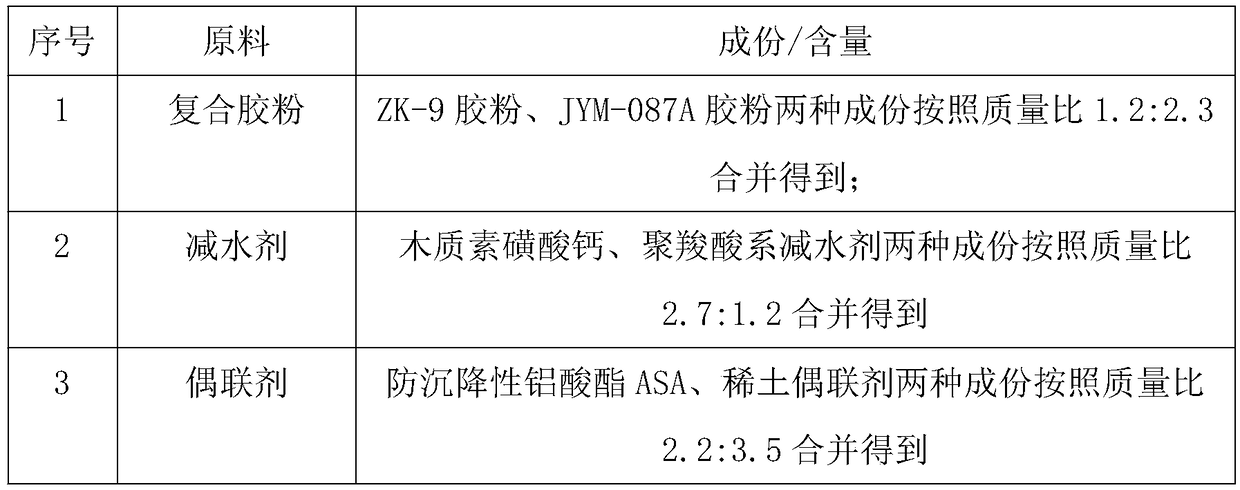

[0092] The selection of composite rubber powder, water reducer, coupling agent and water repellent in the above raw materials is shown in Table 2 below:

[0093] Table 2

[0094]

[0095]

[0096] Among the above, the polycarboxylate water reducer is generally prepar...

Embodiment 3

[0103] This embodiment relates to a waterproof and alkali-resistant exterior wall putty powder and a preparation method thereof. The putty powder is composed of the following raw materials in parts by weight:

[0104] 48 parts of asbestos flotation tailings;

[0105] 13 parts of bauxite;

[0106] 2.8 parts of brucite wool;

[0107] 5 parts of bismuth vanate;

[0108] Pozzolanic Portland cement 32.5R 24 parts;

[0109] 6 parts of 100,000 viscosity HPMC;

[0110] Dispersant FT-78 2 parts:

[0111] 7 parts of compound rubber powder;

[0112] 2.5 parts of water reducing agent;

[0113] 1.5 parts of coupling agent;

[0114] 2.5 parts of water repellent;

[0115] 21 parts of magnetized water.

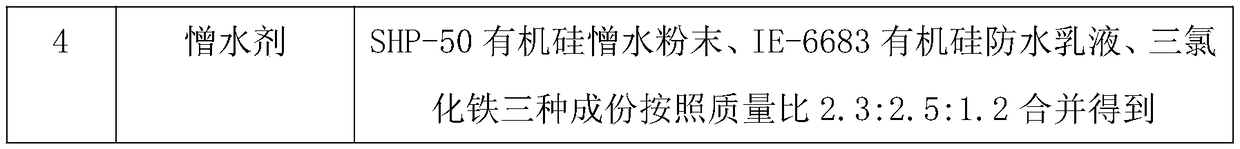

[0116] The selection of composite rubber powder, water reducer, coupling agent and water repellent in the above raw materials is shown in Table 3 below:

[0117] table 3

[0118]

[0119] Among the above, the polycarboxylate water reducer is generally prepared by the following f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com