Preparation method of multifunctional inner-wall environment-friendly putty

A multi-functional, interior wall technology, applied in the direction of filling slurry, etc., can solve the problems of application performance limitation, insufficient functionality, and lack of ability to improve the indoor environment, and achieve good low-temperature storage stability, strong humidity control performance, and light Effects of small radiation hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment relates to a multifunctional interior wall environment-friendly putty and its preparation method. The putty is composed of the following raw materials in parts by weight:

[0054] 24 parts of 325 white cement;

[0055] 20 parts of perovskite tailings powder;

[0056] Coumarone resin 14 parts;

[0057] 10 servings of banana juice;

[0058] 8 parts of bismuth vitrinate powder;

[0059] 16 parts of sea pumice powder;

[0060] 15 parts of mordenite powder;

[0061] 1.5 parts of 2-ethyl-4 methylimidazole;

[0062] 2 parts of tributoxyethyl phosphate;

[0063] 4 parts toughening agent;

[0064] 2 parts of compound coupling agent;

[0065] 1.5 parts of compound water repellent;

[0066] 12 parts of compound rubber powder;

[0067] 30 parts of magnetized water.

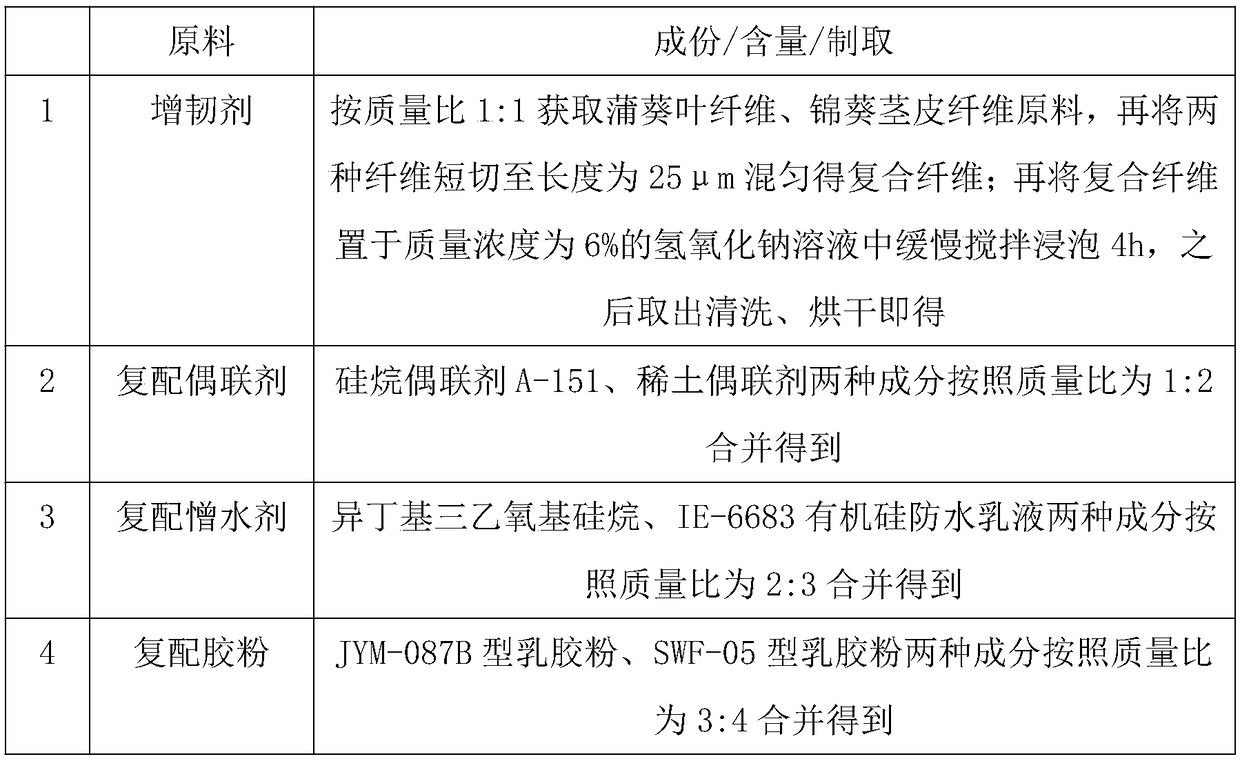

[0068] The selection and preparation of the toughening agent, compounded coupling agent, compounded hydrophobic agent and compounded rubber powder in this example are shown in Table 1 below: ...

Embodiment 2

[0077] This embodiment relates to a multifunctional interior wall environment-friendly putty and its preparation method. The putty is composed of the following raw materials in parts by weight:

[0078] Label 325 white cement 26 parts;

[0079] 22 parts of perovskite tailings powder;

[0080] Coumarone resin 16 parts;

[0081] 12 parts of plantain juice;

[0082] 9 parts of bismuth vitrinate powder;

[0083] 18 parts of sea pumice powder;

[0084] 19 parts of mordenite powder;

[0085] 2 parts of 2-ethyl-4 methylimidazole;

[0086] 2.4 parts of tributoxyethyl phosphate;

[0087] 4.5 parts of toughening agent;

[0088] 2.5 parts of compound coupling agent;

[0089] 1.8 parts of compound water repellent;

[0090] 13 parts of compound rubber powder;

[0091] 32 parts of magnetized water.

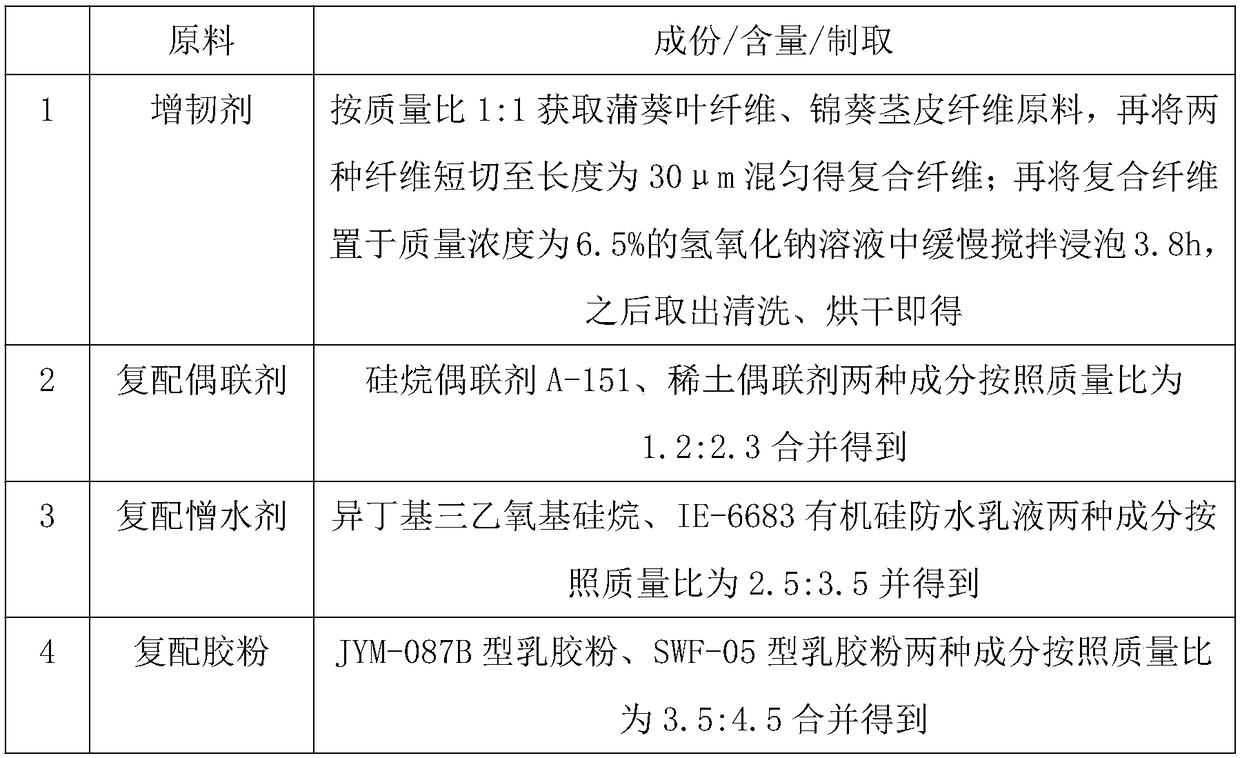

[0092] The selection and preparation of the toughening agent, compounded coupling agent, compounded hydrophobic agent and compounded rubber powder in this example are shown in Table ...

Embodiment 3

[0101] This embodiment relates to a multifunctional interior wall environment-friendly putty and its preparation method. The putty is composed of the following raw materials in parts by weight:

[0102] Label 325 white cement 28 parts;

[0103] 23 parts of perovskite tailings powder;

[0104] Coumarone resin 18 parts;

[0105] 13 servings of plantain juice;

[0106] 10 parts of bismuth vitrinate powder;

[0107] 20 parts of sea pumice powder;

[0108] 21 parts of mordenite powder;

[0109] 2.2 parts of 2-ethyl-4 methylimidazole;

[0110] 2.5 parts of tributoxyethyl phosphate;

[0111] 5 parts of toughening agent;

[0112] 2.7 parts of compound coupling agent;

[0113] 2 parts of compound water repellent;

[0114] 14 parts of compound rubber powder;

[0115] 34 parts of magnetized water.

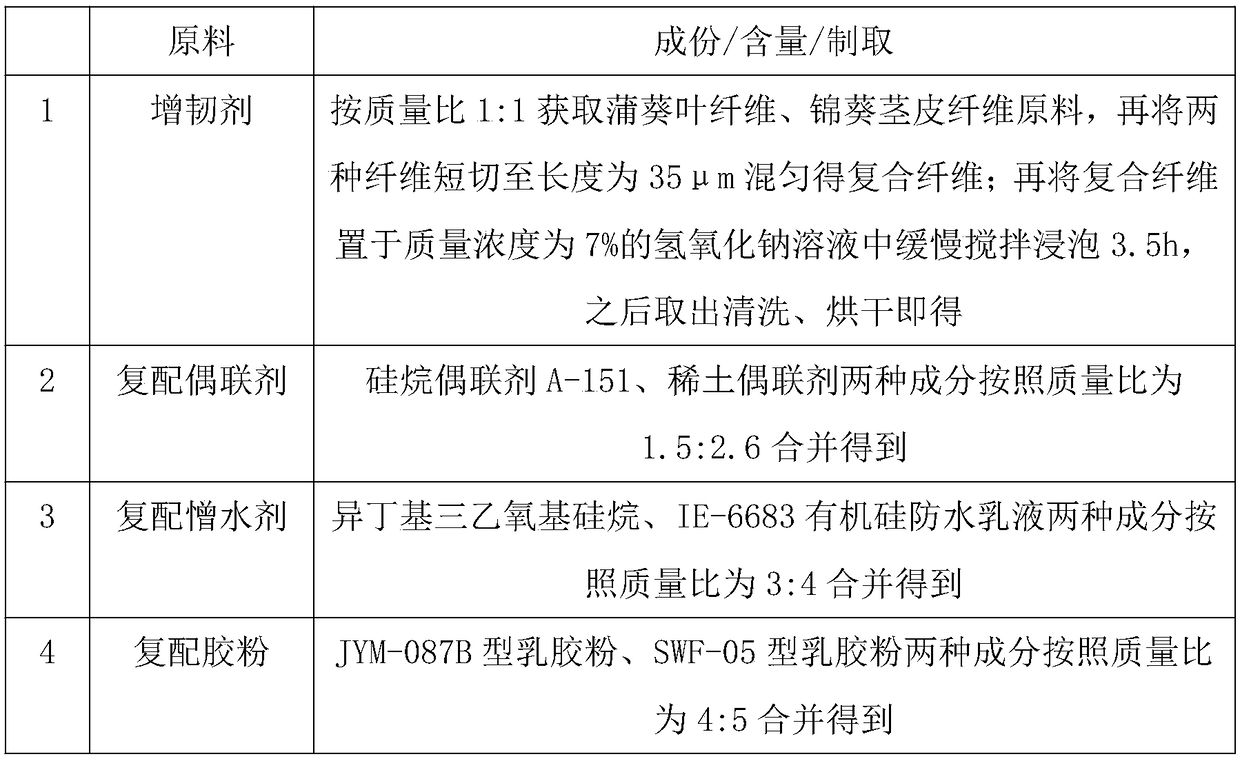

[0116] The selection and preparation of the toughening agent, compounded coupling agent, compounded hydrophobic agent and compounded rubber powder in this example are shown in Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com