A method for processing metal-based hard coating transmission electron microscopy in-situ mechanical specimens

A hard coating, transmission electron microscope technology, used in the preparation of test samples, scientific instruments, material analysis using wave/particle radiation, etc. Material deformation and fracture, inability to achieve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

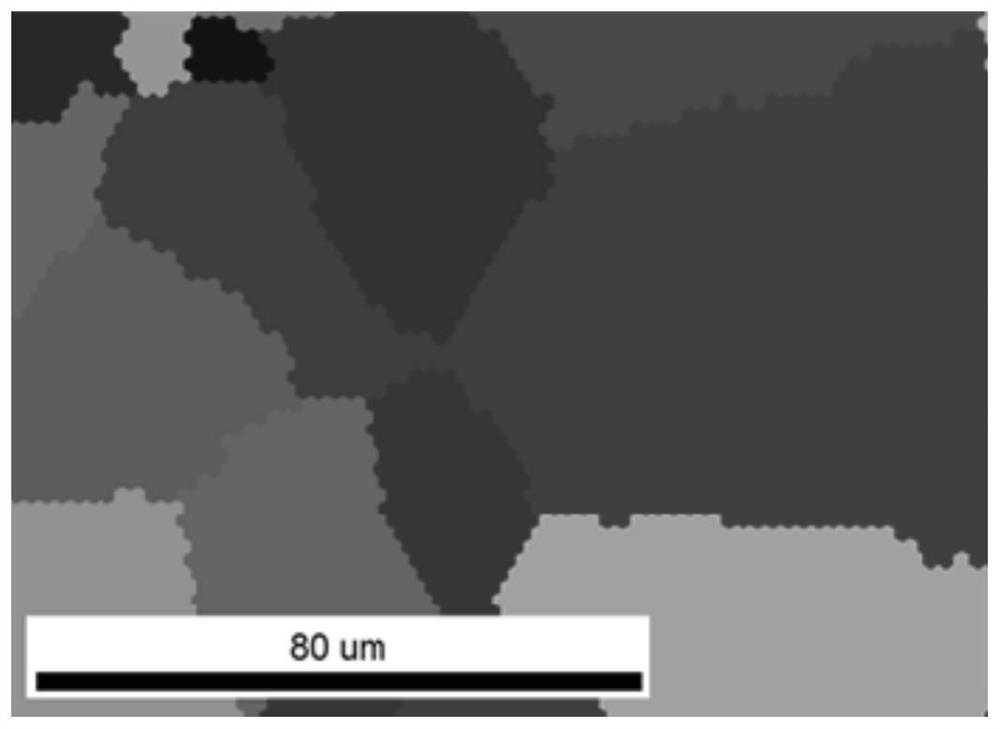

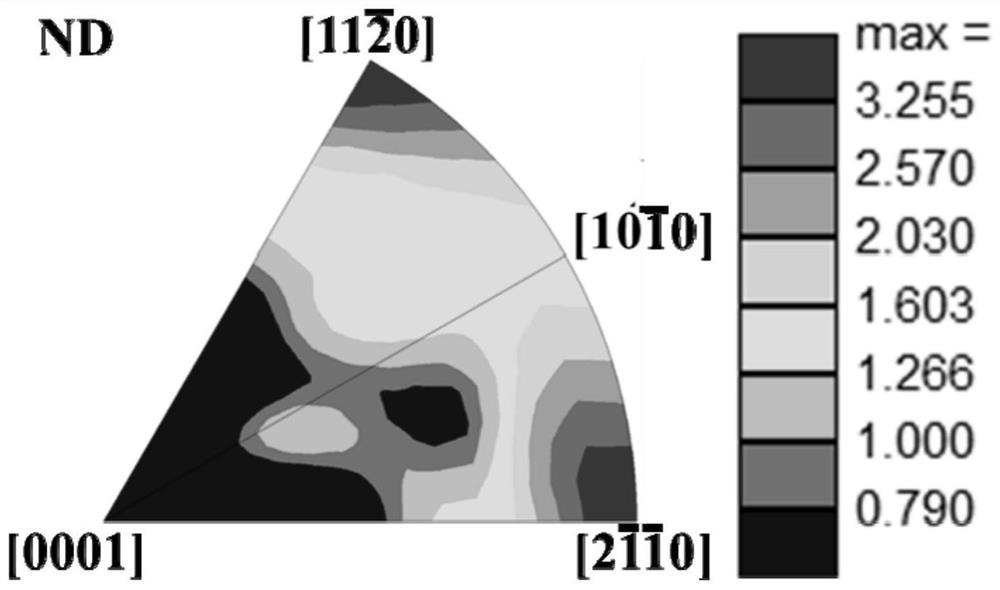

[0029] Specific embodiment one: the present embodiment a kind of method of focused ion beam processing metal-based hard coating transmission electron microscope in-situ mechanical sample, it is finished according to the following steps:

[0030] 1. Pretreatment:

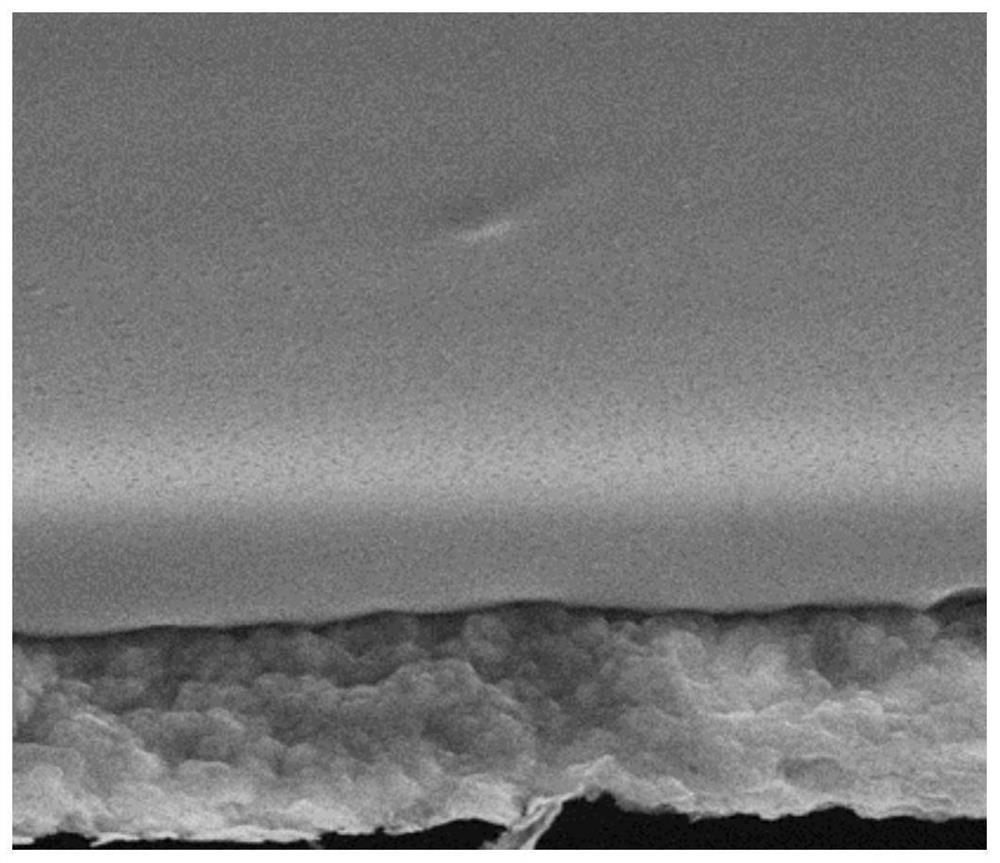

[0031] The metal substrate with a hard coating on the surface is used as the material to be tested, and the cross section of the material to be tested is ground and polished, and then cleaned and dried to obtain a polished sample;

[0032] 2. Electrochemical polishing treatment:

[0033] Place the polished sample in the polishing solution, and perform electrochemical polishing for 30s to 60s under the condition of a current of 0.2A to 5A to obtain an electrochemically polished sample;

[0034] The polishing liquid is mixed by methanol, n-butanol and perchloric acid; the volume ratio of the methanol and perchloric acid is (10~15):1; the volume of the n-butanol and perchloric acid The ratio is (5~9):1;

[0035] 3. S...

specific Embodiment approach 2

[0050] Specific embodiment two: the difference between this embodiment and specific embodiment one or two is that the grinding and polishing described in step one is specifically to adopt 200#, 400# and 1000# metallographic sandpaper in turn to measure the cross-section of the material Grind and polish. Others are the same as in the first or second embodiment.

specific Embodiment approach 3

[0051] Specific embodiment three: the difference between this embodiment and one of specific embodiments one or two is that the cleaning and drying described in step one are specifically cleaned with acetone, absolute ethanol and deionized water successively, and then heated at a temperature of Dry at 40°C to 80°C for 3h to 5h. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com