Adhesive patch containing bisoprolol

A bisoprolol and patch technology, applied in the field of percutaneous absorption type patches, can solve problems such as undescribed exudation, unresearched patch shape, etc., and achieve the effects of inhibiting content drop, sufficient adhesive strength, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

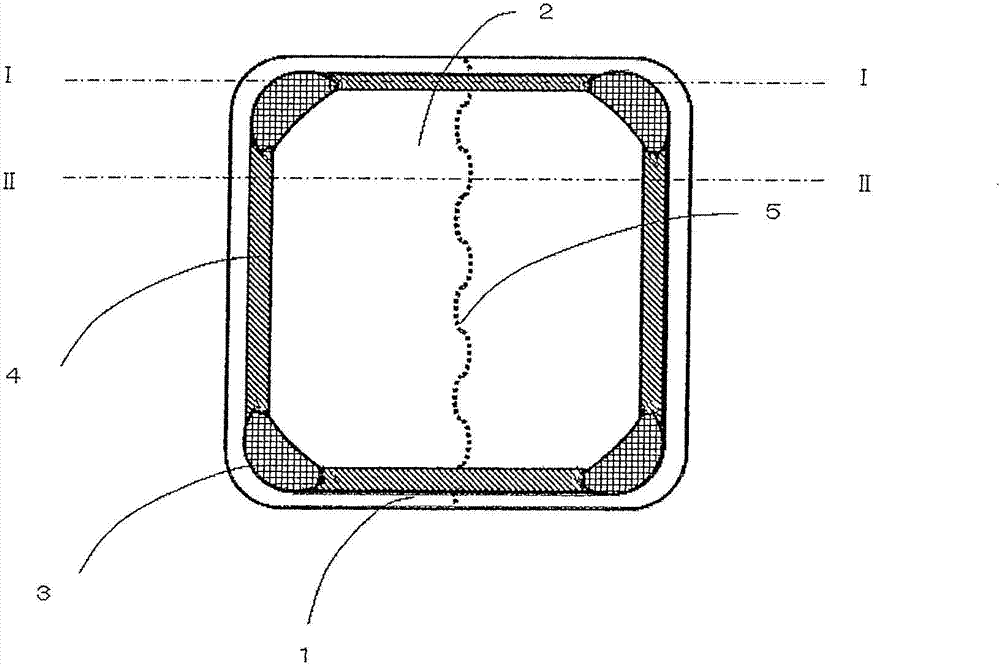

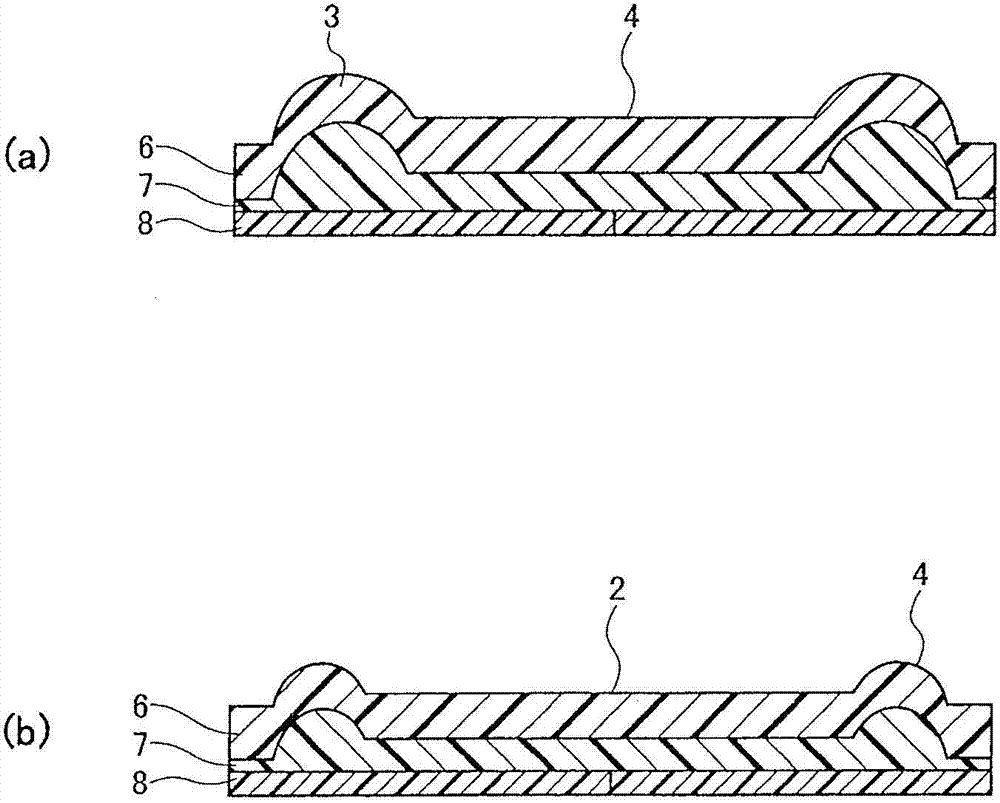

[0109] The adhesive sheet A was set on a press base with a surface temperature of 30°C. Use a heated rectangular stamper (external size 64mm×64mm, the radius of the corner arc part (hereinafter referred to as "R") is 8mm, the inner size is 56mm×56mm, R is 4mm, made of iron Manufacture), heating the surface of the support of the adhesive sheet A under pressure so that the back part of the release liner is near the center of the patch (heating temperature: 150°C, compression molding pressure: 2×10 7 N / m 2 , Heating and pressing time: 0.3 seconds). In such a manner that the heated and pressurized area corresponds to the peripheral portion of the patch obtained later, the patch body and the glass spacer are simultaneously punched out from the heated and pressurized adhesive sheet A using a press knife. Show its schematic plan in figure 1 in. will figure 1 The cross-sections cut along the line I-I and line II-II are shown in figure 2 (a) and (b).

[0110] From figure 1 with figure...

Embodiment 2

[0112] The patch was manufactured in the same manner as in Example 1, except that the conditions of heating and pressing were changed to: heating temperature: 120°C, compression mold pressure: 2×10 7 N / m 2 , Heating and pressing time: 1 second. The shape of the obtained patch and the figure 1 with 2 The shape and the like of the patch of Example 1 shown in are the same.

Embodiment 3

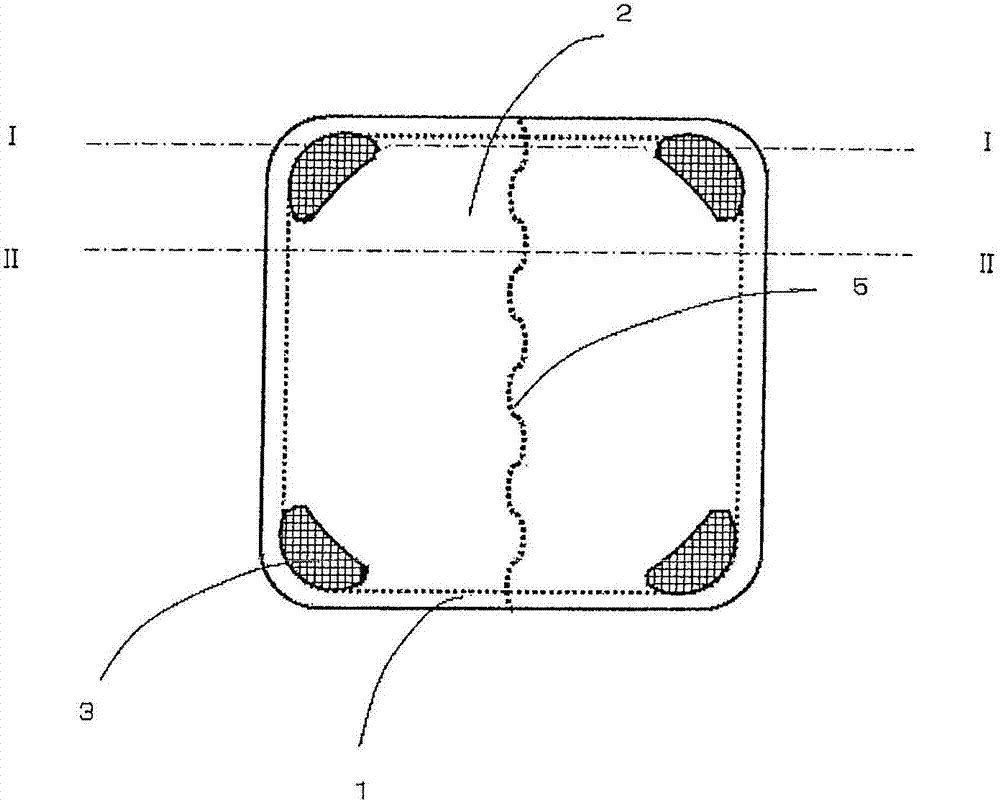

[0114] The patch was manufactured in the same manner as in Example 1, except that the conditions of heating and pressing were changed to: heating temperature: 100°C, compression molding pressure: 2×10 7 N / m 2 , Heating and pressing time: 0.3 seconds. The schematic plan view of the obtained patch is shown in image 3 Middle; the cross section cut along line I-I and line II-II is shown in Figure 4 (a) and (b). From image 3 with Figure 4 Obviously, the shape and the like of the patch of this embodiment are the same as those of the patch of Example 1, but the difference is that the former does not have a band-shaped connecting bulge (3) between adjacent protrusions (3). 4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com