Biaxially orientated polyamide-based resin film and its manufacturing method

A polyamide-based, biaxially oriented technology, applied in the field of polyamide-based biaxially oriented films and their manufacturing, can solve the problems of poor processability, poor adhesion and wettability, and reduced yield, etc. The effect of high transparency, excellent smoothness, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

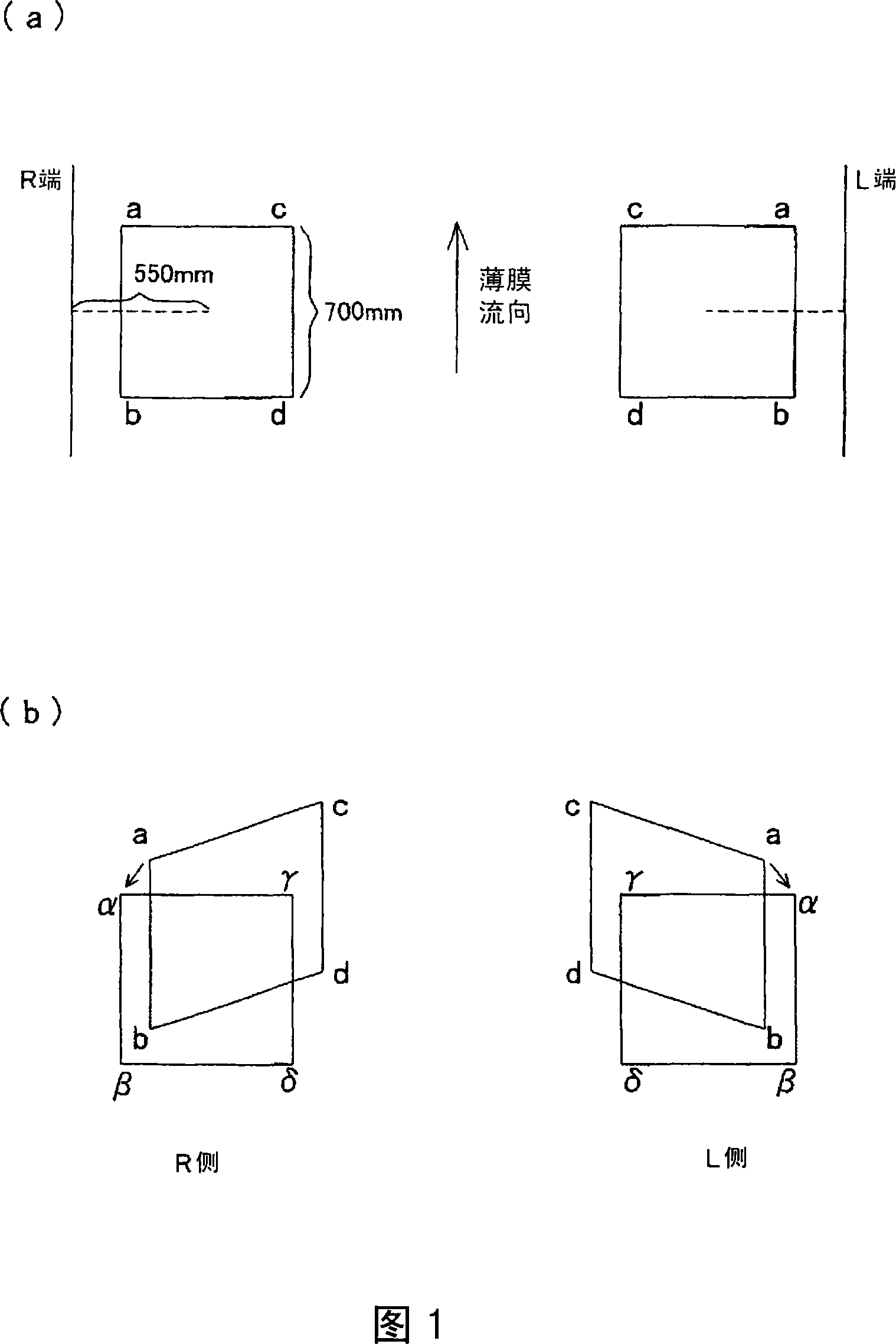

Image

Examples

Embodiment 1

[0075] A 100-liter batch type polymerization tank was used, and nylon 6 obtained by ring-opening polymerization of ε-caprolactate was used as a polyamide-based resin. The nylon 6 chips were extracted with hot water using a batch polymerization tank to reduce the content of monomers and oligomers to 1% by weight, then dried to a moisture content of 0.1% by weight, and put into use. The relative viscosity of the raw nylon 6 and the stretched film is about 2.8 as measured at 20°C using a 96% concentrated sulfuric acid solution. In addition, the microparticles (0.45% by weight) used to form the surface protrusions are silica microparticles (Syrisia 350 manufactured by Fuji Silysia Chemical Co., Ltd.) with a pore volume of 1.6 cc / g and an average particle diameter of 1.8 μm. In the aqueous solution of ε-caprolactam, disperse with a high-speed mixer, add it to the polymerization tank, and disperse it into nylon 6 during the polymerization process. After further compounding 0.15% by...

Embodiment 2~4

[0078] Except having changed stretching conditions as shown in Table 1, it carried out similarly to Example 1, and obtained the biaxially-oriented polyamide-type resin film of Examples 2-4. Table 2 shows the evaluation results of properties of the obtained biaxially oriented polyamide resin film.

Embodiment 5~7

[0084] The micropore volume and the addition concentration of the microparticles for forming surface protrusions used in Example 1 were changed as shown in Table 1, respectively, and the rest was performed in the same manner as in Example 1 to obtain Comparative Examples 3 to 5. Biaxially oriented polyamide resin film. Table 2 shows the evaluation results of properties of the obtained biaxially oriented polyamide resin film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal deformation | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com