Interconnecting method for flexible device and used flexible connector

A flexible connector and flexible device technology, applied in the direction of connection, fixed connection, connection insulation, etc., can solve the problems of low precision, low yield and high cost, and achieve high uniformity and stability, good mechanical properties, and high reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

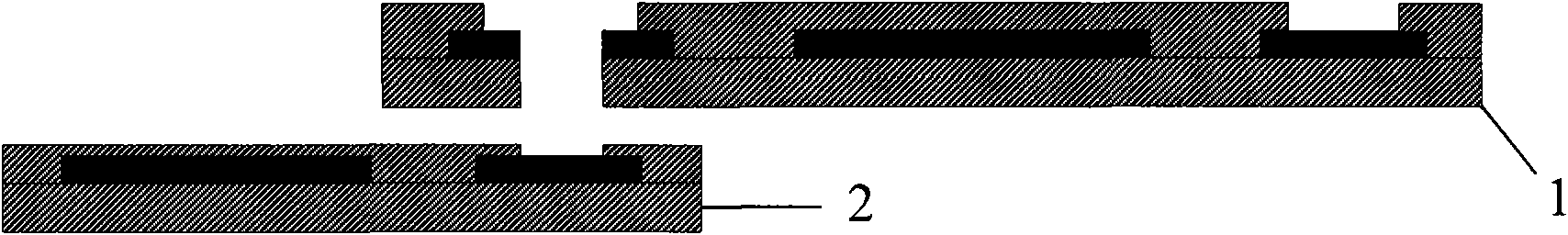

[0028] In this implementation example, the flexible neural microelectrode is taken as an example, and the flexible connector described specifically will realize the interconnection between the flexible device (flexible neural microelectrode) and the device. According to the size of the welding site of the flexible microelectrode (the welding site is a 4×4 lattice, and the size of each site is 400×400 microns). The corresponding flexible connectors are made by MEMS micromachining technology. The connection end of the flexible device and the device is designed as a flat flexible cable interface, which can be directly connected to the flexible cable connector of the device and is easy to replace. The connection end with the flexible device is designed as a through-hole structure, such as figure 1 shown.

[0029] 1. Align the correspondingly manufactured flexible connector 1 with the flexible device 2, such as figure 1 As shown, a flexible connection device with a through-hole ...

Embodiment 2

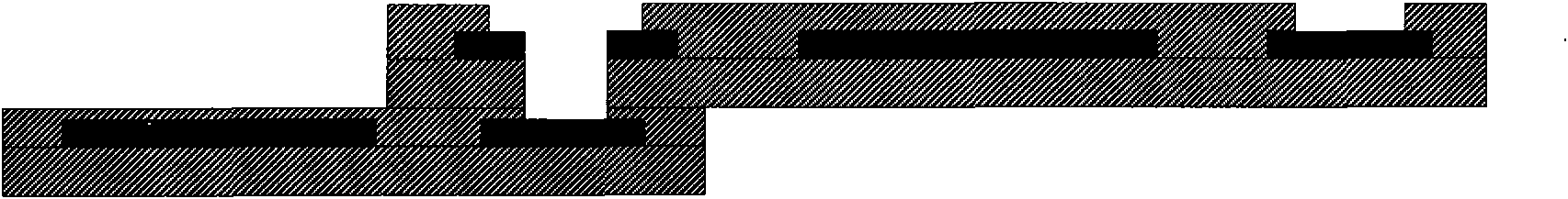

[0036] This implementation example specifically describes the process in which the flexible connector connects the flexible device to the flexible device. The corresponding flexible connectors are made by MEMS micromachining technology. Both ends of the flexible connector are designed as through-hole structures, which are connected with two flexible devices, such as Figure 5 shown.

[0037] 1. Align the correspondingly fabricated flexible connector with the flexible device, such as Figure 5 As shown, a flexible device with a through-hole structure is placed over the flexible device to align the soldering sites.

[0038] 2. Use a small amount of adhesive or glue to attach the flexible device to the flexible connector, such as Figure 6 As shown, it is ensured that the welding position of the flexible device and the flexible connector will not be dislocated during the subsequent operation.

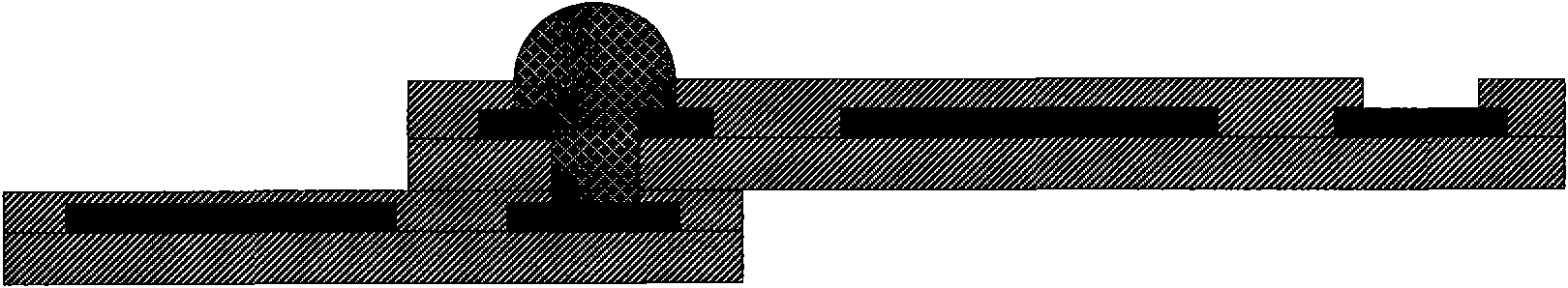

[0039] 3. Drip heat-curable conductive adhesive at each corresponding welding poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com