Method for processing through hole of printed circuit board, printed circuit board and communication equipment

A technology for printed circuit boards and processing methods, which is applied in the fields of printed circuit components, electrical connection formation of printed components, multi-layer circuit manufacturing, etc., and can solve problems such as the inability to realize signal interconnection at any layer, and the inability to separate wires from any layer at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Process the first layer of copper-clad board:

[0058] See Figure 5 , Is a schematic diagram of processing a pair of first-layer copper-clad boards in an embodiment of the present invention:

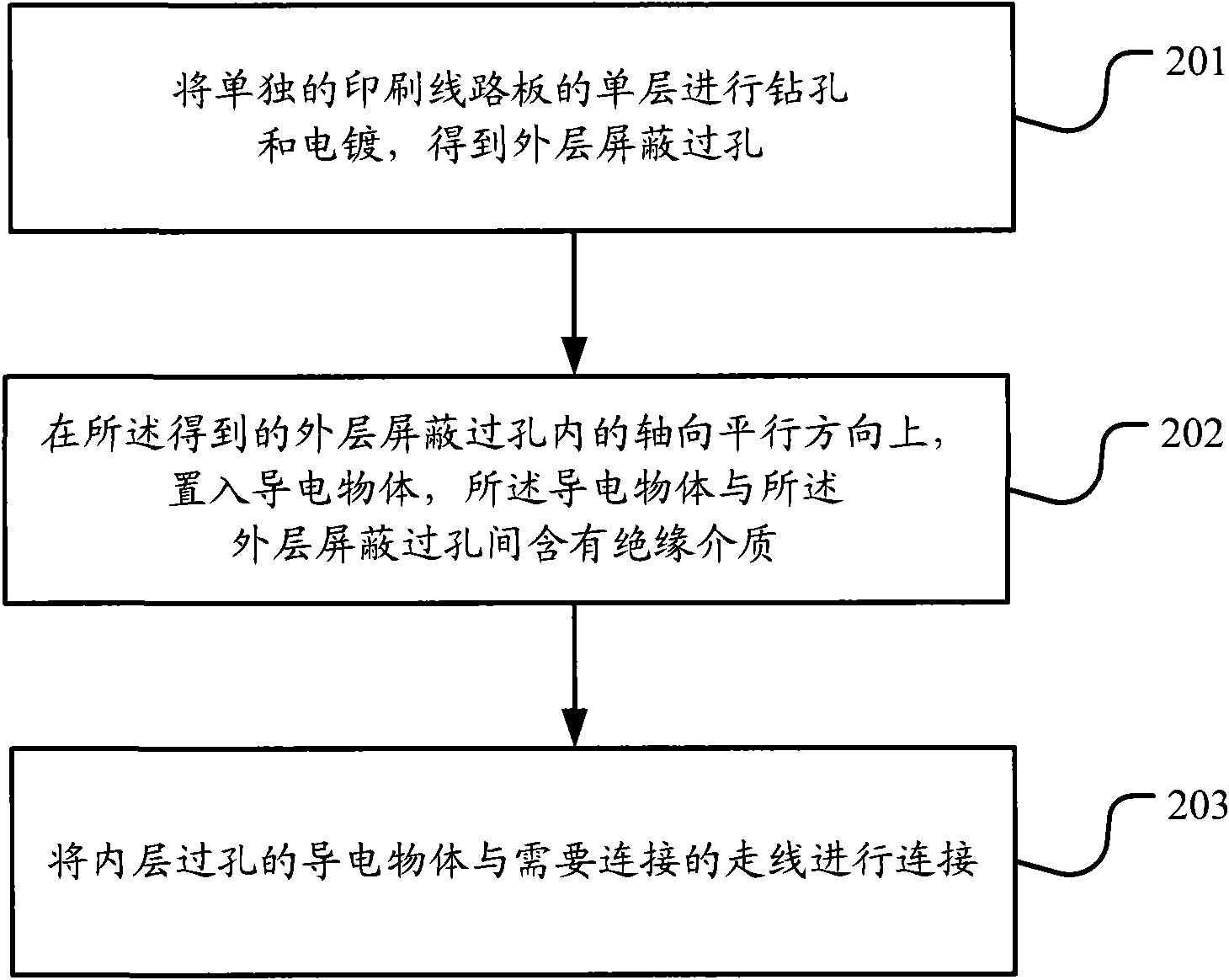

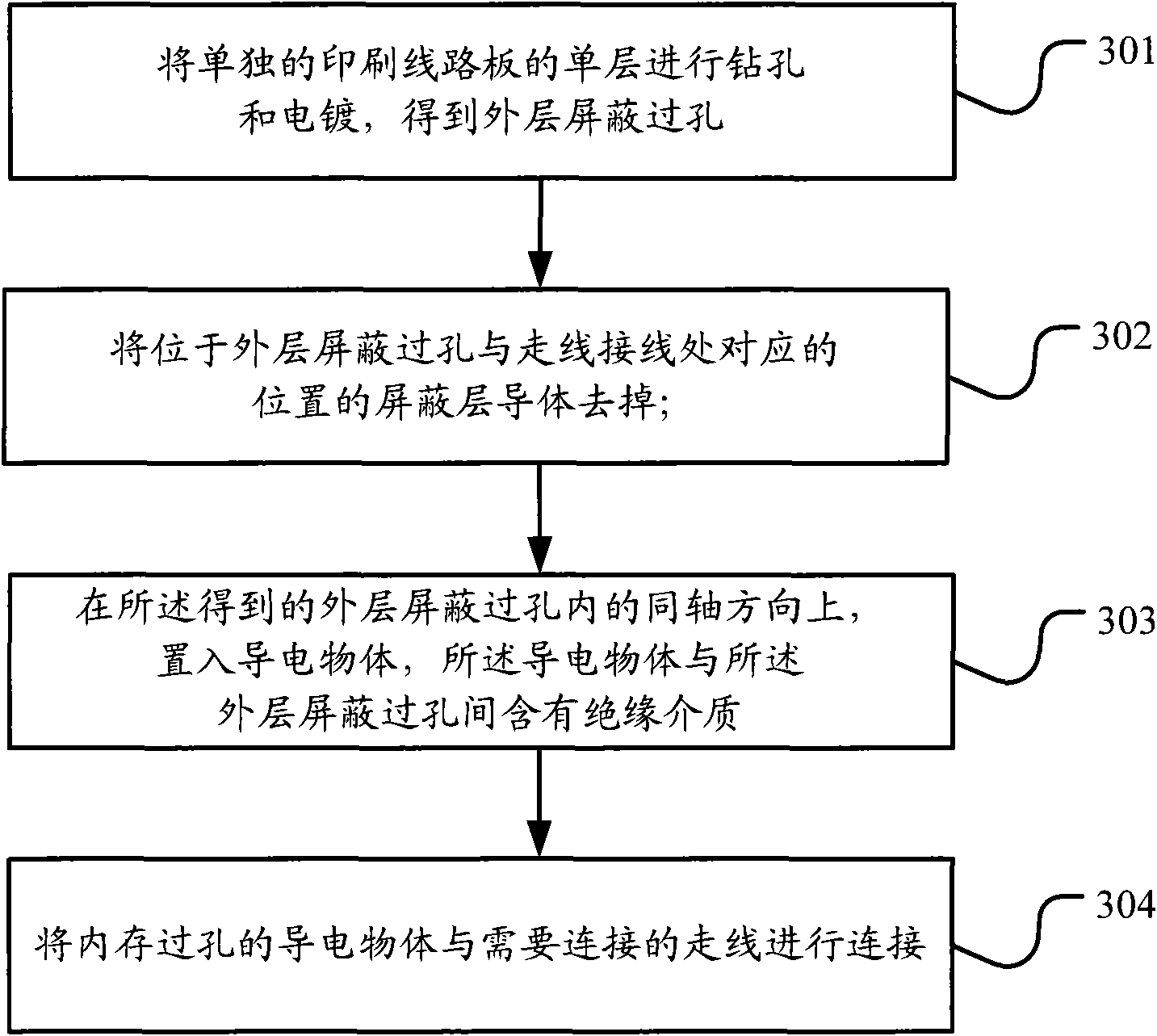

[0059] Steps 501-502, drilling and electroplating the copper-clad board to obtain the first metalized via, that is, the outer shielding via of the coaxial via;

[0060] Step 503: Remove the shielding layer conductor at the position corresponding to the outer shielding via wall and the wiring connection;

[0061] For details about removing the shielding layer conductor, refer to the description in step 302 above.

[0062] It should be noted that if the coaxial inner layer via does not need to be led out of the shielding via with a wire, this step is not available. If it is necessary to use a wire to lead out of the shielding via, perform this step.

[0063] Through this step, it is ensured that the signal trace can be connected to the inner via hole in the same layer of the shieldi...

Embodiment 2

[0087] The technical solution of the second embodiment can also achieve the beneficial effects described in the first embodiment, and the implementation can be simpler by adopting the method of pressing into the conductor with insulating medium.

[0088] The following describes the third embodiment of the present invention. The technical solution of the third embodiment is basically the same as that of the first embodiment. The main difference is that after the outer shielded via hole that has been filled with an insulating medium is drilled, the newly drilled hole is not filled with a conductor. A layer of chemical copper is deposited on the wall of the newly drilled hole or a layer of metal is attached by electroplating, which also functions as a conductor. For the copper-clad board, after the inner layer via hole is drilled, it is not electroplated immediately, but after the pattern is completed, the inner layer via hole will be hollow instead of solid. For the insulating diele...

Embodiment 3

[0089]The technical solution of the third embodiment can also achieve the beneficial effects described in the first embodiment, and provides another method of filling the conductor by depositing a layer of chemical copper on the wall of the newly drilled hole or attaching a layer of metal by electroplating. the way.

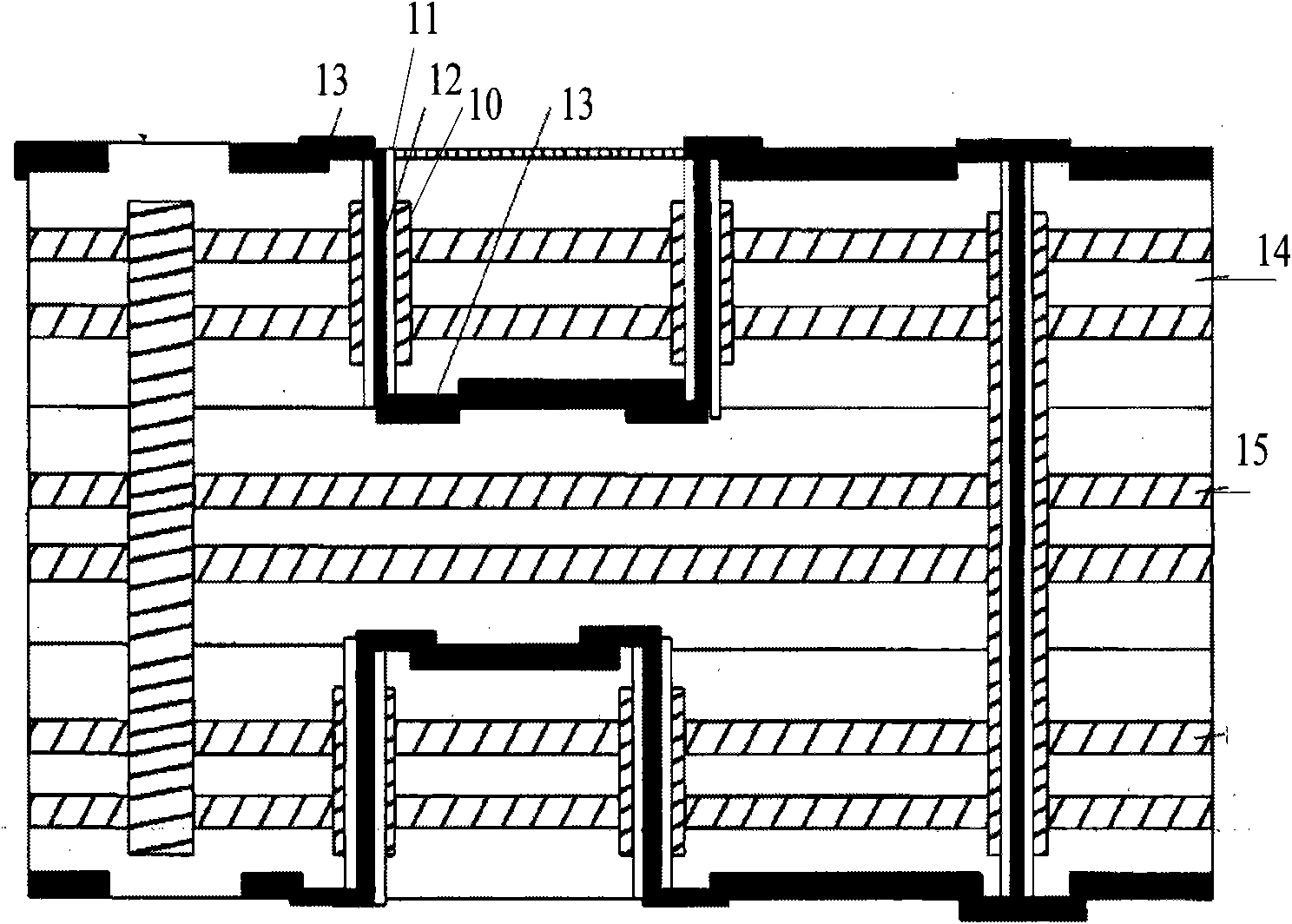

[0090] The following describes the fourth embodiment of the present invention, please refer to Figure 13 , Is a schematic diagram of alternative steps for implementing one in the fourth embodiment of the present invention. Figure 14 , Is a cross-sectional view of the central control deep borehole in the fourth embodiment of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com