Honey extracting device

A kind of equipment and technology of honey bucket, which is applied in A01K59/00: the field of honey collection, which can solve the secondary pollution of honey, thrown out, the larvae first break through the wax seal layer and then hit the wall of the honey bucket, and the larvae die, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

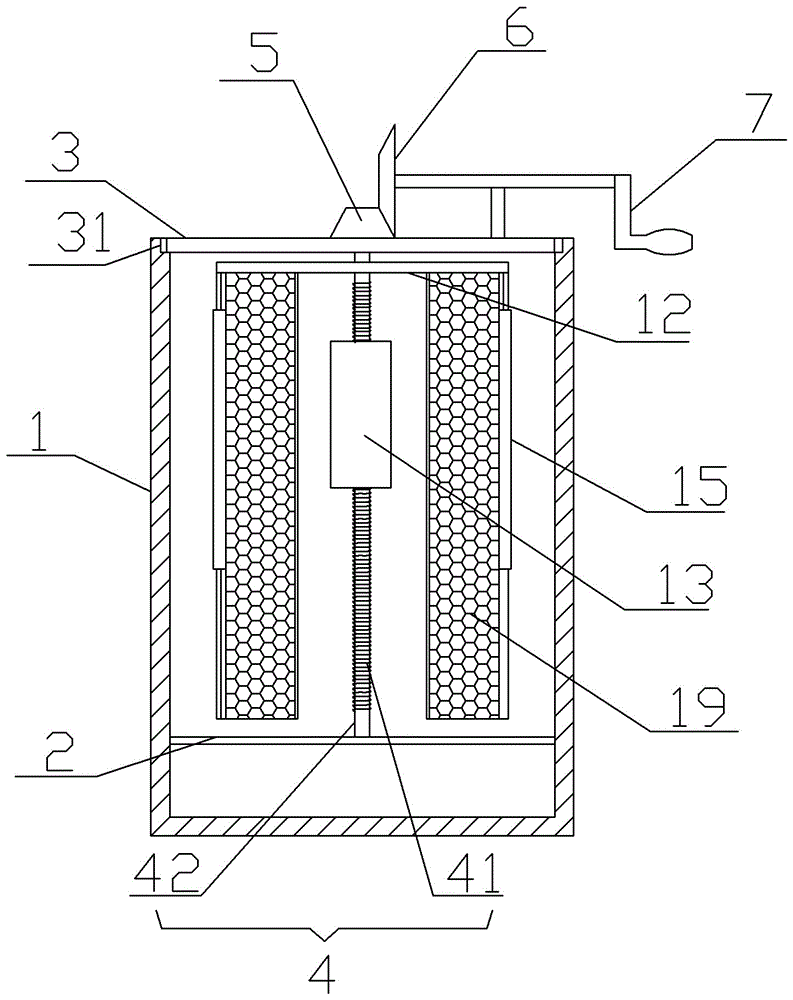

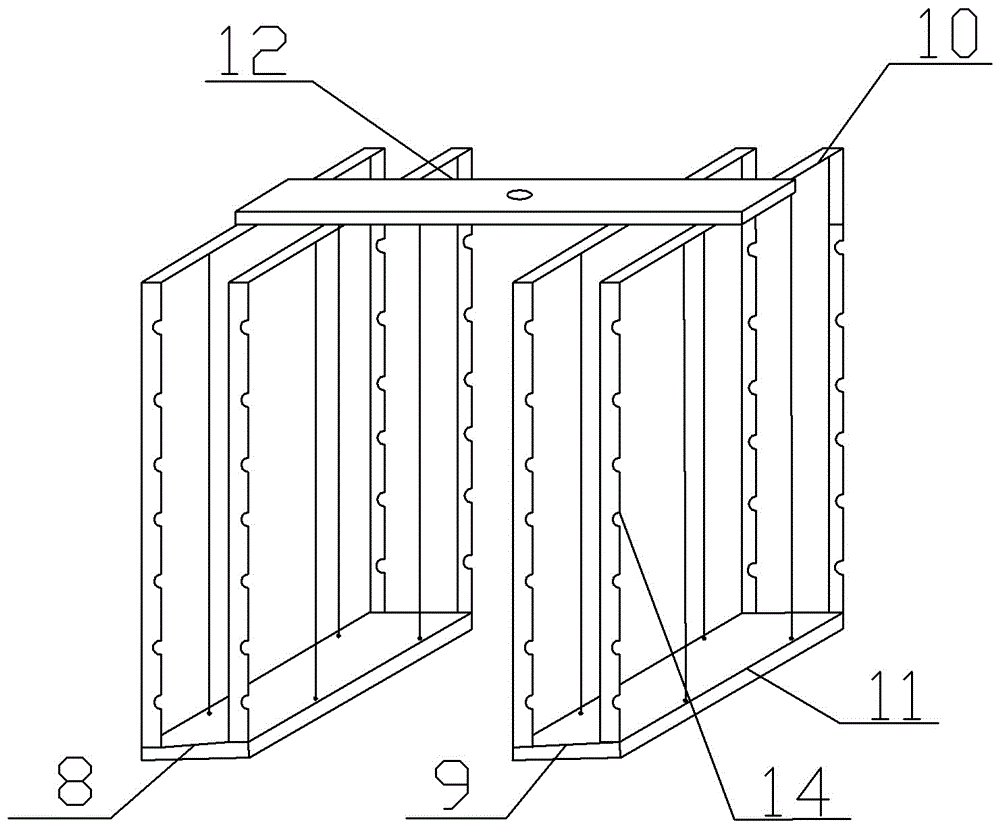

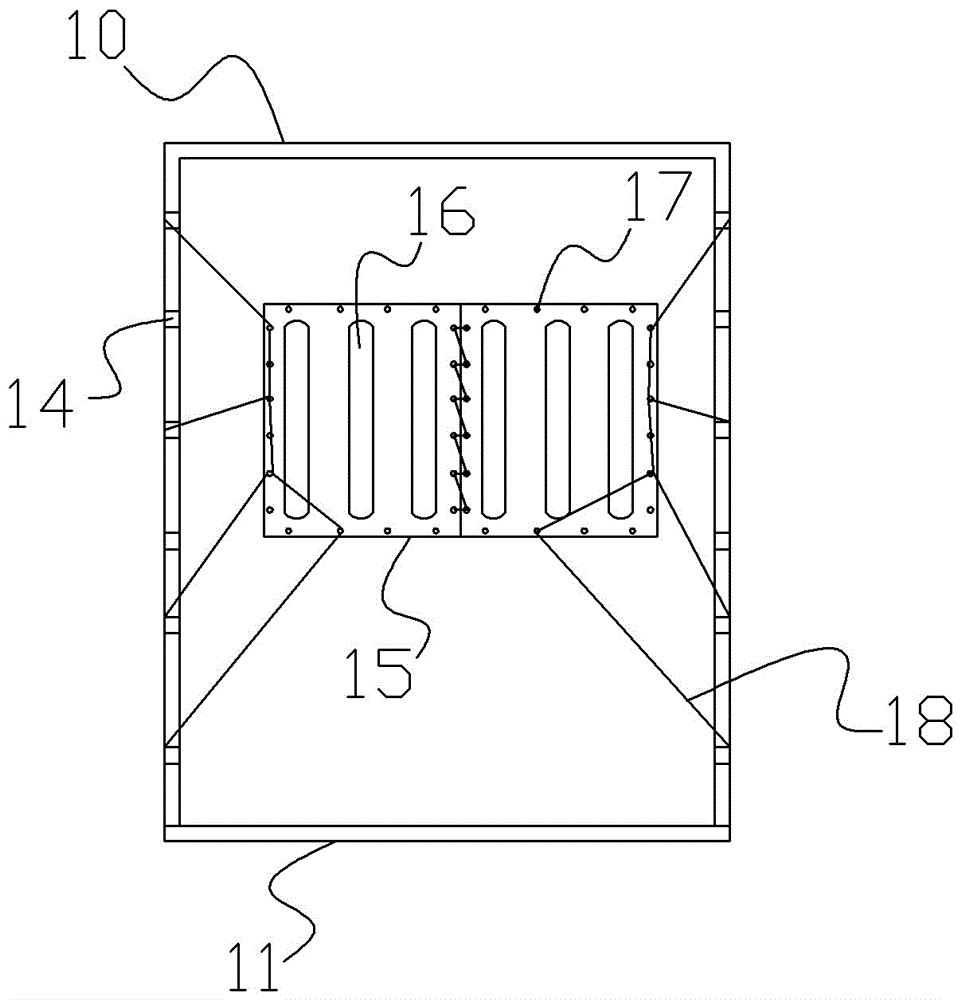

[0018] Embodiment 1: The equipment for shaking honey is basically as attached figure 1 , figure 2 , image 3 Shown: comprises the honey shake bucket 1 that is made of plastics, and the barrel wall of shake honey bucket 1 is bolt-connected with horizontal lower crossbeam 2, and this lower crossbeam 2 is 10cm higher than the bottom of shake honey bucket 1. There are two notches at the mouth of the honey bucket 1 along the radial direction of the mouth. The two ends of the upper beam 3 protrude to form legs 31 that can be placed in the notches. The upper beam 3 and the lower beam 2 are located on the same vertical direction.

[0019] The transmission shaft 4 is coaxial with the honey shaker 1, the lower end of the transmission shaft 4 is rotationally connected with the lower beam 2 through a ball bearing, and the upper end of the transmission shaft 4 penetrates the upper beam 3 and is connected with a flat key of the bevel gear 5, the bevel gear 5 The large surface of the beve...

Embodiment 2

[0030] Embodiment 2: The difference from Embodiment 1 is that the permanent magnet 13 is replaced by an electromagnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com