Propylene polymer, propylene polymer composition, pellet, and adhesive agent

一种聚合物、丙烯类的技术,应用在丙烯类聚合物组合物领域,能够解决粘附物污染、充分考虑等问题,达到改善粘合性、加工性容易、加工性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

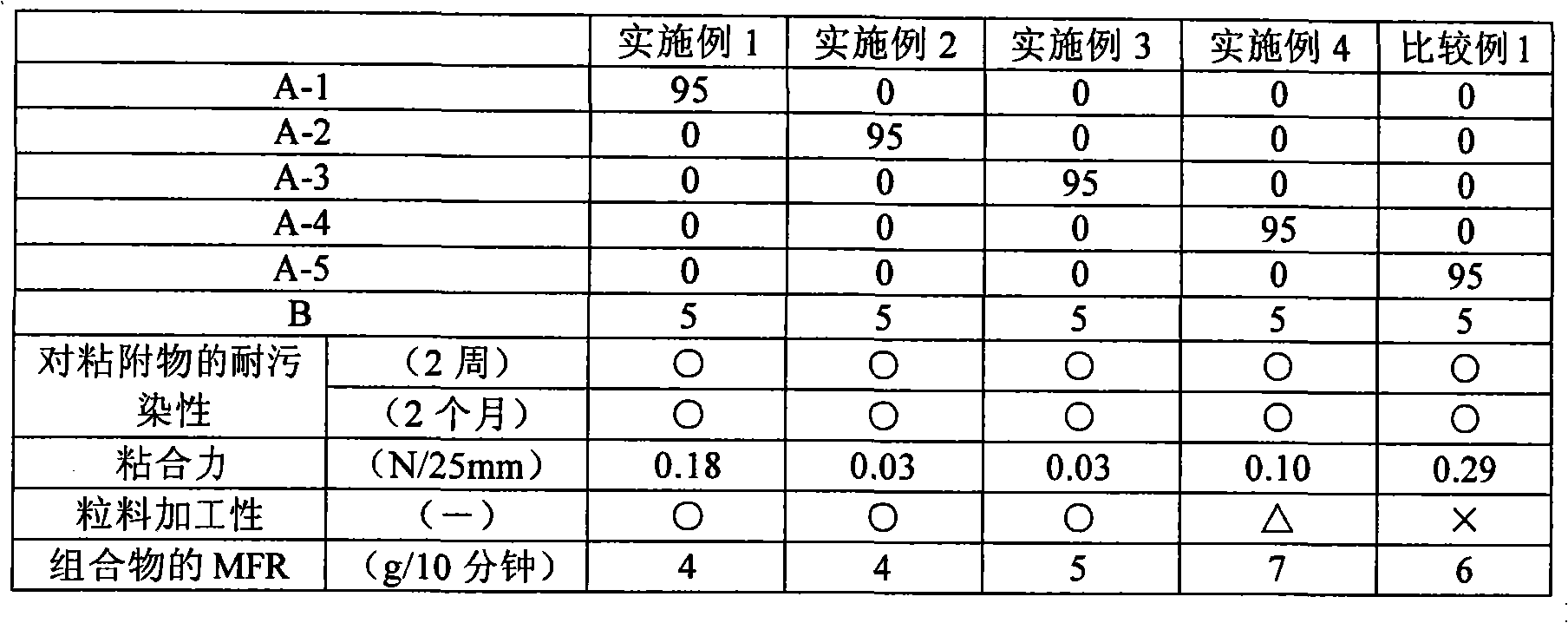

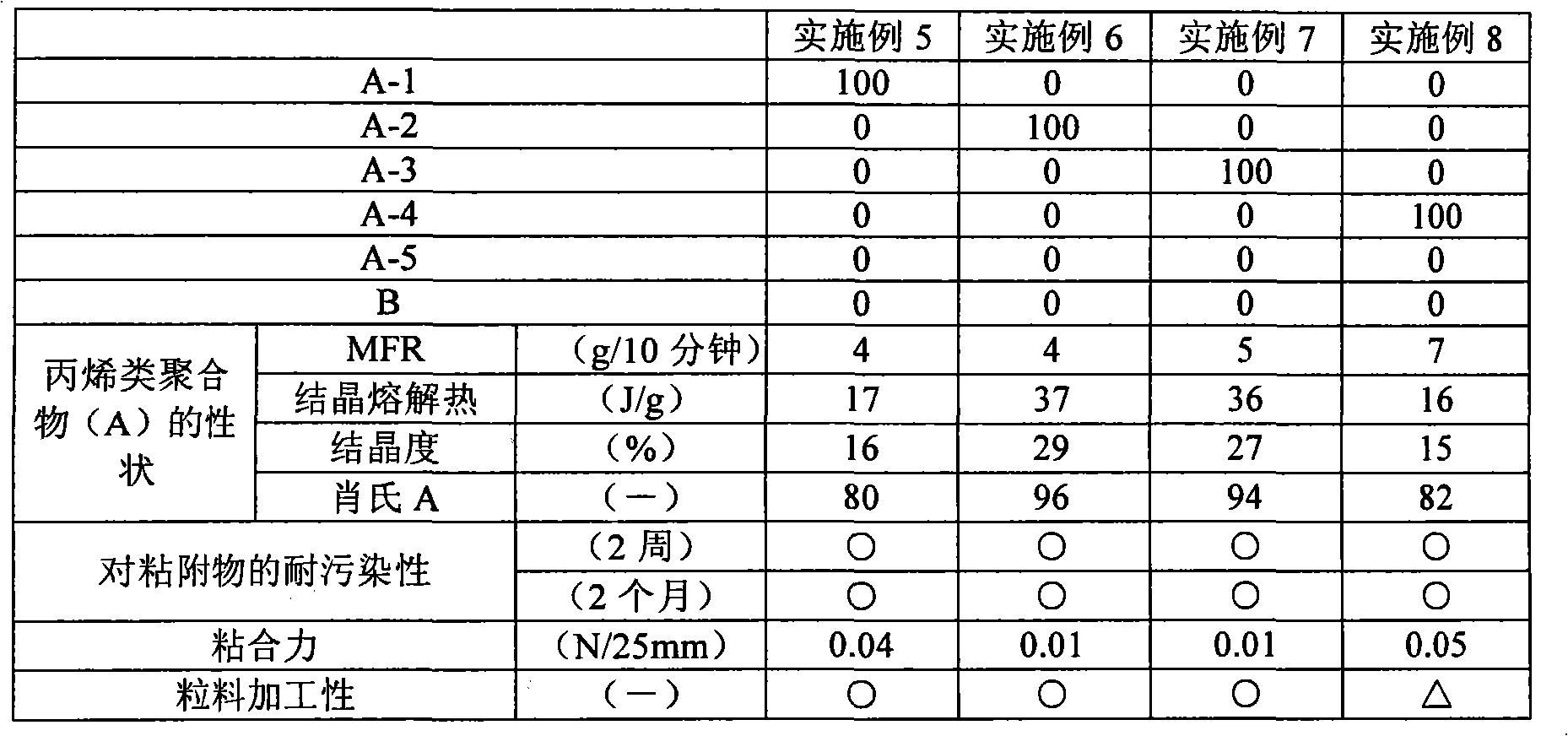

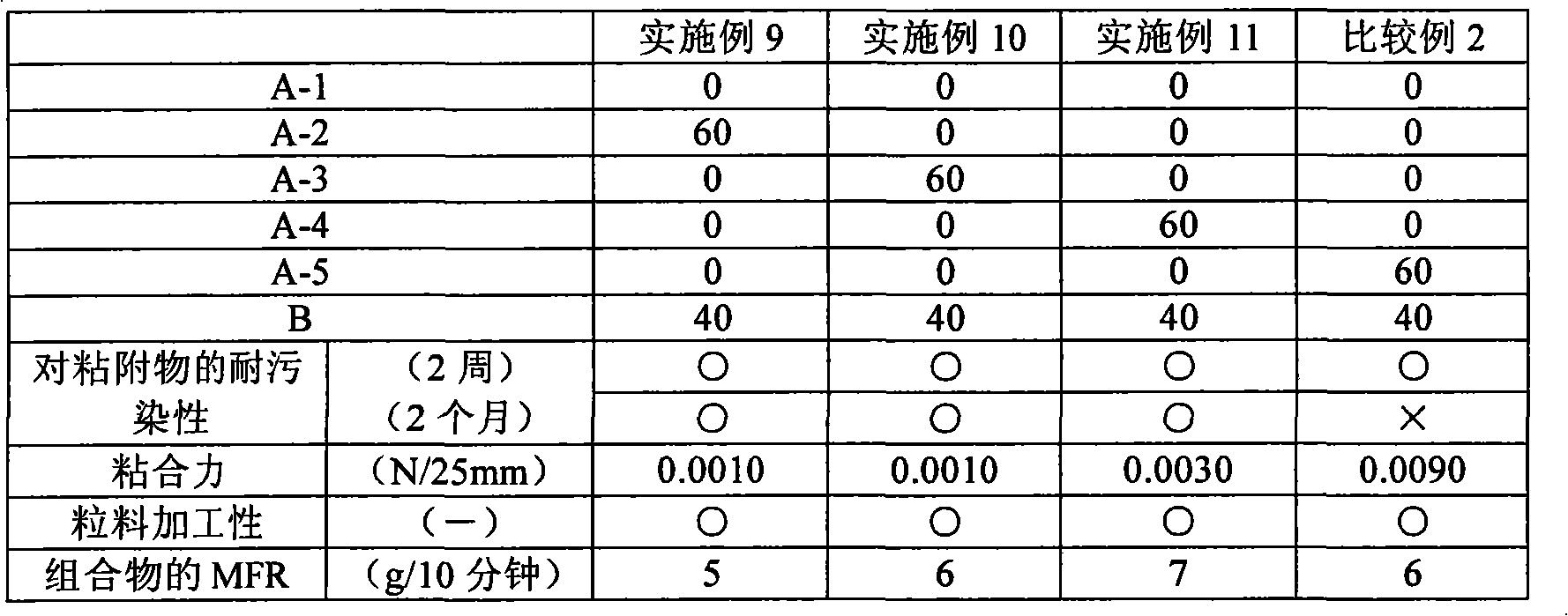

[0087] Next, the present invention will be described in further detail with examples given.

[0088] Among them, the evaluation items and evaluation methods of the adhesive of the present invention are as follows.

[0089] [E1] Stain resistance to adherents

[0090] Using a rubber roller, stick the adhesive layer of the adhesive film sample on a black ceramic tile (manufactured by INAX Co., Ltd., trade name INTERIOR TILE INAX, model SPKC-100, color number L06-J, a square with a side length of 100) (room temperature ) to prepare test samples. The test samples were placed in a thermostatic chamber under an atmosphere of 40° C., aged for two weeks and two months, respectively, and the adhesive film samples were peeled off from each test sample, and whether there was transfer on the tile surface was visually evaluated. The evaluation criteria are as follows.

[0091] ○: No pollution,

[0092] ×: Contaminated.

[0093] [E2] Adhesion

[0094] The adhesive force was measure...

Synthetic example 1

[0114] Synthesis of metallocene compounds

[0115] Diphenylmethylene(3-tert-butyl-5-methyl-cyclopentadienyl)(2,7-di-tert-butylfluorenyl)zirconium dichloride According to International Publication No. 2004-087775 pamphlet The synthesis sequence described in Example 3c was synthesized.

Synthetic example 2

[0117] Preparation of propylene-ethylene-butene copolymer (A-1)

[0118] At normal temperature, after adding 780 ml of dry hexane, 70 g of 1-butene and triisobutylaluminum (1.0 mol) to the 2000 ml polymerization device fully replaced by nitrogen, the internal temperature of the polymerization device was raised to 55 ° C, and Propylene was pressurized so that the pressure in the system was 0.7 MPaG. Then, the pressure in the system was adjusted to 0.72 MPaG with ethylene. Next, the diphenylmethylene (3-tert-butyl-5-methyl-cyclopentadienyl) (2,7-di-tert-butylfluorenyl) prepared in Synthesis Example 1 was added to the polymerizer ) zirconium dichloride 0.001mmol and a toluene solution obtained by contacting 0.3mmol of aluminum-converted methylalumoxane (manufactured by Tosoh Fine Chem Co., Ltd.), at an internal temperature of 55°C, the internal pressure of the system was maintained at 0.72MPaG with ethylene While performing polymerization for 30 minutes, 20 ml of methanol was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com