Explosive welding device for joint of zirconium-alloy transition tube and stainless-steel transition tube

A technology of explosive welding and stainless steel, applied in welding equipment, welding/welding/cutting items, metal processing, etc., can solve the problems of poor quality of pick alloy and stainless steel transition pipe joints, etc., to save scarce precious metals, prevent cracking, good The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

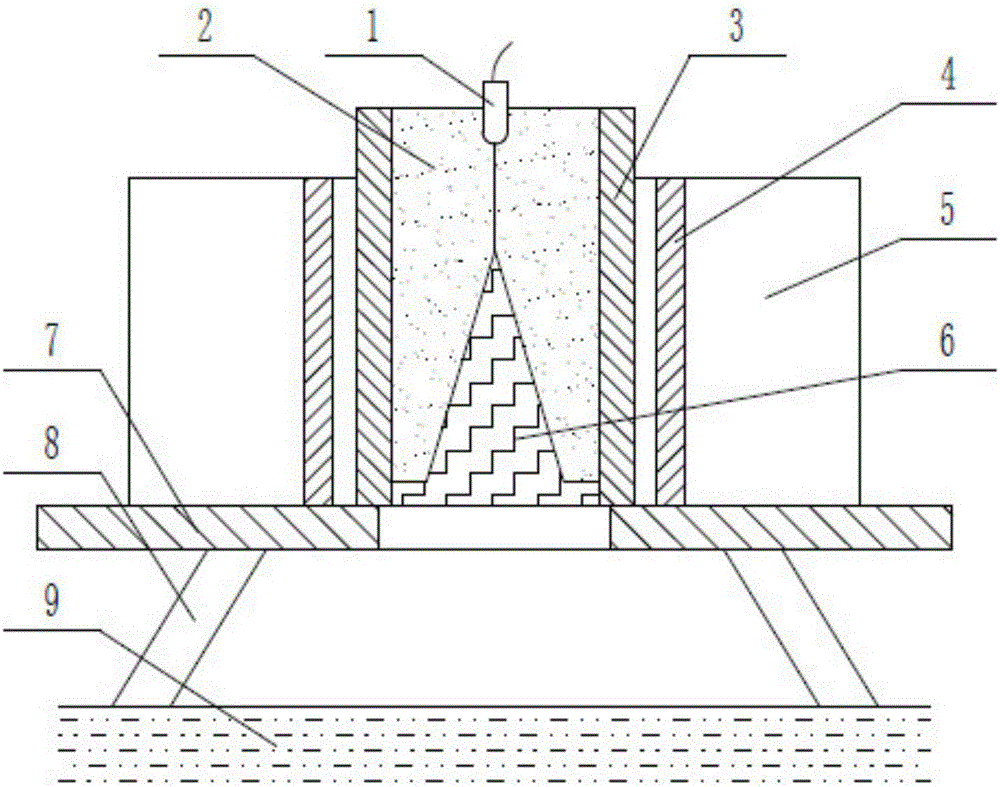

[0025] This embodiment includes a detonator 1, an explosive 2, a pickaxe alloy composite tube 3, a stainless steel base tube 4, a mold 5, a bracket 7, a leg 8, and a non-metallic cone 6, and the bracket 7 is symmetrically provided with a leg 8, and the bracket 7 passes through the bottom The supporting feet 8 are placed on the ground 9, and the mold 5 is arranged on the support 7. The mold 5 is in the shape of a hollow truncated circle, and the mold 5 is a melt of asphalt and sand. A stainless steel base pipe 4 is set inside the mold 5, and the stainless steel base pipe 4 is a 1Cr18Ni9Ti base pipe. A pick alloy multiple tube 3 is arranged coaxially inside the stainless steel base tube 4, and the pick alloy multiple tube 3 is a Zr-2 alloy multiple tube. There is a gap between the inner surface of the stainless steel base pipe 4 and the outer surface of the alloy composite pipe 3, and the gap between the inner surface of the stainless steel base pipe 4 and the outer surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com