Drive switching and transmission variable speed system of hollow motor type electric vehicle

An electric vehicle, motor-type technology, applied in the direction of electric power unit, power unit, vehicle components, etc., can solve the problems of large space occupation, system dispersion, and complex power transmission system structure, so as to reduce the space occupation and cooperate with the structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

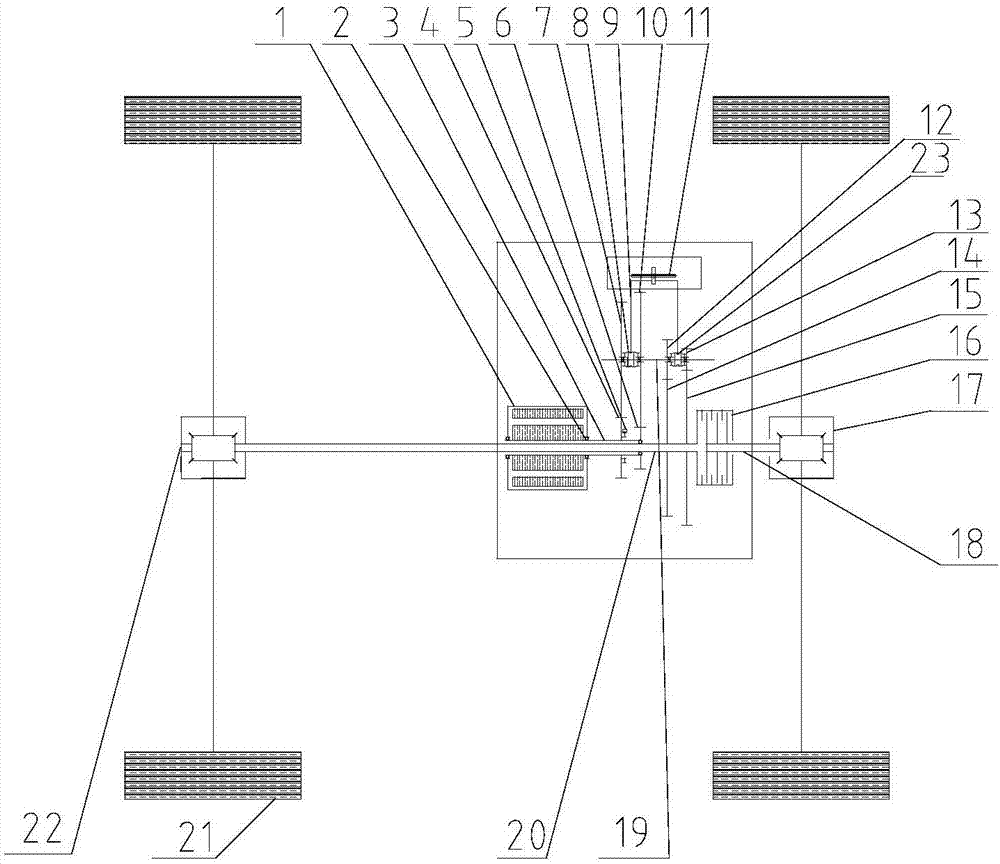

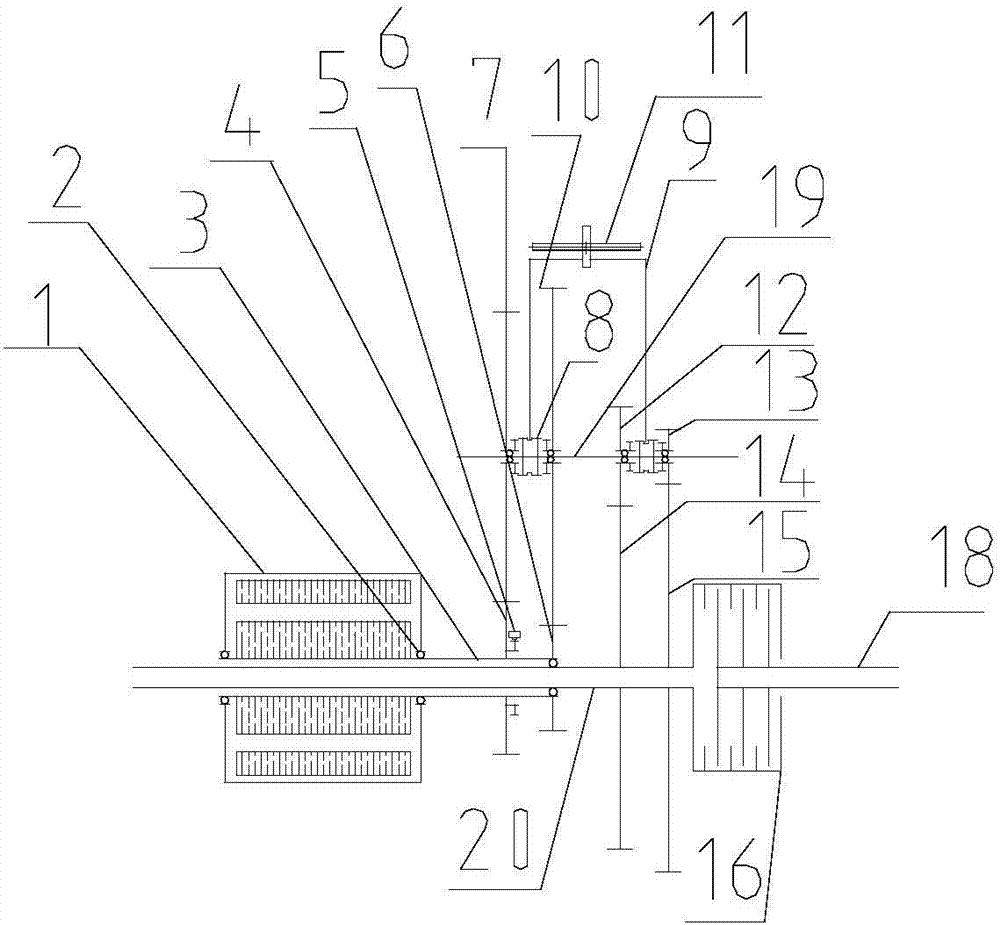

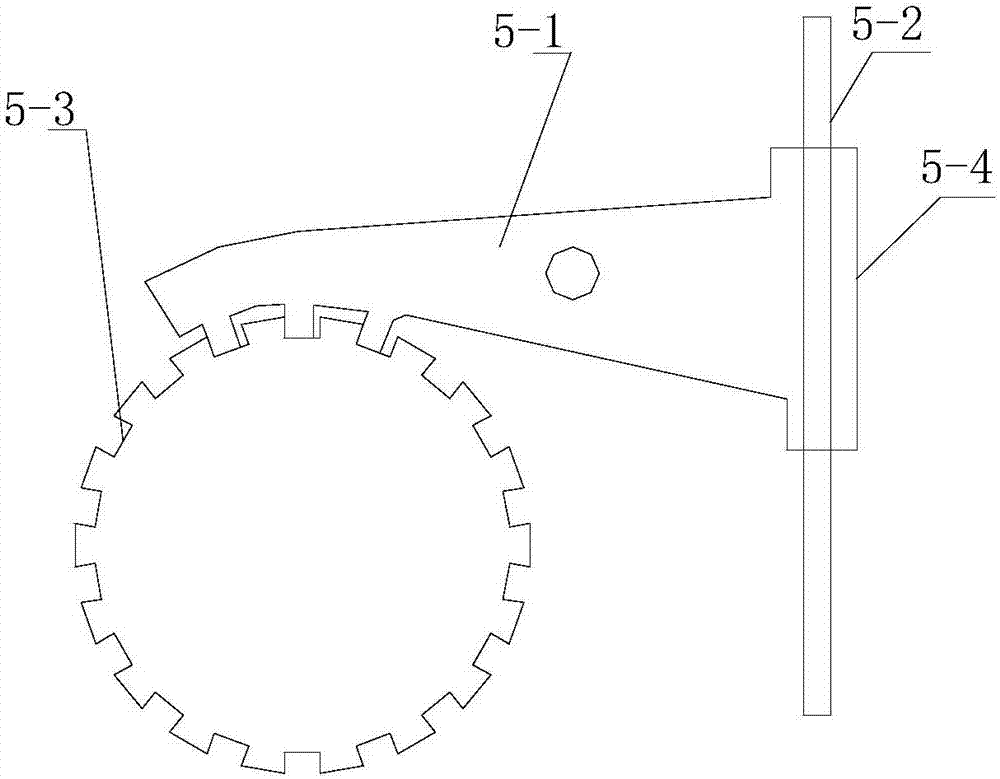

[0019] figure 1 It is a schematic diagram of cooperation between the present invention and the automobile wheel system, figure 2 It is a schematic diagram of the overall structure of the present invention, image 3 It is a schematic structural diagram of the parking stop device in the present invention, as shown in the figure: the hollow motor type electric vehicle drive switching and transmission transmission system of this embodiment includes a hollow motor 1 and a transmission, and the transmission includes a transmission assembly and a front output shaft 20. The hollow power shaft 3 of the hollow motor 1 cooperates with the transmission assembly for power input. The front output shaft 20 forms the power output end of the transmission and is used to output power to the front wheels 21 of the car. The inner sleeve of the front output shaft 20 runs through the hollow The power shaft 3 is set and can rotate relatively; the drive switching and transmission transmission system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com