Elevator traction bearing component and elevator

A load-bearing component and elevator traction technology, applied in elevators, transportation and packaging, etc., can solve problems such as reducing its own weight, and achieve the effects of improving operating comfort, reducing noise, and enhancing corporate competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

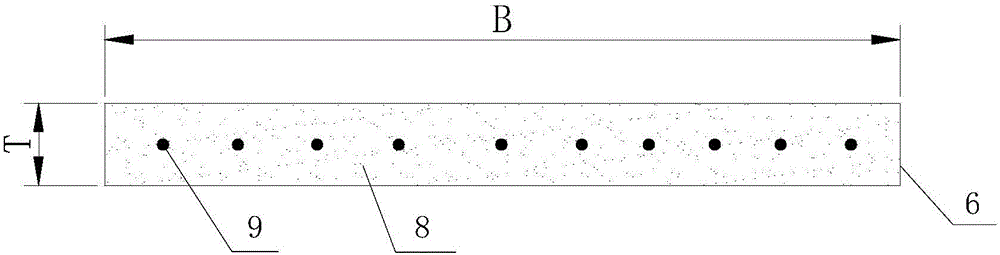

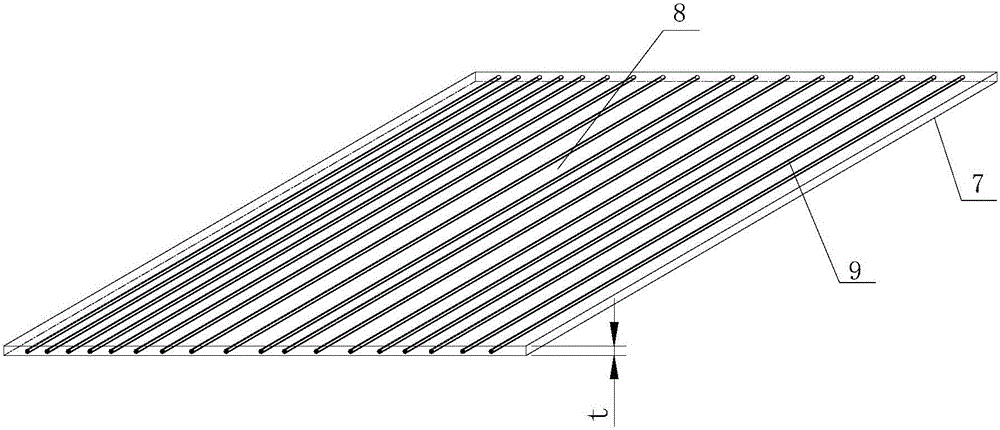

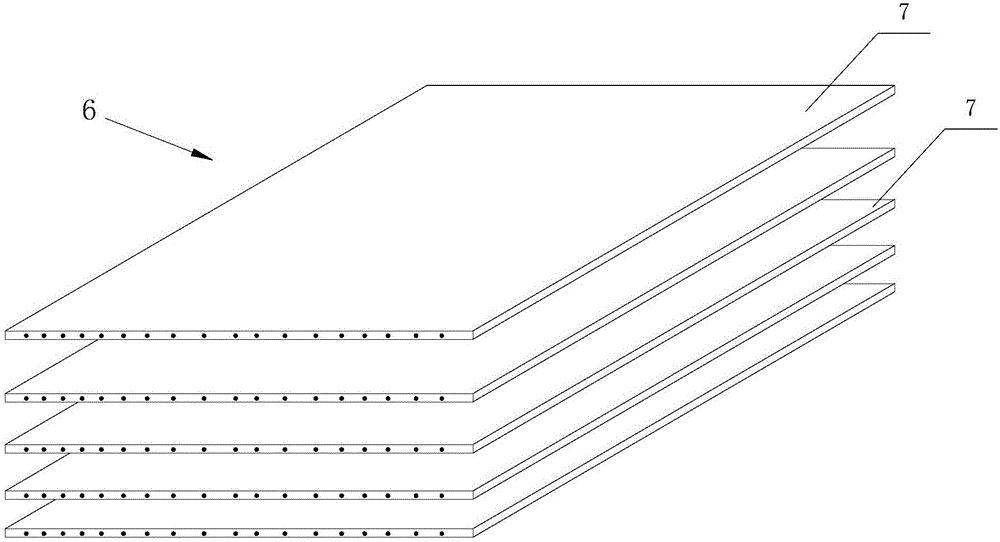

[0034] see Figures 1 to 3 , an elevator traction bearing member 6, comprising a plurality of traction bearing units 7 stacked together along the thickness direction. Each traction bearing unit 7 includes a polymer substrate 8 and a plurality of non-metallic fiber filaments 9 embedded in the polymer substrate 8 and extending continuously along the length direction of the traction bearing unit 7 . In this embodiment, the polymer substrate 8 is epoxy resin, and the non-metal fiber filament 9 is carbon fiber.

[0035] In the present embodiment, the diameter d of the non-metallic fiber wire 9 is 3 μm, and the traction bearing unit 7 is a flat belt-like structure without teeth on the surface. The thickness t of each traction bearing unit 7 is 4 μm, and the traction bearing member 6 of the elevator The section thickness T is 0.1 mm, and the section width B of the elevator traction bearing member 6 is 10-250 times of the section thickness T. According to needs, the diameter d of th...

Embodiment 2

[0038] see Figure 4 The difference between this embodiment and Embodiment 1 is that: the elevator traction bearing member 6 of this embodiment is formed by arranging a plurality of traction bearing units 7 along the width direction, wherein the thickness of each traction bearing unit 7 is 7mm, the cross-sectional thickness of the elevator traction bearing member 6 is also 4mm; the polymer substrate 8 constituting the traction bearing unit 7 is rubber, specifically TPU; the non-metal fiber filament 9 is glass fiber, and the diameter of the non-metal fiber filament 9 is d is 80 μm.

Embodiment 3

[0040] see Figure 5 The difference between this embodiment and Embodiment 1 is that the traction bearing unit 7 constituting the elevator traction bearing member 6 in this embodiment is a toothed belt-shaped structure with a plurality of teeth 71 on the lower surface, and fine concaves on the upper surface. The groove 72; the polymer substrate 8 is rubber, specifically CR; the non-metal fiber filament 9 is nylon fiber, and the diameter of the non-metal fiber filament 9 is 40 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com