Test tube sealing cover assembling equipment and sealing cover assembling method

A technology for assembling equipment and test tubes, which is applied in the directions of sealing containers tightly with lids, packaging, closing plugs, etc., which can solve the problems of inability to meet the needs of automatic assembly, low efficiency, difficult to turn over and seal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

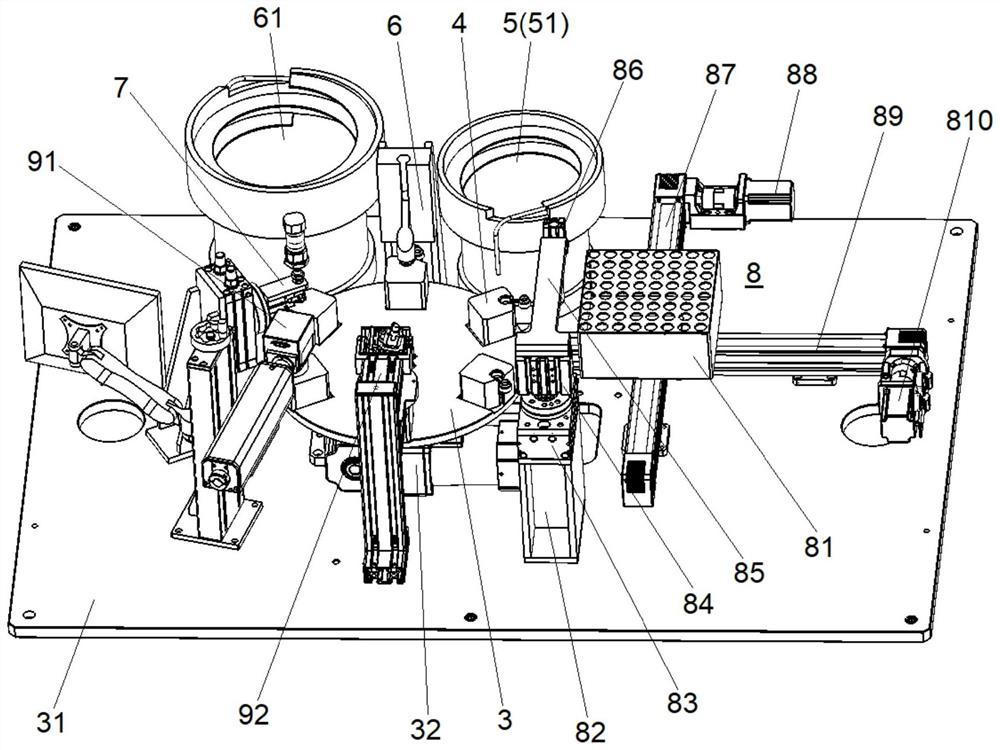

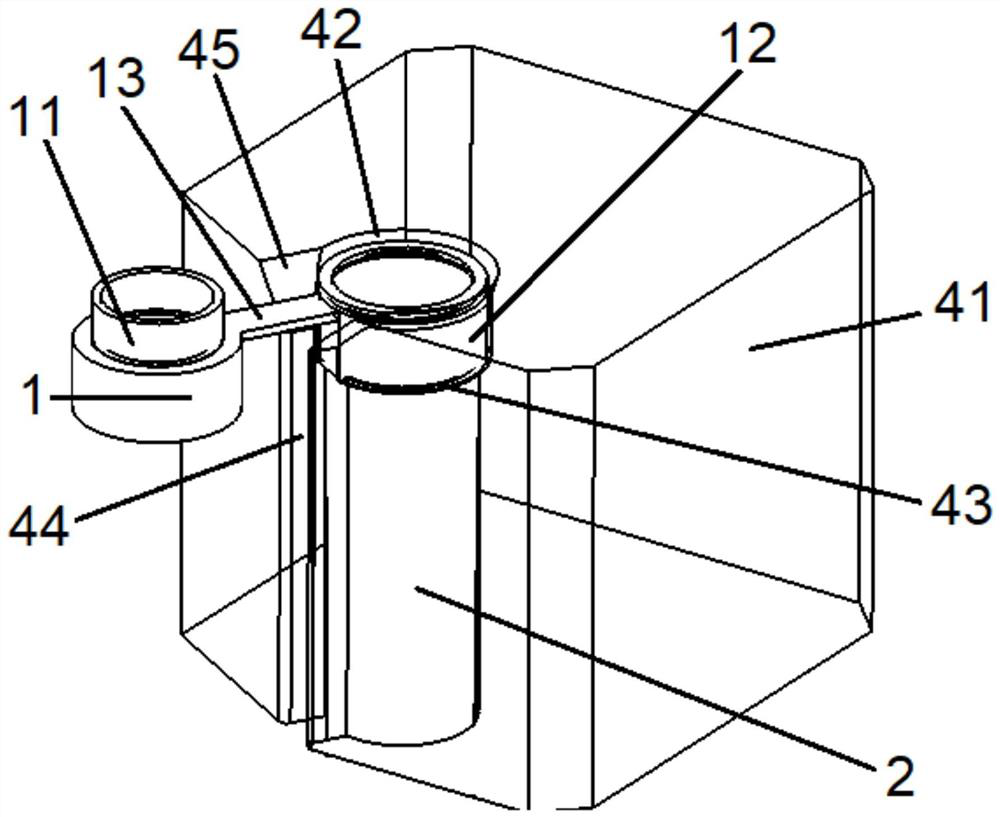

[0032] Such as figure 1 As shown, embodiment 1 of the present invention provides a kind of test tube cover assembly equipment, applicable plug cover 1 is made up of plug head 11, collar 12 and the connecting part 13 that connects both, can refer to figure 2 . The plug cover 1 is made of elastic material such as rubber as a whole. The capping process is to first set the collar 12 on the outside of the test tube 2 port, and then rely on the elastic force of the material itself to fix it, and then insert the plug head 11 into the test tube 2 port after turning over. , forming a plug seal.

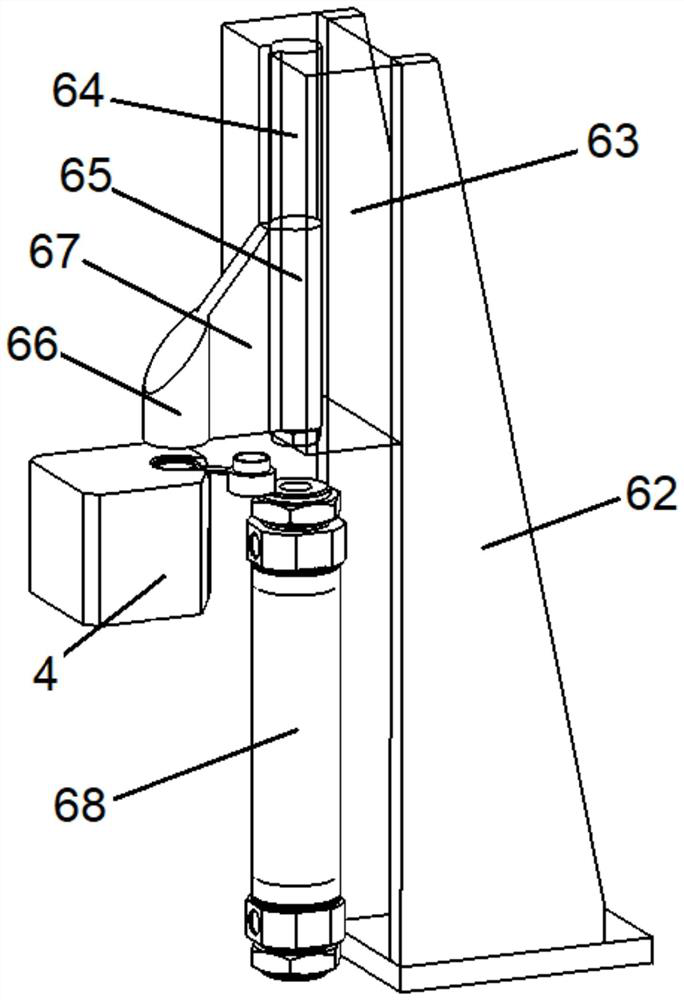

[0033] Test tube capping equipment such as figure 1As shown, it includes a conveying table 3, on which a plurality of test tube clamps 4 for clamping test tubes are arranged, and the conveying table 3 sequentially transports the test tube clamps 4 to the plug cover feeding station, the test tube feeding station, the plug Cap flipping station and unloading station, when the test tube fixtur...

Embodiment 2

[0045] Embodiment 2 of the present invention provides a test tube capping assembly method, which is completed by using the equipment in Embodiment 1, and specifically includes the following steps

[0046] Step 1, feeding the plug cap 1 into the test tube fixture 4, so that the collar 12 of the plug cap 1 is located on the step 43, and the plug head 11 is in an upside-down state;

[0047] Step 2, loading the test tube 2 and inserting it into the test tube clamp 4, so that the test tube 2 passes through the collar 12, until the collar 12 is sleeved on the outside of the test tube 2 and elastically fixed;

[0048] Step 3, the plug 11 is clamped by the clamping mechanism, and the clamping mechanism is driven to rotate eccentrically, so that the plug 11 is turned over and aligned with the test tube 2;

[0049] Step 4, drive the plug head 11 to insert the test tube 2 through the plugging mechanism and tighten it to form a sealed state;

[0050] In step five, the test tube 2 with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com