Cold water phase change machine and heat pump system

A cold water and phase change technology, applied in the energy field, can solve problems such as inability to achieve deicing, and achieve the effects of facilitating debugging and observation, improving heat exchange efficiency, and enhancing ice removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

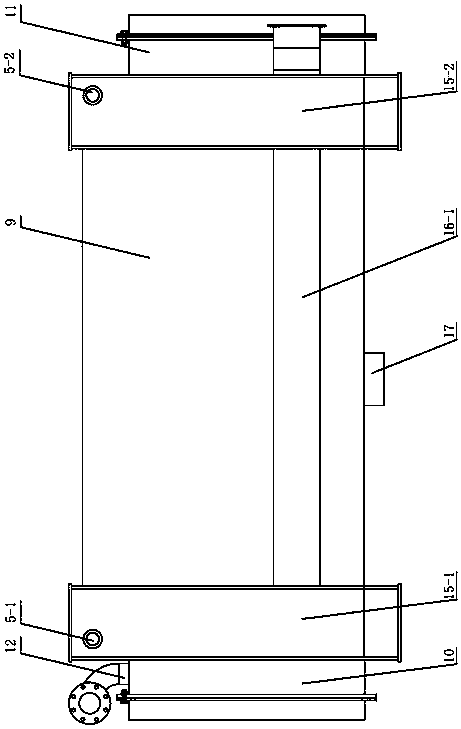

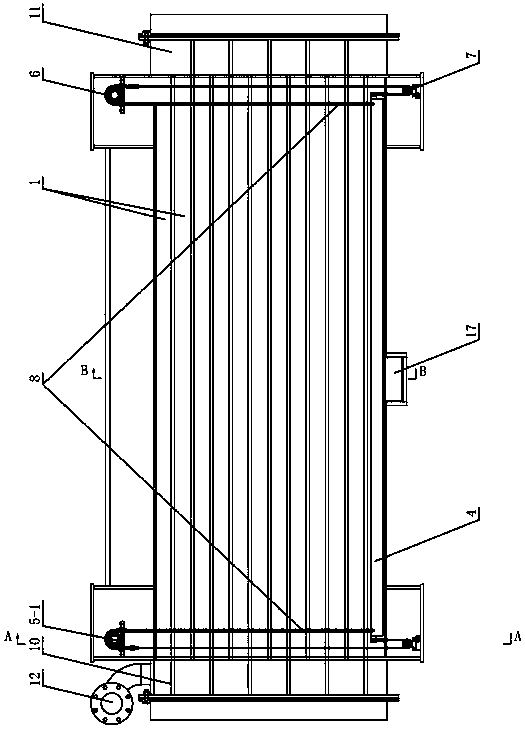

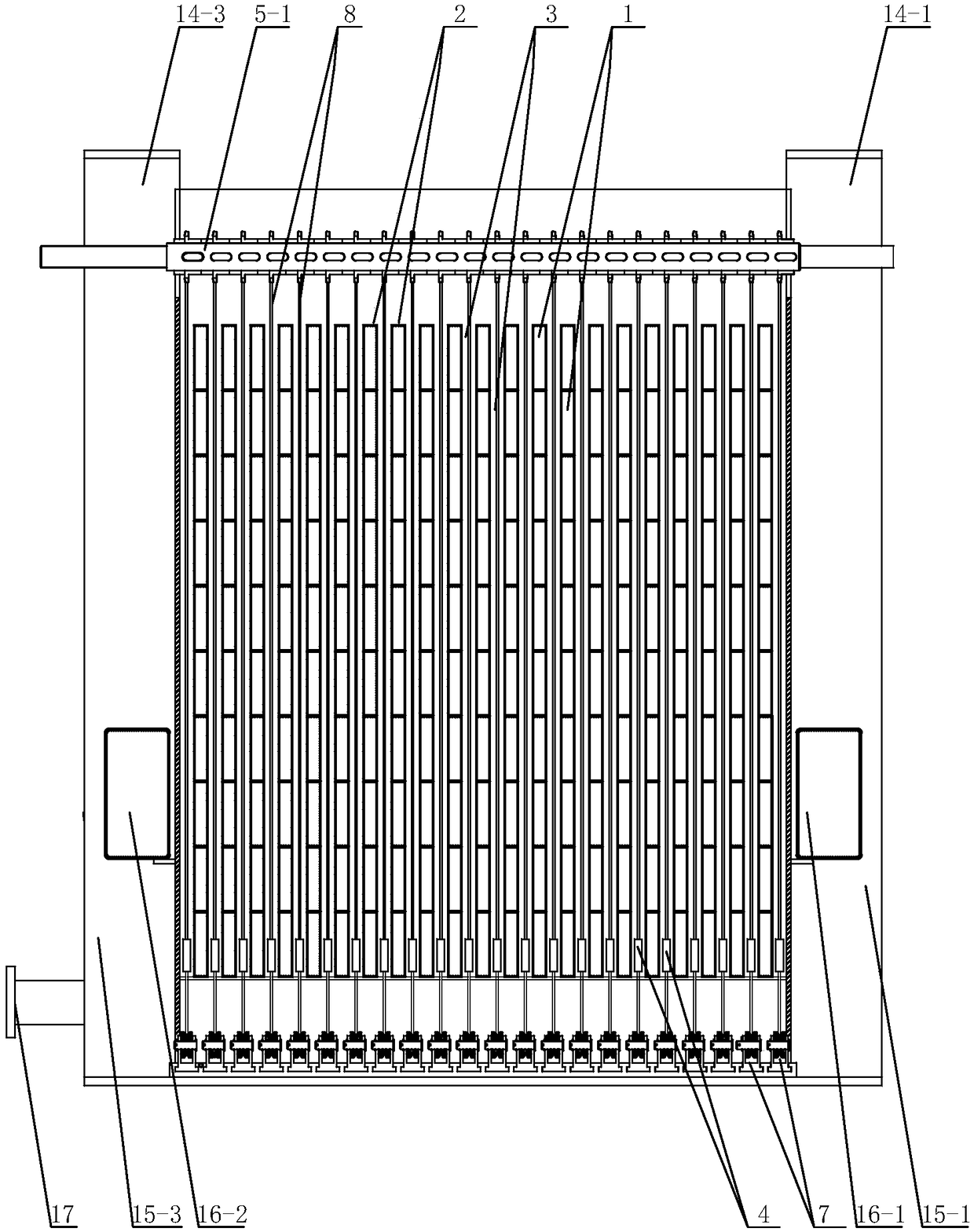

[0042] Specific implementation mode one, such as Figure 1~5 As shown, a cold water phase change machine of this embodiment is composed of a heat exchange tube 1, a tube row 2, a cold water flow channel 3, a scraper 4, a main shaft 5-1, a main shaft 2 5-2, an upper transmission wheel 6, a lower Transmission wheel 7, transmission chain 8, housing 9, left diversion box 10, right diversion box 11, antifreeze solution inlet 12, antifreeze solution outlet 13, ice discharge port one 14-1, ice discharge port two 14-2, Ice discharge port three 14-3, ice discharge port four 14-4, ice discharge channel one 15-1, ice discharge channel two 15-2, ice discharge channel three 15-3, ice discharge channel four 15-4, ice discharge channel Tube 1 16-1, ice discharge tube 2 16-2, cold water inlet 17, cold water inlet chamber 18 and cold water inlet 19, the plurality of heat exchange tubes 1 form a tube row 2 in the vertical direction, Both ends of a plurality of heat exchange tubes 1 are respect...

specific Embodiment approach 2

[0043] Specific implementation mode two, such as Image 6 As shown, a cold water phase change machine of this embodiment also includes a transmission motor one 20-1, a transmission motor two 20-2, a transmission motor reducer 21-1 and a transmission motor reducer two 21-2, so Described main shaft one 5-1 is connected with transmission motor reducer one 21-1; Described transmission motor reducer one 21-1 is connected with transmission motor one 20-1; Described main shaft two 5-2 and transmission The second motor reducer 21-2 is connected; the second transmission motor reducer 21-2 is connected to the second transmission motor 20-2. The beneficial effect of this embodiment is that the motor provides power for the main shaft.

specific Embodiment approach 3

[0044] Specific implementation mode three, such as Figure 7 As shown, a cold water phase change machine in this embodiment also includes a motor transmission chain 22, and the said main shaft two 5-2 is connected with the main shaft one 5-1 through the motor transmission chain 22. The beneficial effect of this embodiment is that the use of one motor is reduced through the transmission effect of the motor transmission chain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com