Patents

Literature

110results about How to "Prevent horizontal movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

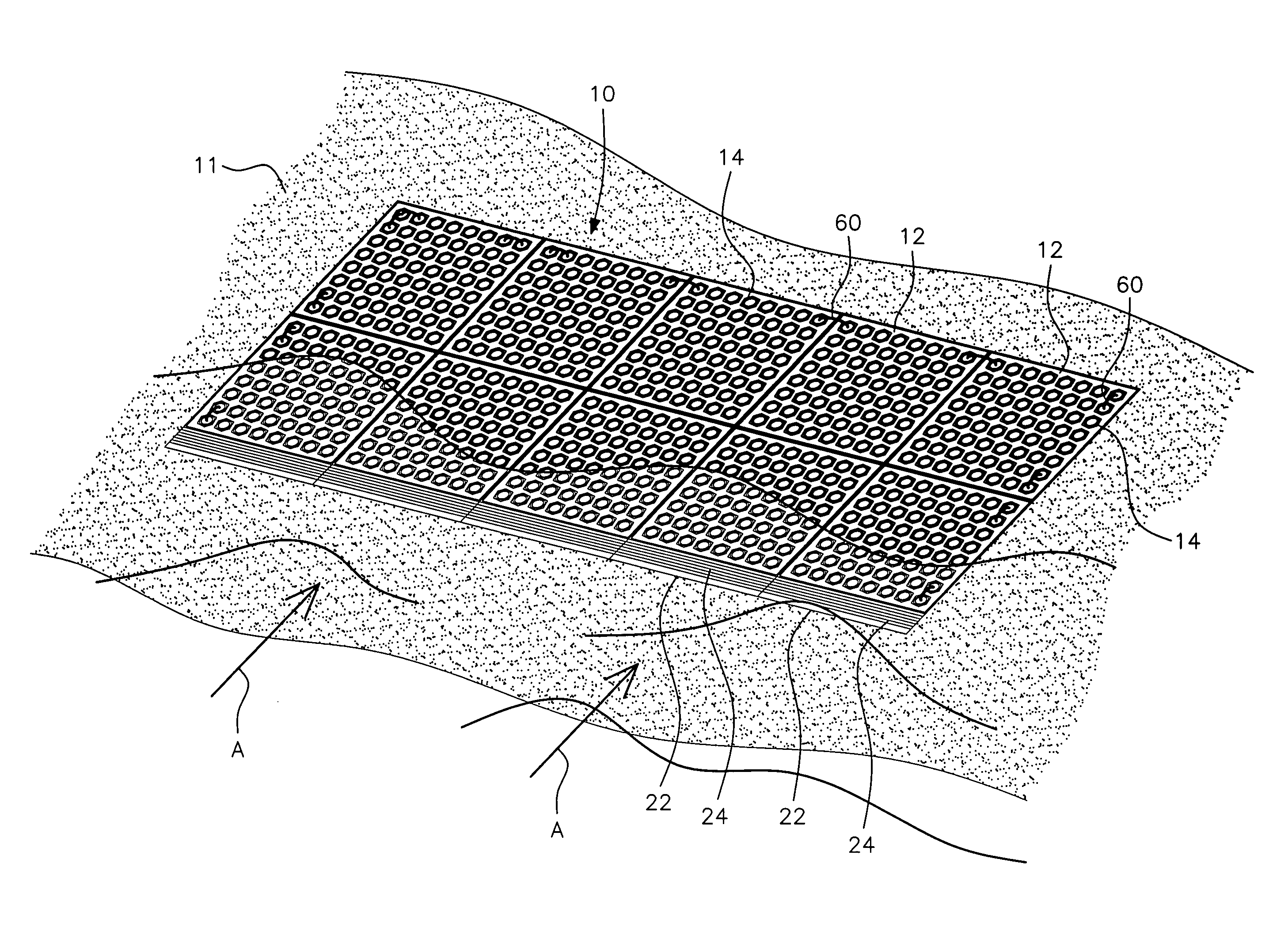

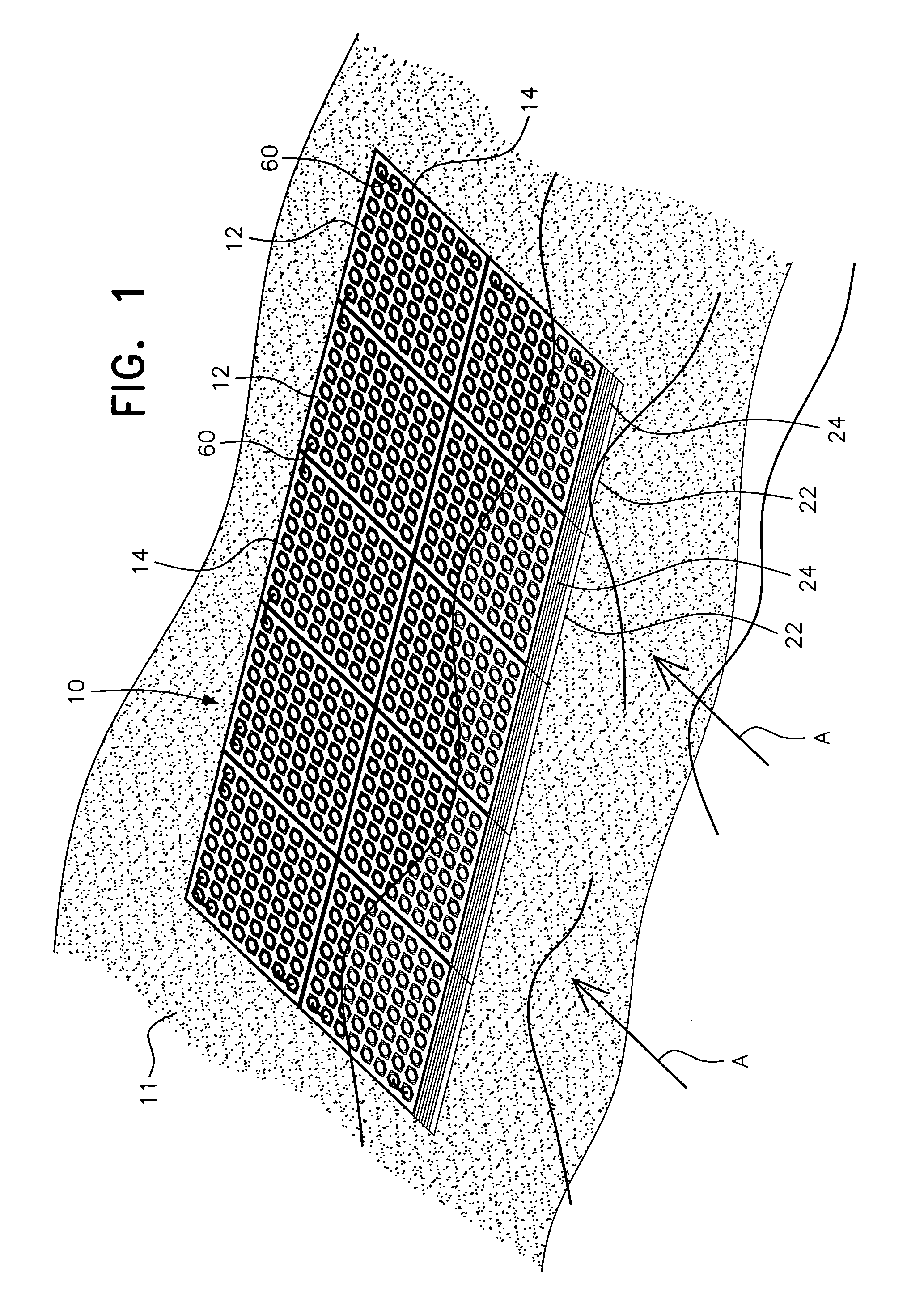

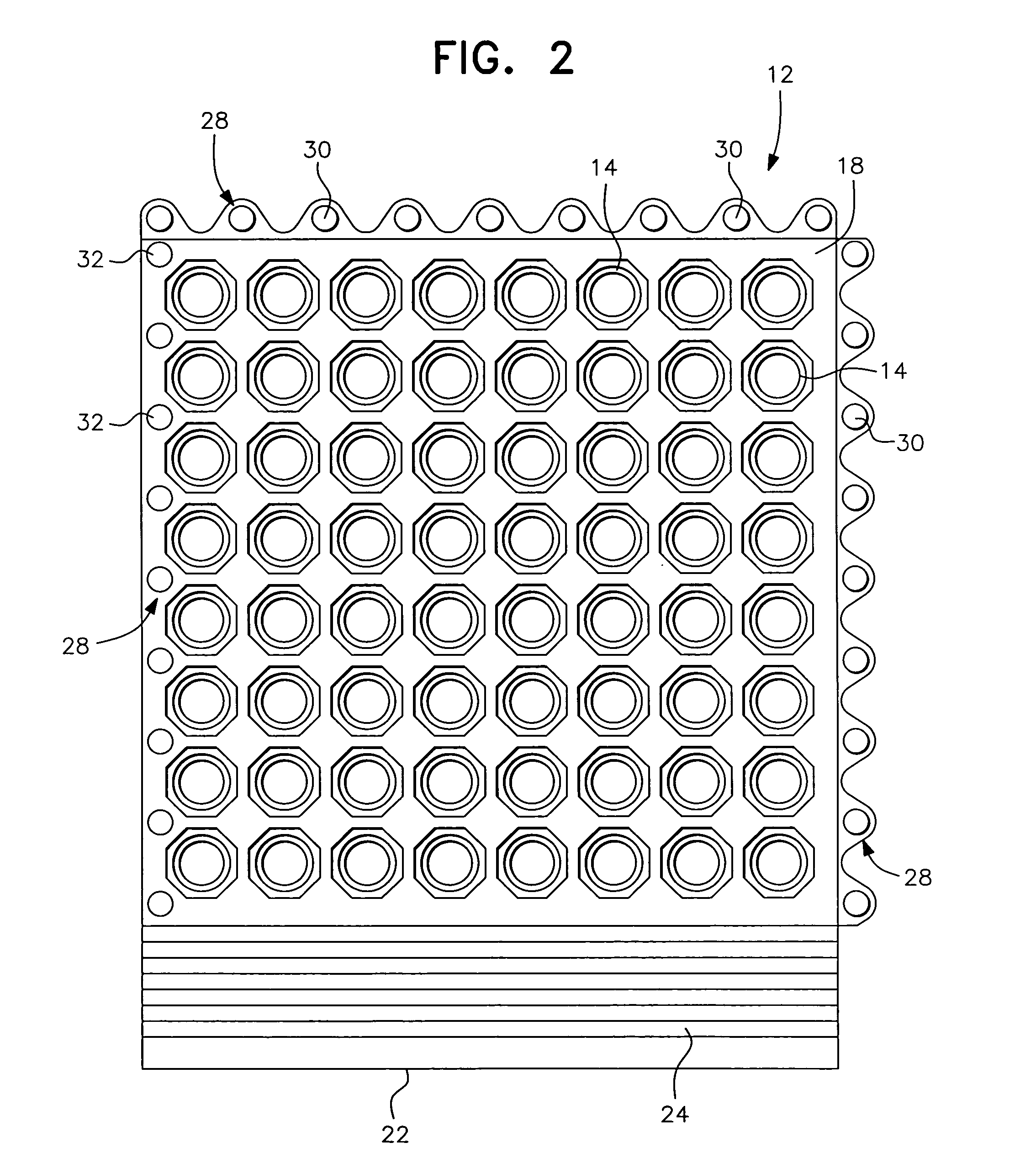

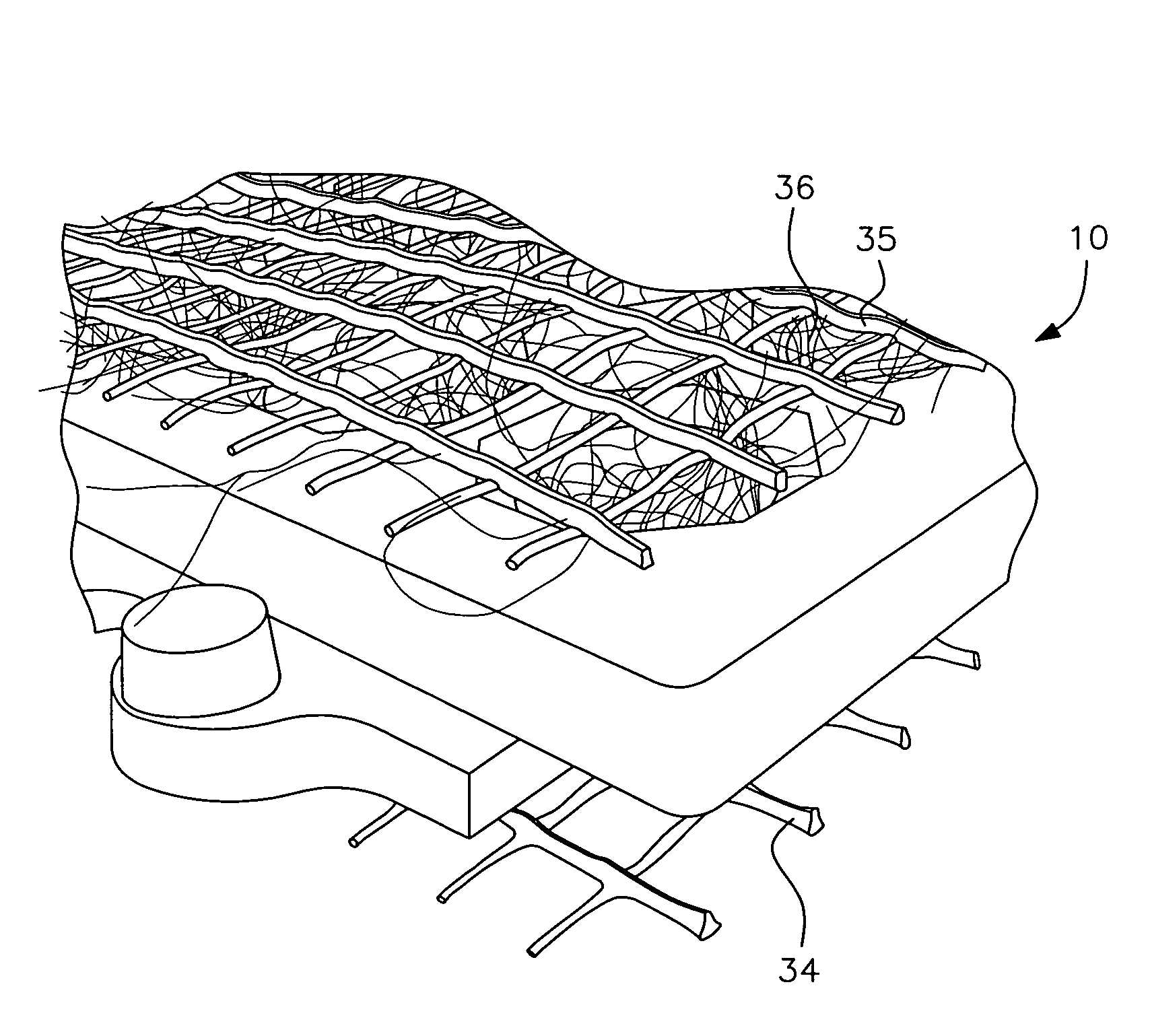

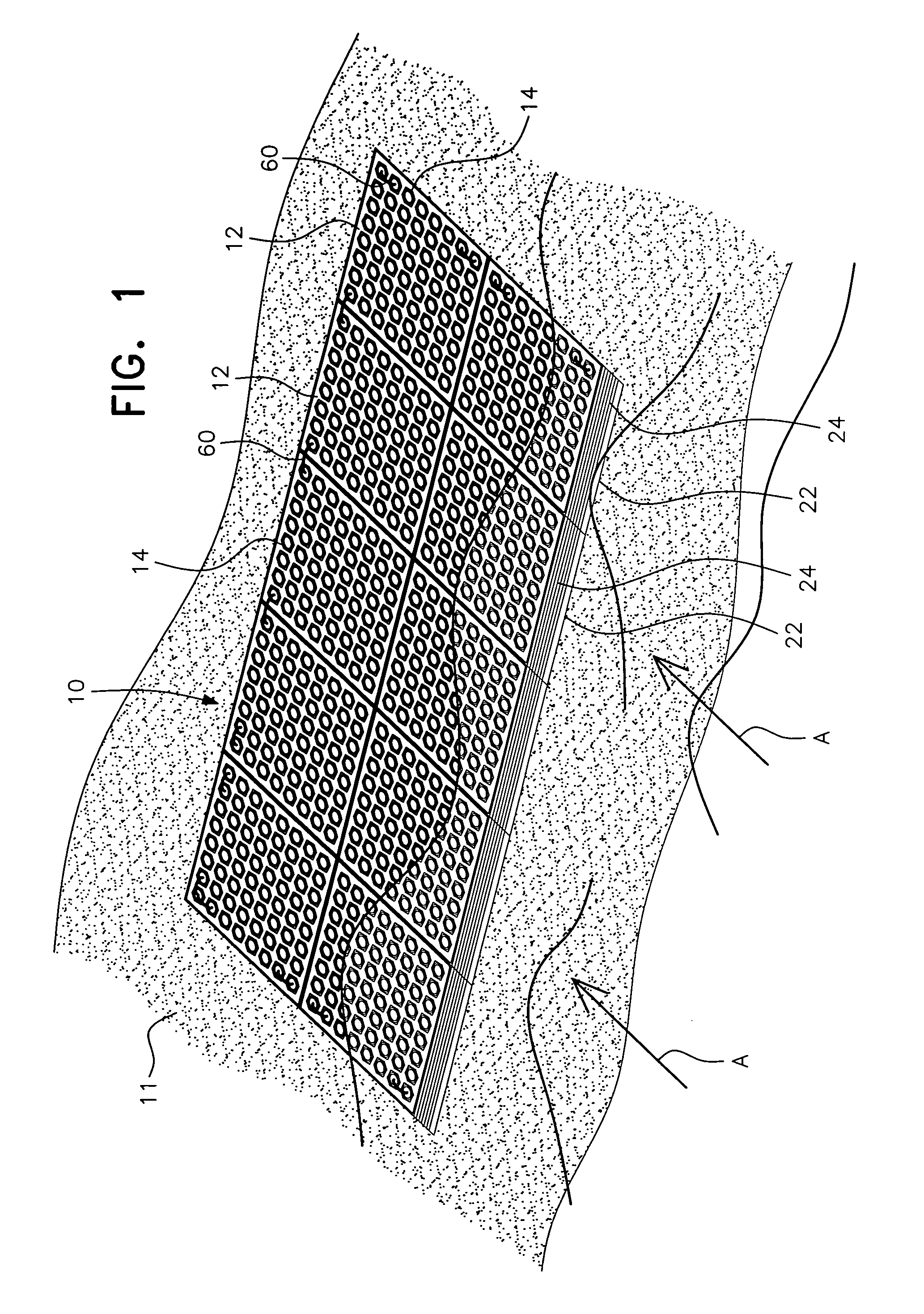

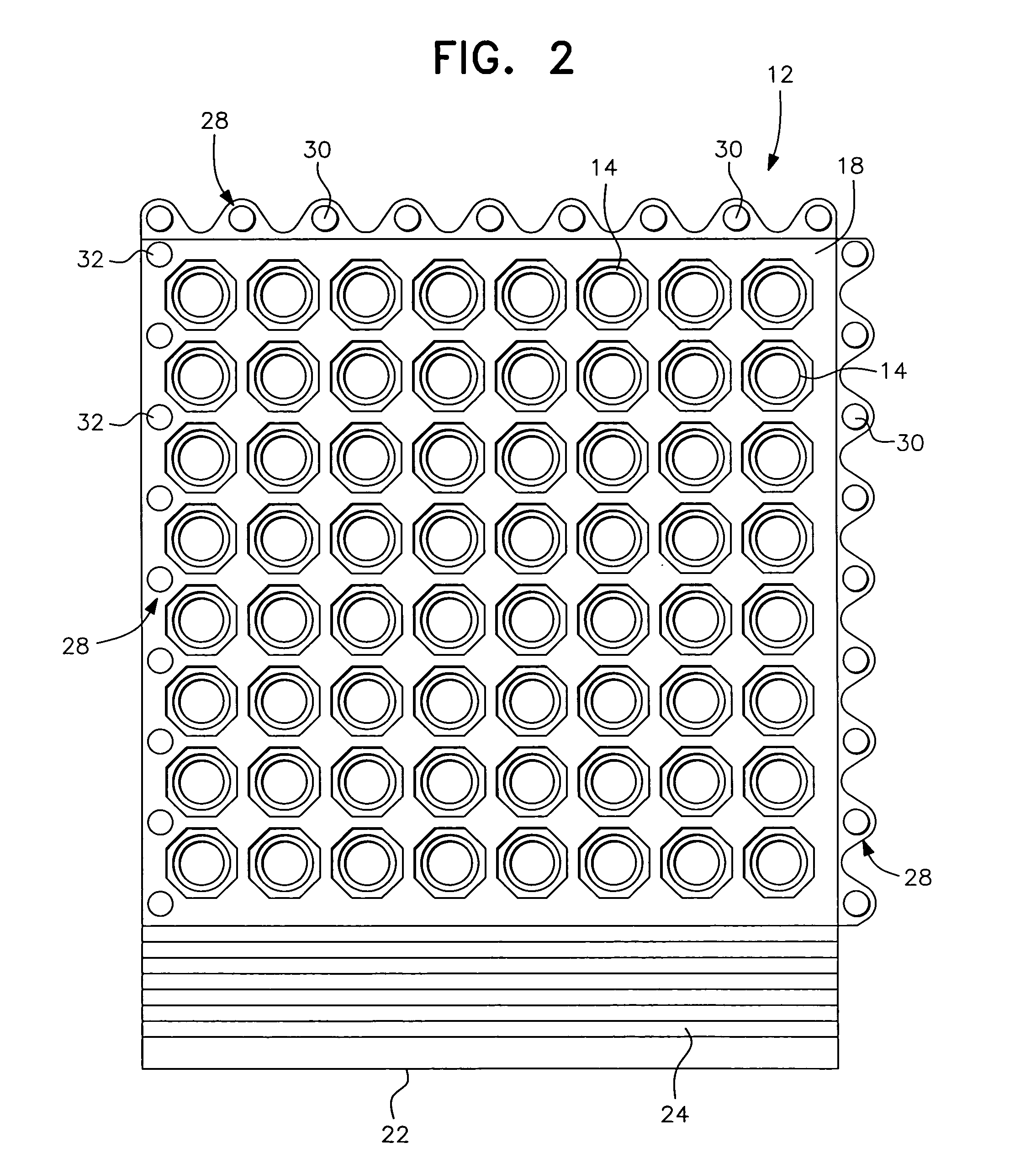

Erosion control ballast and soil confinement mat

ActiveUS20110044759A1Not to damageSafe and high-traction surfaceCoastlines protectionExcavationsVegetationWater flow

An erosion control ballast and soil confinement mat for use in water flow conditions is provided. The mat is made of a non-buoyant, relatively heavy and substantially flexible material with a plurality of pores stamped or pre-cast therein that allow for the inflow of water, the establishment of vegetation growth through the mat, and the in-filling of the pores with supplemental ballast materials such as gravel or soil. The bottom side of the mat has protrusions that extend into the underlying surface to prevent horizontal shifting and confine soil materials and / or another erosion control mat such as an erosion control blanket or turf reinforcement mat, while also preventing migration of the mat itself under high shear force water flow. The top surface of the mat may be provided with flaps that cover the pore openings during periods of strong water flow to prevent excessive water flow from entering the pores and eroding the underlying soil.

Owner:WESTERN GREEN LLC

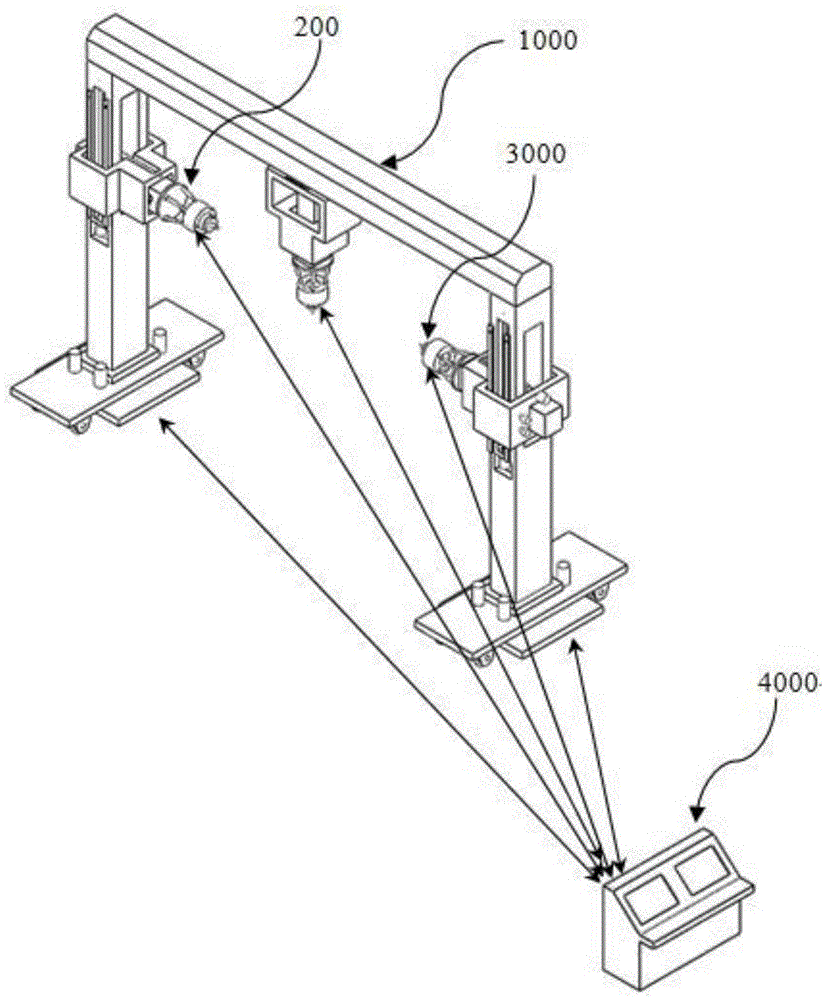

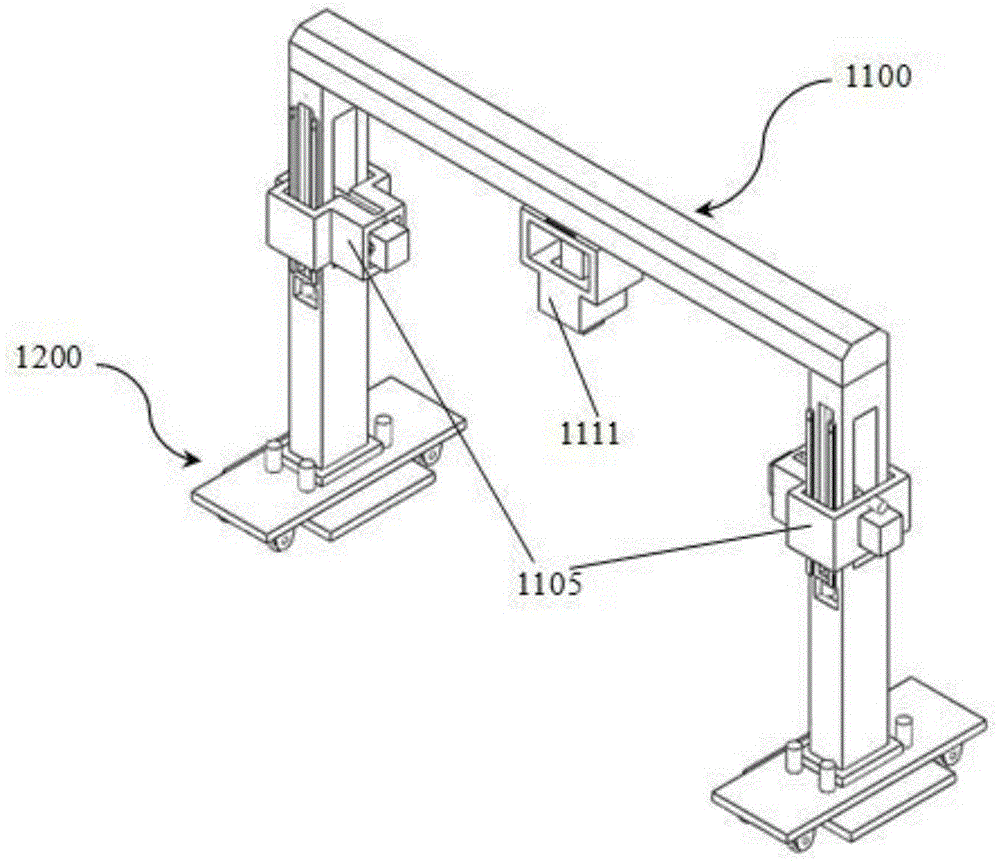

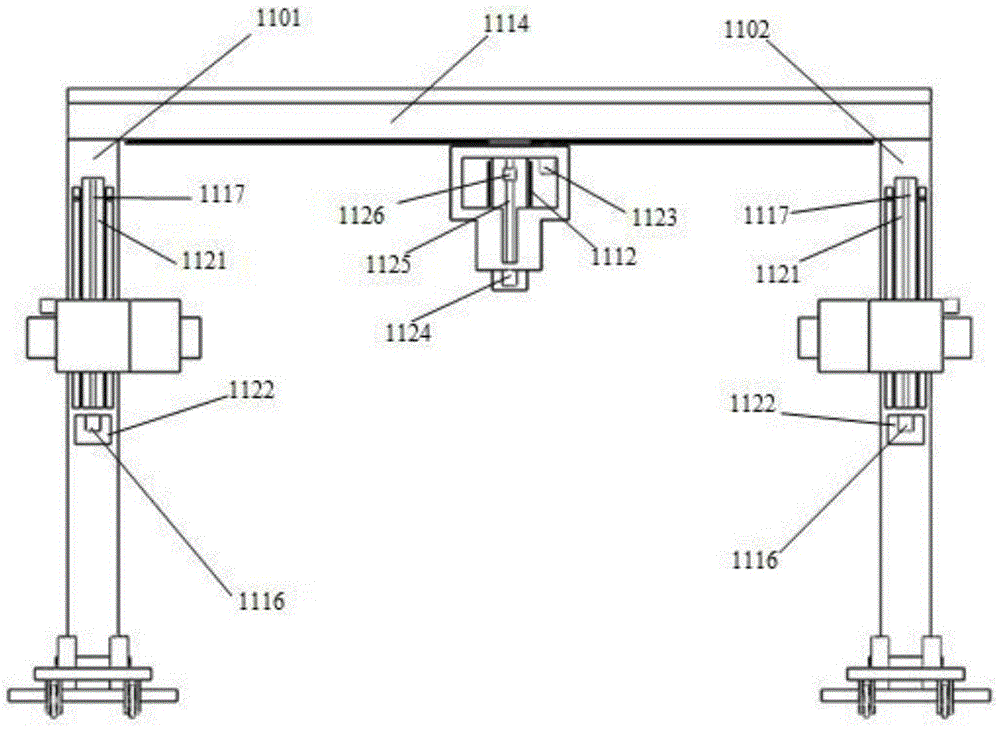

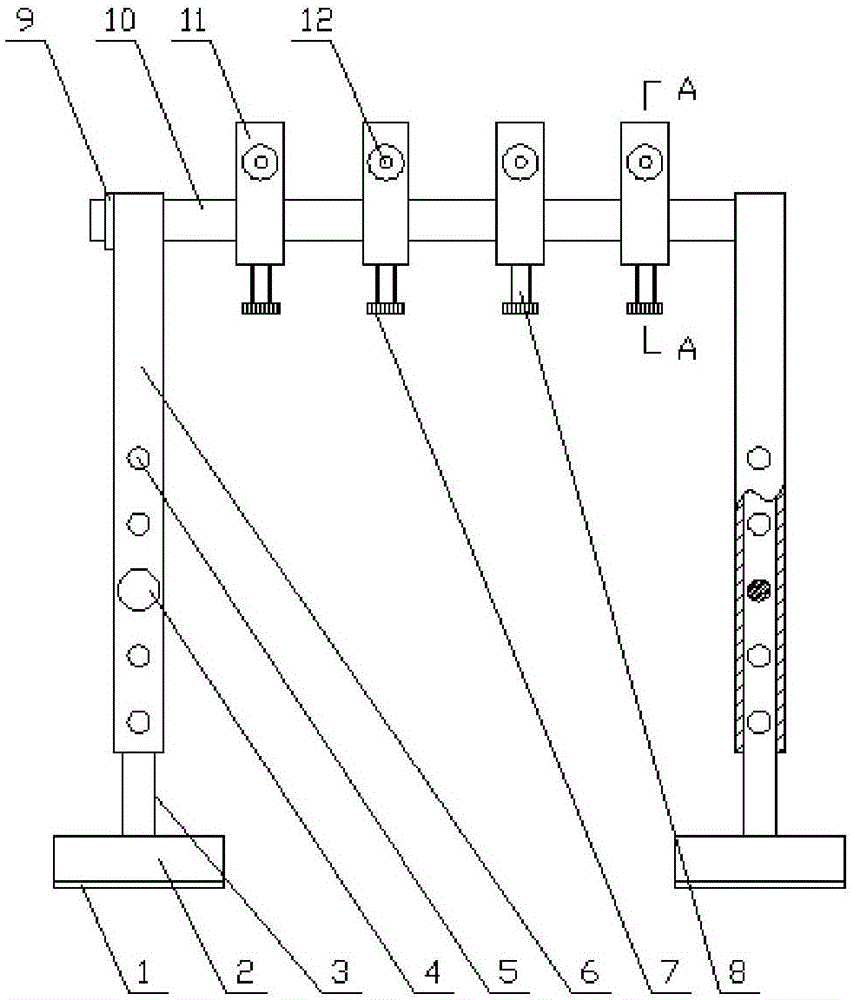

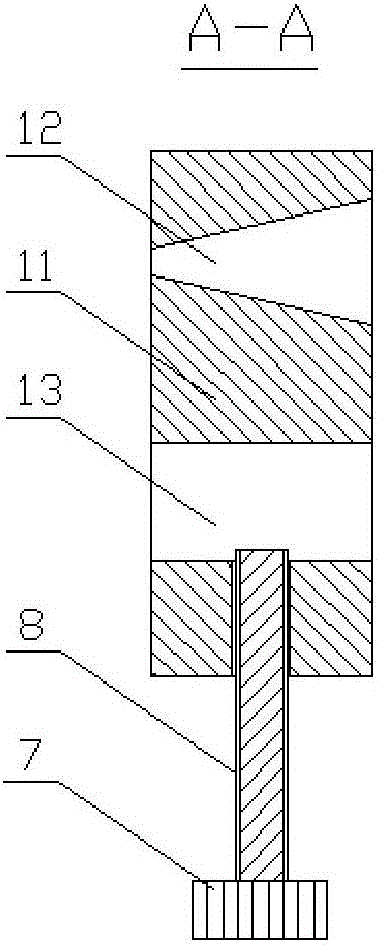

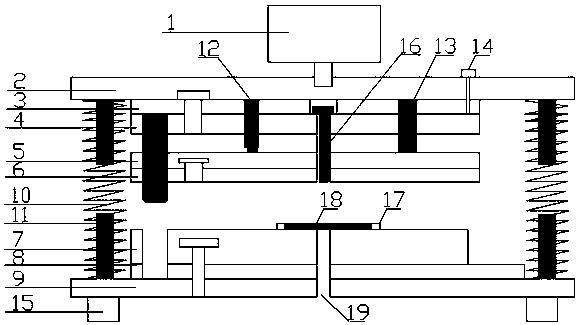

Gantry type numerical control hole manufacturing system used for airplane wing body abutting joint

ActiveCN105618809AAchieve horizontal movementRealize normal attitude adjustmentLarge fixed membersBoring/drilling machinesNumerical controlJet aeroplane

The invention provides a gantry type numerical control hole manufacturing system used for airplane wing body abutting joint. The gantry type numerical control hole manufacturing system comprises a gantry bracket assembly, three four-rod pose adjusting mechanisms and three terminal hole manufacturing units. The gantry bracket assembly comprises a door shaped bracket, two perpendicular lifting devices and a horizontal sliding device. Each four-rod pose adjusting mechanism comprises a movable platform, a fixed platform, a first electric telescopic rod, a second electric telescopic rod, a third electric telescopic rod and a fourth electric telescopic rod. Each terminal hole manufacturing unit comprises a T-shaped feed supporting shell body, a T-shaped revolution supporting shell body, a U-shaped revolution shell body, a U-shaped rotation supporting shell body and a rotation driving device. The gantry type numerical control hole manufacturing system is capable of remarkably improving the efficiency and the quality of hole manufacturing of wing body abutting joint and assembly and especially suitable for hole manufacturing of large-size airplane wing body abutting joint and assembly.

Owner:NANJING COLLEGE OF INFORMATION TECH

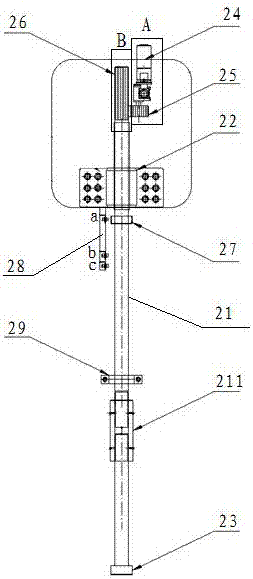

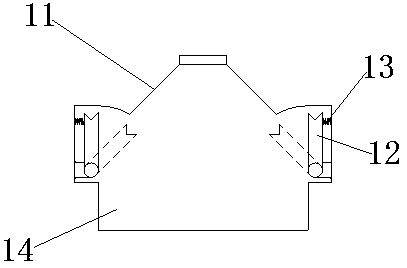

Windproof bridge crane anchoring system and method

ActiveCN107032233APlay the role of windproof and anti-overturningPrevent horizontal movementTrolley cranesTravelling gearEngineering

The invention discloses a windproof bridge crane anchoring system and a method. The system comprises a bridge crane, four windproof pull rods arranged on the bridge crane, and four sets of windproof ground foundations corresponding to the four windproof pull rods; the windproof pull rods include pull rod bodies, pull rod nuts, driving devices and lock pins; the pull rod bodies are connected with the pull rod nuts fixed above the bridge crane based on threads; driven devices are fixed at the top ends of the pull rod bodies, and the lock pins are connected to the bottom ends of the pull rod bodies; lock pin fixing grooves are formed in the windproof ground foundations, and notches the lock pin fixing grooves are provided with fixing plates with first and second notches near each other; windproof anchor control modules drive the driving devices to work, so that the pull rod bodies are descended to extend into the lock pin fixing grooves by the second notches; and after the bridge crane moves to reach a set anchor position in the direction of the first notches, the driving devices reversely work, so that the pull rod bodies are ascended until the lock pins are limited in the lock pin fixing grooves under limiting by the first notches to realize fixed connection between the pull rod bodies and the windproof ground foundations.

Owner:QINGDAO PORT INT +1

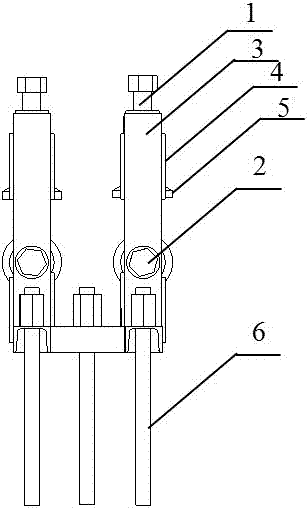

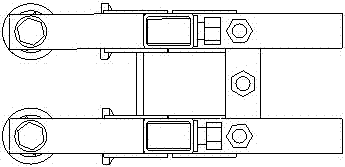

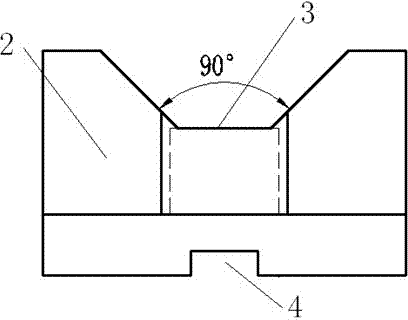

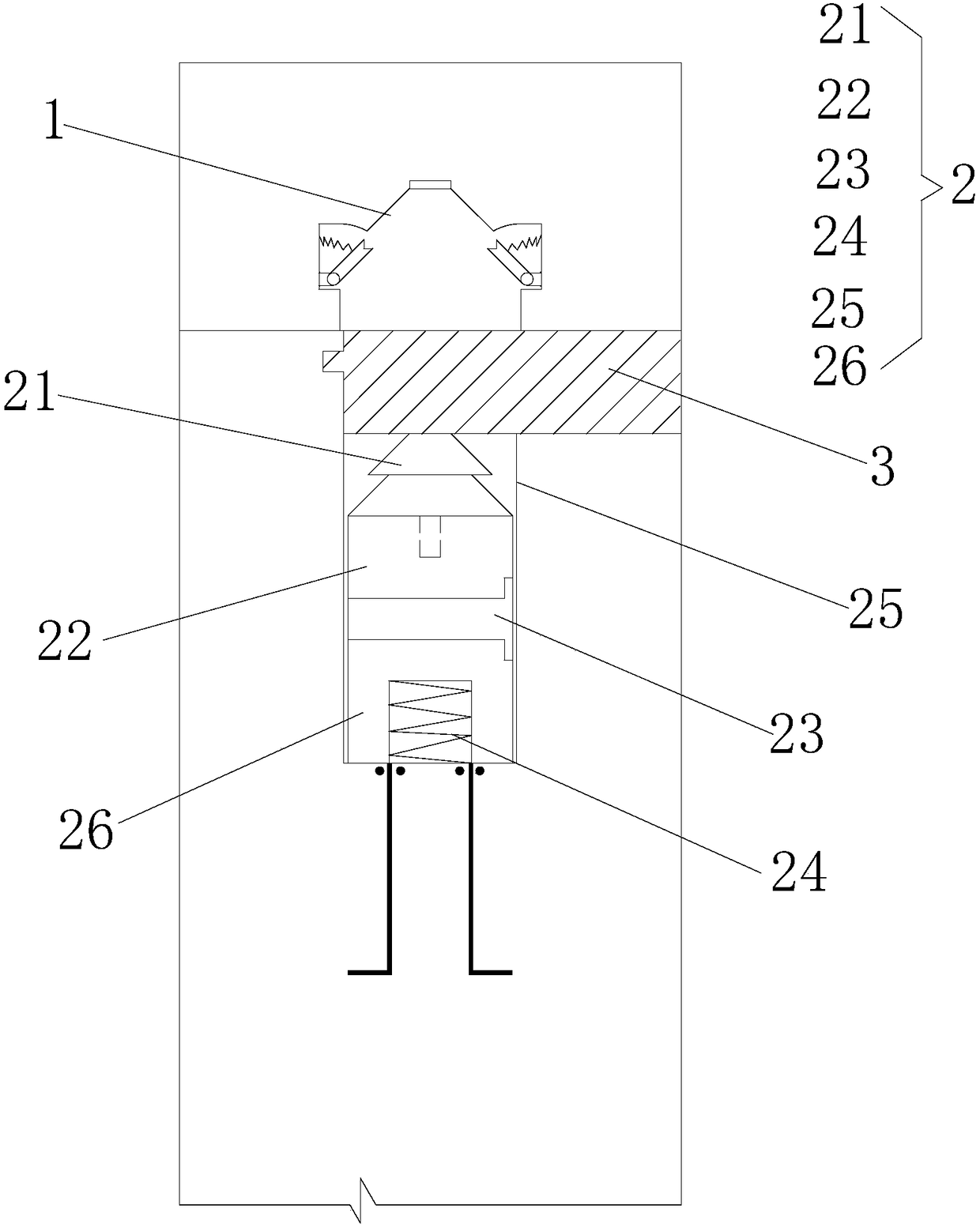

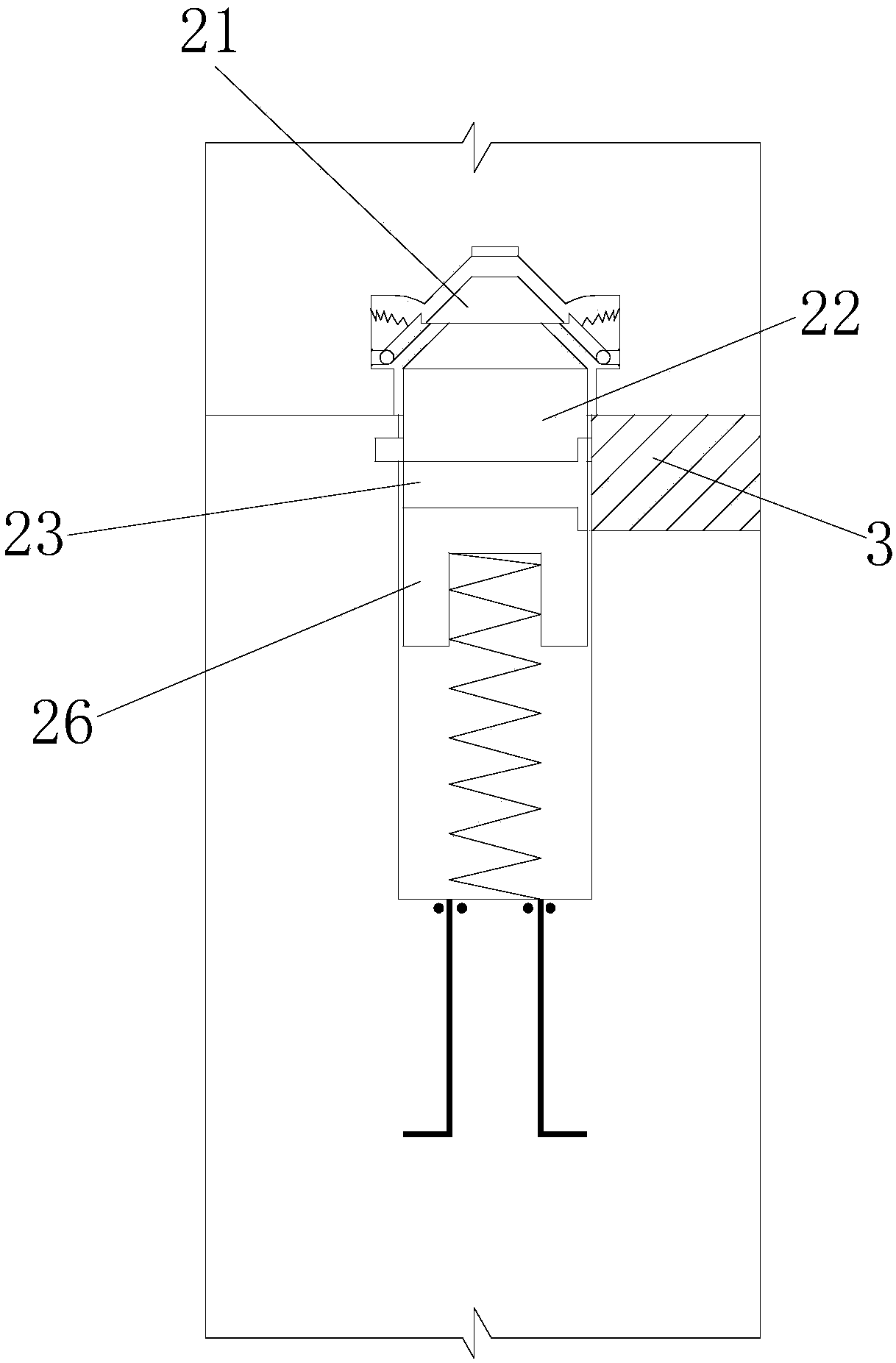

Pressing limiting device and method for slab ballastless track structure

ActiveCN108004855AMeet the needs of compression limitSmall and lightBallastwayStructural engineeringEngineering

The invention discloses a pressing limiting device and method for a slab ballastless track structure, which are used for solving problems of upwarp and warping diseases of the slab ballastless track structure of an operating line, realizing synchronous and integral deviation rectification of the laminated slab ballastless track structure and avoiding the dislocation of the laminated structure andupwarp secondary disease of a track slab in the deviation rectifying process.

Owner:沪杭铁路客运专线股份有限公司 +3

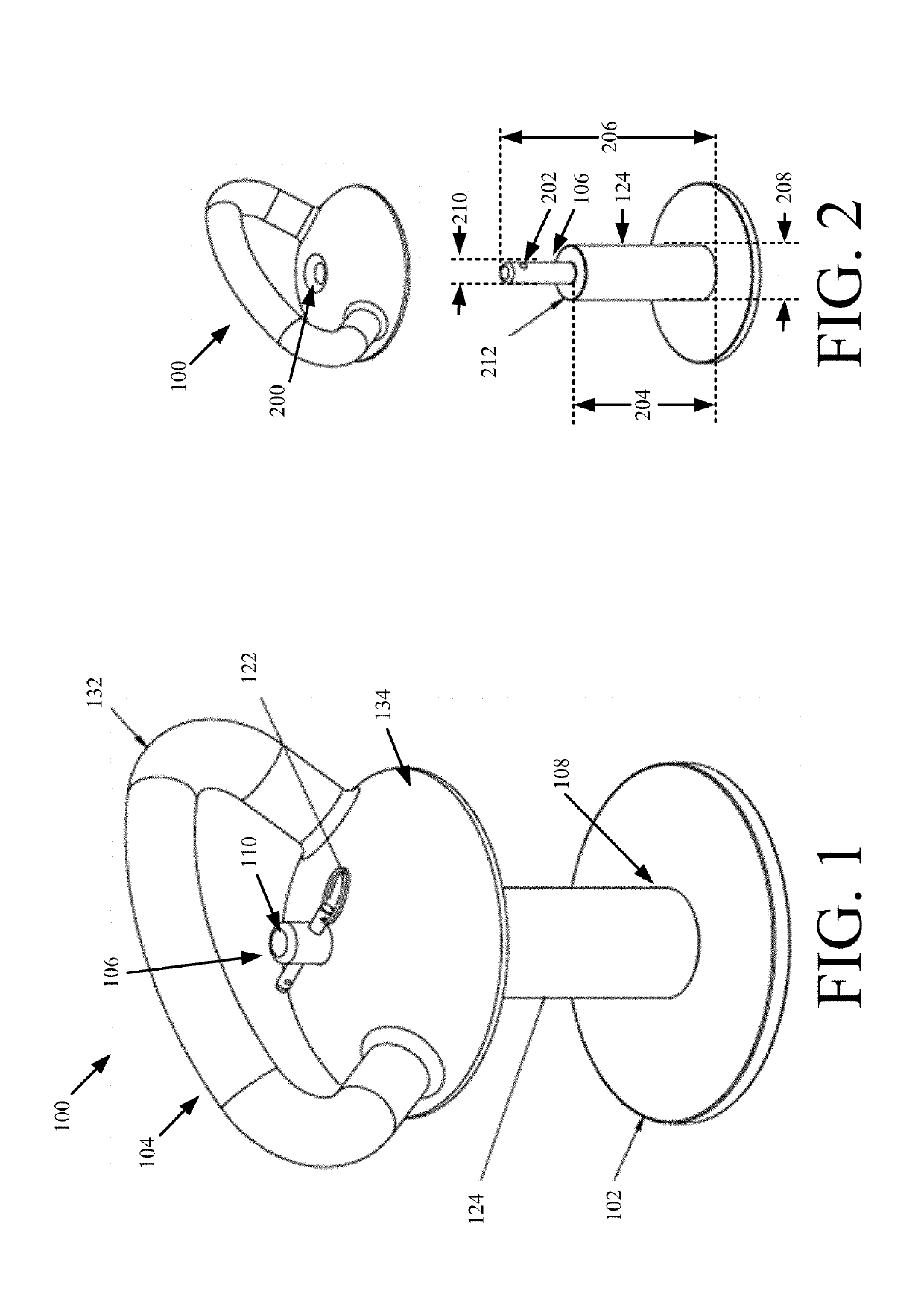

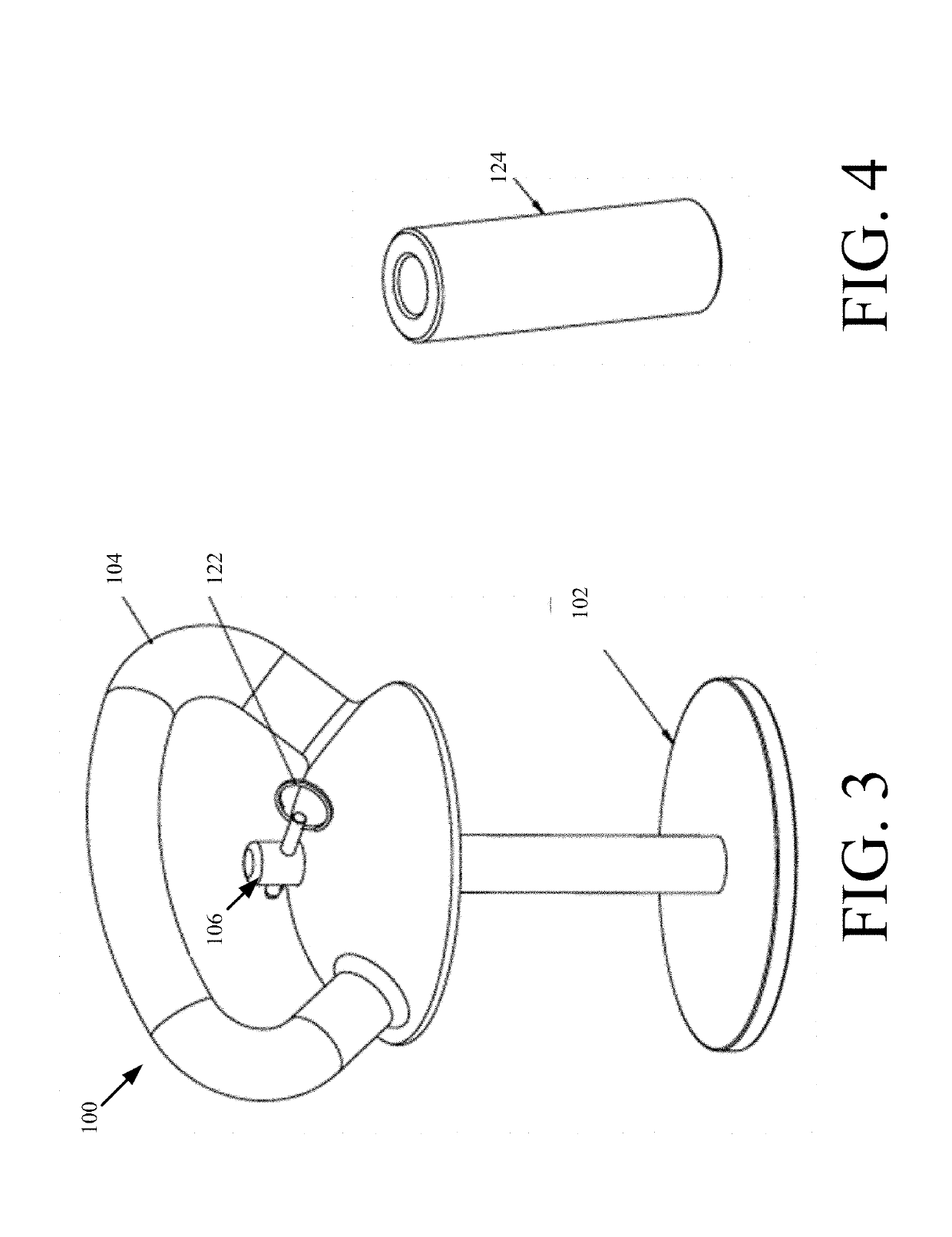

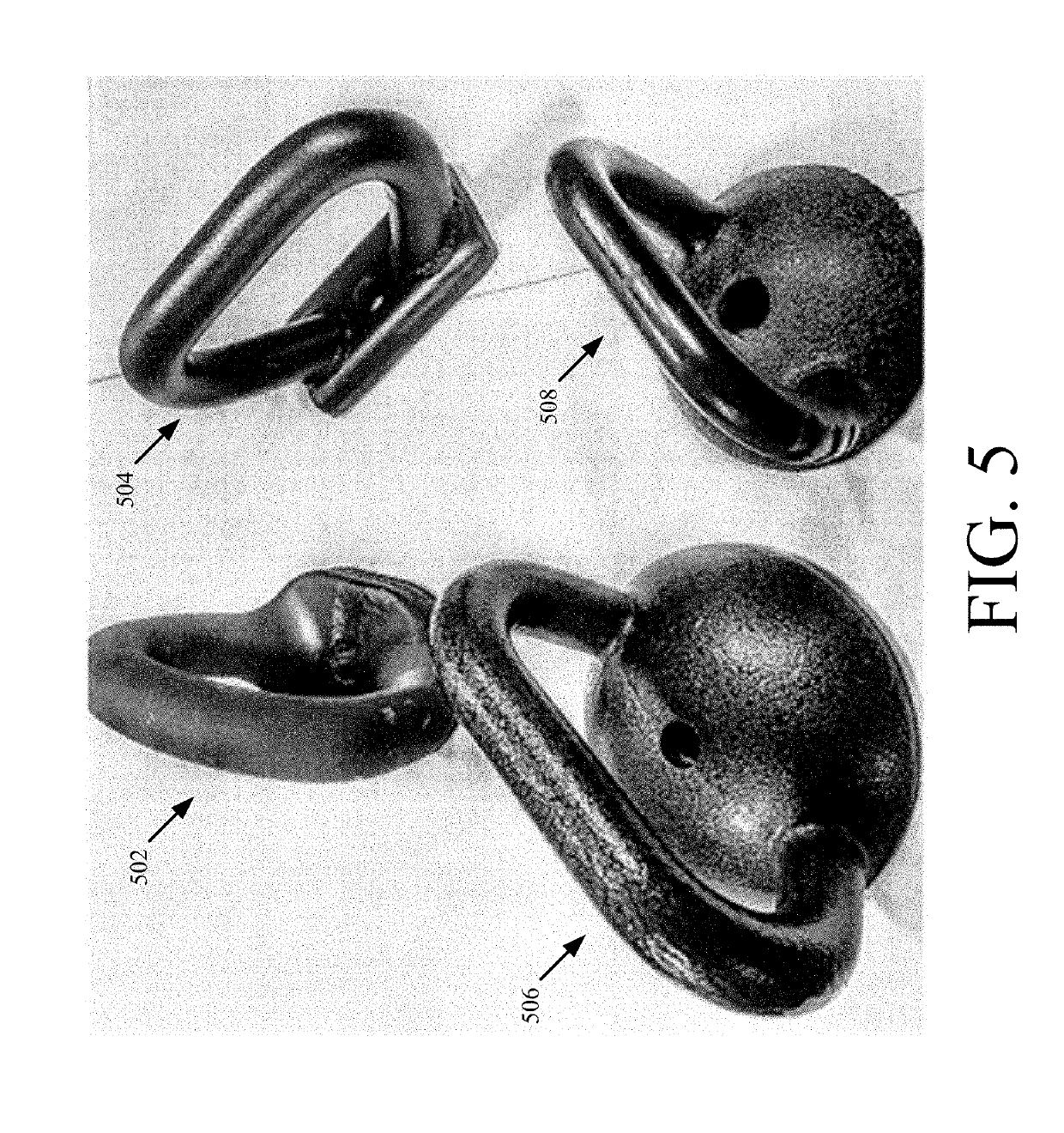

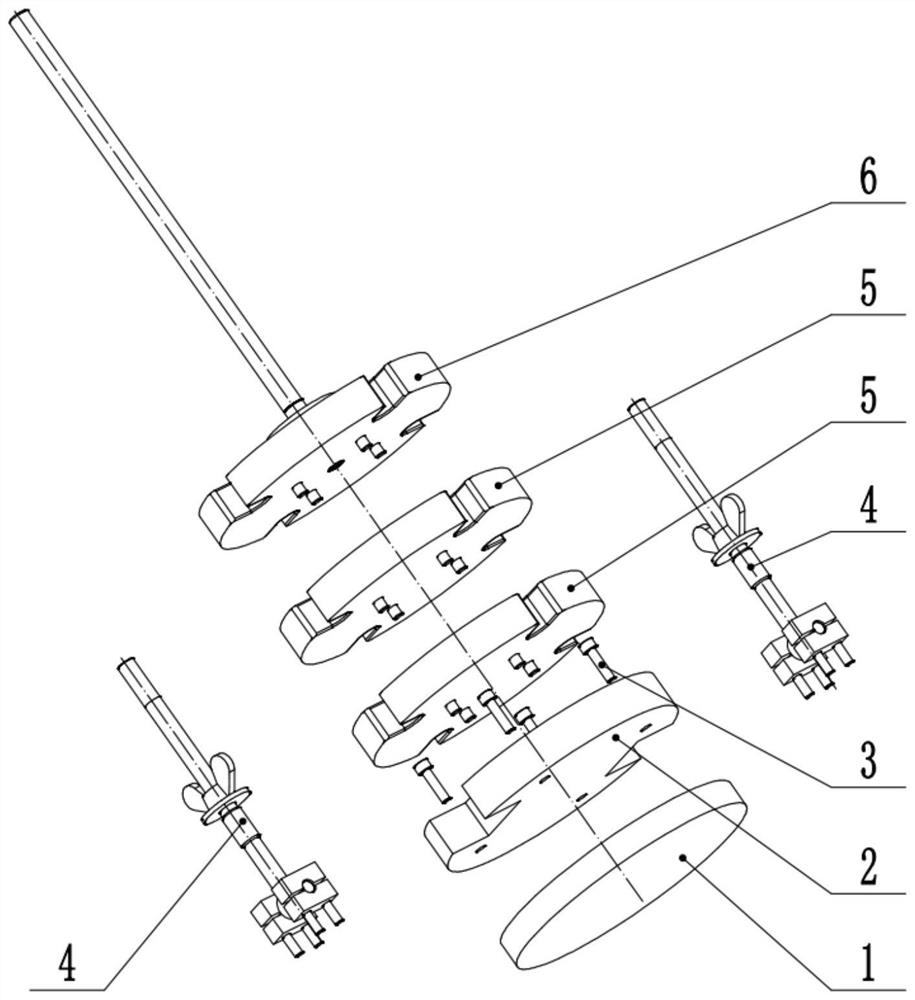

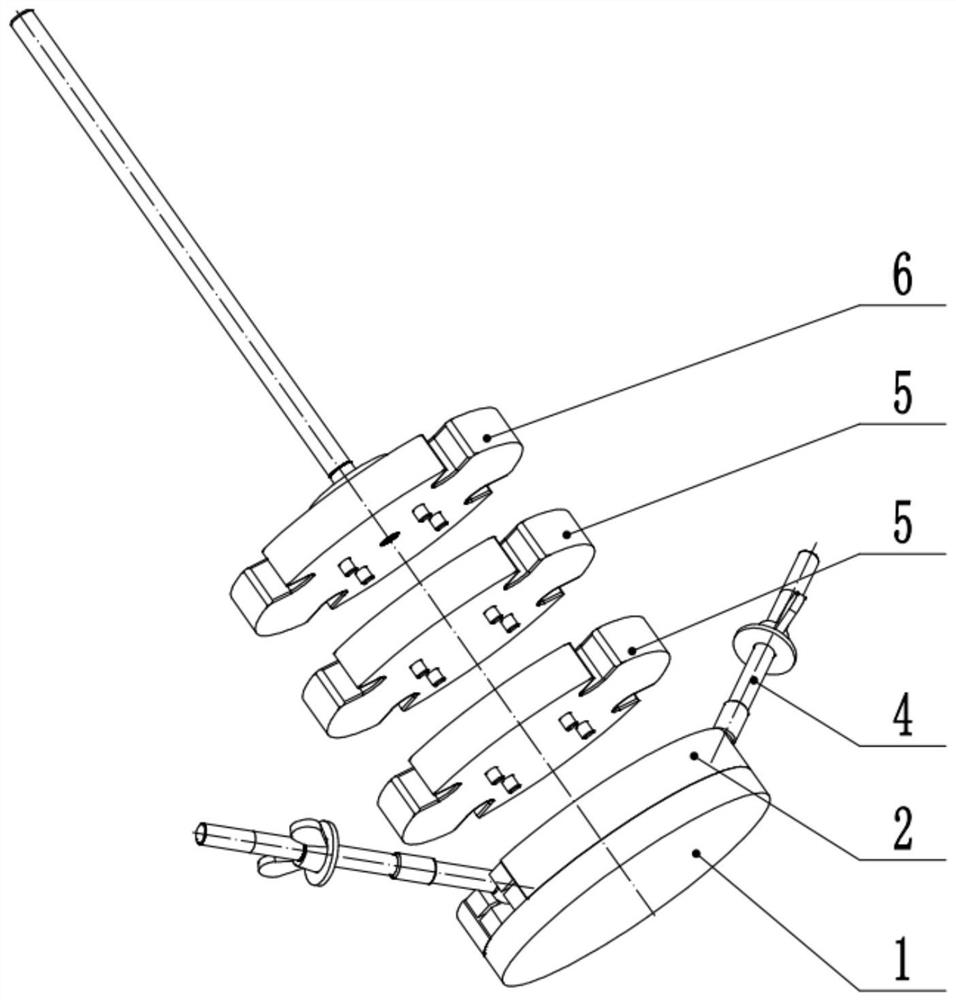

Adjustable kettlebell device

ActiveUS20190217146A1Easy to addEasy to removeDumb-bellsHorizontal barsEngineeringClassical mechanics

Systems and methods for using an Adjustable Kettlebell Device (“AKD”). AKD comprises a base, post, sleeve and handle. The post has an outer diameter that allows AKD to be compatible with a first weight plate of a first type. The sleeve which slides over the post has an outer diameter that allows AKD to be compatible with a second weight plate of a second different type. The handle is configured to facilitate an addition / removal of the first and second weight plates from AKD, a retention to the first weight plate on the post, and a retention of the second weight plate on the sleeve. The post is used to prevent horizontal movement of the first weight plate relative to the base and handle during a first time period. The sleeve to prevent horizontal movement of the second weight plate relative to the base and handle during a second time period.

Owner:SISLER CRAIG LOUIS

Erosion control ballast and soil confinement mat

ActiveUS8651770B2Prevent horizontal movementStable flowCoastlines protectionExcavationsVegetationWater flow

An erosion control ballast and soil confinement mat for use in water flow conditions is provided. The mat is made of a non-buoyant, relatively heavy and substantially flexible material with a plurality of pores stamped or pre-cast therein that allow for the inflow of water, the establishment of vegetation growth through the mat, and the in-filling of the pores with supplemental ballast materials such as gravel or soil. The bottom side of the mat has protrusions that extend into the underlying surface to prevent horizontal shifting and confine soil materials and / or another erosion control mat such as an erosion control blanket or turf reinforcement mat, while also preventing migration of the mat itself under high shear force water flow. The top surface of the mat may be provided with flaps that cover the pore openings during periods of strong water flow to prevent excessive water flow from entering the pores and eroding the underlying soil.

Owner:WESTERN GREEN LLC

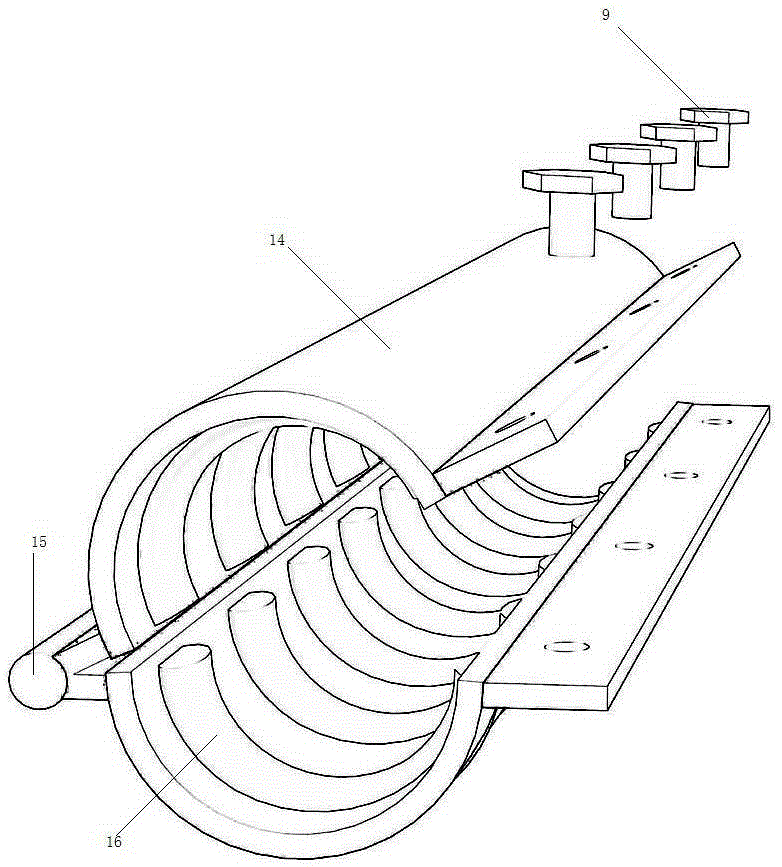

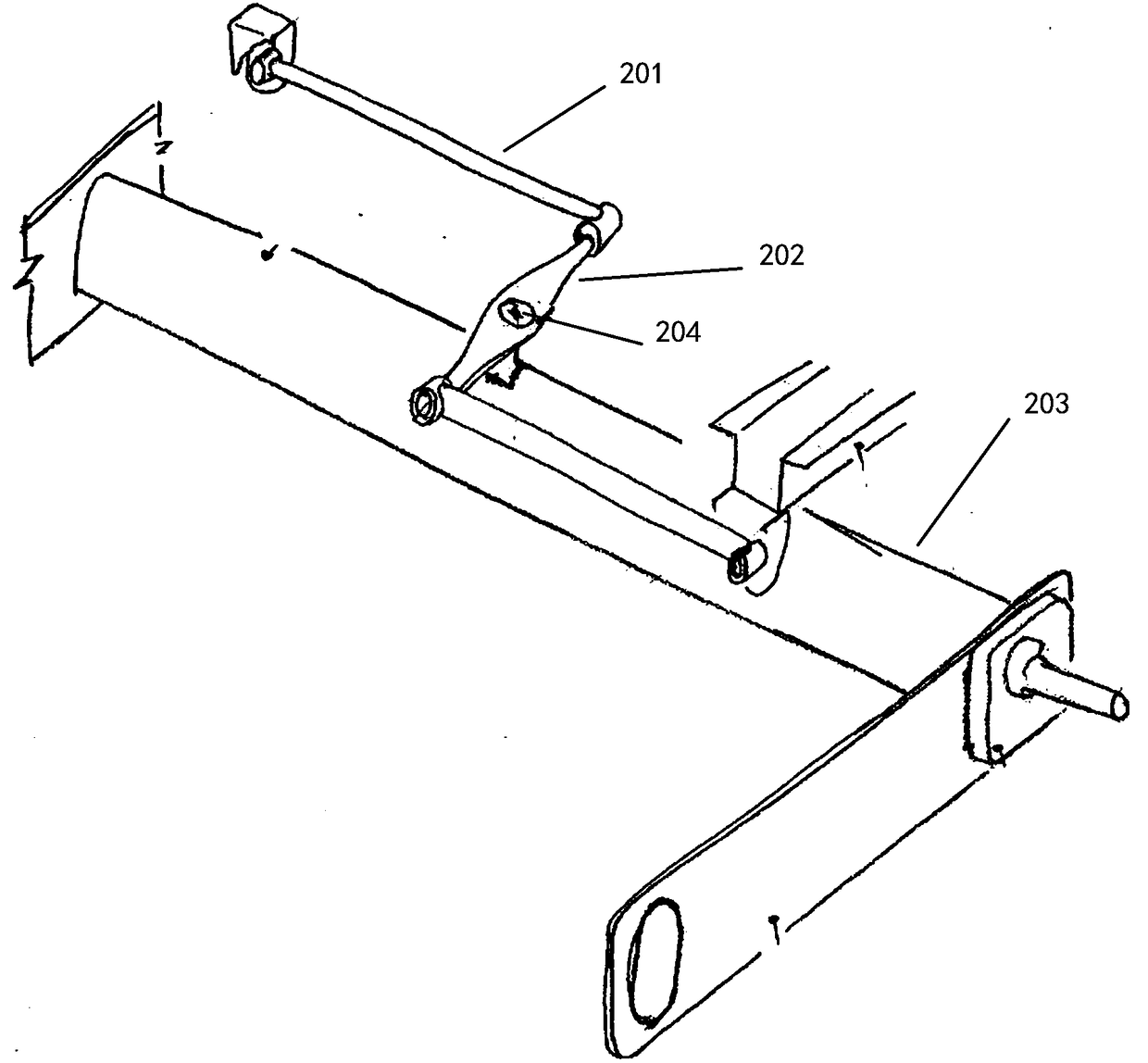

Yarn correction device for spinning

The invention relates to the field of spinning, in particular to a yarn correction device for spinning. By the adoption of the yarn correction device for spinning, the yarn inlet height can be adjusted while the yarn inlet direction is changed, and the problem that yarns are worn due to the angle problem when leaving a yarn drum or entering a spinning machine, and the quality of textile fabrics is affected is avoided. The yarn correction device structurally comprises a sliding rod, and the sliding rod is of a cylinder structure; the sliding rod is supported by first supports and second supports at the two ends, and one side of the sliding rod penetrates out of the first supports; the second supports are sleeved with the first supports; the outer surfaces of the first supports and the outer surfaces of the second supports are each provided with multiple locating holes, and the locating holes penetrate the first supports and the second supports; pin shafts penetrate the locating holes in the overlapped positions of the first supports and the second supports; and bases are arranged at the lower ends of the second supports. The yarn correction device for spinning is convenient and efficient to use, low in use cost and suitable for yarn correction in the spinning working procedure.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

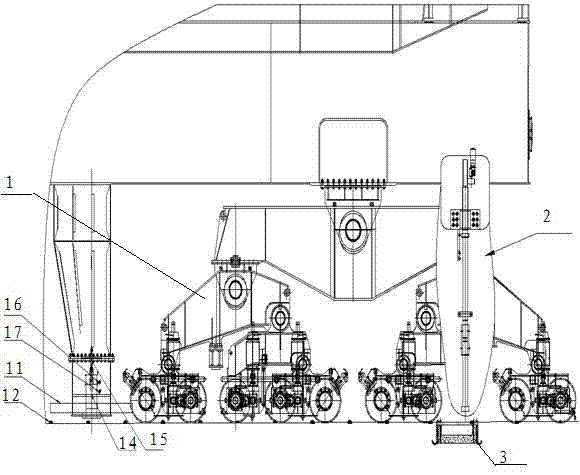

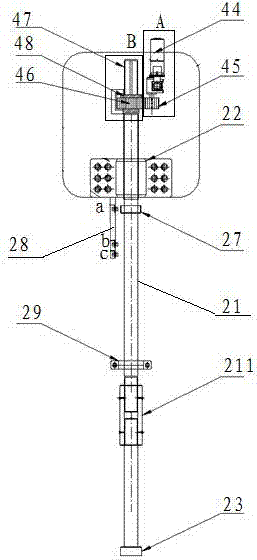

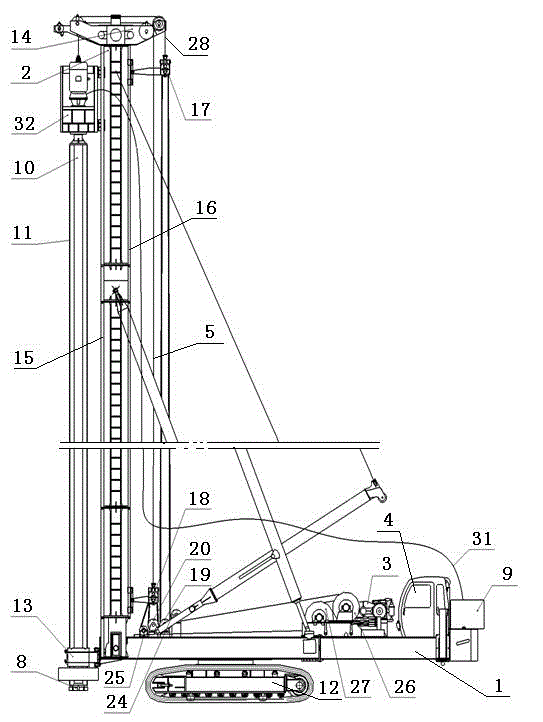

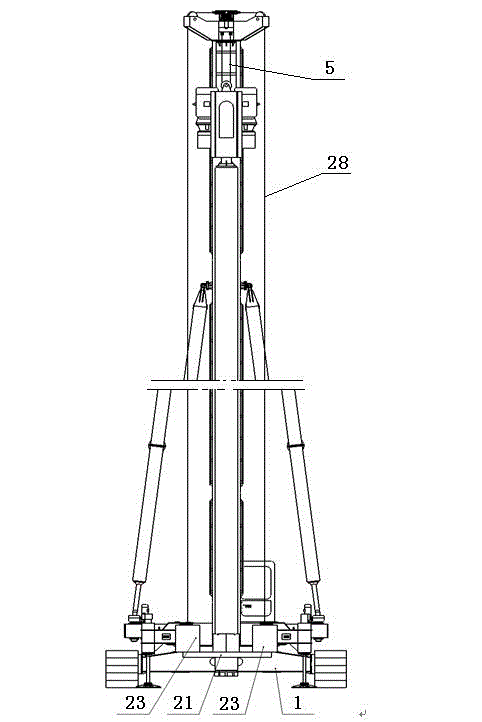

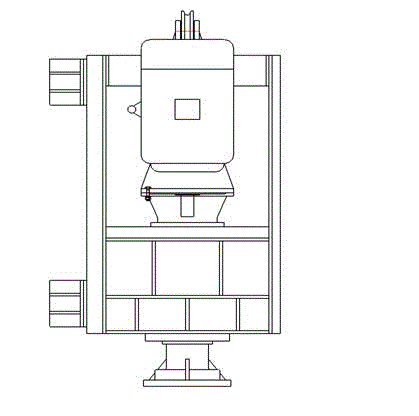

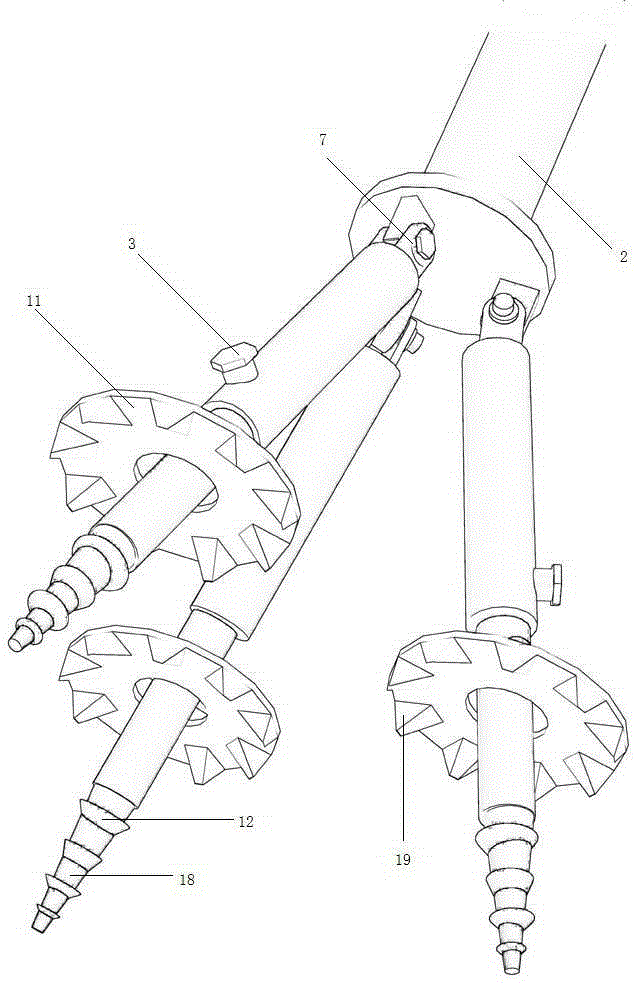

Follow-up drilling machine for sleeve of down-the-hole hammer

InactiveCN102747951APrevent horizontal movementTo achieve the role of clamping and positioningDrilling rodsBorehole drivesBlock and tackleClassical mechanics

The invention relates to the technical field of engineering pile machines, in particular to a follow-up drilling machine for a sleeve of a down-the-hole hammer. The follow-up drilling machine for the sleeve of the down-the-hole hammer comprises a supporting machine, an impact device, a vibrating hammer, a drill stem and the sleeve, wherein the supporting machine comprises a base, an upright post, a winding engine, an operating room and a towing steel rope; the impact device comprises the down-the-hole hammer and an air compressor; the sleeve is sleeved outside the drill stem; a top pulley block is arranged at the upper end of the upright post; and guide slide rails are arranged at two sides of the upright post. The follow-up drilling machine for the sleeve of the down-the-hole hammer is characterized in that a power head is arranged on the guide slide rail at the front side of the upright post; a movable pulley block I and a movable pulley block II are arranged on the guide slide rail at the rear side of the upright post; a fixed pulley block I and a fixed pulley block II are arranged on the base; a beam is arranged at the lower part of the sleeve in front of the base, and the drill stem is a bladeless steel tube. The structure is adopted, so that the follow-up drilling machine for the sleeve of the down-the-hole hammer has the advantages of simple structure, low center of gravity, high stability, low device cost and the like.

Owner:威海市海泰起重机械有限公司

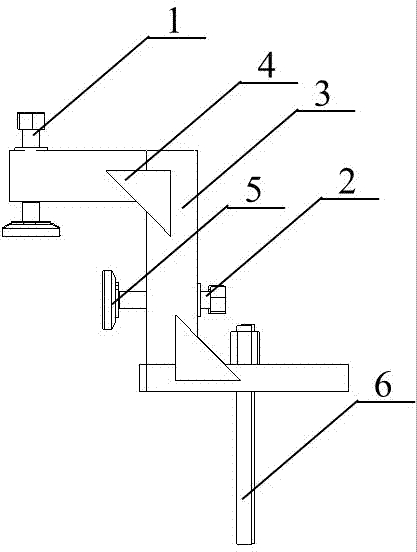

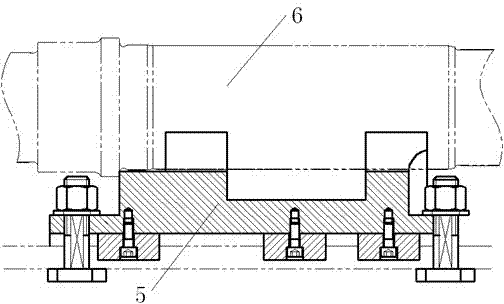

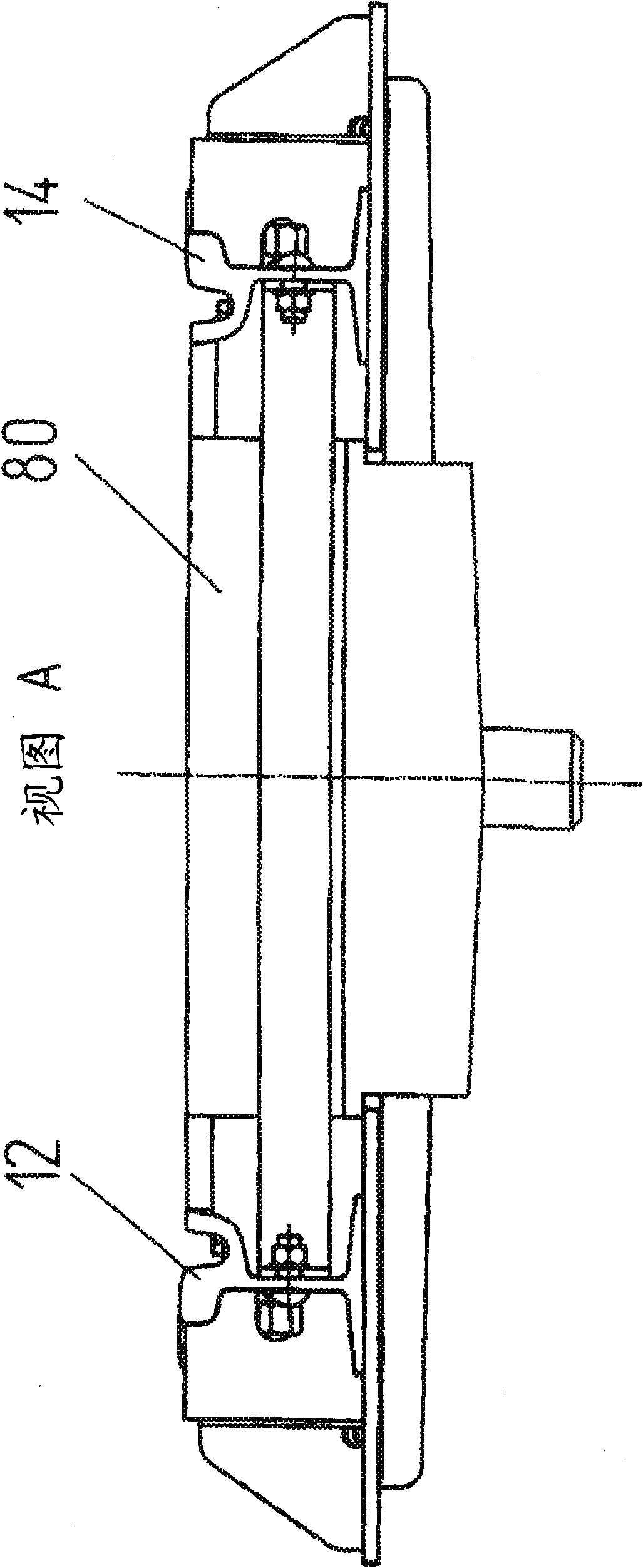

Processing method of oblique oil hole in revolving shaft of traction motor and auxiliary processing device

ActiveCN103028915AGuaranteed widthGuaranteed positioning accuracyPositioning apparatusMetal-working holdersHigh volume manufacturingElectric machinery

The invention discloses a method for processing an oblique oil hole in a revolving shaft, and an auxiliary processing device of an oblique oil hole in a revolving shaft of a traction motor, which is provided according to the method, is designed by using the characteristic of length consistence of fine control processing of the revolving shaft, and can be used for controlling six degrees of freedom of the revolving shaft. An entire technical process is optimized, an oil groove is subjected to technical treatment once again, processing is performed according to the practical size of a design figure, and the width of the oil groove is ensured; and secondly, a drilling technology of the oblique oil hole is improved, a special device which can be arranged on a five-axle processing center is designed according to the characteristic of length size consistence of fine control processing of the revolving shaft, the device is provided with a shaft shoulder positioning step, the revolving shaft is erected on the device, a shaft shoulder is pressed against the positioning step, and the revolving shaft is compressed by using a foundry weight and a T-shaped screw rod, so that six degrees of freedom of the revolving shaft are controlled. Through the five-axle linkage function of five small axles, the consistence of a positioning point of the oblique oil hole of each revolving shaft is ensured. The position of the oblique oil hole is ensured strictly. The method disclosed by the invention has the advantages of reliability, stable processing quality, low cost, high efficiency and suitability for large-scale production of high-accuracy revolving shafts.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

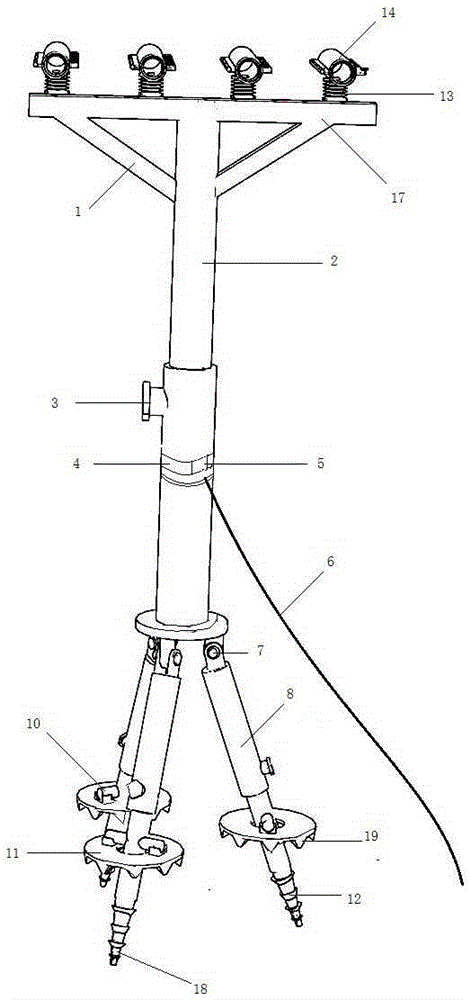

Convenience emergency utility pole

InactiveCN105317262AEasy to fixSimple stepsSuspension arrangements for electric cablesTowersEngineeringElectric power

The invention discloses a convenience emergency utility pole and relates to the technical field of power operation maintenance. The convenience emergency utility pole comprises a pole body and a triangular support. The upper end of the pole body is perpendicularly fixed to a transverse beam of the triangular support. Insulators are evenly mounted on the triangular support in the length direction. Each insulator is fitted with a cable fixture; the cable fixtures comprises: two semicircular hoops; the two hoops are fixedly connected on one side through a rotary shaft and on the other side through a bolt tightened; semicircular soft pads are evenly arranged in each hoop in the length direction; three support legs are mounted at the lower end face of the pole body and are disposed at 120 degrees intervals; each support leg is fastened to the pole body through a spindle bolt; the lower end of each support leg is a conical tip. The convenience emergency utility pole has the advantages that the traditional method of burying the utility poles is changed, erection time of cables is shortened, the convenience emergency utility pole is applicable to emergency relief sites and features scientific design, operational simplicity, safety and reliability and the like.

Owner:DONGYING POWER SUPPLY COMPANY STATE GRID SHANDONG ELECTRIC POWER +2

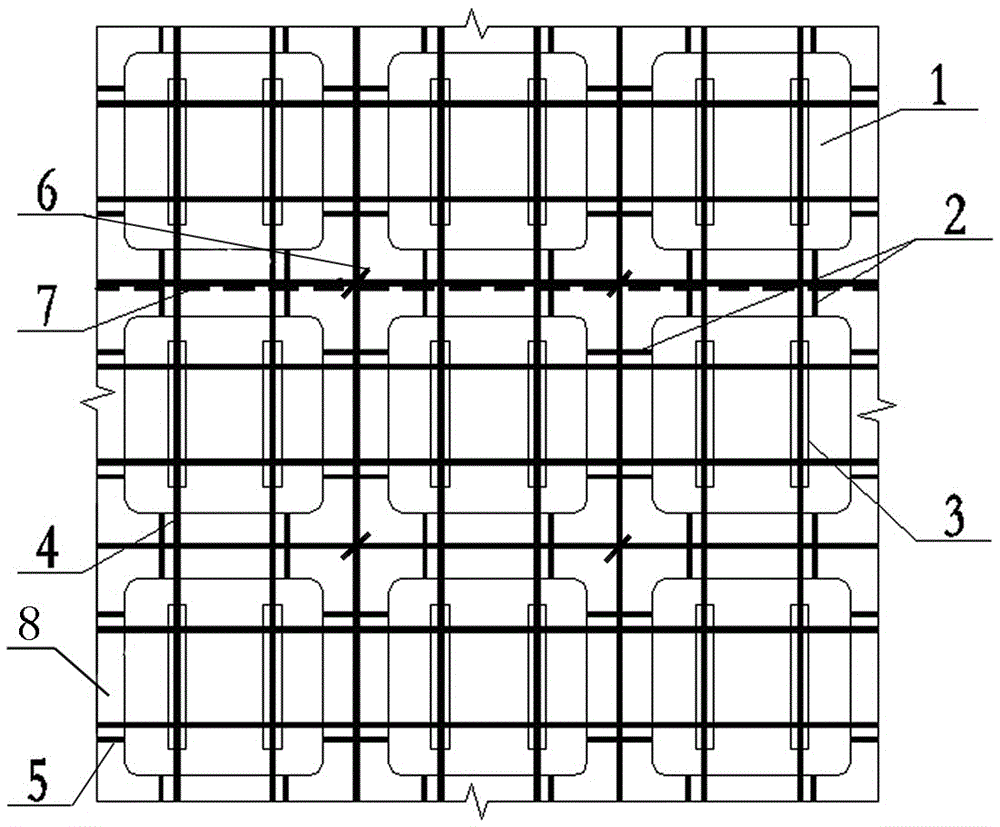

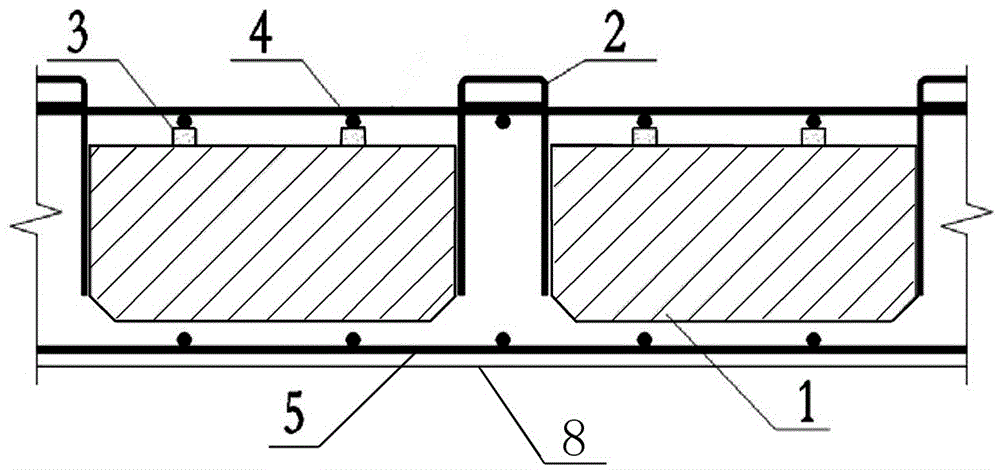

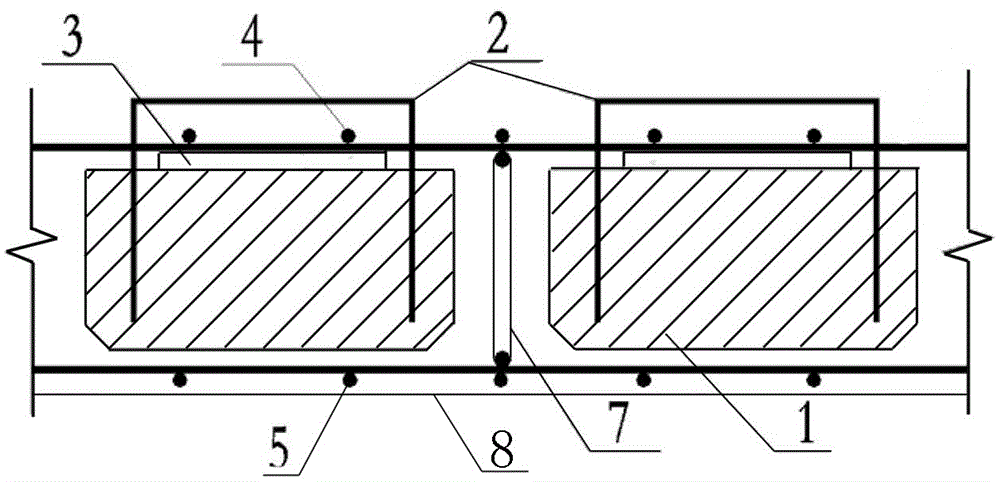

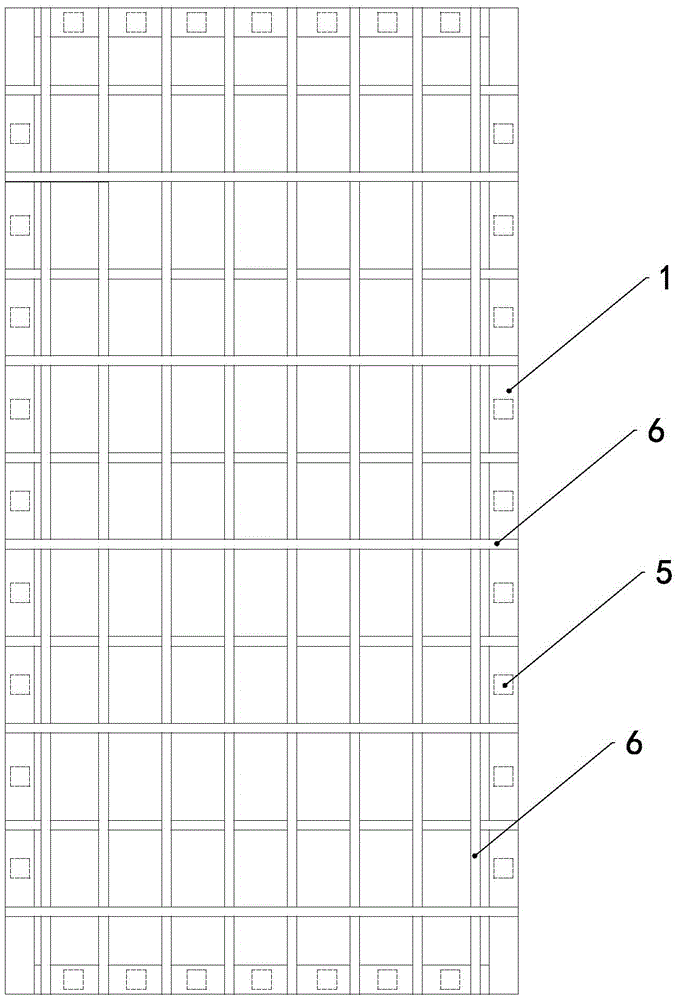

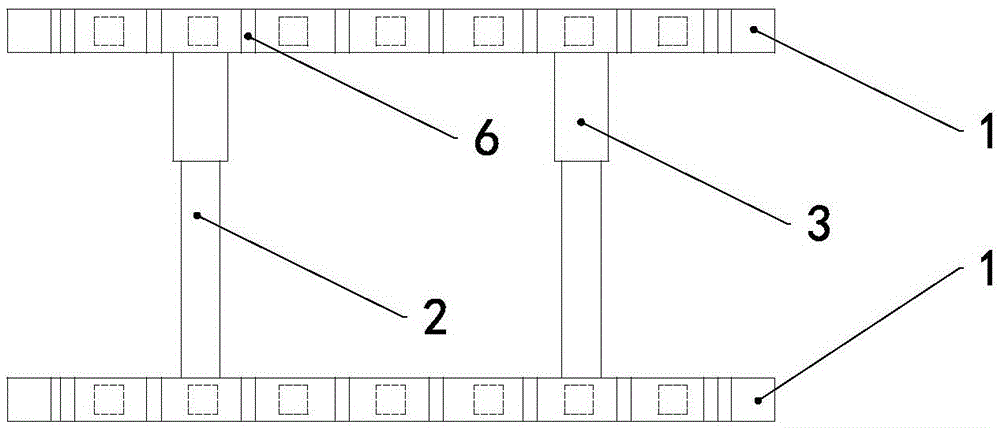

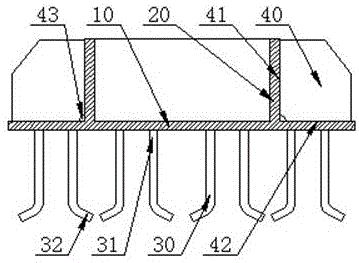

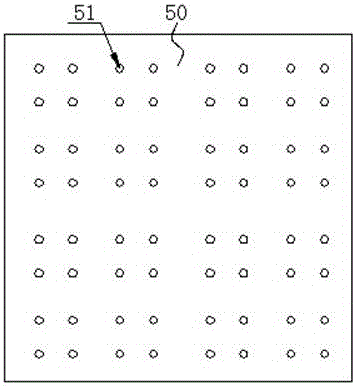

Hollow floorslab core mold fixing device and construction method thereof

The invention discloses a hollow floorslab core mold fixing device, which comprises a bottom die plate, a plate bottom bar-mat reinforcement, a plate top bar-mat reinforcement, a group of core molds and plain concrete cushion blocks, wherein the group of core molds are arranged between the plate bottom bar-mat reinforcement and the plate top bar-mat reinforcement, and are arranged in a matrix manner, the plain concrete cushion blocks are arranged between the tops of the core molds and the plate top bar-mat reinforcement; the plate top bar-mat reinforcement is in bound connection with the plain concrete cushion blocks, and is connected with the bottom die plate through a connecting piece; the cross sections of the core molds are rectangle, gaps are reserved between the bottoms of the core molds and the plate bottom bar-mat reinforcement; four vertical side faces of the core molds are all provided with rebar fixtures, so as to clamp the corresponding core molds among the rebar fixtures; the tops of the rebar fixtures exceed the plate top bar-mat reinforcement, and two side faces of each rebar fixture are respectively tightly pressed on the side faces of two adjacent core molds; vertical supports are arranged among the core molds, the upper ends of the vertical supports are connected with the plate top bar-mat reinforcement and the lower ends of the vertical supports are connected with the plate bottom bar-mat reinforcement. The hollow floorslab core mold fixing device has the advantage that the technical problems of the traditional core mold fixing method that the workload is heavy, the integral bar-mat reinforcement rigidity is low, the core mold is easy to damage and the late repair workload is heavy are solved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

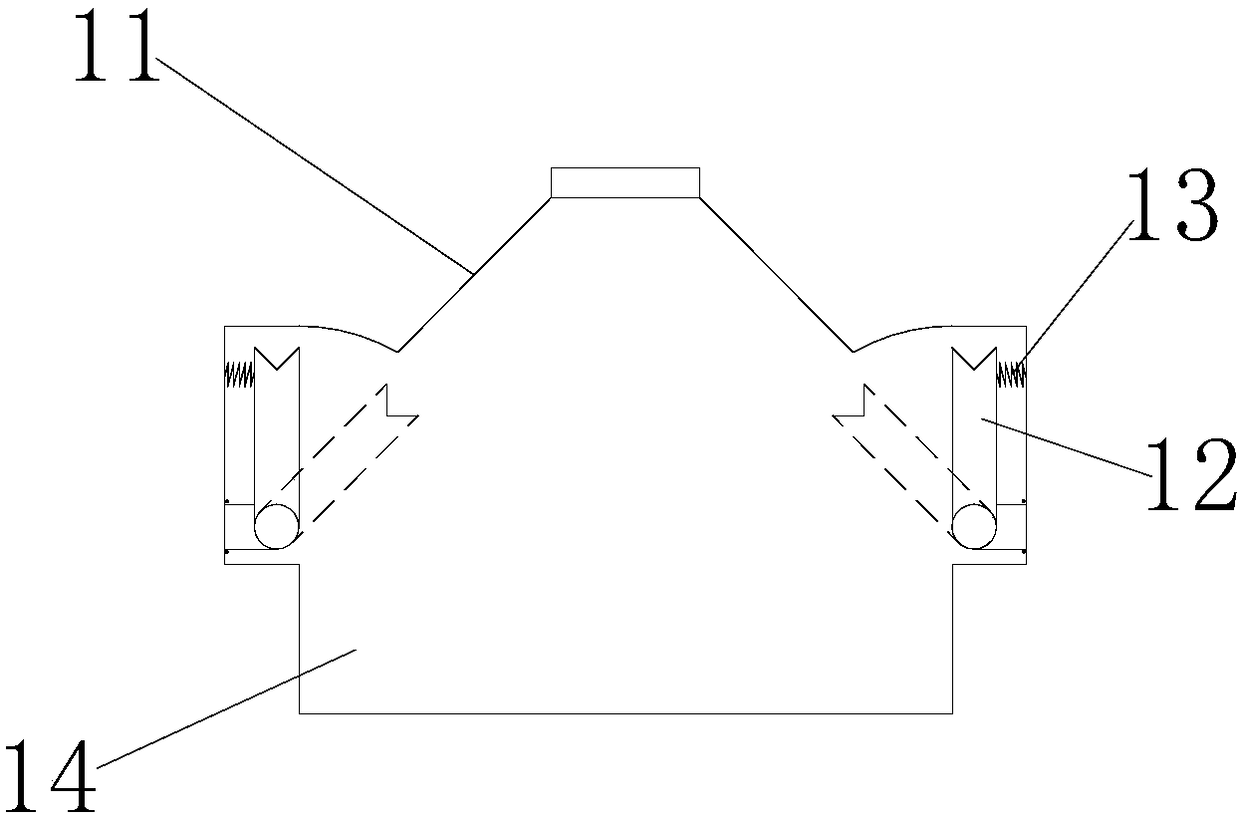

Fabricated wallboard and assembly method and disassembly method of fabricated wallboard

ActiveCN108532793APrevent horizontal movementReduced strength requirementsWallsNon destructiveEngineering

The invention discloses a fabricated wallboard. A tenon and a mortise are separately formed in the two sides of a main body of the wallboard in the height direction of the main body of the wallboard.A pre-buried wall clamping member for connecting a beam is arranged at the top of the main body of the wallboard, wherein the wall clamping member comprises a wall clamping member shell, an ejection member, an intermediate joint, a shearing resistance member and a clamping head which can be connected to a beam clamping member in a clamped mode. The ejection member includes an ejection spring, andthe ejection spring can eject the clamping head into the beam clamping member and connected with the beam clamping member in a clamped mode. A notch is formed in the wall clamping member shell, and acover plate passage communicating with the notch is arranged on the wall facade. The invention also discloses an assembly method for assembling the beam and a wall by using the fabricated wallboard. The invention also discloses a disassembly method of the prefabricated wallboard. The technical problem that the connection between a fabricated wall body and the beam and wall needs to be wet worked in the prior art is solved, the wet installation can be realized, the detachable installation can be realized, and the wall body can be disassembled from the beam by means of non-destructive disassembly.

Owner:CHONGQING UNIV

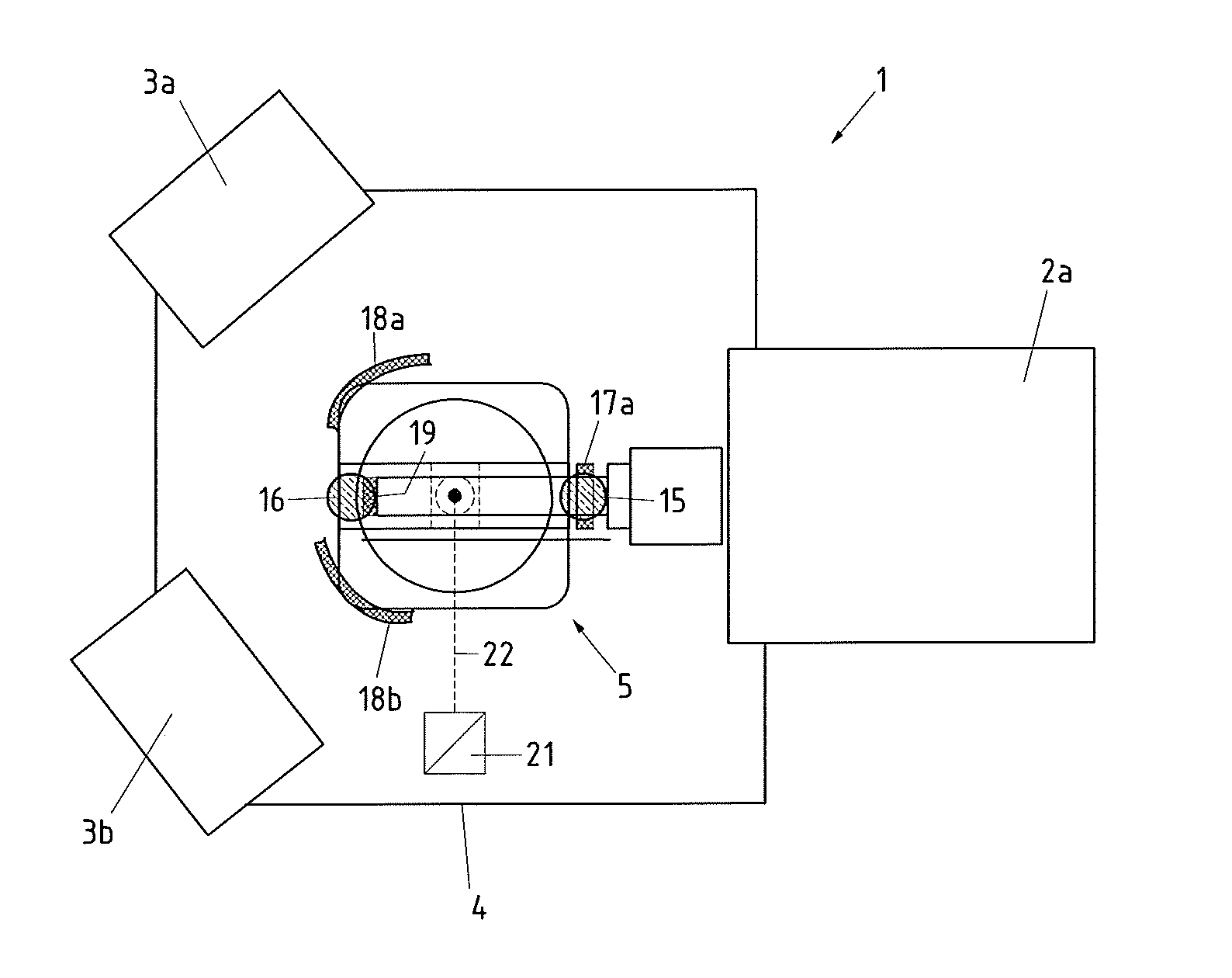

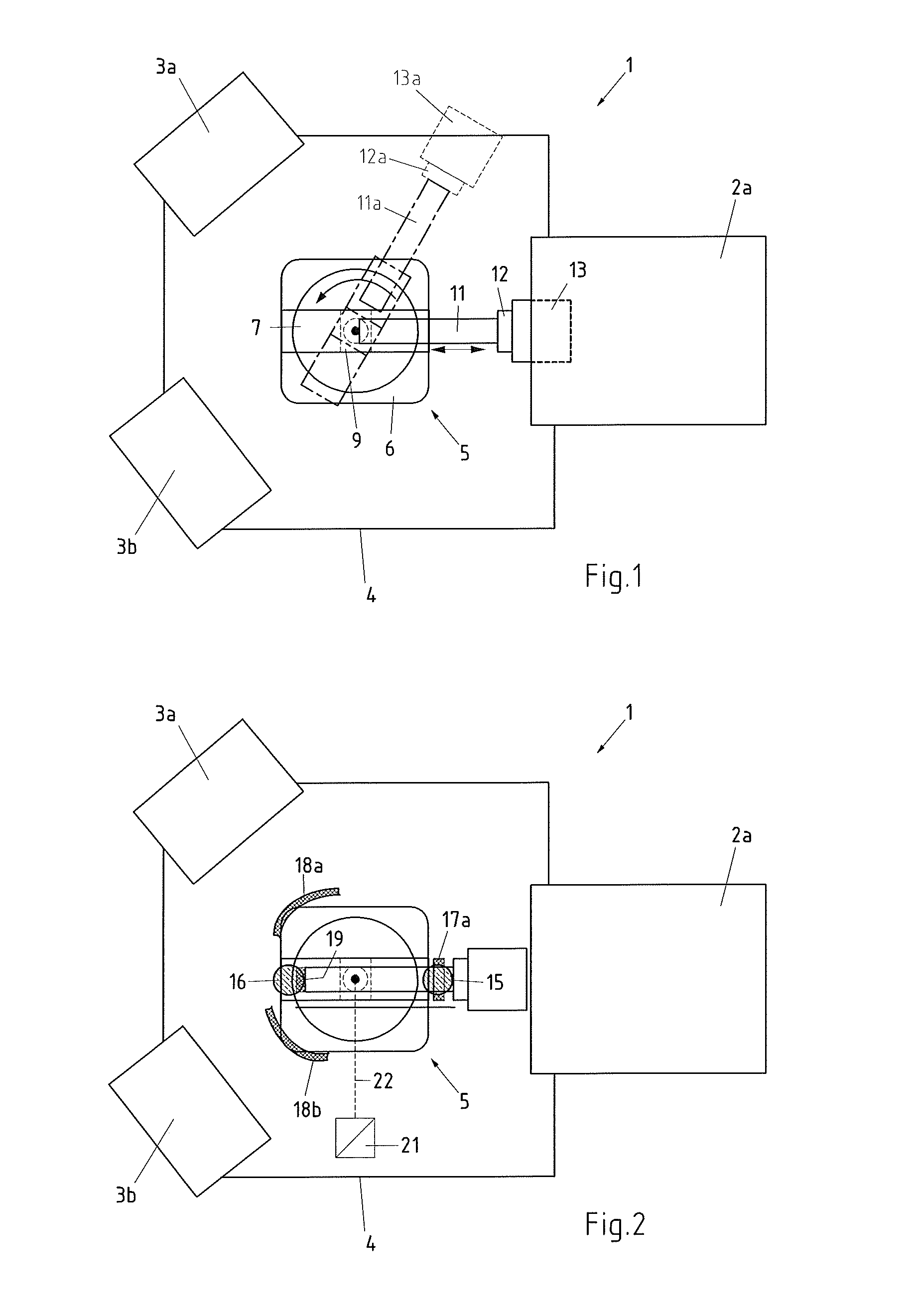

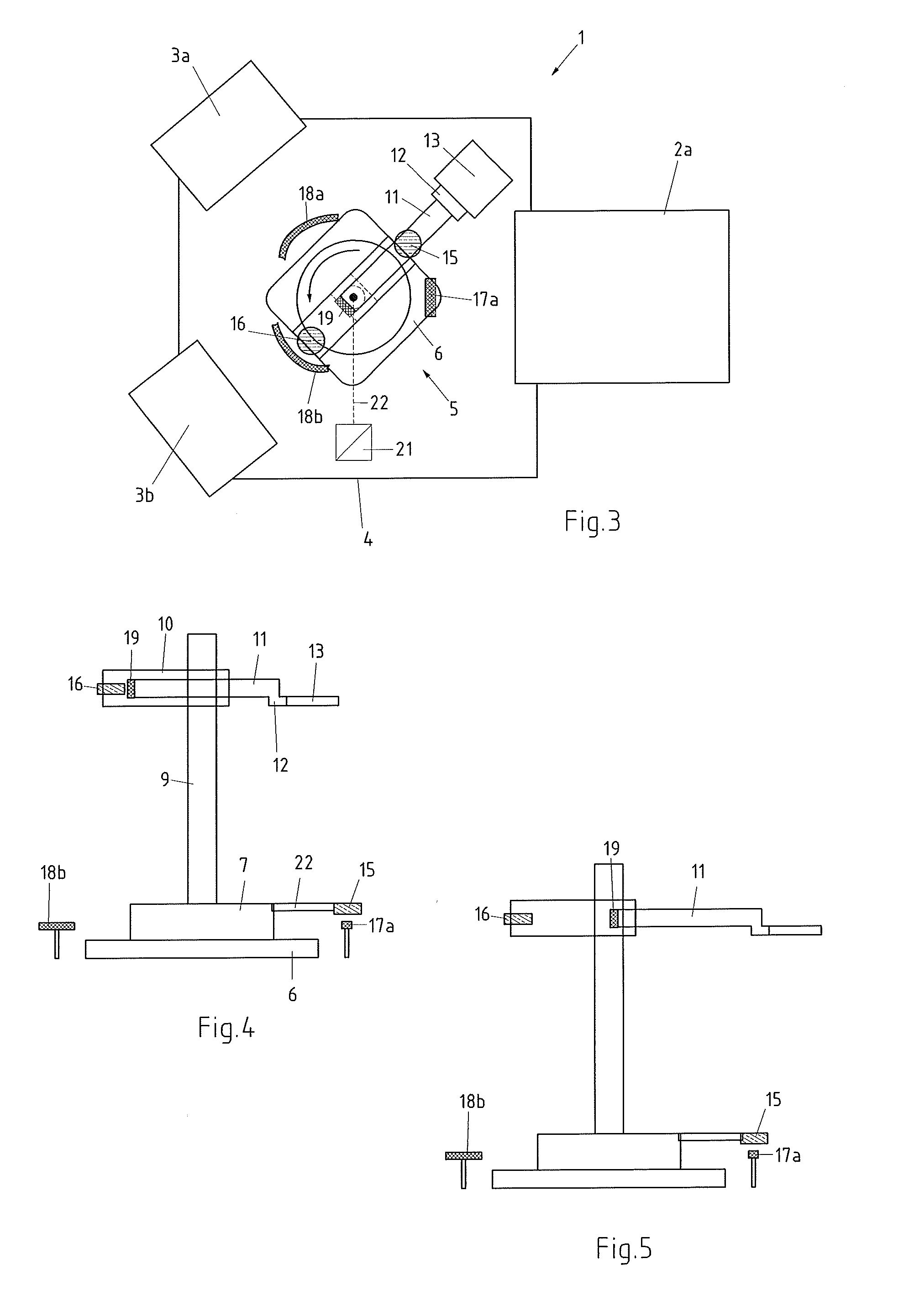

Monitoring Device For Position Monitoring A Robotic Device and Production System Including A Monitoring Device

InactiveUS20130297071A1Safe operationPrevent horizontal movementProgramme controlProgramme-controlled manipulatorEngineeringRobotic arm

Owner:EROWA

Coal mine large-caliber solid material vertical feeding buffer device

InactiveCN111115293AMeet the requirement of 2 million tons without replacementImprove securityLoading/unloadingMining engineeringStructural engineering

The invention discloses a coal mine large-caliber solid material vertical feeding buffer device. The coal mine large-caliber solid material vertical feeding buffer device comprises a protective cover,an energy storage damping device and a bridge type damping beam, wherein the protective cover is conical, and the topmost end of the protective cover is a platform surface; a guide shaft is vertically and fixedly arranged at the top end of the protective cover downwards, and the guide shaft is connected with the wall of the protective cover through a plurality of fixing supports; a buffer base iswelded to the bottom of the protective cover, a guide sleeve is vertically arranged in the center of the buffer base, and a guide shaft is inserted into the guide sleeve for fixed connection; and theenergy storage damping device is composed of a plurality of buffer springs, the upper portions and the lower portions of the buffer springs are fixed to the corresponding positions of the fixing supports and the buffer base of the protective cover, each buffer spring is provided with a guide rod, and the guide rods are fixed to the corresponding positions of the fixing supports and the buffer base of the protective cover; and the protective cover is connected with the bridge type damping beam through the buffer base in a sleeved mode. Falling materials can be effectively buffered, deceleratedand then fallen, and the falling materials are scattered to the storage bin at a low speed after being buffered by the protective cover.

Owner:SHANDONG KANGER ENERGY TECH CO LTD

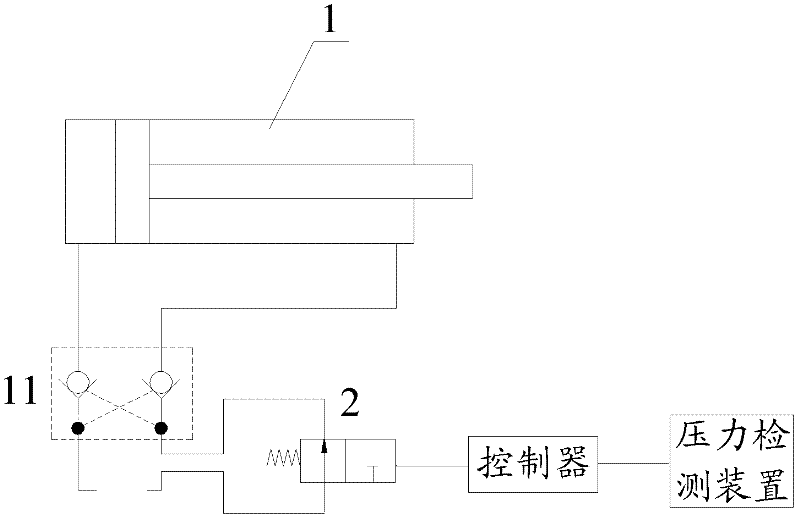

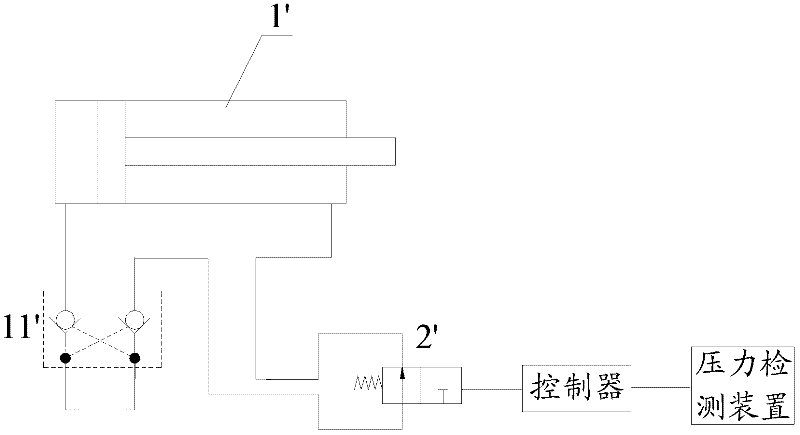

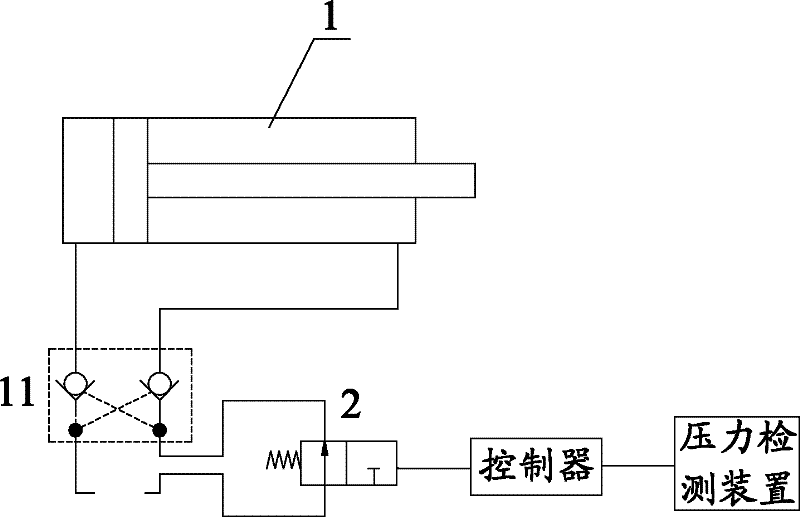

Landing leg locking system and mobile engineering machinery

InactiveCN102352878AEnsure safetyBlock oilVehicle fittings for liftingFluid-pressure actuatorsElectric controlSafety risk

The invention relates to the technical field of engineering machineries, and discloses a landing leg locking system for locking a landing leg after the landing leg is landed. The system comprises a pressure detection device, a controller and an electric control switch module, wherein the electric control switch module is connected to an inlet oil line or outlet oil line of a landing leg expansion oil cylinder in series; the pressure detection device is used for detecting pressure in a rodless cavity of a landing leg support oil cylinder, and sending pressure signals to the controller; the controller receives the pressure signals, and compares the detected pressure with the preset value; and if the detected pressure is greater than the preset value, the electric control switch module is controlled in a close state. The landing leg locking system locks the landing leg after the landing leg is landed, so that the damage of the landing leg because of error operation can be prevented effectively, and the safety hazard is reduced; and the performances are reliable, and the locking effect is obvious. The invention also discloses mobile engineering machinery with the landing leg locking system.

Owner:SANY AUTOMOBILE MFG CO LTD

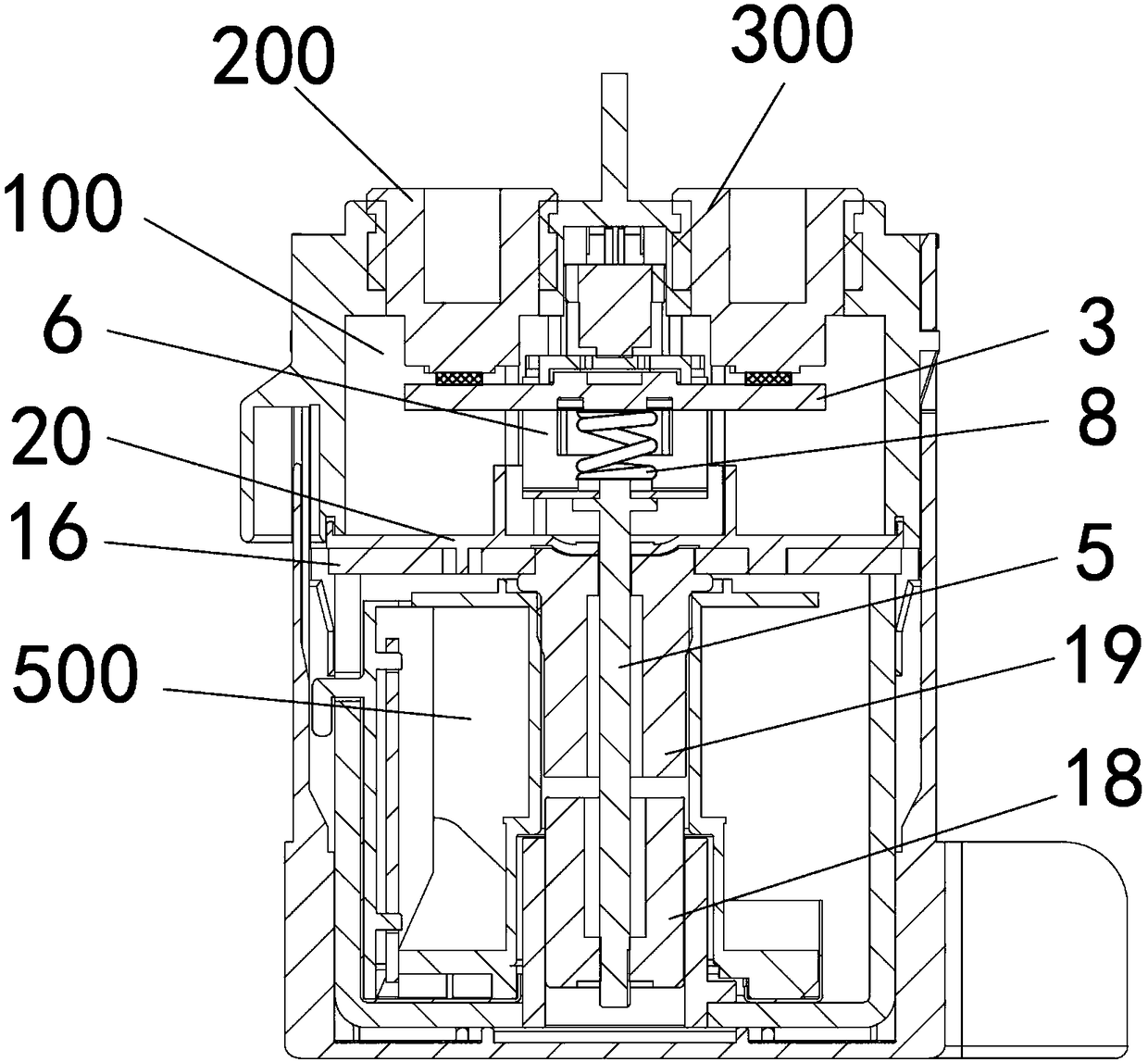

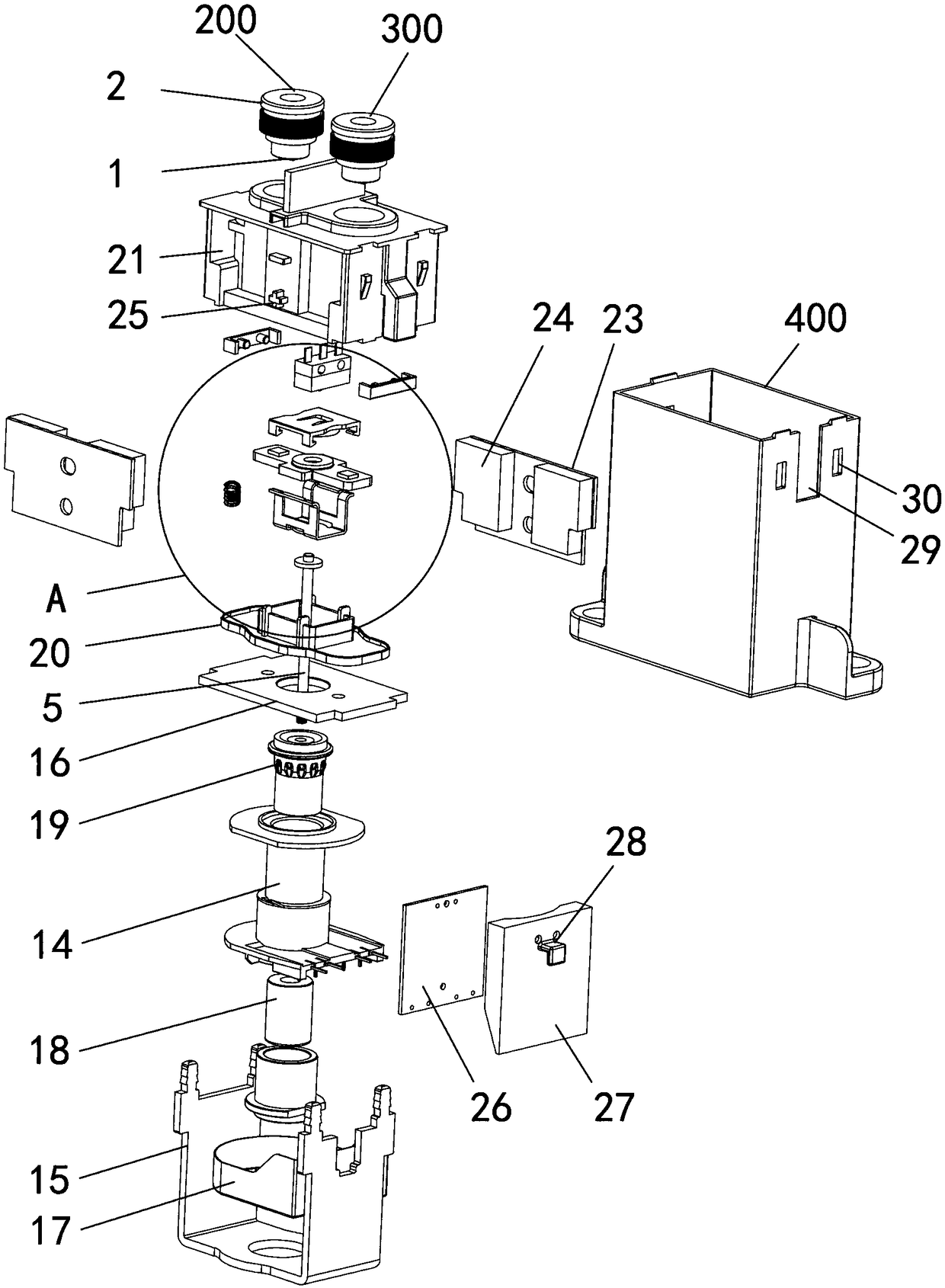

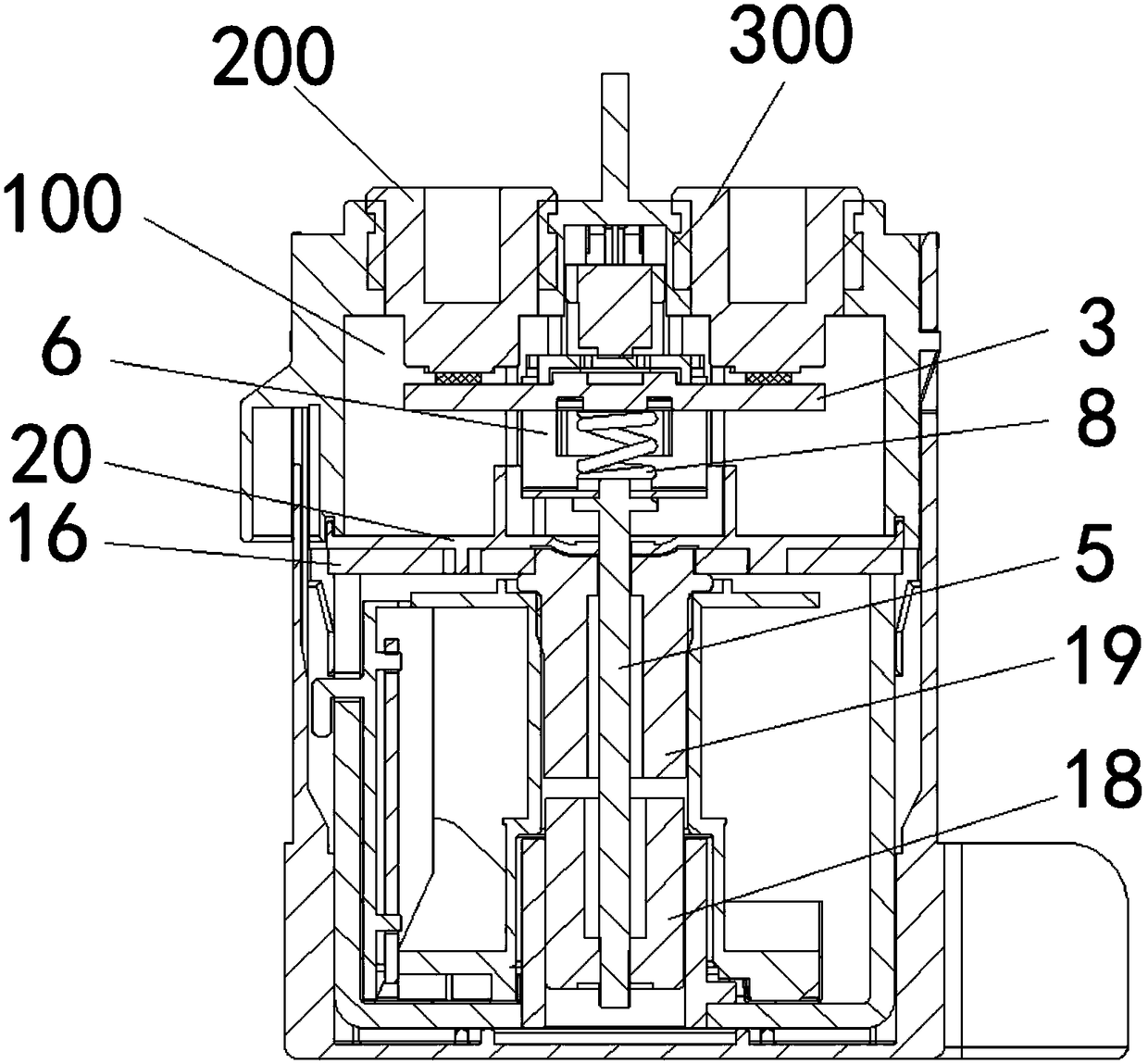

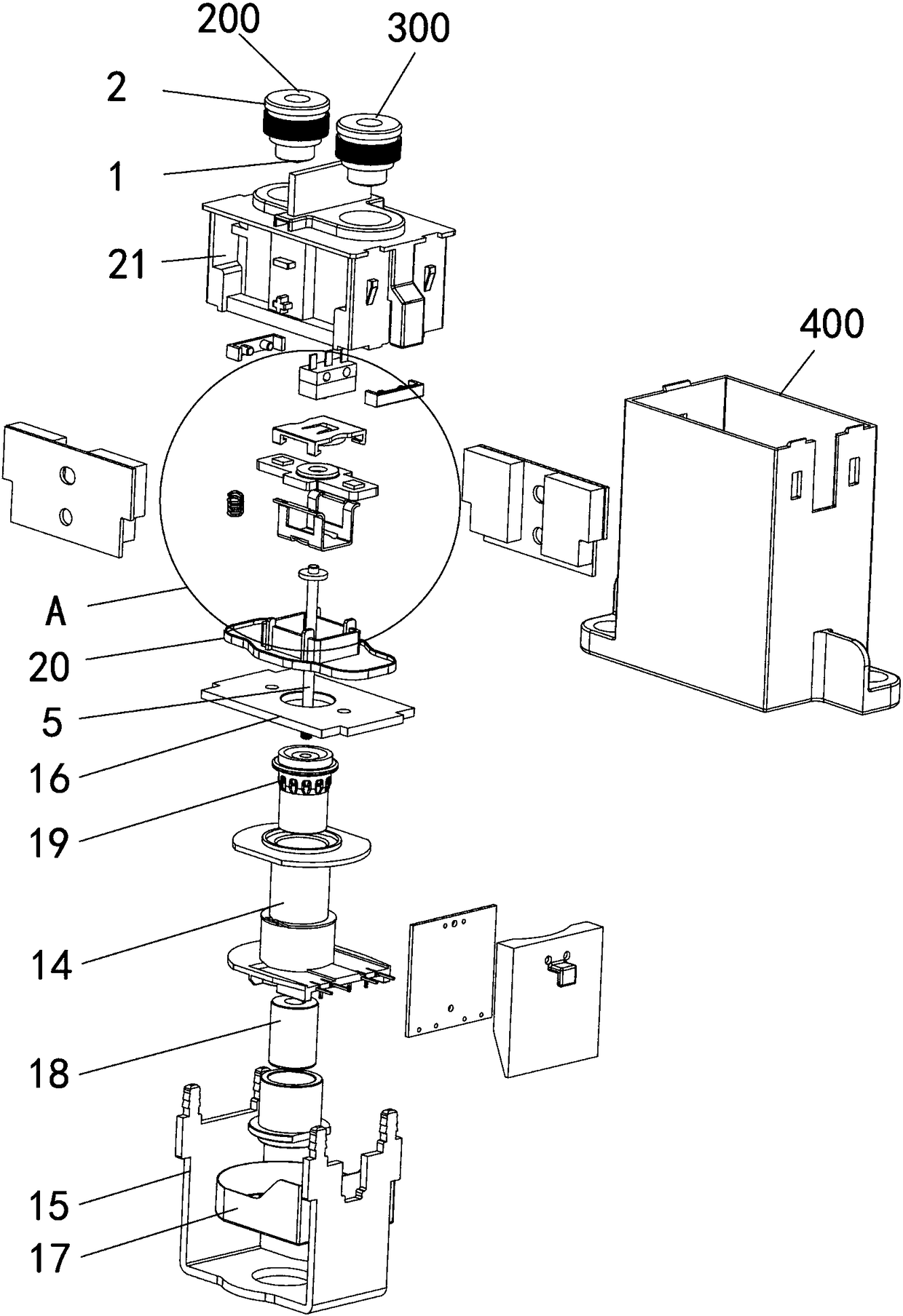

High-voltage DC on-off device

PendingCN108400061AChange the usual way of thinkingImprove securityElectromagnetic relay detailsEngineeringArc resistance

The invention discloses a high-voltage DC on-off device. The high-voltage DC on-off device comprises an outer shell, a contact chamber and an electromagnetic conversion chamber; the contact chamber and the electromagnetic conversion chamber are arranged at the interior of the outer shell a drive rod in the electromagnetic conversion chamber moves up and down to drive a contact bridge in the contact chamber to move up and down and further enable a movable contact and a fixed contact to be connected or disconnected; the contact chamber is closed space formed by a guiding bottom plate and an inner shell covering the guiding bottom plate by adopting an insertion form; the guiding bottom plate and the inner shell are made of arc resistant plastic; and the electromagnetic conversion chamber is ametal framework is formed by encircling a shielding bracket and a shielding upper plate. The high-voltage DC on-off device is simple in structure, good in arc resistance and long in service life.

Owner:苏州超云新能源有限公司

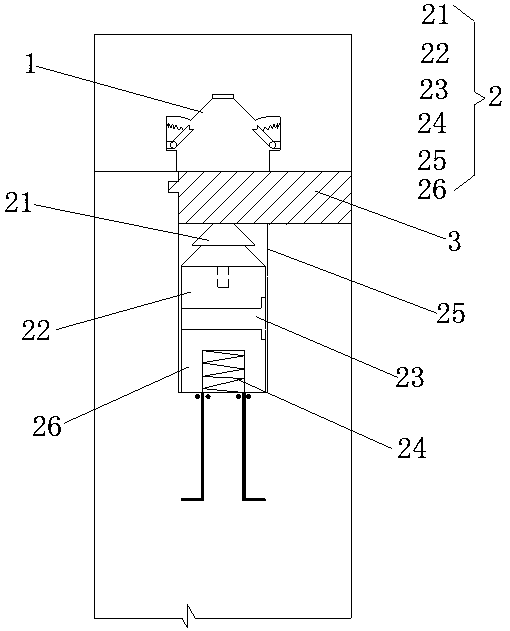

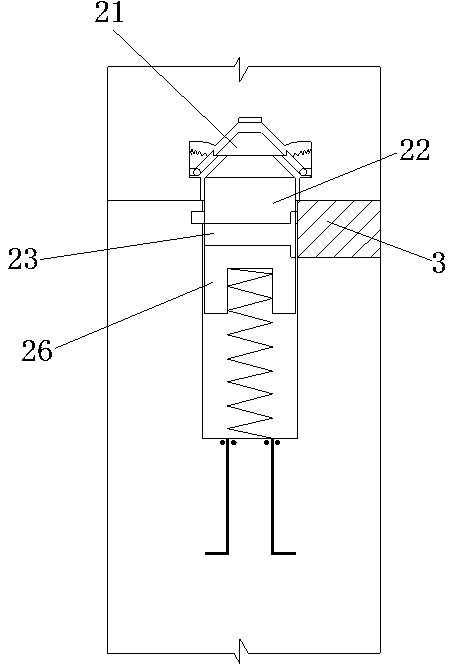

High-voltage DC on-off device anti-deflection mechanism and high-voltage DC on-off device

PendingCN108400064AChange the usual way of thinkingImprove securityElectromagnetic relay detailsEngineeringMechanical engineering

The invention discloses a high-voltage DC on-off device anti-deflection mechanism. The high-voltage DC on-off device anti-deflection mechanism comprises a contact chamber, a contact bridge and movablecontacts; a first contact member and a second contact member are arranged in the contact chamber; the movable contacts are arranged at the left and right ends of the contact bridge; a drive rod movesup and down to drive the contact bridge to move up and down and further enable the movable contacts to connect or disconnect with fixed contacts; the top end of the drive rod is fixedly provided witha limitation clamping spring; the limitation clamping spring is provided with a horizontal limiting frame for limiting the horizontal movement of the contact bridge; and the limitation clamping spring is also internally provided with an axial spring for limiting the axial movement of the contact bridge. The high-voltage DC on-off device anti-deflection mechanism has the beneficial effects that the limitation clamping spring performs complete limitation in the horizontal direction on the contact bridge so as to completely fix the limitation clamping spring and the contact bridge horizontally,and a horizontal movement problem of the contact bridge caused by aging failure of the spring is avoided.

Owner:苏州超云新能源有限公司

Fabricated pre-embedded assembly for beam and wall connecting and using method thereof

ActiveCN108505627APrevent horizontal movementFirmly connectedBuilding constructionsEngineeringPre embedding

The invention discloses a fabricated pre-embedded assembly for beam and wall connecting and further discloses a using method of the fabricated pre-embedded assembly. The fabricated pre-embedded assembly comprises a beam clamping piece and a wall clamping piece; the wall clamping piece comprises a wall clamping piece shell which is internally sequentially provided with an ejecting piece, a shear-resisting piece and a clamping head capable of being clamped on the beam clamping piece; and the ejecting piece comprises an ejecting spring, and the ejecting spring can utilize elastic potential energyto eject the shear-resisting piece and the clamping head outwards together. The using method of the fabricated pre-embedded assembly comprises the steps that a cover plate is additionally mounted onthe wall clamping piece so as to compress the ejecting spring; then the wall clamping piece and the beam clamping piece are pre-embedded in a wall and a beam correspondingly; a cover plate channel isformed in the wall, the cover plate is pulled out, thus the ejecting spring extends to eject the clamping head and the shear-resisting piece into the beam clamping piece, and the clamping head and thebeam clamping piece are clamped; and a part of the shear-resisting piece is reserved in the beam, and the other part of the shear-resisting piece is reserved in the wall, so that a wall body is prevented from horizontally moving. The technical problem that when the wall body and the beam are prefabricated, wet operation needs to be conducted is solved.

Owner:CHONGQING UNIV

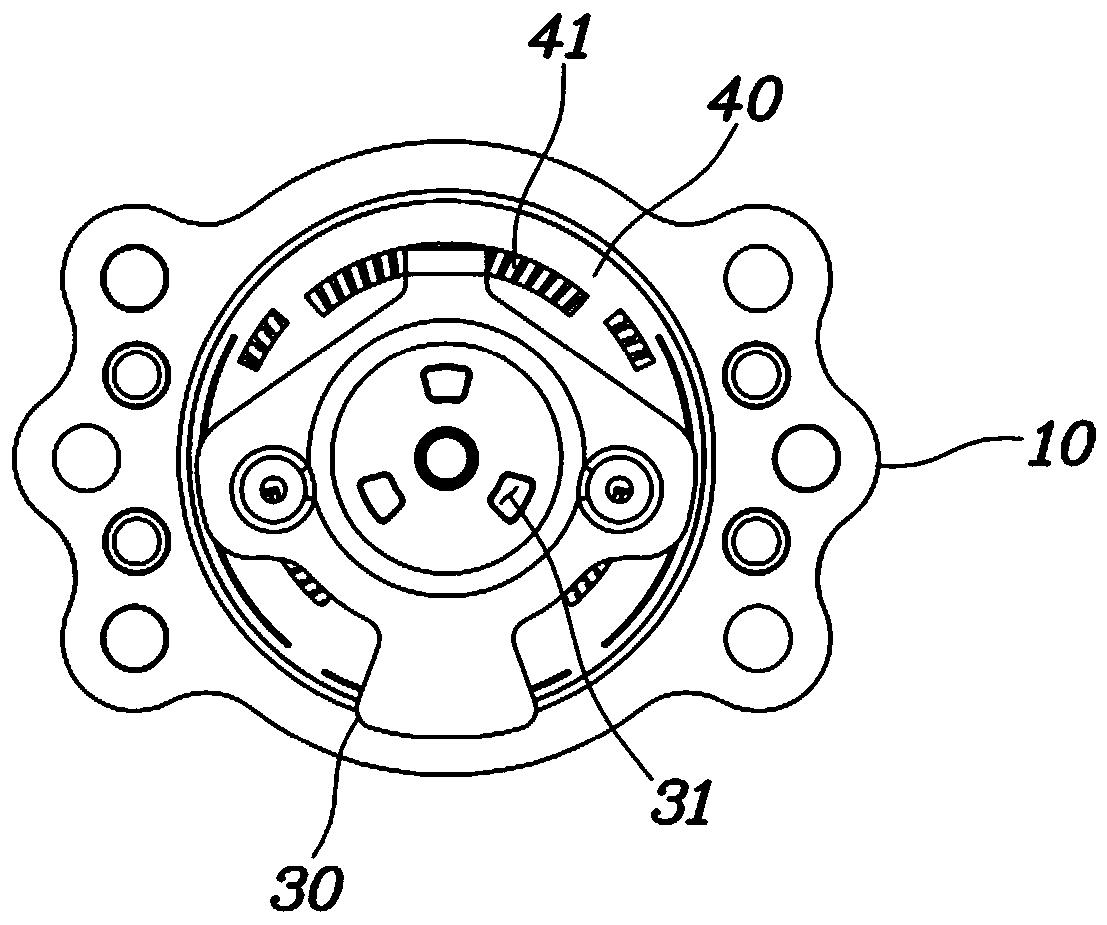

Seat pumping device for vehicle

Disclosed is a seat pumping device for a vehicle. The seat pumping device includes: a housing having a through hole formed therein; a clutch cam positioned on an inside of the housing and coupled suchthat a coupling protrusion protruding outwardly of the housing through the through hole is turnable relative to the housing; a lever bracket positioned on an outside of an upper surface of the housing so as to face the clutch cam with the housing interposed therebetween, the lever bracket being coupled to the coupling protrusion of the clutch cam to be turned integrally with the clutch cam; and asupporting portion protruding from one of the upper surface of the housing and a lower surface of the lever bracket toward a remaining one, the upper surface of the housing and the lower surface of the lever bracket facing each other, the supporting portion supporting the lever bracket and the housing so as to be spaced apart from each other at a regular interval.

Owner:HYUNDAI DYMOS

Novel cutting die capable of automatically discharging waste

PendingCN108145786APrevent horizontal movementAvoid deformationMetal working apparatusEngineeringScrap

The invention provides a novel cutting die capable of automatically discharging waste. The novel cutting die comprises an upper die portion, a lower die portion, a guide rod system, an die opening spring system and a driving device, wherein the guide rod system is connected with the upper die portion and the lower die portion. The upper die portion sequentially comprises an upper die seat, an upper base plate, an upper clamping plate, an upper die plate and an upper stripping plate from top to bottom, wherein punch through holes are formed in the corresponding positions of the upper base plate, the upper clamping plate, the upper die plate and the upper stripping plate, and a punch is arranged in the punch through holes; and the lower die portion comprises a lower die plate, a lower base plate and a lower die seat, wherein positioning protrusions are arranged on the lower die plate; waste discharging holes are formed in the positions, corresponding to the punch, of the lower die plate,the lower base plate, and the lower die seat. The positioning protrusions and a raw material groove which are arranged on the lower die plate are utilized, so that the raw materials of a plastic-absorbing box type product can be prevented from being deformed under the extrusion effect; and meanwhile, the waste discharging holes formed in the lower die plate, the lower base plate and the lower dieseat are utilized, so that the waste can be directly discharged, the follow-up manual waste discharging work is avoided, and the production efficiency is improved.

Owner:郑州领胜科技有限公司

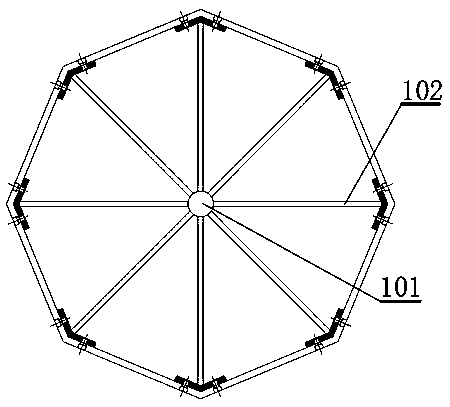

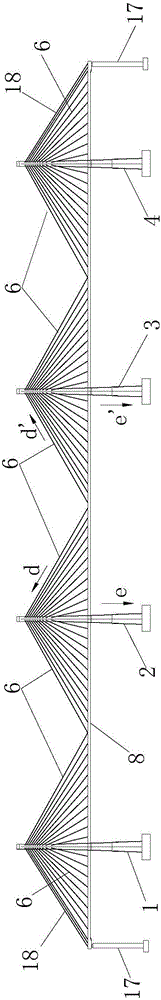

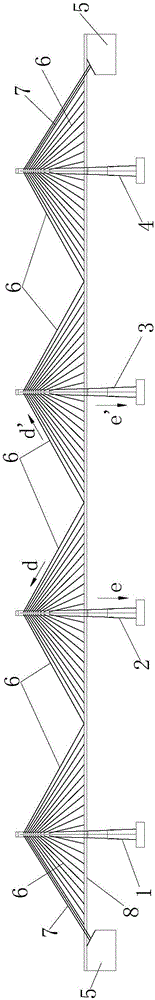

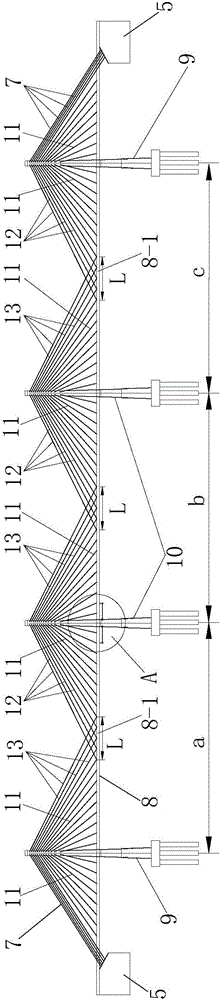

Stay cable intersected multi-pylon cable-stayed bridge

InactiveCN106012796ANovel and reasonable structureImprove the forceCable-stayed bridgeBridge structural detailsCable stayedEngineering

Owner:XIAN UNIV OF SCI & TECH

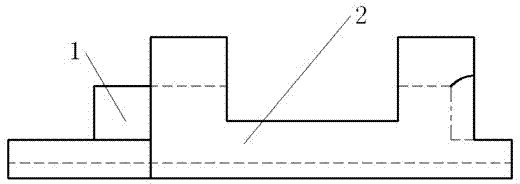

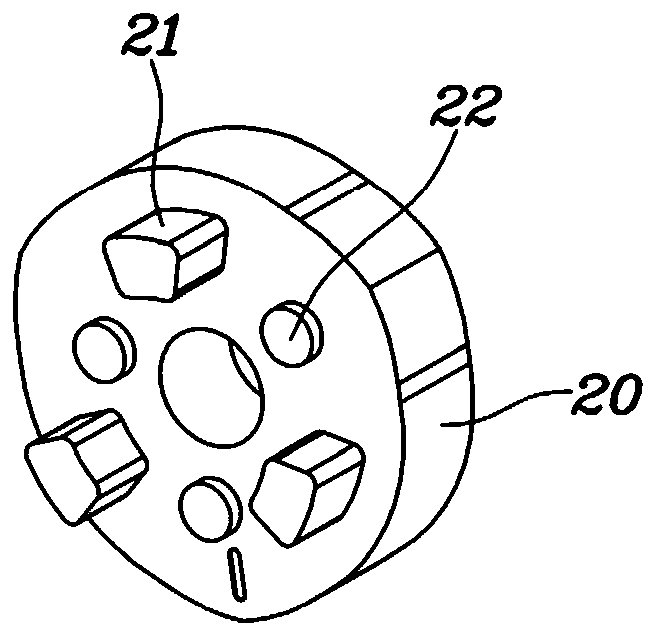

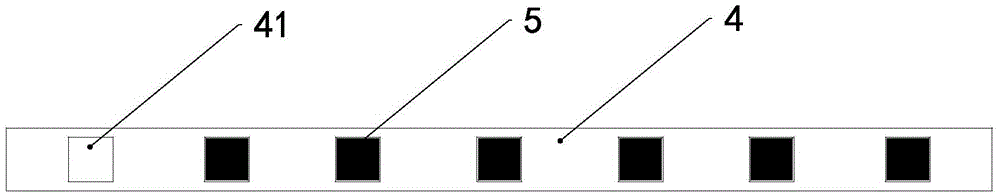

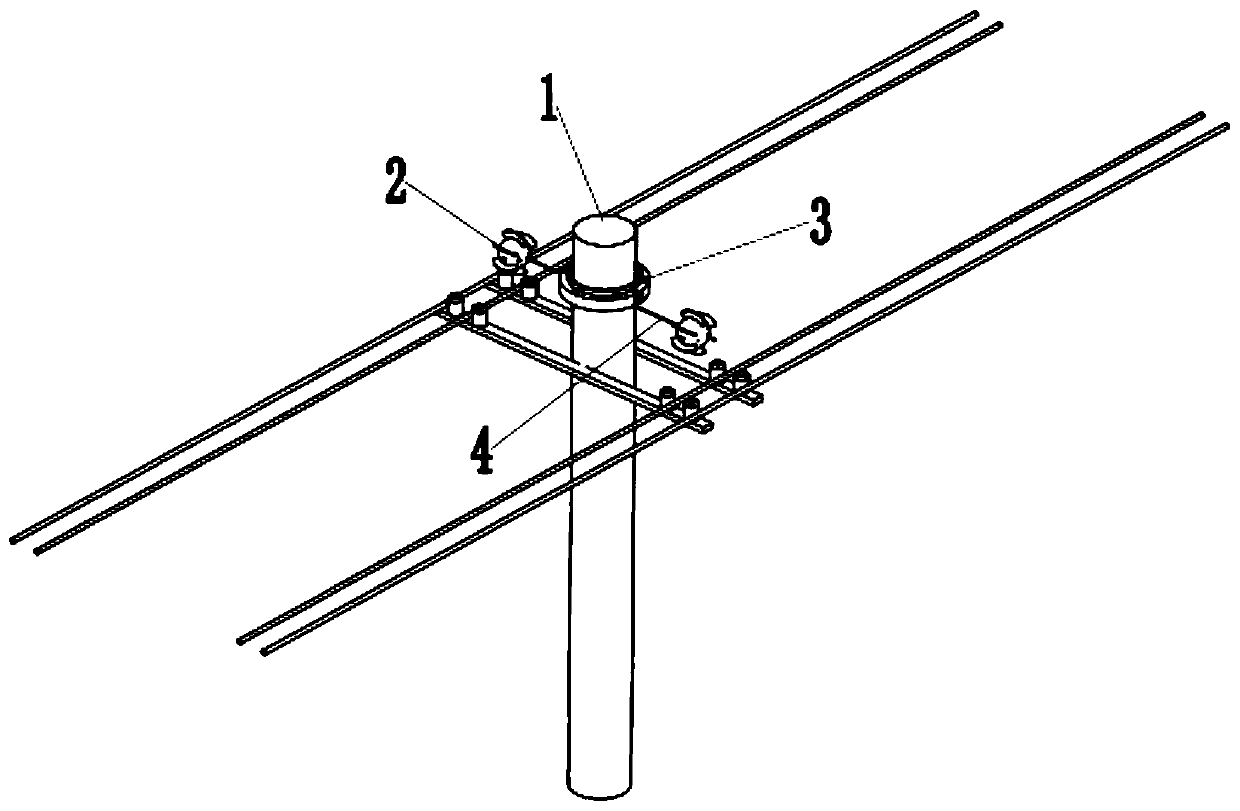

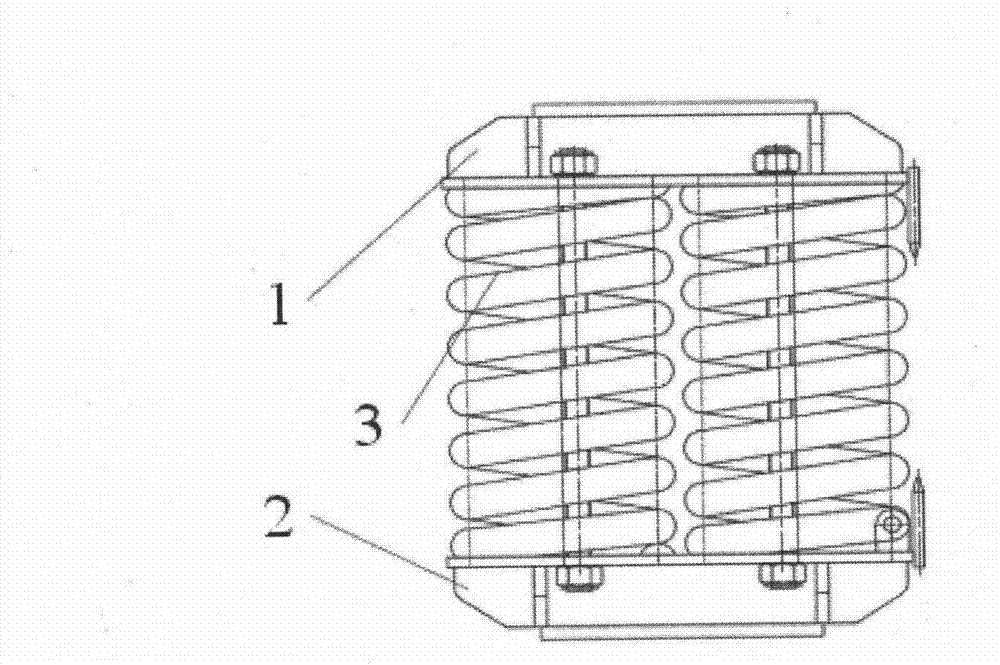

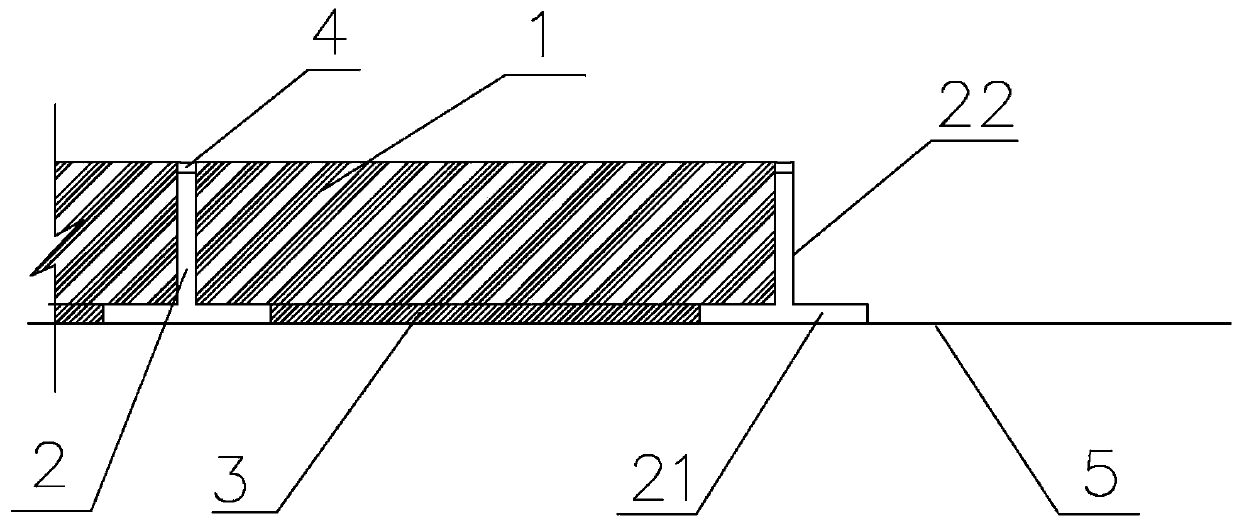

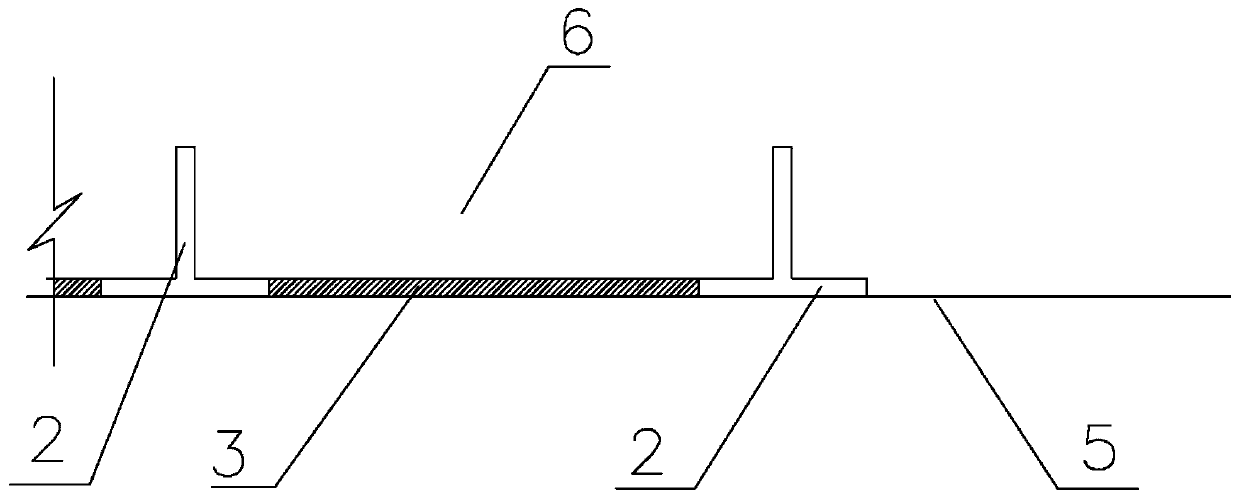

Magnetic suspension health care mattress

InactiveCN105520432ASimple structurePrevent horizontal movementStuffed mattressesSpring mattressesHuman bodyTherapeutic effect

The invention provides a magnetic suspension health care mattress, which comprises two support frameworks (1) in relative arrangement at the upper side and the lower side, wherein the two support frameworks (1) are connected into a whole through a sliding element (2) and a guide tube (3); a slide block (21) of the sliding element (2) is clamped in the guide tube (3); each support framework (1) is of a hollow structure; a reinforcing element (4) is inserted in a cavity of each support framework (1); a plurality of through grooves (41) are formed in the reinforcing element (4); and a rare earth magnet (5) is fastened in each through groove (41). By using the technical scheme, the magnetic suspension health care mattress has the advantages that the structure is simple; the precise positioning of magnets in the upper and lower support frameworks is realized; and the horizontal moving of the mattress is avoided. Meanwhile, the rare earth magnets in permanent-magnet materials are used, so that the long-time good and stable magnetic therapy effect is achieved; the sleeping quality of a user can be ensured; meanwhile, the cell metabolism and the blood circulation are promoted; and the human body immunity is enhanced and improved.

Owner:LUOYANG WOHUI MACHINERY CO LTD

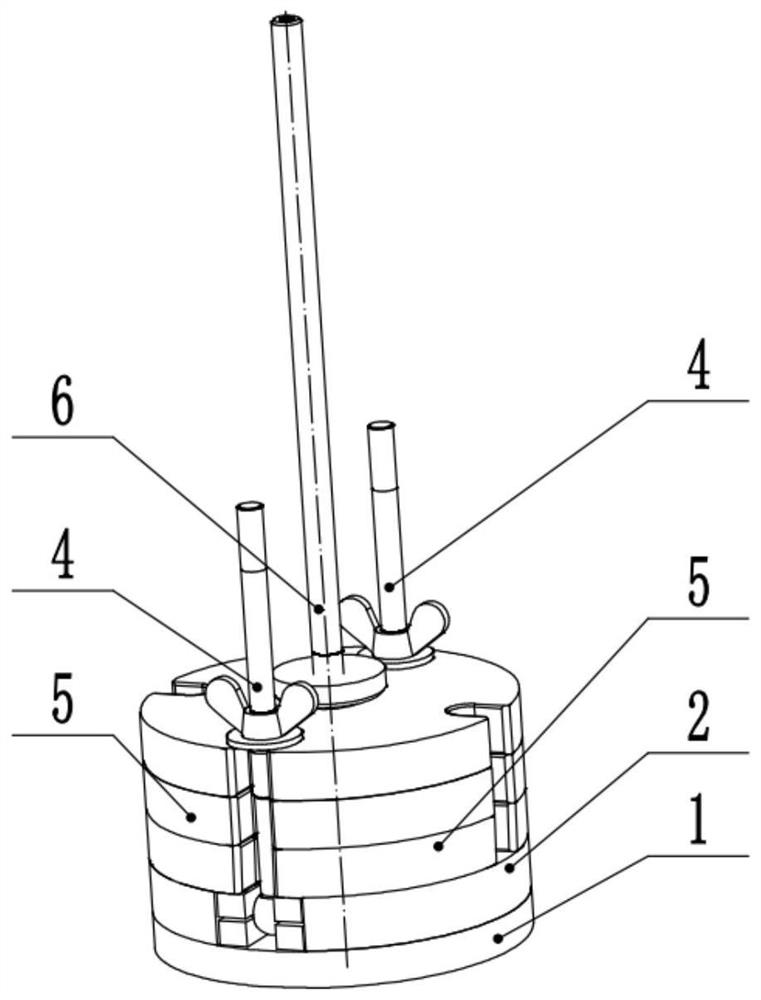

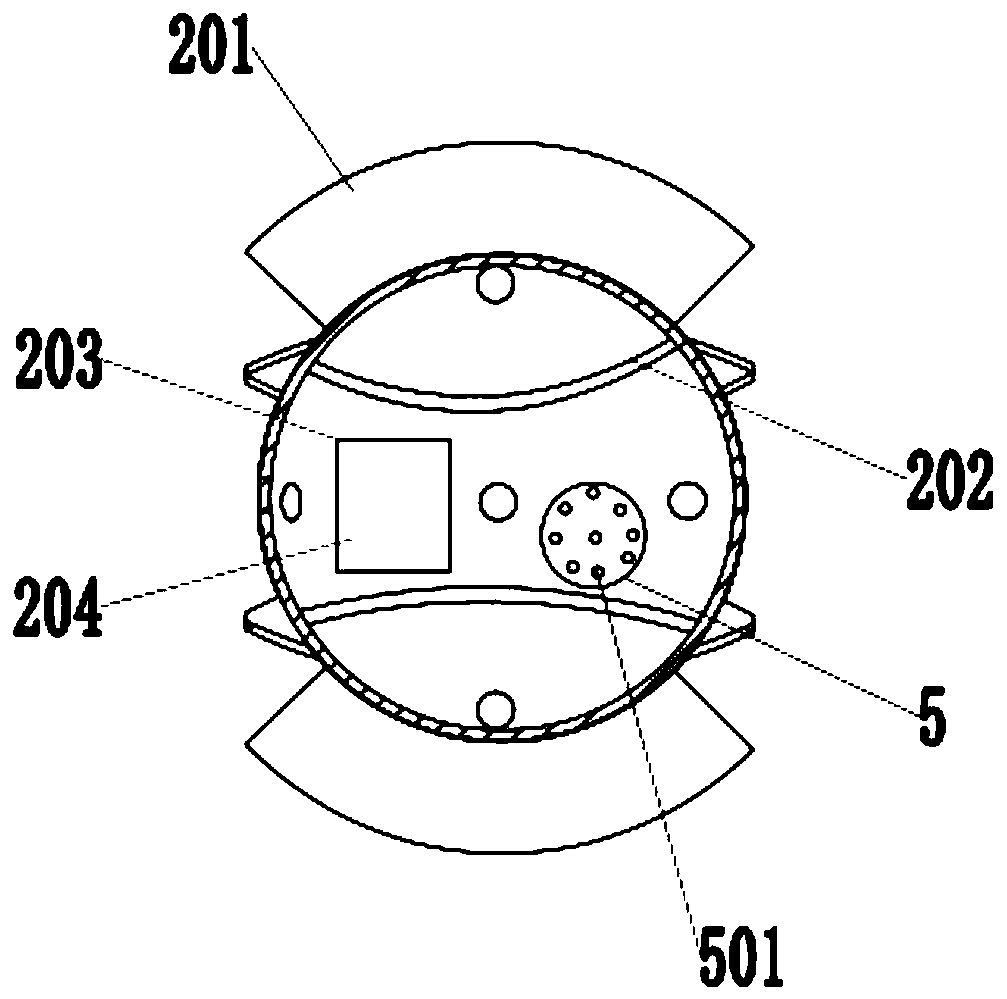

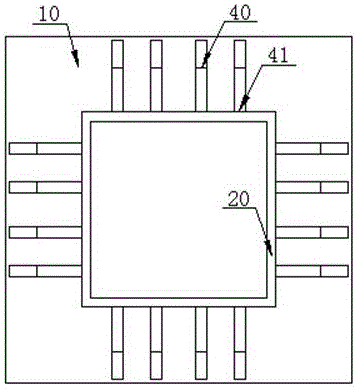

Slipknot screw type rapid combined circular quality system with guide rod

PendingCN113701972AEnsure balancePrevent horizontal movementMaterial strength using repeated/pulsating forcesVibration testingVibration transmissionMechanical engineering

The invention aims to overcome the defects of high manufacturing cost and inconvenience in use of a whole mass block in a buffer material vibration transmission characteristic test system, repeated disassembly of bolts in a combined mass system, low combination efficiency of nuts, and no horizontal limiting function of the mass system with a guide device. A slipknot screw type rapid combined circular quality system with a guide rod is developed, and the vibration transmission characteristic test of the buffer material is carried out in cooperation with a table board fixing device. The bottom face of the mass system is of a circular structure and is rapidly locked through a weight type combination and a slipknot screw combination, and the top of the mass system is provided with a single-rod guide device. Compared with a combined mass block, when the mass is adjusted, the weights of the mass system can be quickly locked and combined only by adjusting the compression nut in a small range, and the mass system is of a rigid structure after being locked; and meanwhile, the mass system is provided with a vertical movement single-rod guide device, and after the vertical movement single-rod guide device is matched with the fixing device, the mass system can be prevented from moving in the horizontal direction in the vibration process.

Owner:QINGDAO UNIV OF SCI & TECH

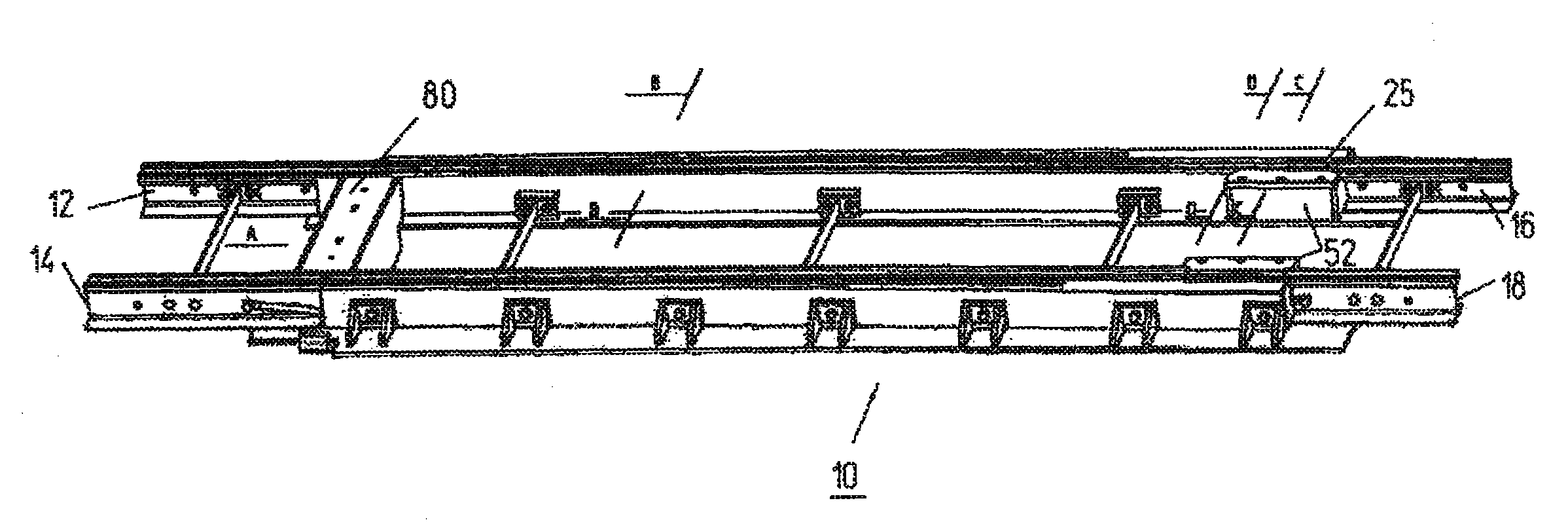

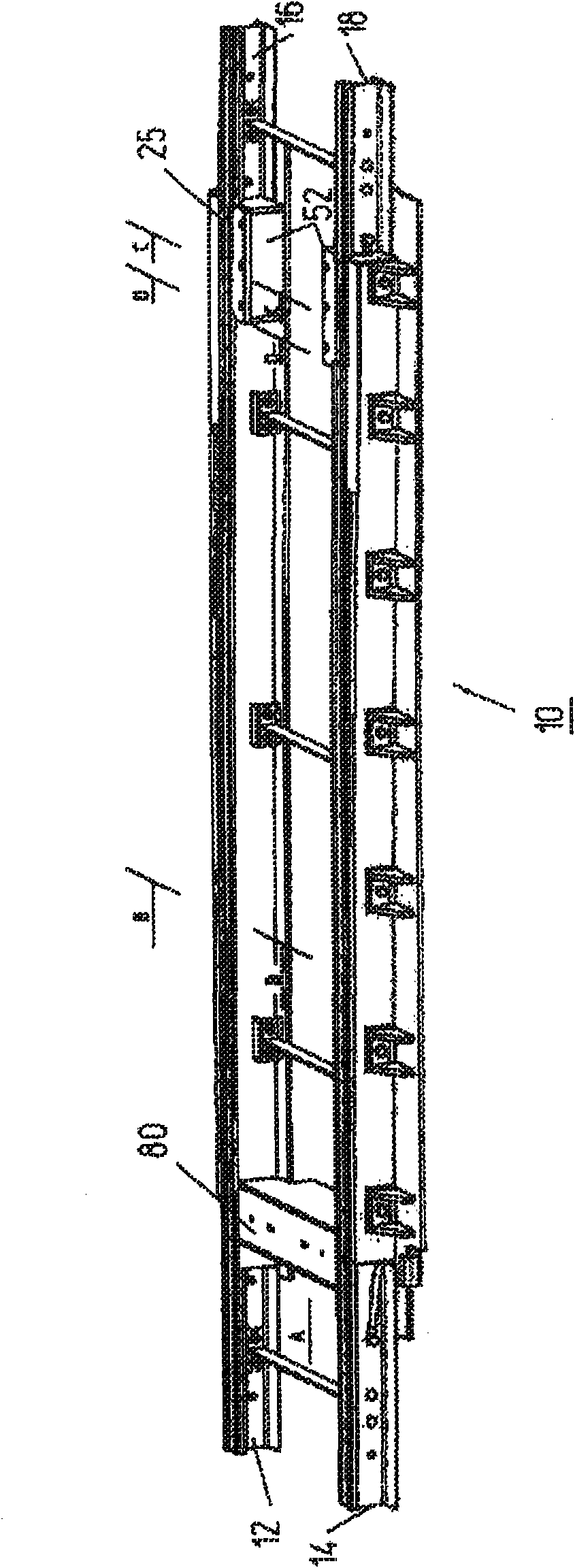

Rail expansion device

ActiveCN101815823AAvoid vertical movementAchieve supportRail switchesRail jointsEngineeringMechanical engineering

Owner:VOESTALPINE BWG GMBH & CO KG +1

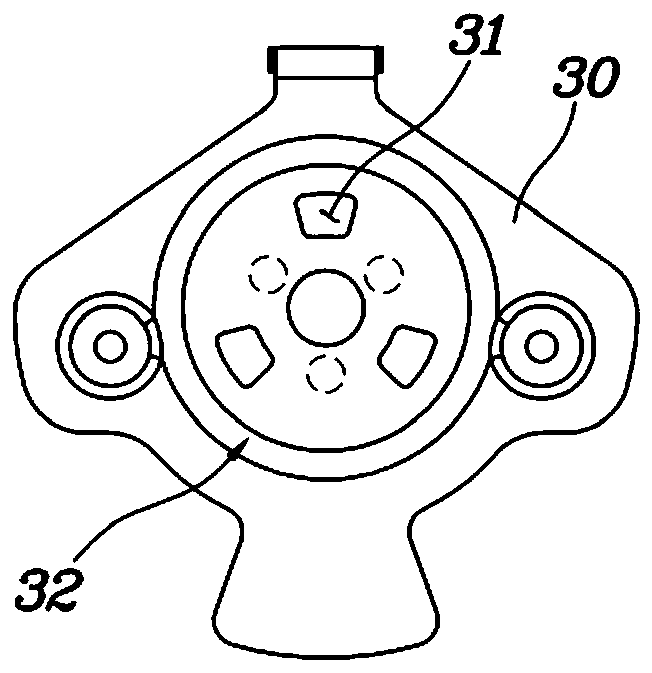

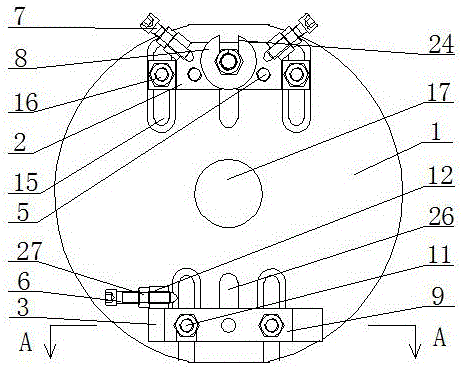

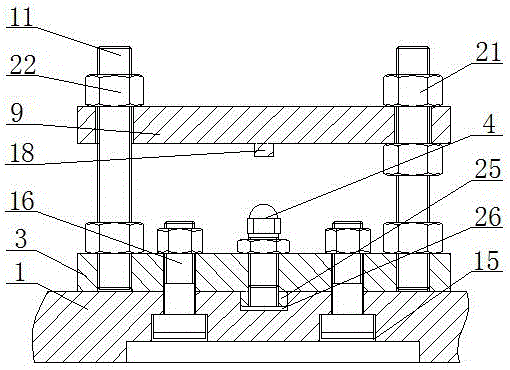

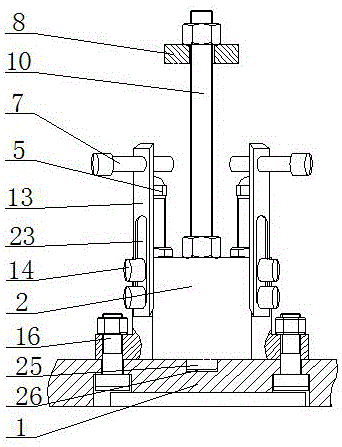

Brake baseplate machining fixture

InactiveCN106514320ASimple structureEasy to useWork clamping meansPositioning apparatusEngineeringMachining

The invention relates to a brake baseplate machining fixture, and belongs to the technical field of brake baseplate machining equipment. The machining fixture consists of a baseplate, support nails B, a positioning nail A, a positioning nail B, a pressing block, a pressing plate, a pressing screw rod and fastening screw rods; a mounting plate and a mounting base are symmetrically arranged on the baseplate; the positioning nail A is mounted on the inner side of one end of the mounting plate through a mounting block by a thread; the pressing plate is mounted above the mounting plate through the fastening screw rods symmetrically arranged; the support nail A is fixedly mounted below the pressing plate; the pressing block is arranged at the upper end of the mounting base through the pressing screw rod; and the support nails B are symmetrically arranged on the inner side of the pressing screw rod. The brake baseplate machining fixture is simple in structure and convenient to use, solves the problems of high model change labor intensity, low working efficiency and high machining cost in clamping of the brake baseplate by a traditional fixture, and satisfies the clamping demands of the brake baseplate.

Owner:JINGZHOU HENGFENG BRAKE SYST CO LTD

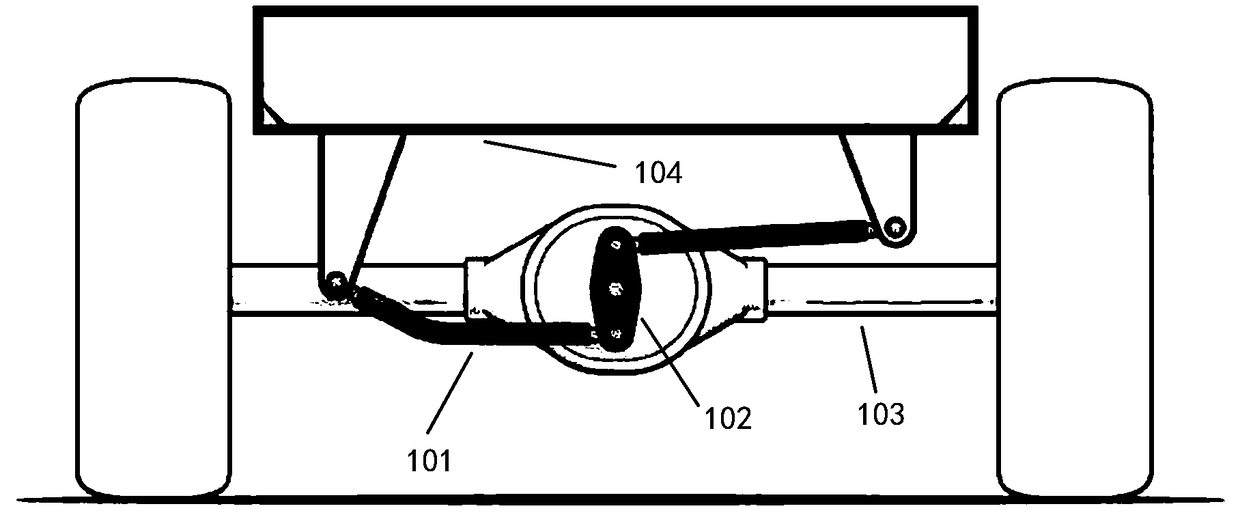

Watt connecting rod installation structure

PendingCN108407567AImprove safety performanceImprove stabilityInterconnection systemsPush pullEngineering

A watt connecting rod installation structure comprises a coupled lever horizontally lying above a torsion beam. The middle portion of the coupled lever is hinged to the torsion beam through a fixed shaft fixed to the upper side of the torsion beam. Two horizontally-arranged push-pull rods are hinged to the two ends of the coupled lever. The other ends of the two push-pull rods are hinged to the portions, on the two sides, of an automobile body. Due to the fact that the structure is installed at the upper end of the torsion beam and occupies the horizontal space above the torsion beam, the longitudinal space of a chassis does not need to be occupied, the structure can be suitable for a vehicle model which is provided with a low base and cannot reserve a longitudinal space for a traditionalwatt connecting rod, the application range of the structure is wider, and the structure at the bottom of an automobile is more compact. Due to the fact that the two ends of each push-pull rod are directly connected to the automobile body, an axial support is additionally provided for each of the two sides equivalently, and connection is more stable.

Owner:马瑞利汽车零部件(广州)有限公司

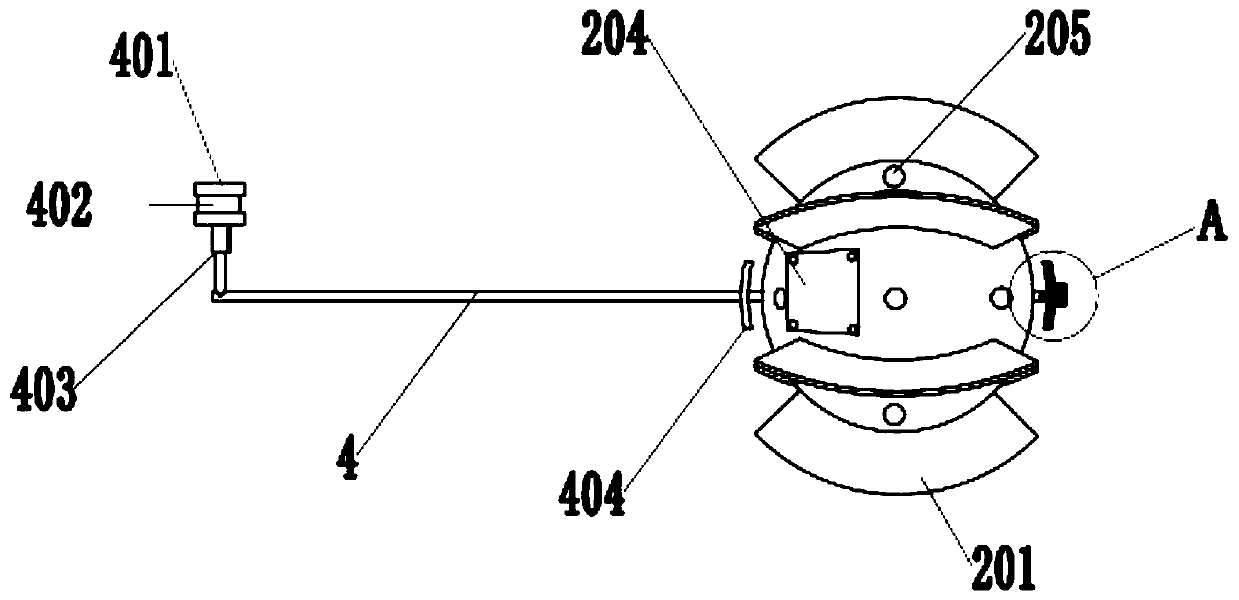

Bird repelling device for telegraph pole

ActiveCN110250152APlay a driving roleSolve the problem of declining effect after long-term useOverhead installationAnimal repellantsEngineeringMultiple methods

The invention discloses a bird repelling device for a telegraph pole. The device comprises a fixed base, bird repelling balls and a support rod. The fixed base comprises two clamp half bodies, the ends of the two clamp half bodies are butt-joined, then the clamp half bodies sleeve the telegraph pole, and each clamp half body comprises an inner clamping plate and an outer clamping plate, wherein the outer clamping plate is arranged on the outer side of the inner clamping plate, the upper end of the outer clamping plate is connected with the outer clamping plate through a connecting plate, and the inner clamping plate is provided with a compression bolt connected with the telegraph pole; a rolling wheel is arranged at one end of each support rod and arranged between each inner clamping plate and the corresponding outer clamping plate, the bird repelling balls are in rotating connection with the other ends of the support rods, and each bird repelling ball is internally provided with a chemical ball, wherein the chemical ball is internally provided with a granular bird repelling agent, outer chemical outlet holes are formed in the side wall of the bird repelling ball, and inner chemical outlet holes are formed in the surface of the chemical ball. According to the device, birds can be repelled through multiple methods at the same time, the problems that at present, a bird repelling device is monotonous in bird repelling method, and after long-term use, the effect is reduced are solved, and the bird repelling effect is obvious.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

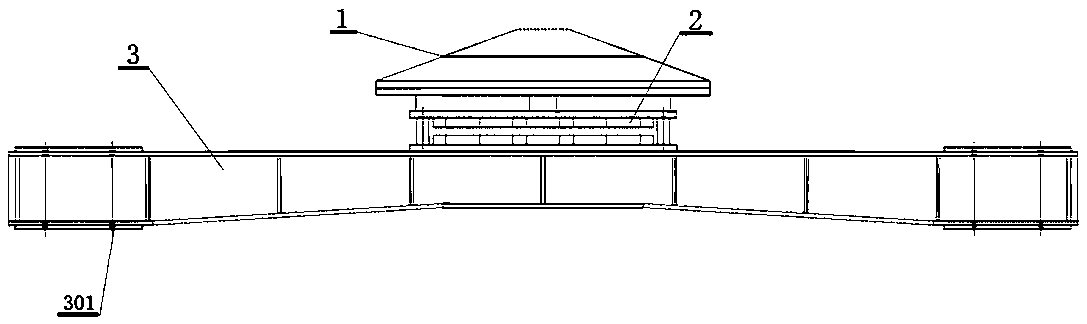

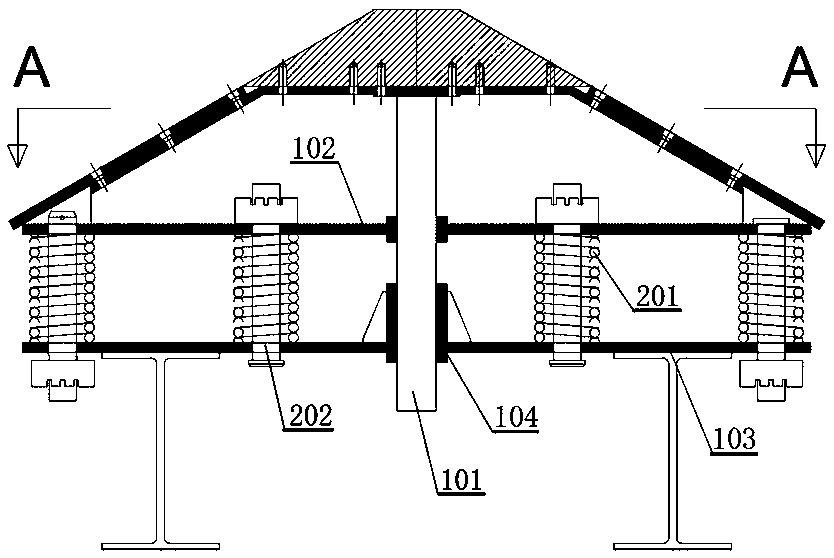

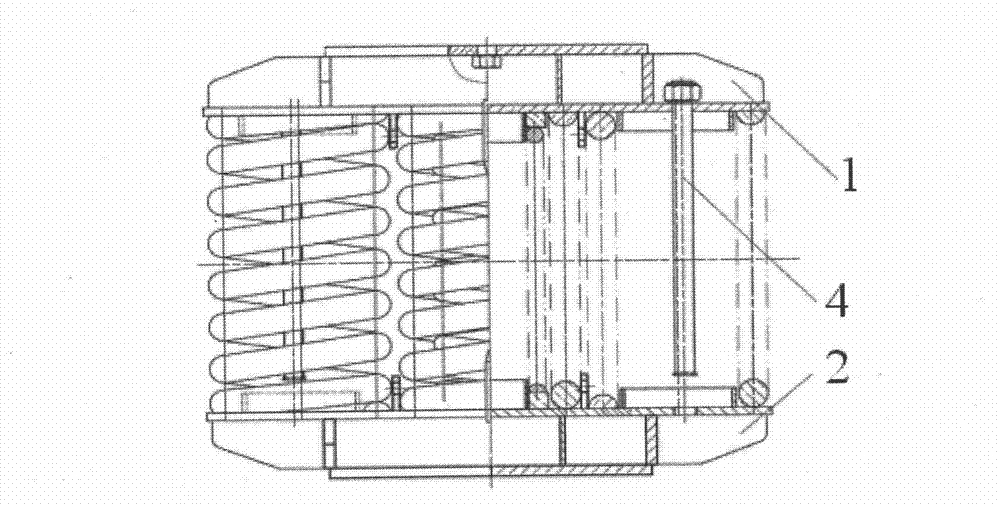

Spring support of condenser of 1,000MW nuclear power unit

InactiveCN102900799APrevent horizontal movementMeet support requirementsWound springsLow internal friction springsNuclear powerNuclear engineering

The invention provides a spring support of a condenser of a 1,000MW nuclear power unit. The spring support is characterized by comprising a lower shell and an upper shell arranged above the lower shell, wherein a spring group is arranged between the lower shell and the upper shell and comprises six large springs which are arranged into two rows and three columns; and small springs are arranged inside the large springs from the middle to the two sides. By the spring support, the shortcomings in the prior art are overcome; since the small springs are arranged inside the large springs and limiting rings are arranged on the upper shell and the lower shell, the spring support meets the supporting requirement of the condenser of the1,000MW nuclear power unit and has high stability.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Bridge cushion pad embedded installation seat machining method

ActiveCN105887663AStable structureThe structure is not easy to deformBridge structural detailsRebarEmbedded system

The invention discloses a bridge cushion pad embedded installation seat machining method. The method comprises the following steps that a cushion pad limiting frame, embedded anti-floating rebars, an installation seat bottom plate and anti-deformation reinforced rib plates are machined; the above-mentioned components are welded together to form the bridge cushion pad embedded installation seat; surface oil cleaning and shot blasting treatment are conducted on the bridge cushion pad embedded installation seat; the whole bridge cushion pad embedded installation seat is immersed in a Dacromet coating solution; two corners, located at the two ends of a diagonal line respectively, of the installation bottom plate of the bridge cushion pad embedded installation seat are clamped and fixed, the level heights of the two fixed corners are the same, positions of the two fixed corners are fixed, and the bridge cushion pad embedded installation seat rotates around a connecting line between the two fixed corners to be leached; the bridge cushion pad embedded installation seat is sent to drying equipment to form a Dacromet coating; a cushion pad installation groove is fixed downwards and sprayed with a normal temperature curing blocking fluid, the attitude is kept, redundant closing fluid is leached, normal temperature curing is conducted, and a closing layer is formed.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

Construction method of indoor floor plate dry method mixing laying

ActiveCN110206313APrecise blanking processingSolve the slow construction speedBuilding material handlingMeasuring instrumentLaser scanning

The invention relates to a construction method of indoor floor plate dry method mixing laying. The construction method includes the following steps that (1), floor BIM technology modeling is carried out according to architectural design drawings; (2), indoor floors are scanned with a laser scanner, and measuring instruments are matched to obtain constraints of floors and surrounding walls and floor smoothness data; (3), limiting profiles are machined according to the shape and scale designed by BIM; (4), the limiting profiles are assembled on the floors according to the design requirements, and the elevation of the limiting profiles is positioned; (5), dry laying base materials are laid in a limiting interval enclosed by the limiting profiles, and a floating rule is placed on the flange plates of the limiting profiles opposite to the limiting interval to scrape horizontally; (6) the designed and machined floor plates are placed in the limiting interval; and (7) gaps between the floor plates are subjected to gluing. According to the construction method of indoor floor plate dry method mixing laying, the blanking of the limiting profiles and the floor plates can be precisely machined, and the construction speed and accuracy are effectively improved.

Owner:浙江华汇装饰工程股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com