Processing method of oblique oil hole in revolving shaft of traction motor and auxiliary processing device

An auxiliary processing and traction motor technology, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the opening of the inclined oil hole cannot completely fall into the oil groove, the drilling position of the inclined oil hole is off, and the notch of the oil groove Narrowing and other issues, to achieve the effect of low cost, high processing efficiency and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the present invention provides a kind of method of rotating shaft oblique oil hole processing, comprises the following steps:

[0031] Step 1: Optimizing the process of finishing the oil tank. Under the premise of not changing the design requirements, the width of the oil tank is forcibly guaranteed during the process. The maximum width of the oil tank on the design drawing is taken as the reference width, and a certain angle is drawn to the taper surface of the rotating shaft. Angle and tangent to the arc surface of the oil groove as a smooth transition between turning and grinding, the angle range between the oblique line and the taper surface of the rotating shaft is: 4 ° ≤ C ≤ 15 °, according to the size of the rotating shaft and the size of the oil groove to choose a certain A suitable angle value avoids the influence of the grinding allowance on the tapered surface of the rotating shaft on the groove shape accuracy and groove width of the oil groove, ...

Embodiment 2

[0036]Embodiment 2 is different from Embodiment 1 in that the processing equipment used is a horizontal machining center.

Embodiment 3

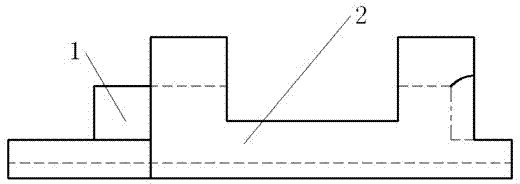

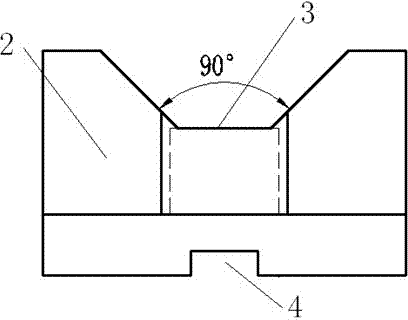

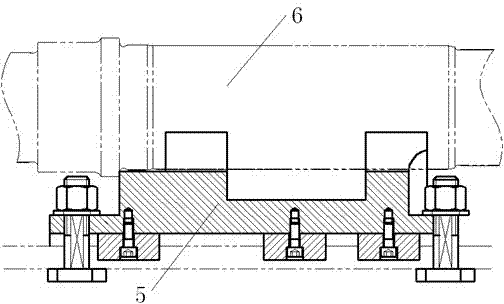

[0037] Embodiment 3: According to the above-mentioned method for machining the oblique oil hole of the rotating shaft, and utilizing the characteristics of the length consistency of the precision-controlled machining of the rotating shaft 6, the present invention also provides an auxiliary machining of the inclined oil hole of the traction motor rotating shaft that can control 6 degrees of freedom of the rotating shaft Device: an auxiliary processing device for the inclined oil hole of the traction motor shaft 6, including a base 2, a weight 8 and a T-shaped screw 7; the base 2 is provided with a shaft fixing groove 3, a shaft shoulder positioning step 1, and a mounting groove 4 , the rotating shaft fixing groove 3 is a groove with a trapezoidal cross-section, and the two slopes of the rotating shaft fixing groove 3 are perpendicular to each other, and are used to place the rotating shaft 6 and prevent the rotating shaft 6 from moving radially during processing; the shoulder pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com