Edge pressing sample trimmer

A technology of cutting and side pressing, applied in metal processing and other directions, can solve the problems of error in test results, inability to guarantee verticality, large uncertainty of measurement results, etc., and achieve the effect of ensuring verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described below in conjunction with specific embodiments.

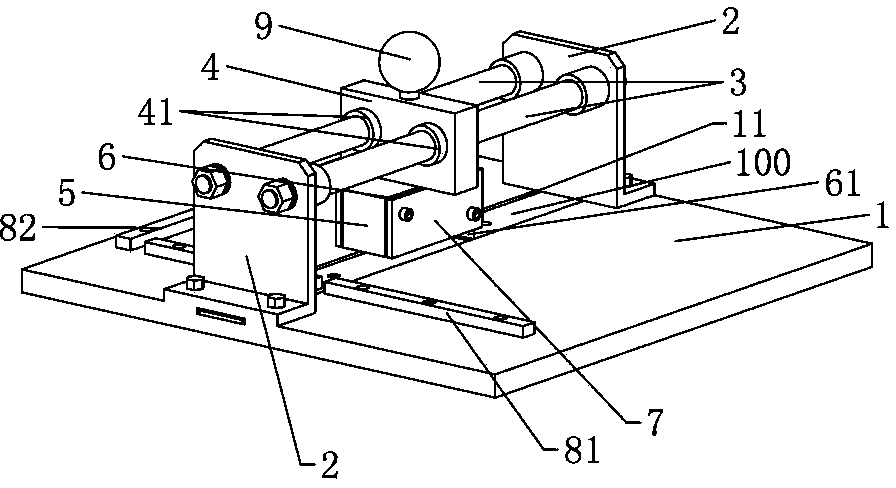

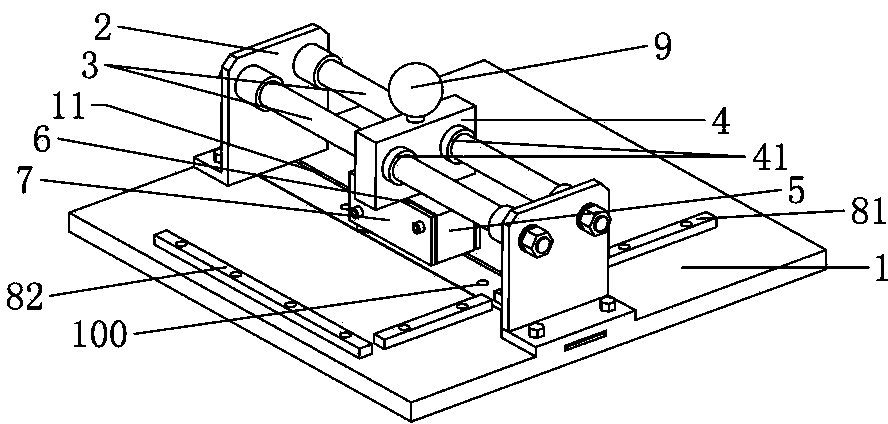

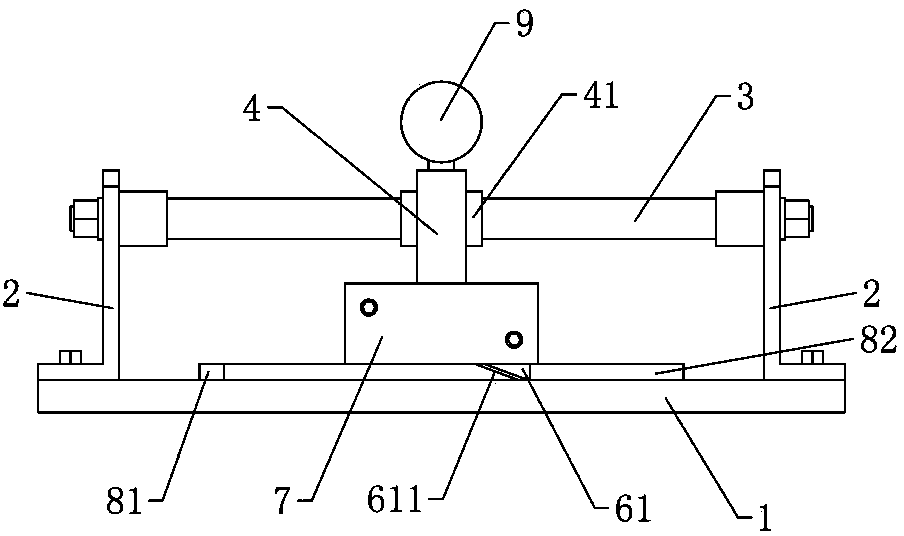

[0035] Such as Figure 1 to Figure 3 As shown, the edge pressure sample cutter includes a base 1, the upper surface of the base 1 is provided with an avoidance groove 11 extending forward and backward, and a cutting width positioning block 100 is installed in the avoiding groove 11, and the cutting width positioning block 100 The upper surface is lower than the upper surface of base 1 about 1mm, between the left end surface of the cutting width positioning block 100 and the left side wall of the avoidance groove 11, and between the right end surface of the cutting width positioning block 100 and the right side wall of the avoidance groove 11, there is an avoidance gap; the upper surface of the base 1 is in the The front end and the rear end of the avoidance groove 11 are respectively equipped with a fixed base 2, and two horizontally parallel guide columns 3 arranged at intervals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com