NC Grinding Method for Side Relief Surface of Plane Secondary Envelope Toroidal Worm Gear Hob

A technology of plane secondary enveloping and worm wheel hobs, which is applied in metal processing equipment, milling cutters, milling machine equipment, etc., can solve the problems of complex production, inconsistent side relief angles, and difficult production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

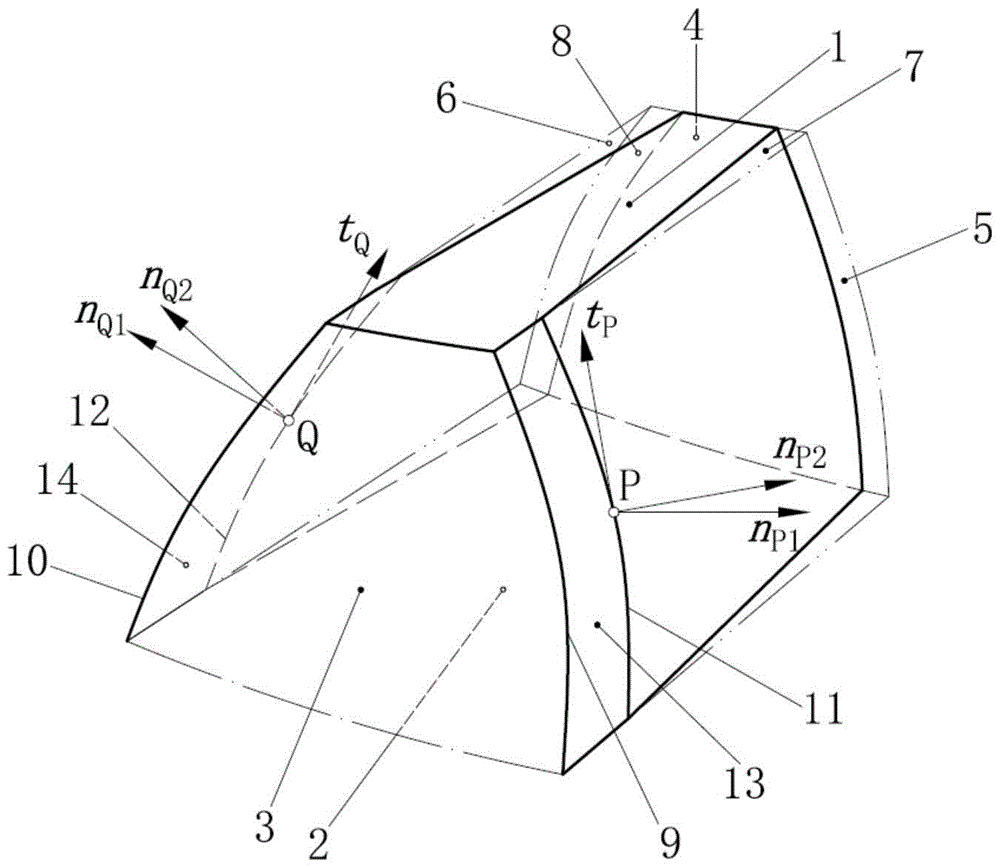

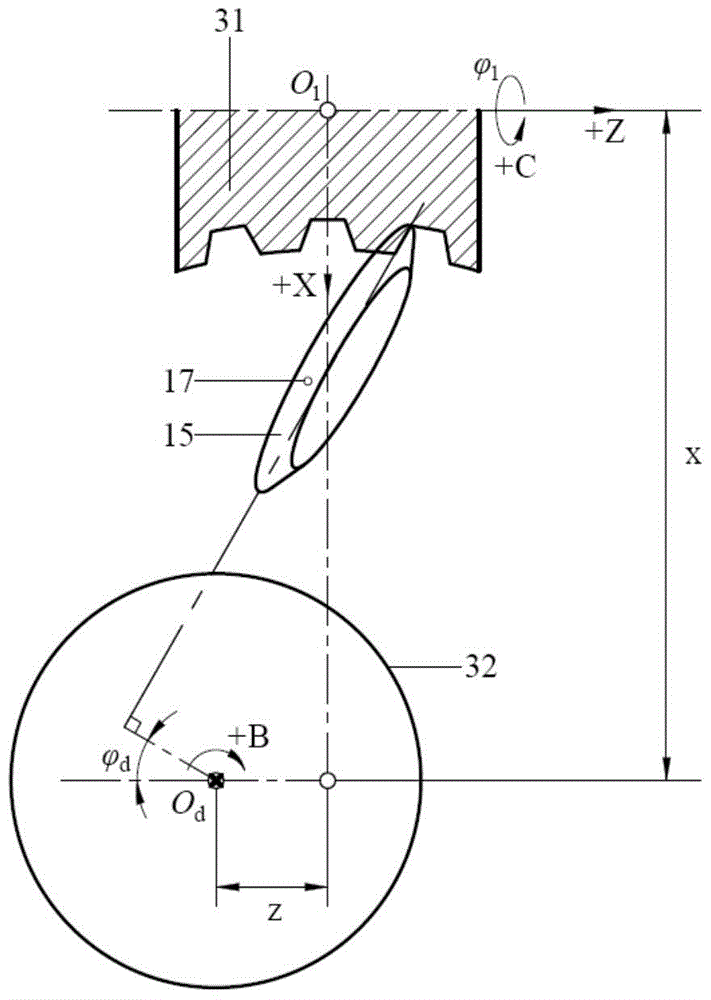

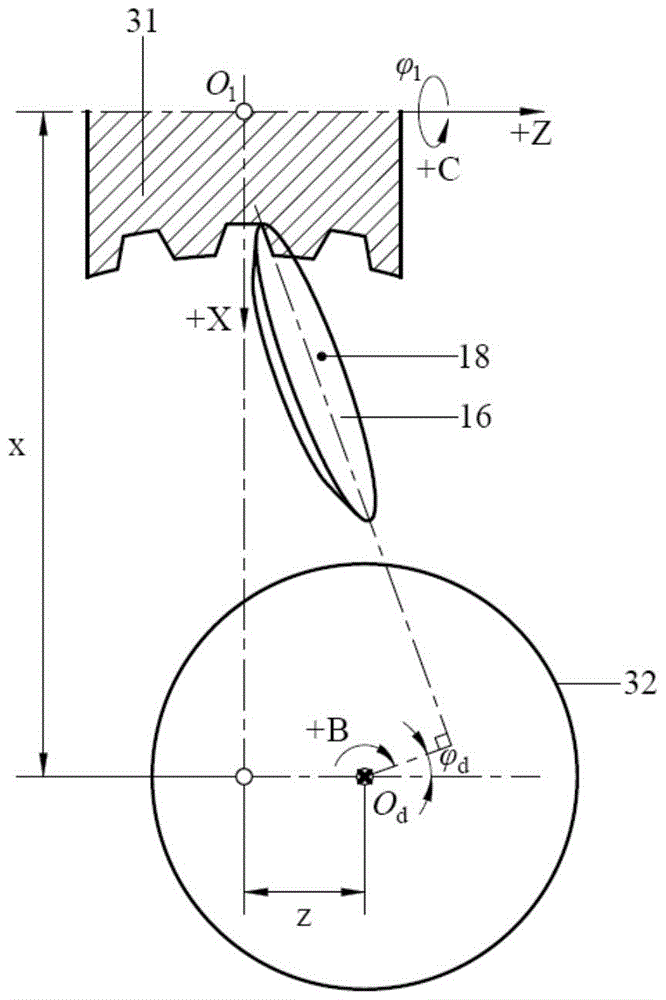

[0012] Embodiments of the present invention will be described below according to the accompanying drawings.

[0013] The planar quadratic enveloping torus worm wheel hob is used to hob the worm gear of the planar quadratic enveloping torus worm pair. The parameters of the plane quadratic enveloping toroidal worm pair are: center distance a=225mm, right-handed worm number of heads z 1 = 2, the number of worm gear teeth z 2 =64, transmission ratio i 12 =32, the diameter of the worm pitch circle d 1 =80mm, worm gear indexing circle diameter d 2 = 370mm.

[0014] According to the principle of the planar quadratic enveloping toroidal worm, the hob’s single tooth’s tooth top torus 1, dedendum torus 2, right helical surface 5 and left helical surface 6 can be obtained to open straight chip grooves Finally, the rake face 3 and the flank face 4 of each tooth are obtained, and the intersection lines of the rake face 3 with the right helicoid 5 and the left helicoid 6 respectively a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com