Needle plate on sewing machine

A sewing machine and needle plate technology, which is applied to sewing machine components, sewing machine casings, sewing equipment, etc., can solve problems such as uneven edge width, difficulty in opening uppers, and affecting the aesthetics of shoes, so as to achieve uniform edge wrapping and ensure consistent width sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

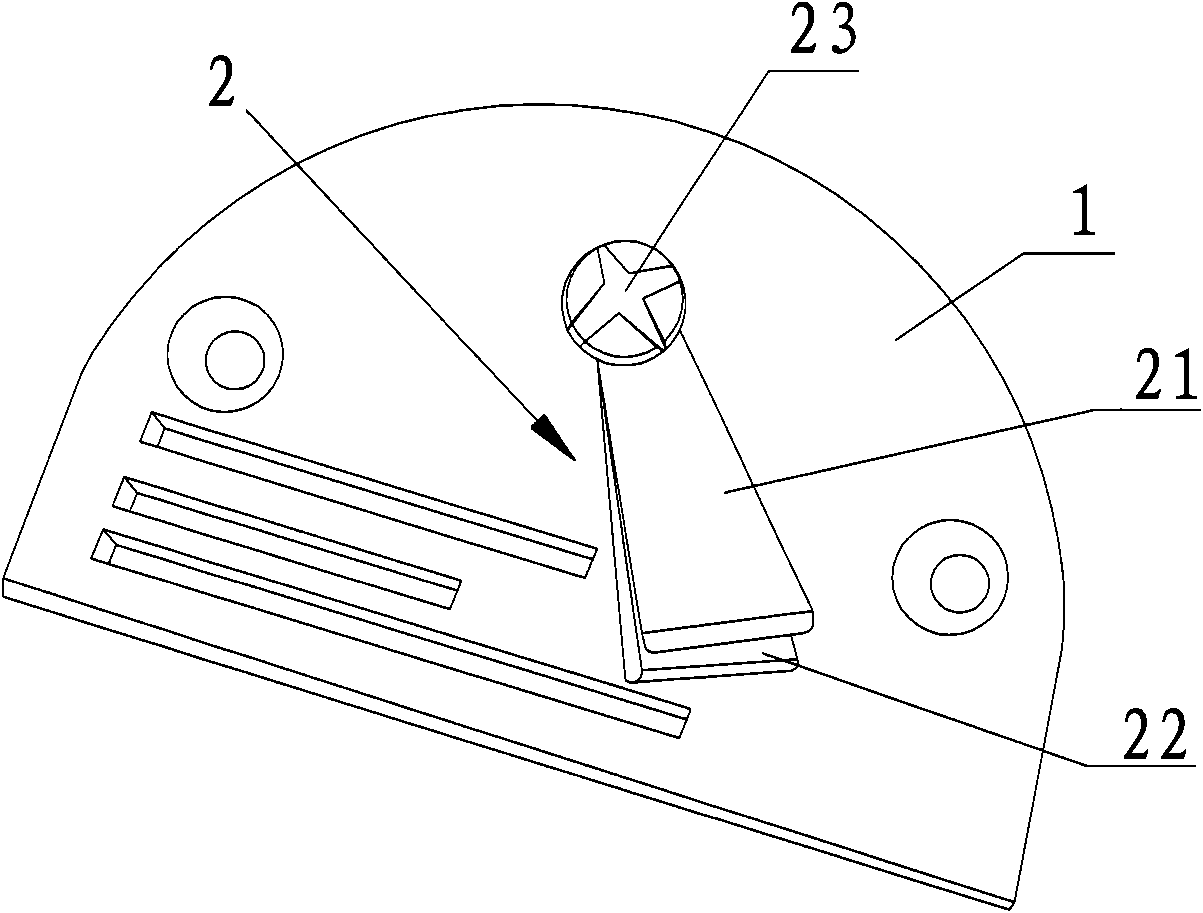

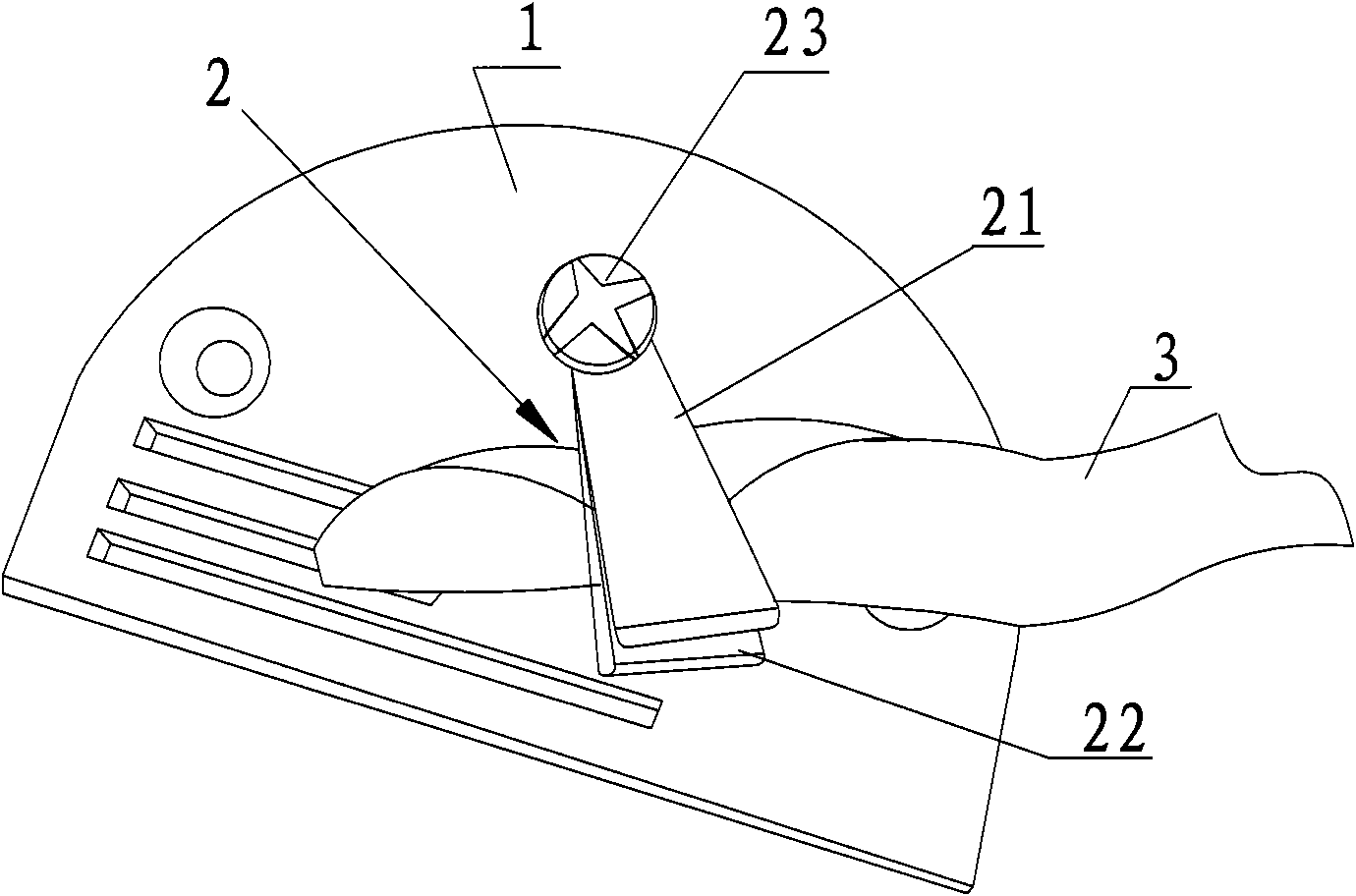

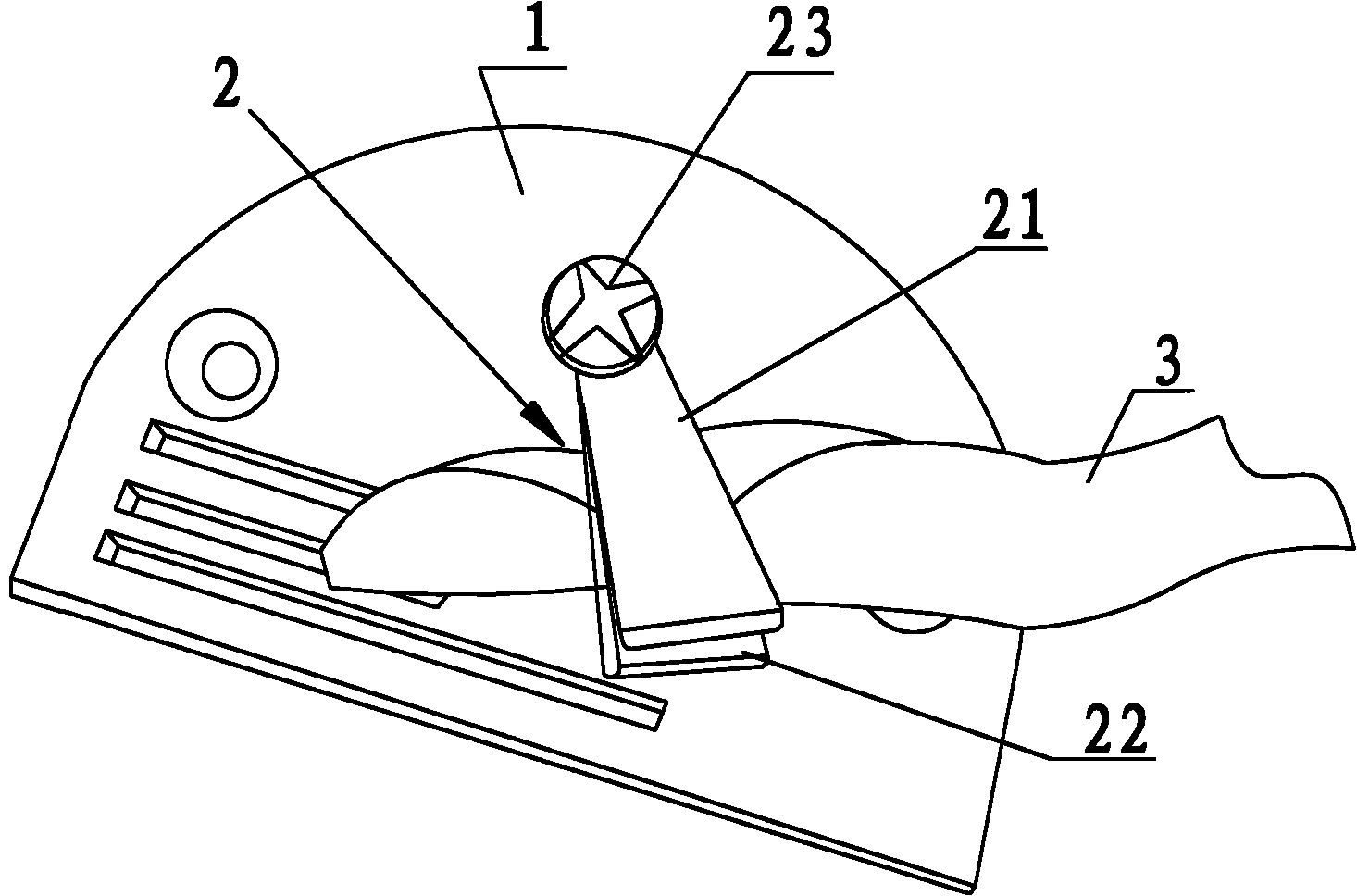

[0009] Such as figure 1 and figure 2 The needle plate shown includes a plate body 1 for installation on a sewing machine, and a crimping device 2 fixedly installed on the plate body 1. The position of the crimping device 2 can be selected according to the actual use. The side device 2 includes an upper roll 21 and a lower roll 22 located below the upper roll 21 , one end of the upper roll 21 is fitted to one end of the lower roll 22 and is fixed to the board body by a fixing member 23 1, the other end of the upper rolled skin 21 is bent downwards and then extended toward its fixed end, and the other end of the lower rolled skin 22 is extended upwards and then extended to its fixed end, so as to be compatible with the upper rolled skin Between 21, there is formed a passing space for the strip cloth 3 to be rolled through.

[0010] Above-mentioned fixing member 23 can be bolt, when in use, according to the width of cloth strip 3, adjust the width of crimping device 2, usually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com