Dispatching optimization method for electroless copper plating process of multiple layers of circuit boards

A process and optimization scheduling technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the heuristic constructive method to optimize poor quality, multi-layer circuit board chemical copper plating process scheduling problem NP Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

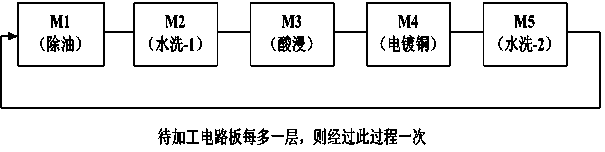

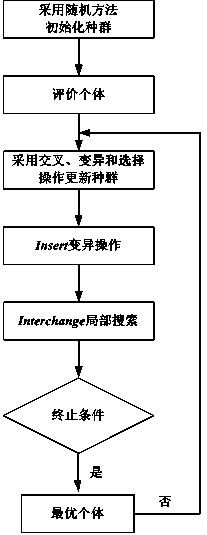

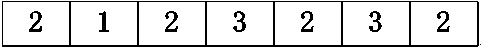

[0039] Embodiment 1: as Figure 1-5 As shown, an optimal scheduling method for the electroless copper plating process of a multi-layer circuit board, by determining the scheduling model and the optimization target of the electroless copper plating process, and using the optimal scheduling method based on the differential evolution algorithm to optimize the optimization target; The scheduling model is established according to the processing completion time of each circuit board on each process equipment, and the optimization goal is to minimize the earliest completion time C max :

[0040]

[0041] In the formula: m 5 sets of process equipment representing the copper plating process, Sum R means all n The sum of layers of circuit boards to be processed, n Indicates the number of circuit boards to be processed, is the process sequence of circuit boards to be processed, ( j =1,..., Sum R ) means sorting π B j position of the circuit board, Indicates the circuit ...

Embodiment 2

[0050] Embodiment 2: as Figure 1-5 As shown, an optimal scheduling method for the electroless copper plating process of a multi-layer circuit board, by determining the scheduling model and the optimization target of the electroless copper plating process, and using the optimal scheduling method based on the differential evolution algorithm to optimize the optimization target; The scheduling model is established according to the processing completion time of each circuit board on each process equipment, and the optimization goal is to minimize the earliest completion time C max :

[0051]

[0052] In the formula: m 5 sets of process equipment representing the copper plating process, Sum R means all n The sum of the layers of each circuit board to be processed (the number of layers of copper plating required for each circuit board is not the same), n Indicates the number of circuit boards to be processed, is the process sequence of circuit boards to be processed, ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com