Pneumatic tyre

A technology for pneumatic tires and tires, applied in tire parts, tire treads/tread patterns, transportation and packaging, etc., can solve the problems of small axial friction, easy lateral sliding, and low handling stability. , to achieve the effect of improving friction, improving handling stability and performance on snow, and improving performance on snow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

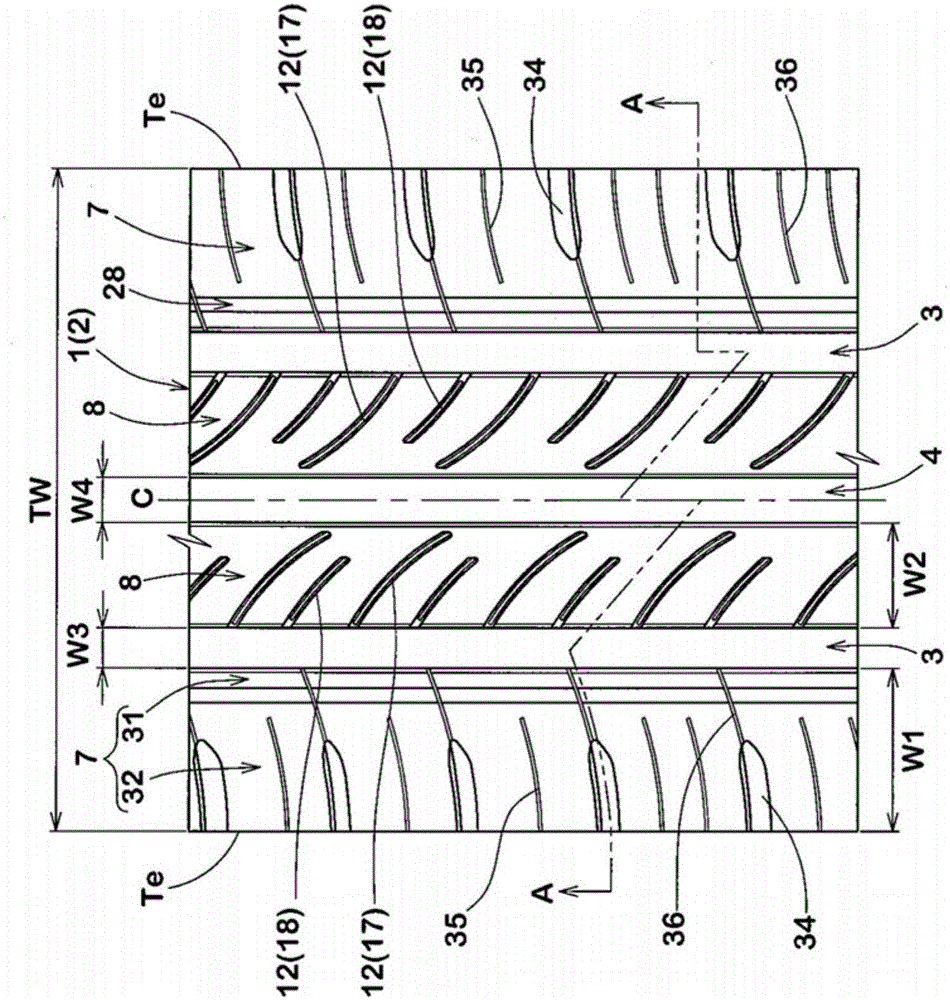

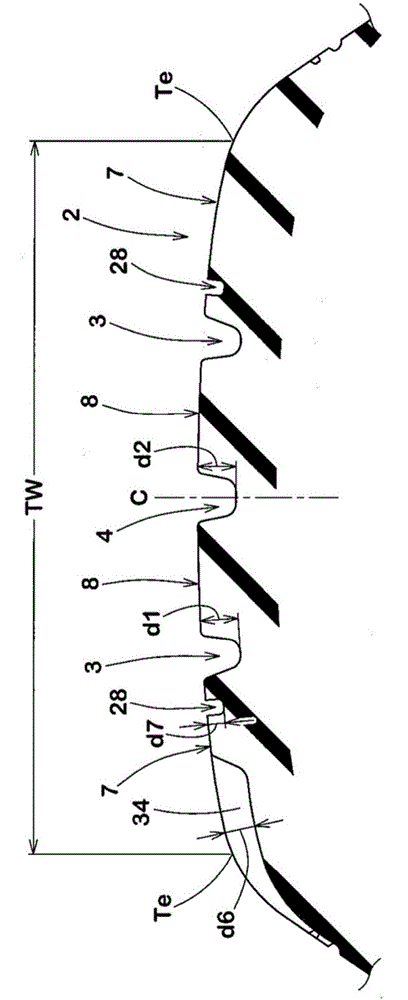

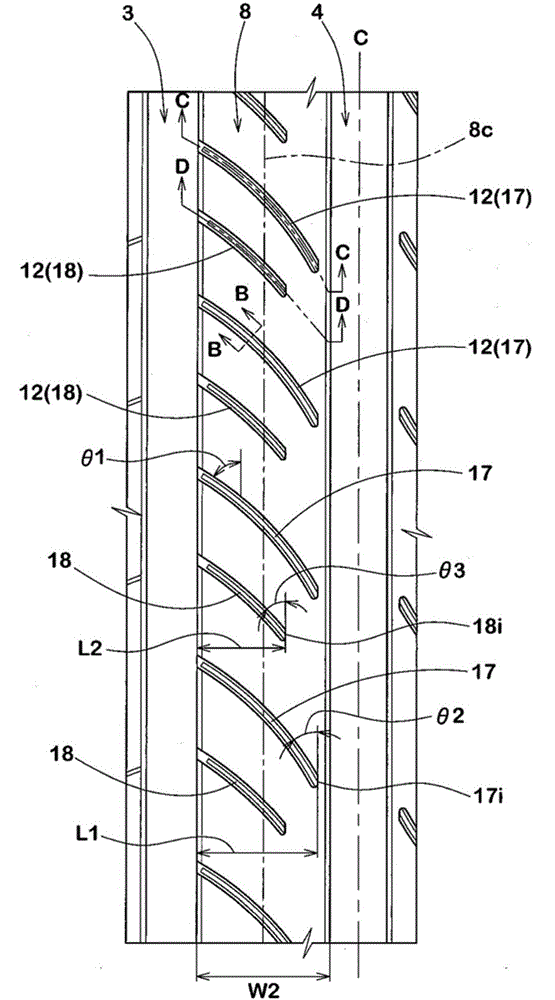

[0089] Based on the specifications in Table 1, prototypes with figure 1 The basic pattern of pneumatic tires. As a comparative example, such as Figure 10 As shown, a tire without a central shallow groove and a shoulder auxiliary groove was trial-manufactured. The handling stability on dry road, wet road performance, and on-snow performance of each test tire were tested. The common specifications of each test tire are as follows.

[0090] Tire size: 185 / 65R15

[0091] Rim size: 15×5.5

[0092] Tire internal pressure: 200kPa

[0093] Tread contact width TW: 132mm

[0094] The groove width W3 of the shoulder main groove and the groove width W4 of the center main groove: 9.0mm

[0095] The groove depth d1 of the shoulder main groove and the groove depth d2 of the center main groove: 7.4mm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com