Watt connecting rod installation structure

A technology of installation structure and watt connecting rod, which is applied in the directions of interconnection system, transportation and packaging, suspension, etc., can solve the problems of insufficiently compact bottom structure, high longitudinal space, difficult application, etc., to achieve compact structure, improve stability, Strong connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

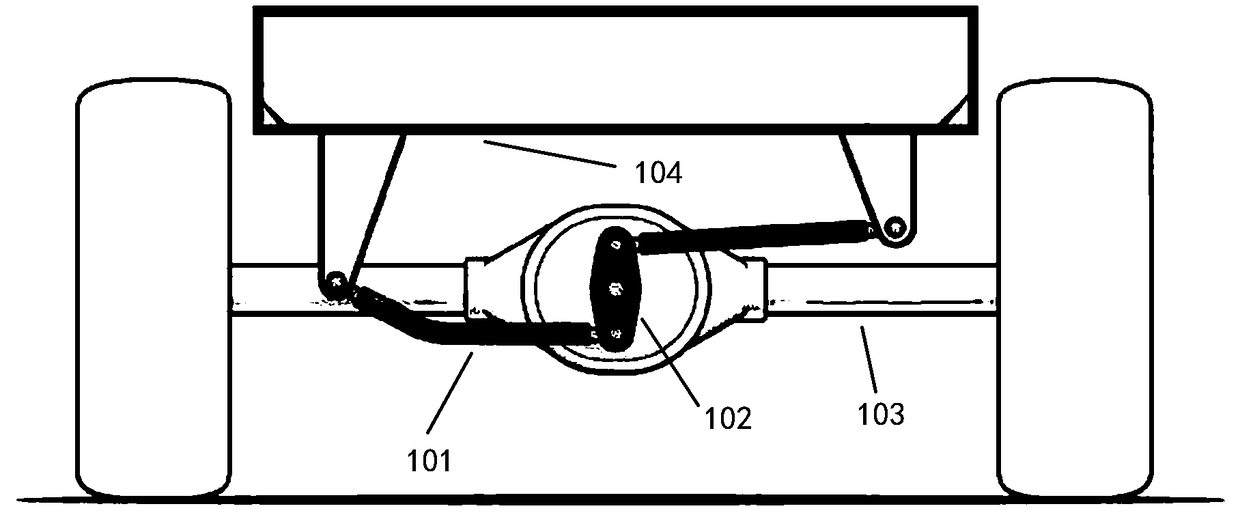

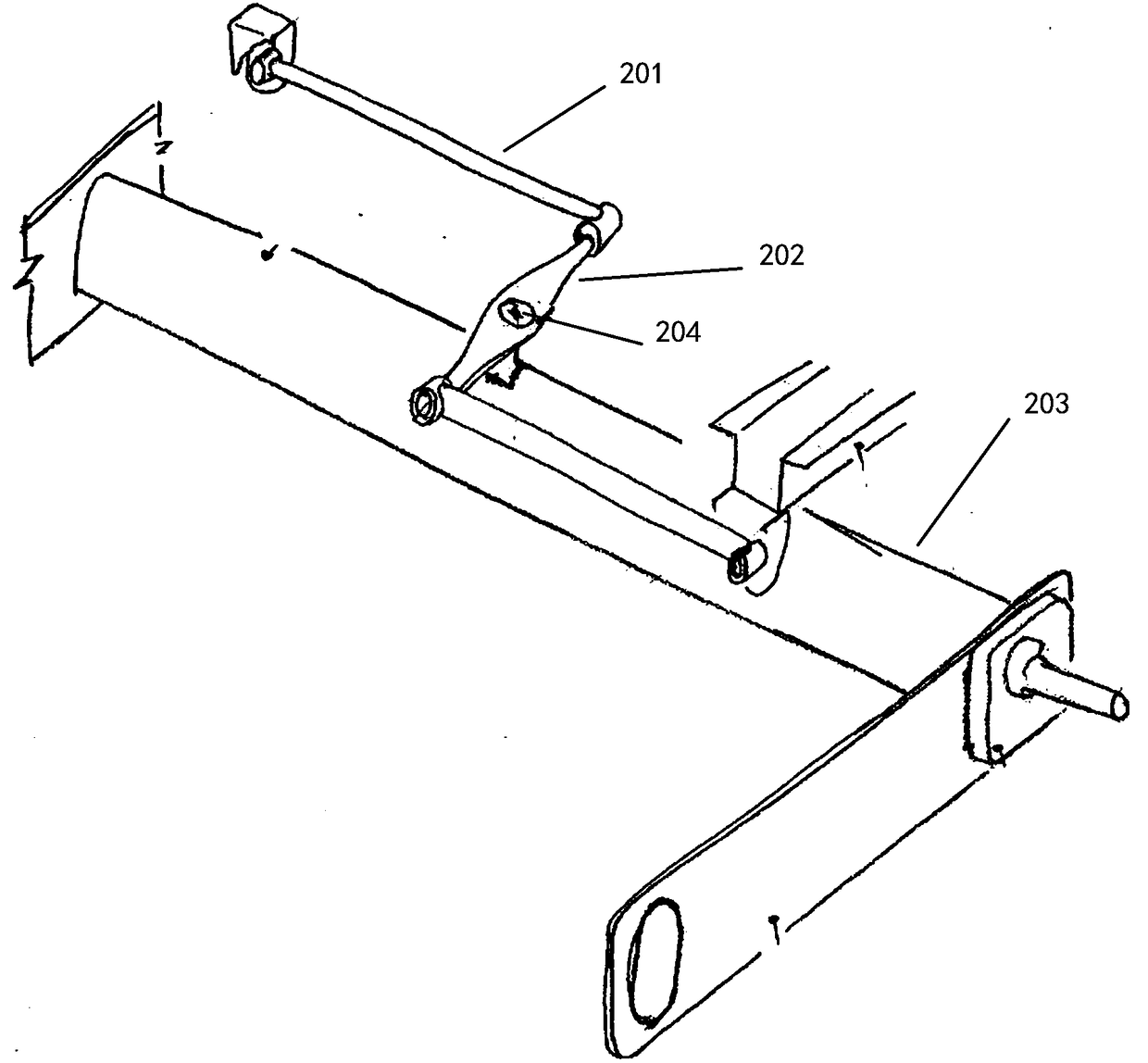

[0011] Such as figure 2 As shown, a Watt connecting rod installation structure includes a coupling lever 202 lying horizontally above the torsion beam. The middle part of the coupling lever is hinged to the torsion beam 203 through a fixed shaft 204 fixed on the upper side of the torsion beam. The two ends of the lever are respectively hinged to a push-pull rod 201 arranged horizontally, and the other ends of the two push-pull rods are respectively hinged to the vehicle bodies on both sides.

[0012] Most intuitively, since the Watt connecting rod installation structure is installed on the upper end of the torsion beam, it occupies the horizontal space above the torsion beam and does not need to occupy the longitudinal space of the chassis. Models with reserved longitudinal space have a wider range of application and make the structure of the bottom of the car more compact.

[0013] The operating principle of the Watt connecting rod installation structure is as follows: For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com