Rail expansion device

A telescopic device and rail technology, applied in the direction of rails, roads, rail joints, etc., can solve the problems that wear-resistant steel cannot be used, difficult to weld, etc., and achieve the effects of reliable guidance, simple structure, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

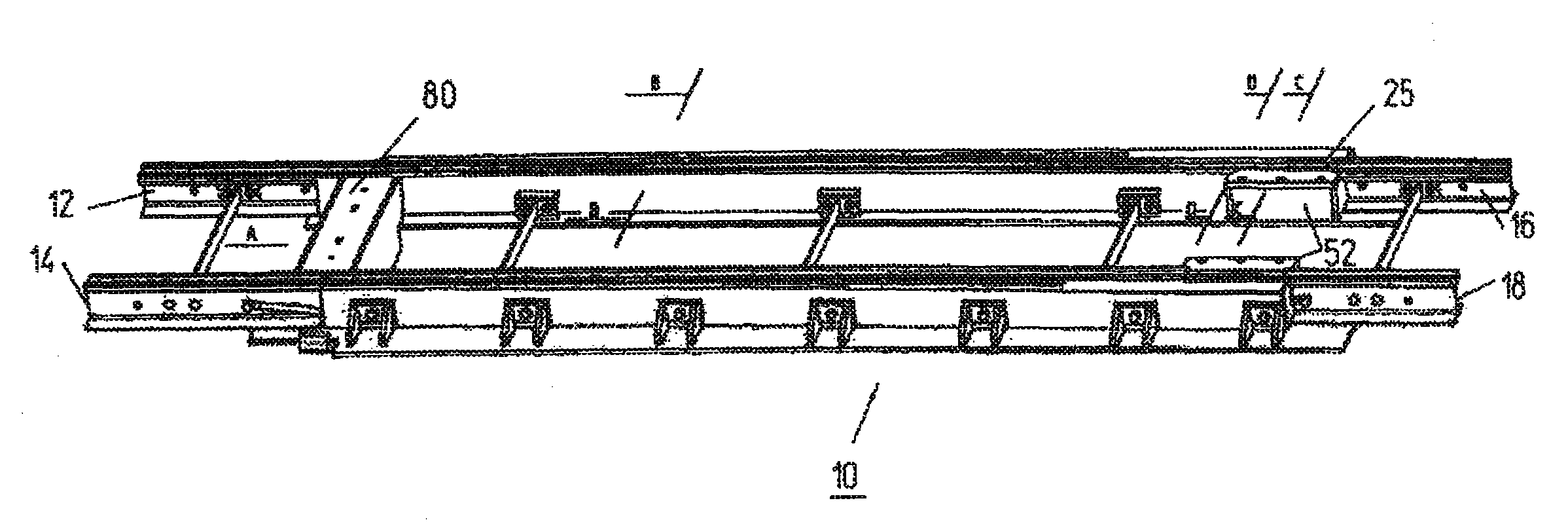

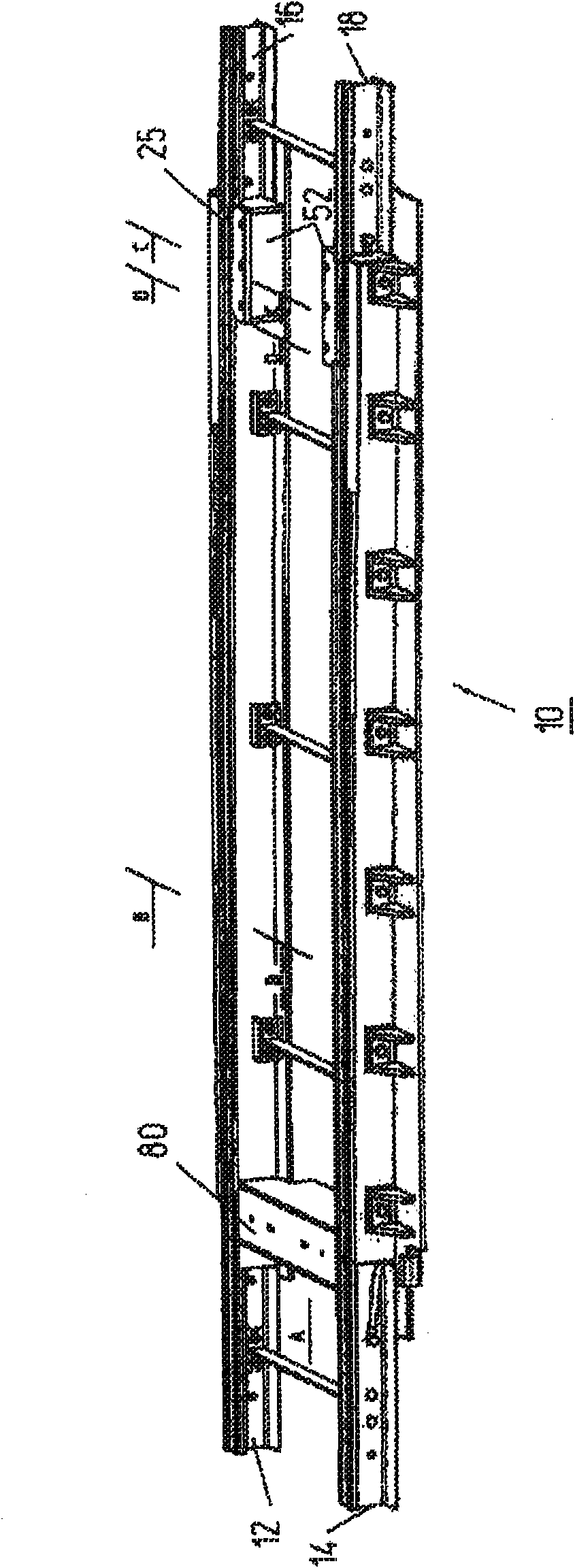

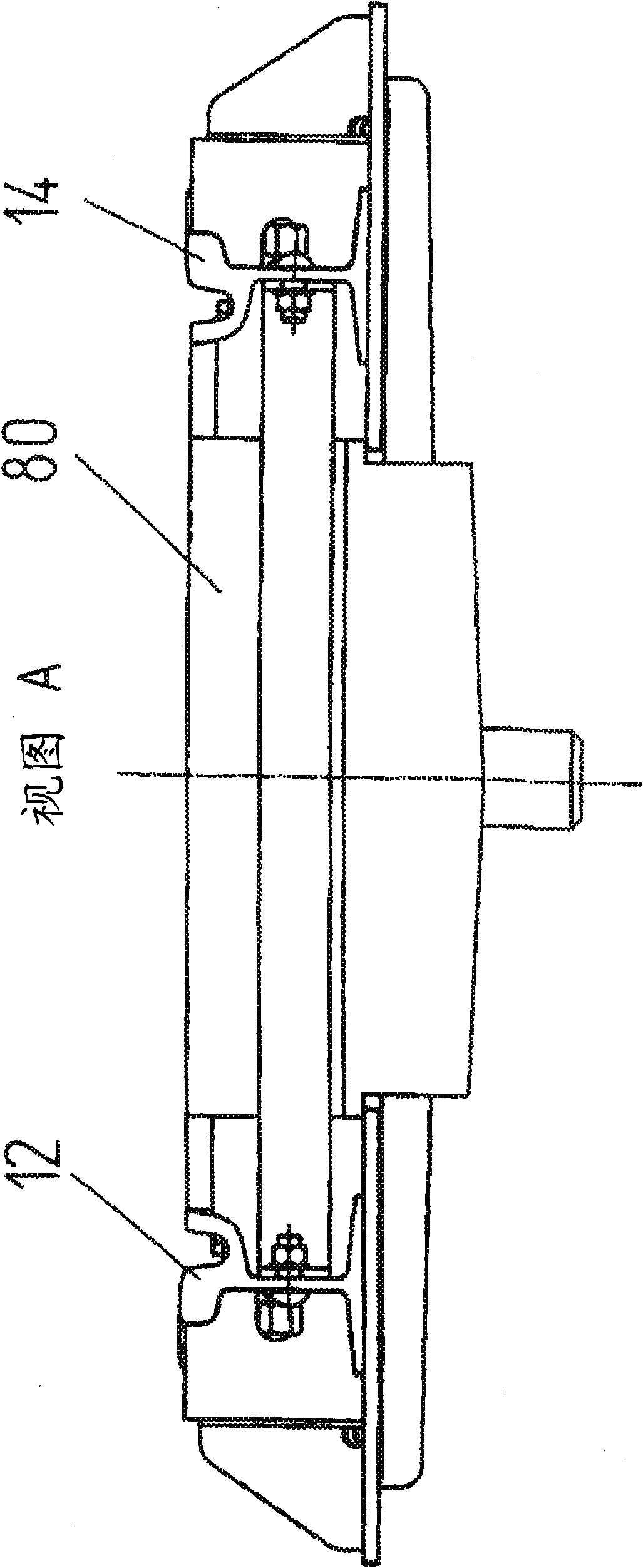

[0025] A purely principled rail telescopic device 10 is shown in the drawing, which is a grooved rail, without thereby restricting the principle according to the invention. Conversely, this arrangement is also suitable for other rail sections, in particular T-shaped rails.

[0026] The track telescoping device 10 generally comprises base rails 12, 14 which are longitudinally displaceable relative to a tip rail 21 which transitions into the control rails 16, 18, the tip portions 20 of which are shown in the views of FIGS. 3 and 4 and a cross-sectional view of the root region 22 . In order to be able to move relative to the current temperature between the base rails 12, 14 and the switch rails 21 transitioning to the control rails 16, 18, the base rails 12, 14 leave the switch rails 21 outwards, so that regardless of the active position of the base rails 12, 14 Regardless of the length, there is always a transition from the tip rail 21 or its tip 20 to the base rail 12 , 14 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com