High-voltage DC on-off device

A high-voltage DC switch-breaker technology, applied in the electric power field, can solve the problems of unreasonable internal structure of high-voltage DC switch-breaker, difficult-to-contact chamber compression, poor sealing and flatness, etc., to ensure consistency and dimensional stability. The effect of high safety, high safety, and improved versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

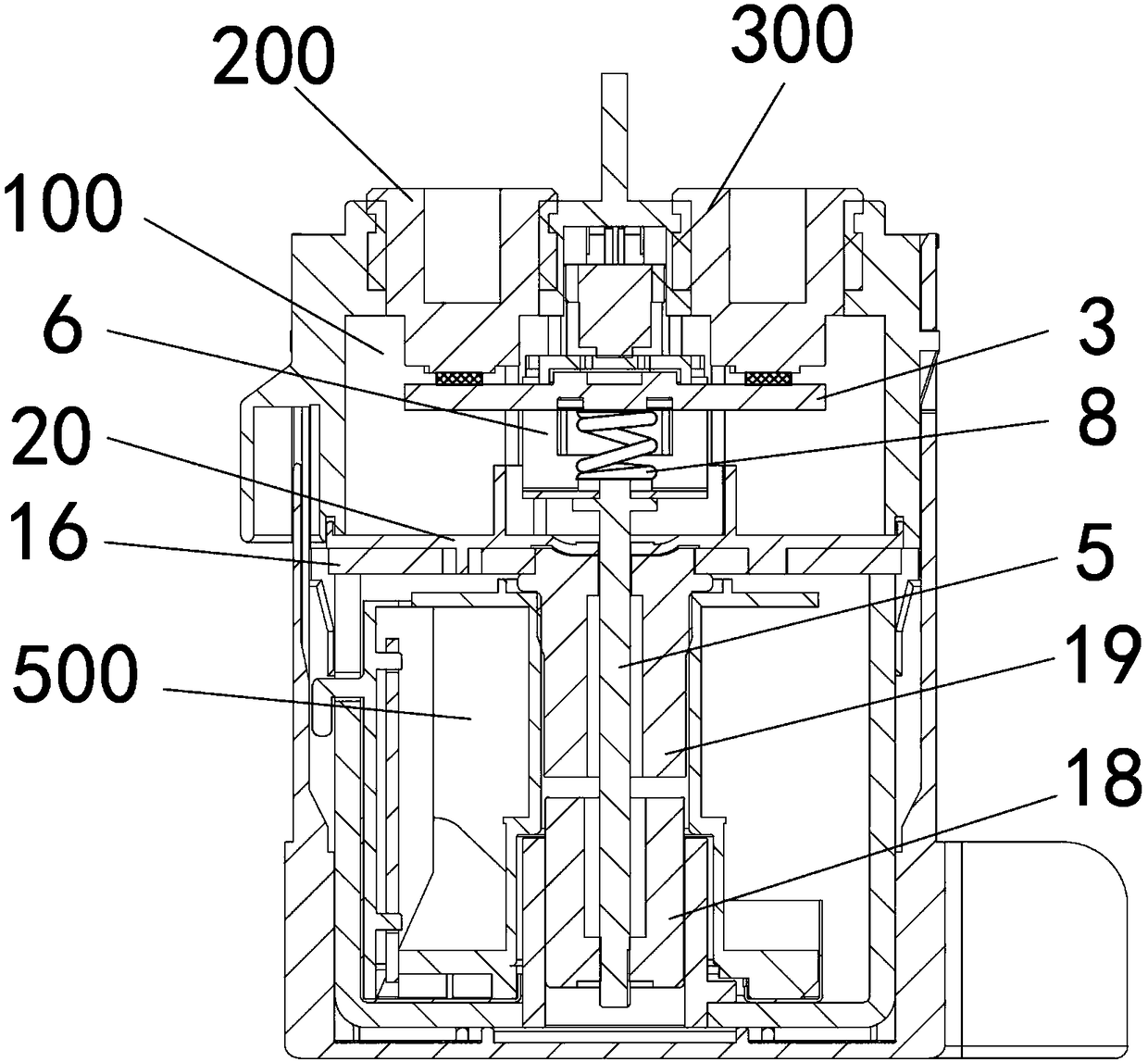

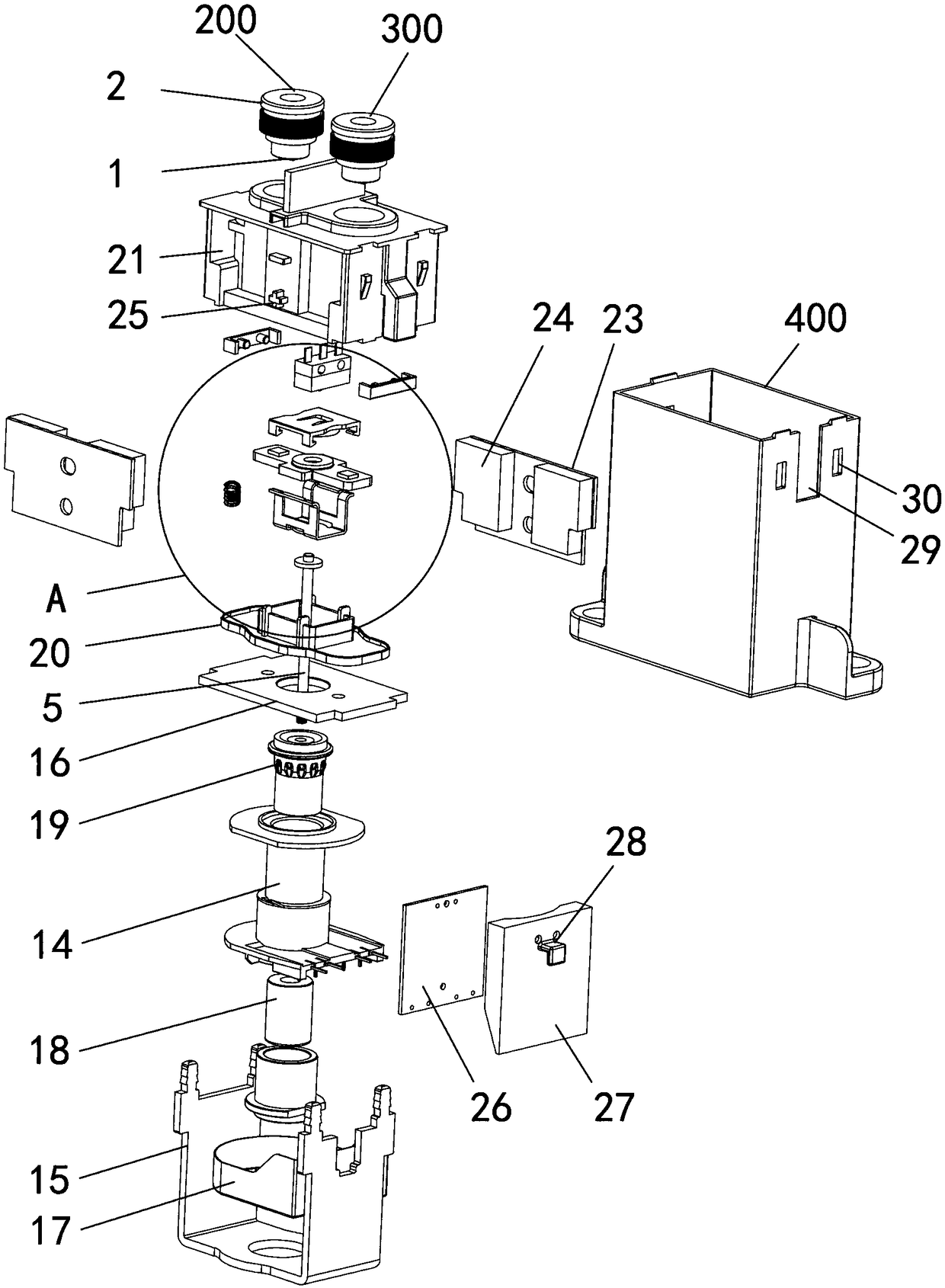

[0028] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

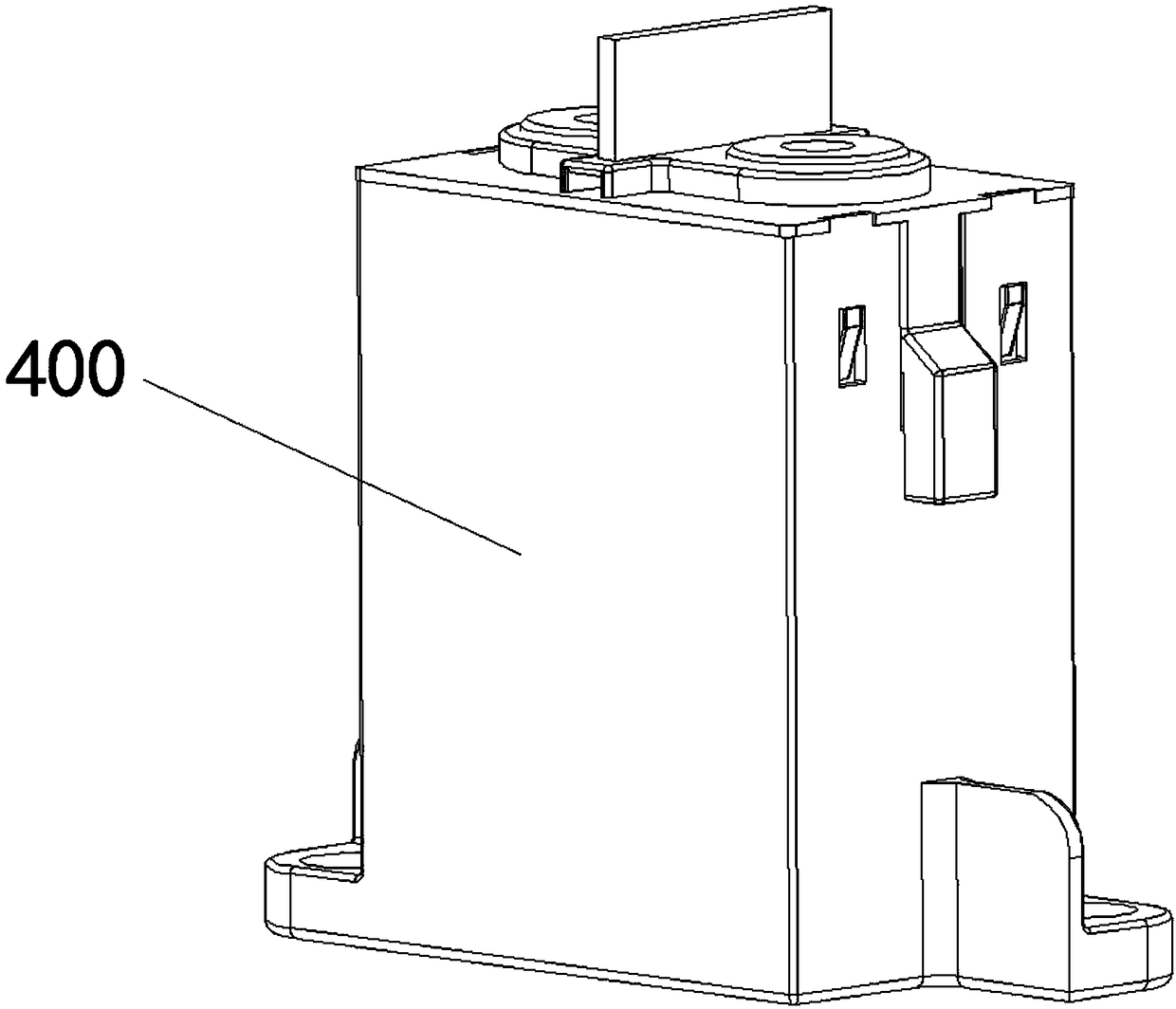

[0029] Such as Figure 1 to Figure 3 As shown, the present invention discloses a high-voltage DC circuit breaker, which includes a housing 400 and a contact chamber 100 and an electromagnetic conversion chamber 500 disposed therein. Like the prior art, a first contact member is arranged in the contact chamber 100 200 and the second contact member 300 , the first contact member 200 and the second contact member 300 have the same shape and both include a fixed point 1 arranged inside the contact chamber 100 and a lead-out end 2 arranged outside the contact chamber 100 .

[0030] The first contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com