Spring support of condenser of 1,000MW nuclear power unit

A technology of spring support and nuclear power unit, applied in the direction of low internal friction spring, spring/shock absorber, coil spring, etc., can solve the problems of poor stability, small load bearing, and large overall weight of condenser, and achieve stable Good performance and meet the support requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

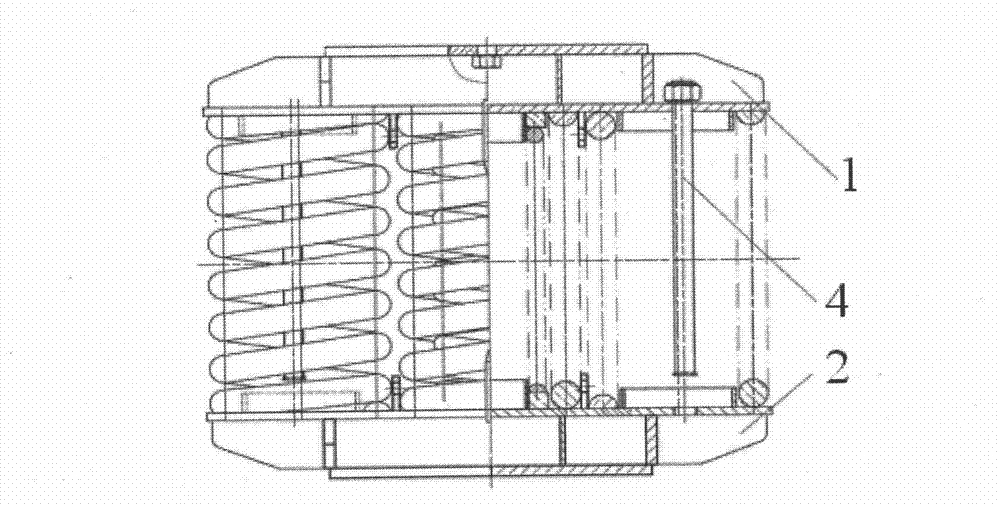

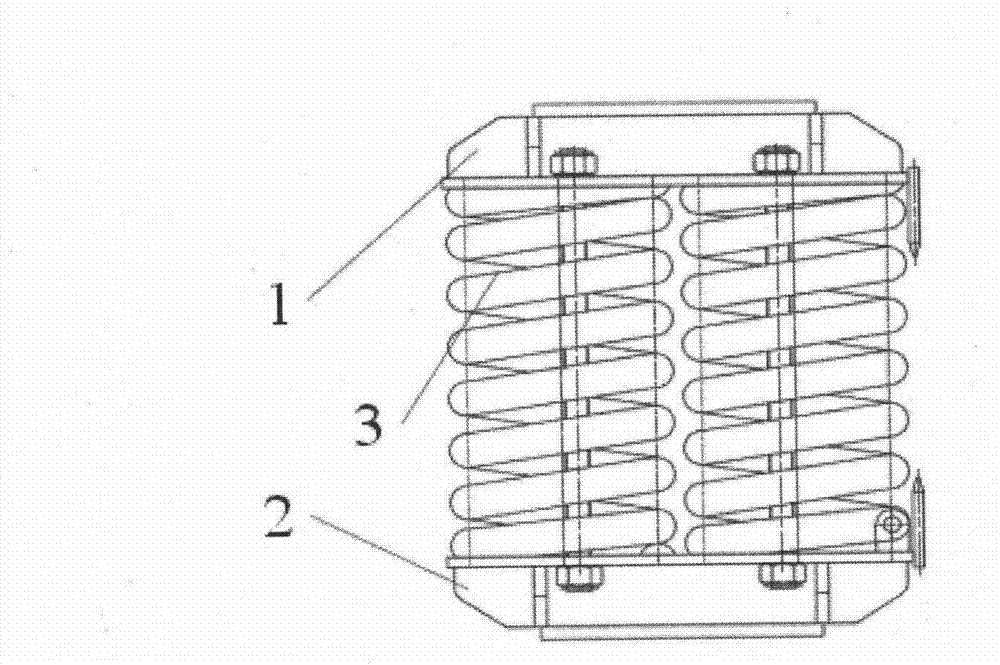

[0016] figure 1 and figure 2 It is respectively a front view and a side view schematic diagram of a 1000MW nuclear power unit condenser spring support provided by the present invention. The described a 1000MW nuclear power unit condenser spring support includes a lower casing 1 and a The upper casing 2 and the spring assembly 3 are installed between the lower casing 1 and the upper casing 2 .

[0017] The spring group 3 is composed of six large springs and N (0≤N≤6) small springs, the diameter D of the large springs ranges from 28mm≤D≤84mm, and the diameter d of the small springs ranges from 16mm≤d≤48mm. Six large springs are arranged in two rows and three columns. The number of small springs can be selected according to the load requirements of the condenser. The number ranges from 0 to 6. The small springs are arranged inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com