Hollow floorslab core mold fixing device and construction method thereof

A technology of hollow floor slabs and fixing devices, which is applied to floors, building components, buildings, etc. It can solve the problems of heavy workload, easily damaged mandrel repair workload, low overall rigidity of steel mesh, etc., and achieve balanced force and simple structure , Improve the effect of vertical stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

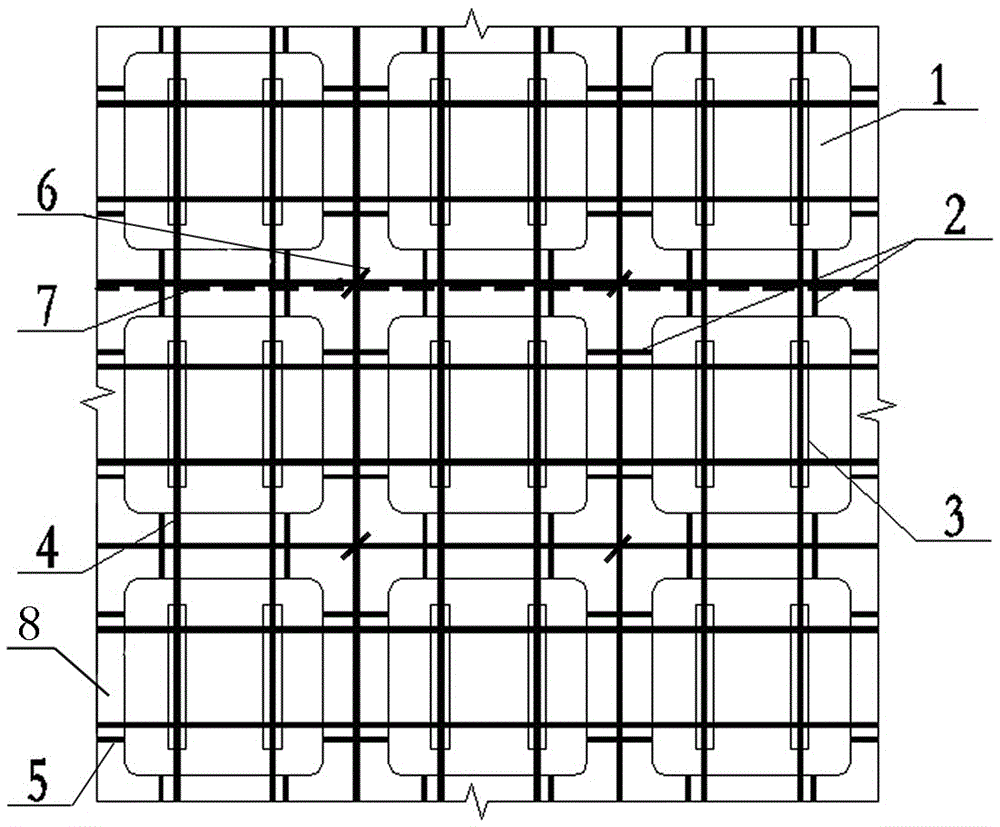

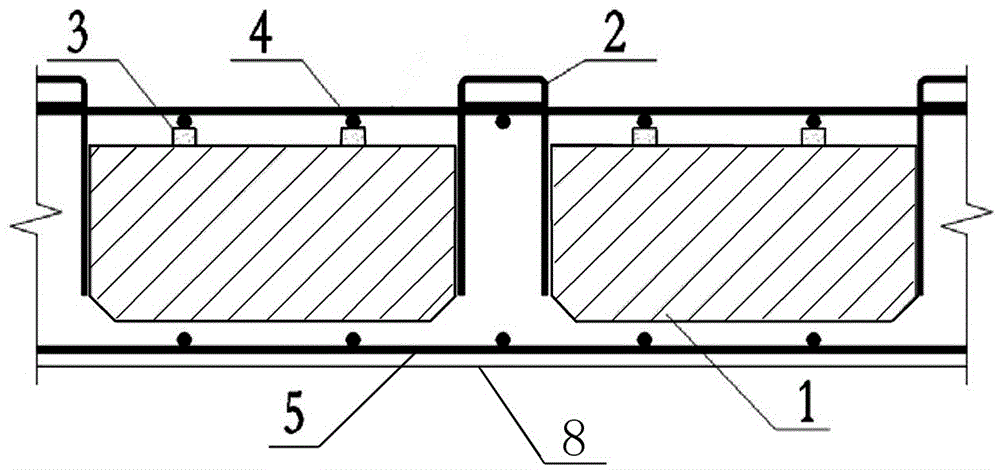

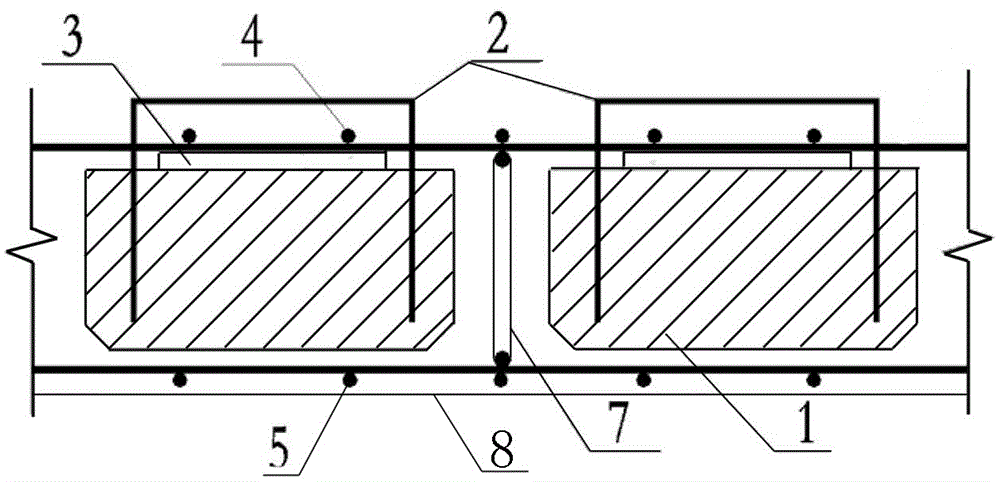

[0047] The fixing method of the mandrel provided by the present invention mainly includes setting a vertical support 7, a plain concrete block 3 and a steel bar fixture 2, which can effectively ensure that the mandrel does not float, deviate, or be damaged when pouring concrete, and can ensure The mandrel spacing and the concrete thickness above and below the mandrel meet the design requirements.

[0048] see you later figure 1 , the constraint mechanism to control the floating of mandrel 1 is: buoyancy of mandrel 1 → plain concrete pad 3 → slab top reinforcement mesh 4 lower reinforcement → slab top reinforcement mesh 4 upper reinforcement → vertical support 7 → slab bottom reinforcement mesh 5 → Fixed to the base mold. The plain concrete spacer 3 adopts a strip shape, which can ensure that the mandrel 1 is evenly and steadily stressed, and can be easily fixed with the steel mesh 3 on the top of the slab.

[0049] like Figure 1-9As shown, this hollow floor mandrel fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com