Coal mine large-caliber solid material vertical feeding buffer device

A technology for solid materials and buffer devices, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of inconvenient maintenance, incompetence for high-strength feeding requirements of large-diameter feeding wells, and complex structure of underground buffer devices, etc. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

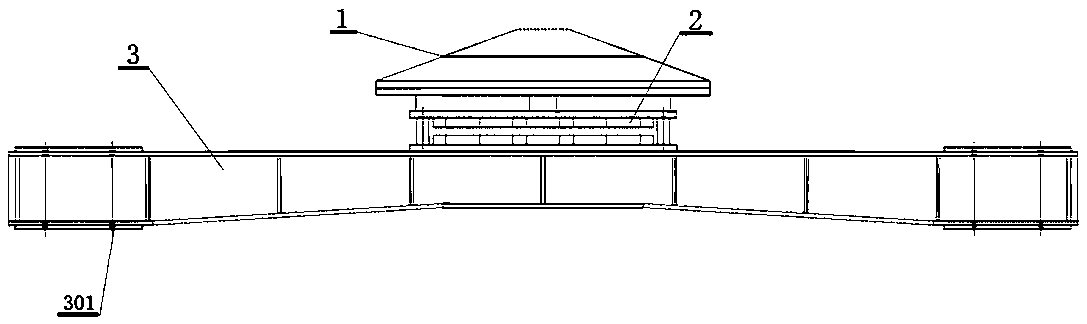

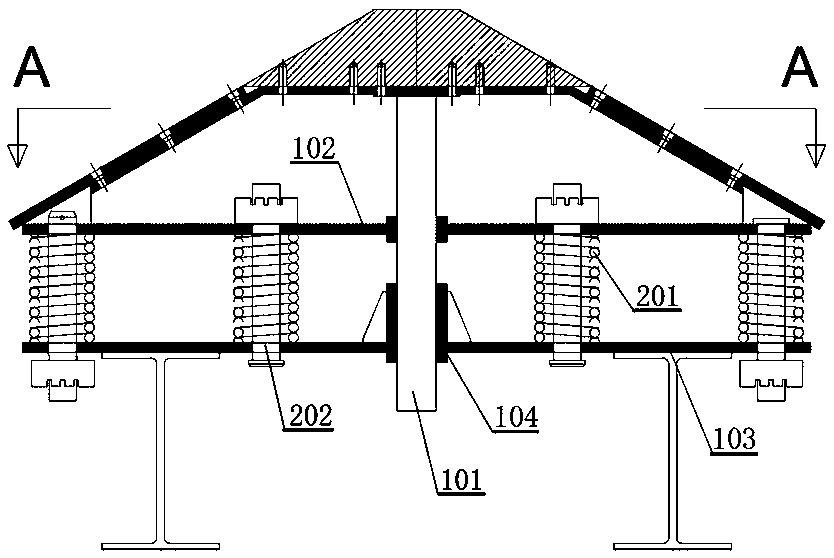

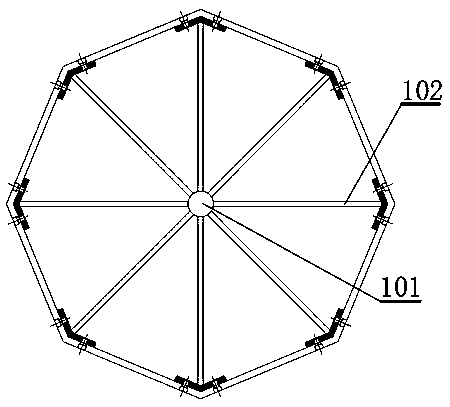

[0021] Such as figure 1 As shown, the present embodiment provides a large-diameter solid material vertical feeding buffer device for coal mines, including a protective cover 1, an energy storage shock absorbing device 2 and a bridge-type shock absorbing beam 3, such as figure 2 As shown, the protective cover 1 is conical, and the top is a platform surface, which can effectively buffer the blanking and make it fall after deceleration. The radius of the orthographic projection circle of the conical surface of the protective cover is 1.5m, and the inclination angle of the conical surface is -60°, the top of the conical protective cover is fixed vertically downward to set the guide shaft 101, such as image 3 As shown, the guide shaft is connected to the wall of the protective cover through several fixed brackets 102; the bottom of the protective cover 1 is welded with a buffer base 103, and the center of the buffer base is vertically provided with a guide sleeve 104, and the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com