Yarn correction device for spinning

A technology of yarn and slider, which is applied in the direction of textiles and papermaking, transportation and packaging, and delivery of filamentous materials, etc. It can solve the problems of affecting the quality of fabrics, different heights and angles, secondary wear of yarns, etc., to avoid Effects of wear, slip prevention, and horizontal movement prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention;

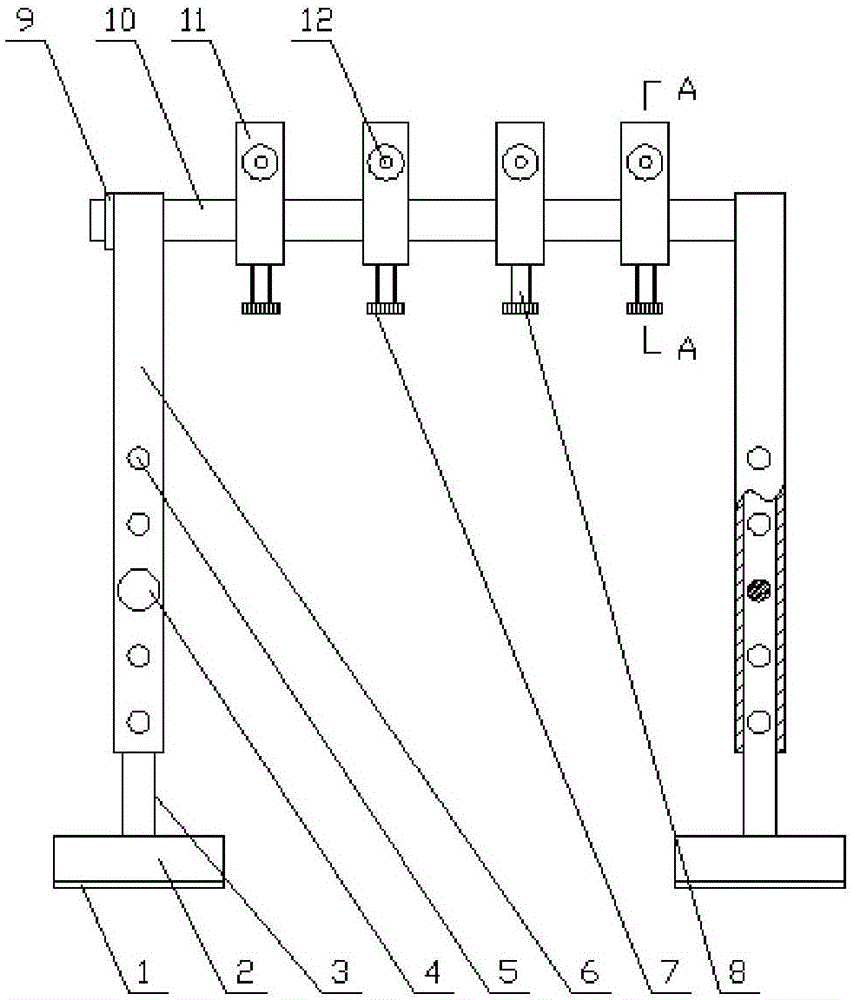

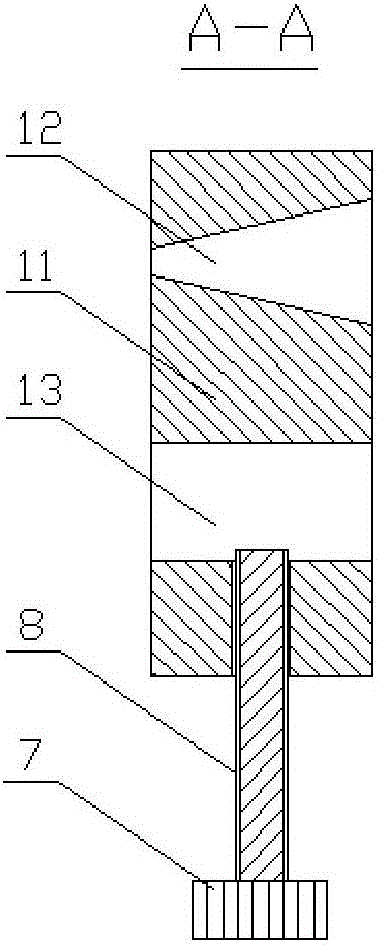

[0022] Such as figure 1 , figure 2 As shown, the yarn straightening device for weaving has a structure comprising a slide bar 10, the slide bar 10 is a cylindrical structure, and the slide bar 10 is used to provide a sliding track for the slide block 11 during use; the slide bar 10 passes through two ends. The first support 6 and the second support 3 are supported, and one side of the slide bar 10 runs through the first support 6, and the first support 6 and the second support 3 are used to provide stable support for the slide bar 10 during use; The bracket 3 is socketed inside the first bracket 6, and the first bracket 6 can be raised according to the height of the textile equipment during use, so that the slide bar 10 and the wire inlet of the textile equipment are in a horizontal plane; the first brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com