Gantry type numerical control hole manufacturing system used for airplane wing body abutting joint

A gantry-type, hole-controlled technology, which is used in manufacturing tools, boring/drilling, drilling/drilling equipment, etc. The effect of precise positioning and micro-adjustment, good adaptability and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

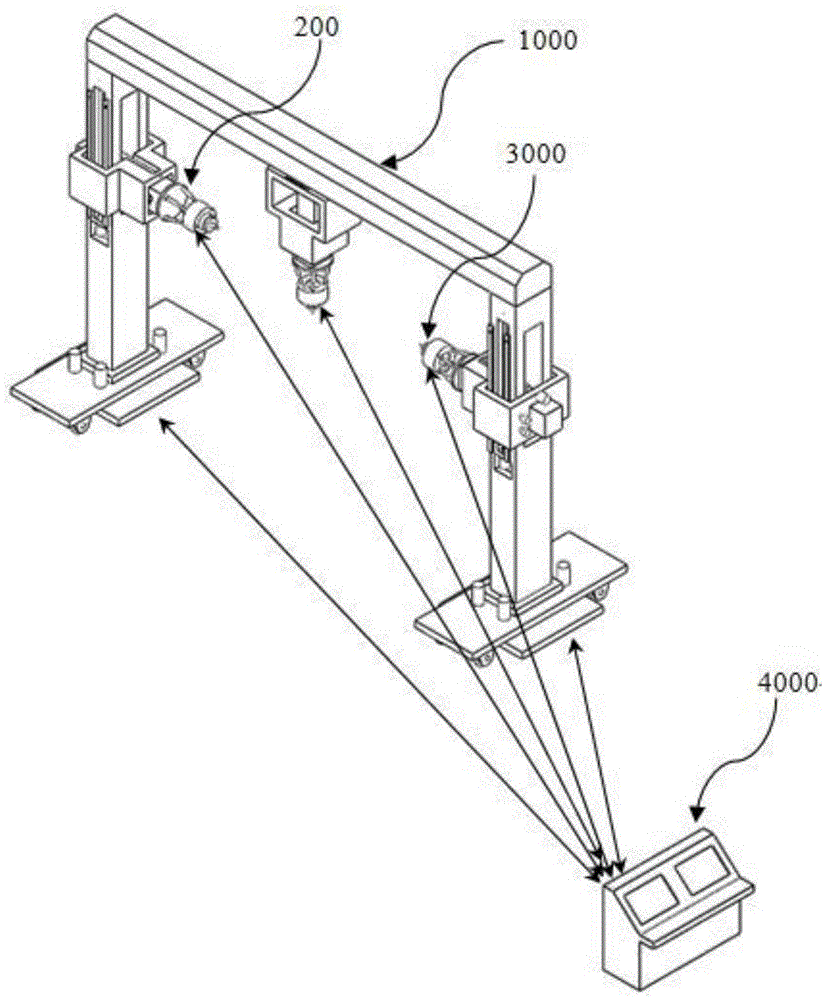

[0028] like figure 1 As shown, the gantry-type digital control hole system for aircraft wing body docking provided by the present invention includes: a gantry bracket assembly 1000 , three four-bar attitude-adjusting mechanisms 2000 and three terminal hole-making units 3000 .

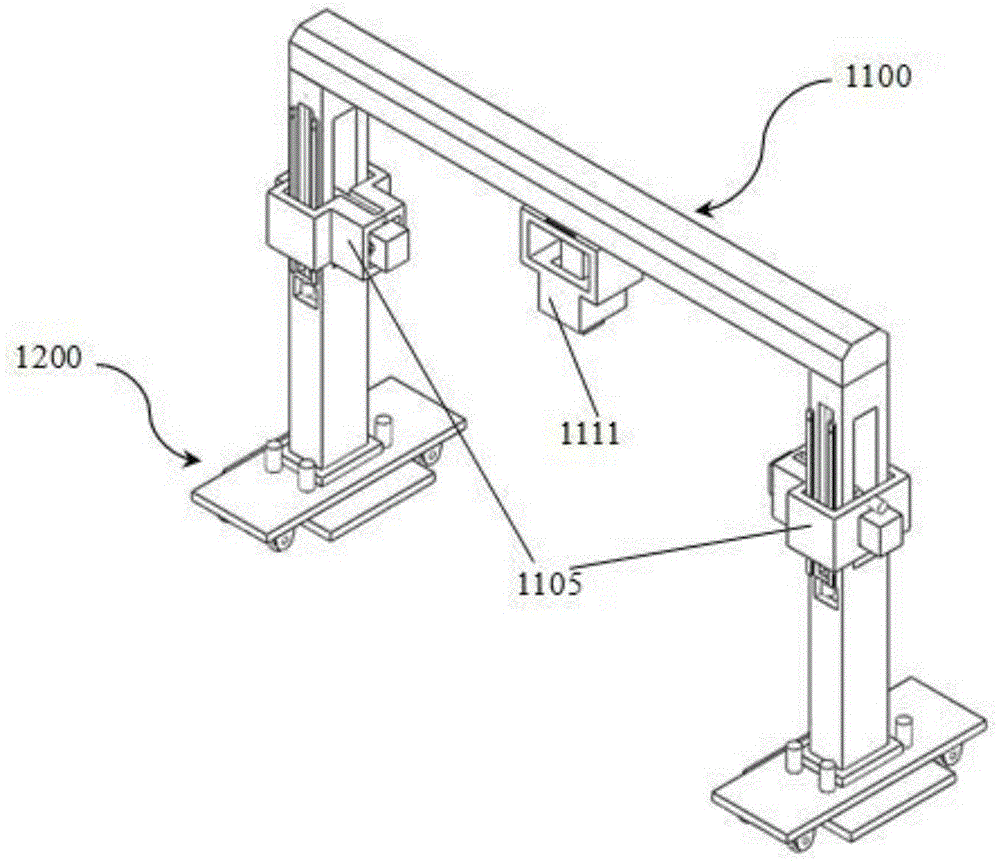

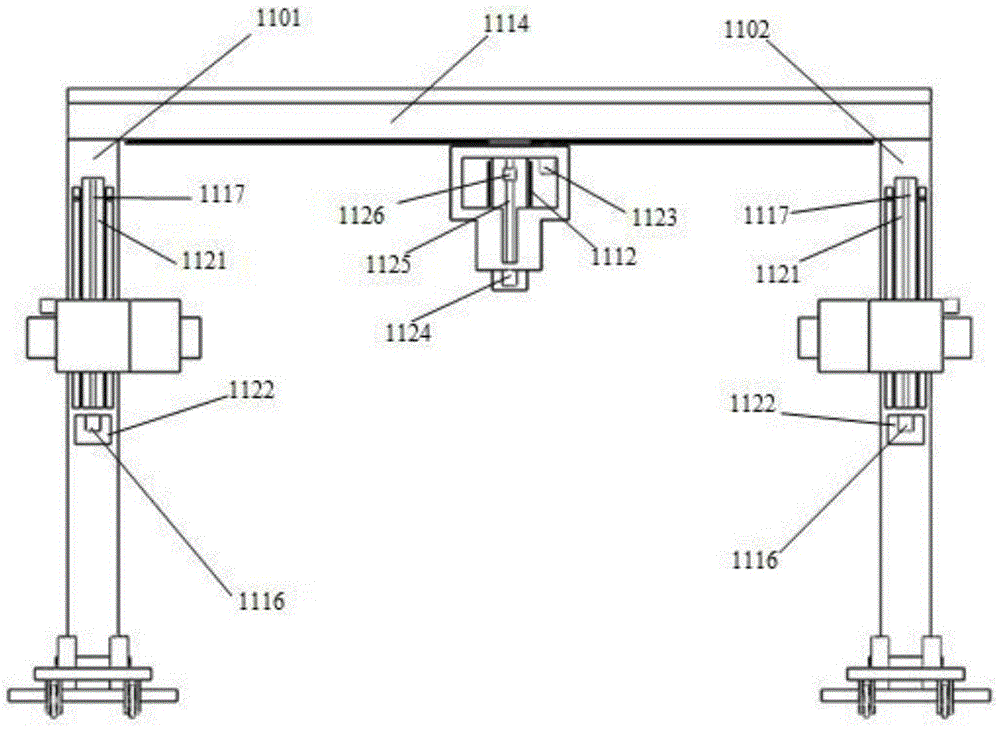

[0029]like Figure 1-7 As shown, the gantry bracket assembly 1000 includes a door-shaped bracket 1100, two vertical lifting devices and a horizontal sliding device; the door-shaped bracket 1100 is composed of a left column 1101, a right column 1102 and a crossbeam 1114; the two vertical lifting devices are slidingly installed On the left column 1101 and the right column 1102, the horizontal sliding device is slidably installed on the beam 1114; a horizontally telescopic ram 1008 is provided on the two vertical lifting devices, and a vertically telescopic ram 1008 is provided on the horizontal sliding device. Ram 1008.

[0030] like Figure 8 As shown, the four-bar attitude adjustment mechanism 2000 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com