Fabricated pre-embedded assembly for beam and wall connecting and using method thereof

A prefabricated and pre-embedded technology, which is applied in the direction of construction and building construction, can solve the problems of large hydropower consumption, unfavorable energy conservation and environmental protection, and flying dust, and achieve the effect of convenient and fast connection, avoiding construction waste, and avoiding horizontal movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

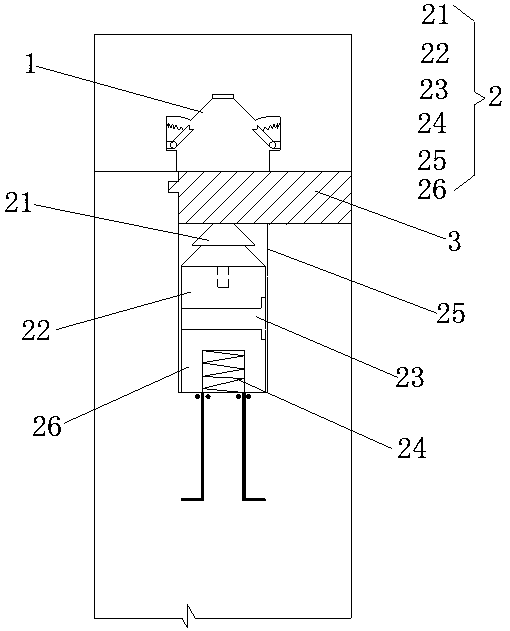

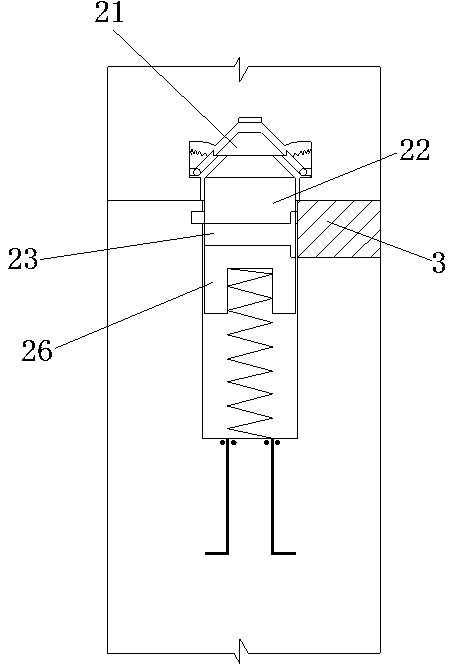

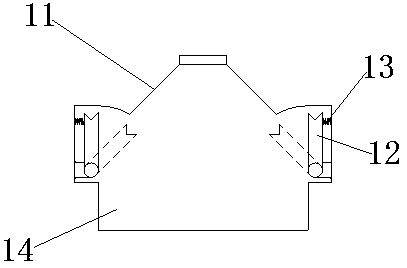

[0035] Such as figure 1As shown, a prefabricated pre-embedded assembly for connecting beams to walls, including beam clips 1 for pre-embedded beams and wall clips 2 for pre-embedded walls; the wall clips 2 includes a wall clamp housing 25, one end of the wall clamp housing 25 is a closed end, and the other end is an open end; inside the wall clamp housing 25, from the closed end to the open end, there are successively The ejection piece, the shear piece 22 and the chuck 21 that can be clamped on the beam clip 1; the shear piece 22 is connected to the ejection piece through an intermediate connecting piece 23, and the chuck 21 is connected to the shear piece 22 Above; the ejection member includes an ejection spring 24, and the ejection spring 24 can be compressed along the direction from the open end of the wall clip housing 25 to the closed end, and can be compressed along the direction from the closed end of the wall clip housing 25 to the closed end. The direction of the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com