Matt waterproof ink-jet printing supplies coating machine

An inkjet printing and coating machine technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of non-waterproof, difficult to dry, uneven squeegee, etc., and achieve low cost, uniform squeegee, running stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

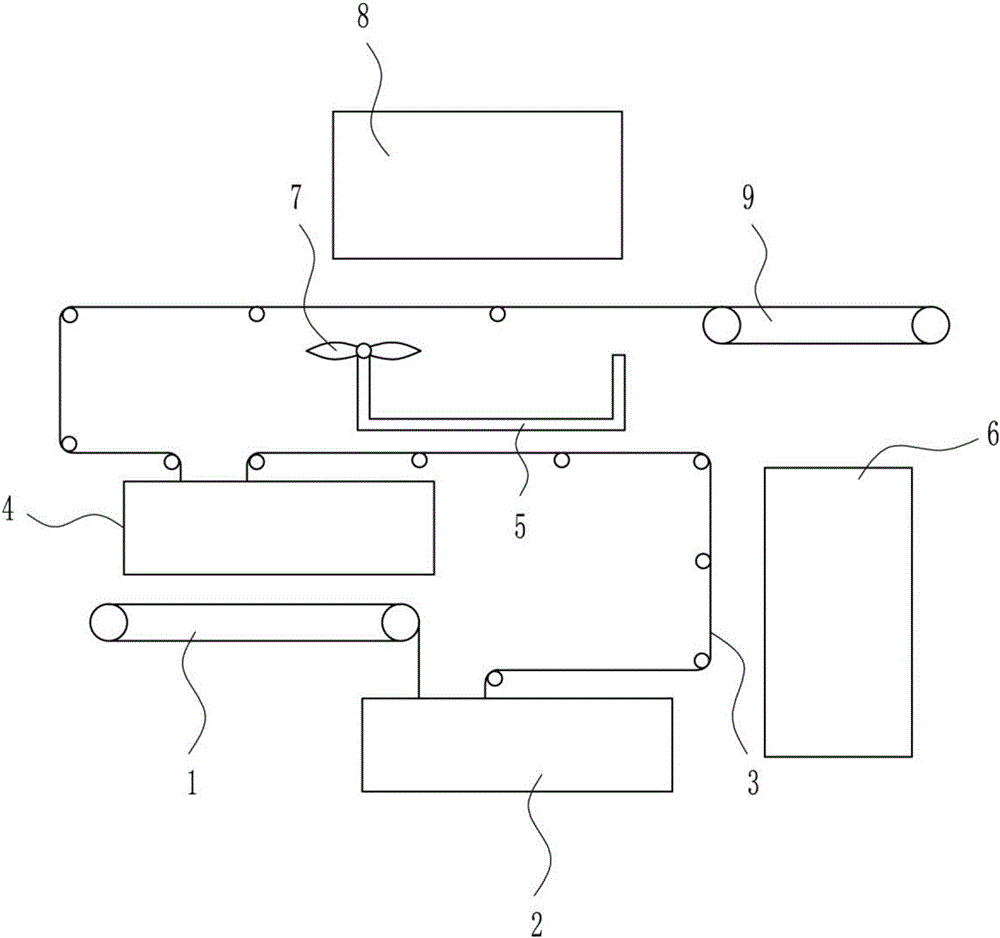

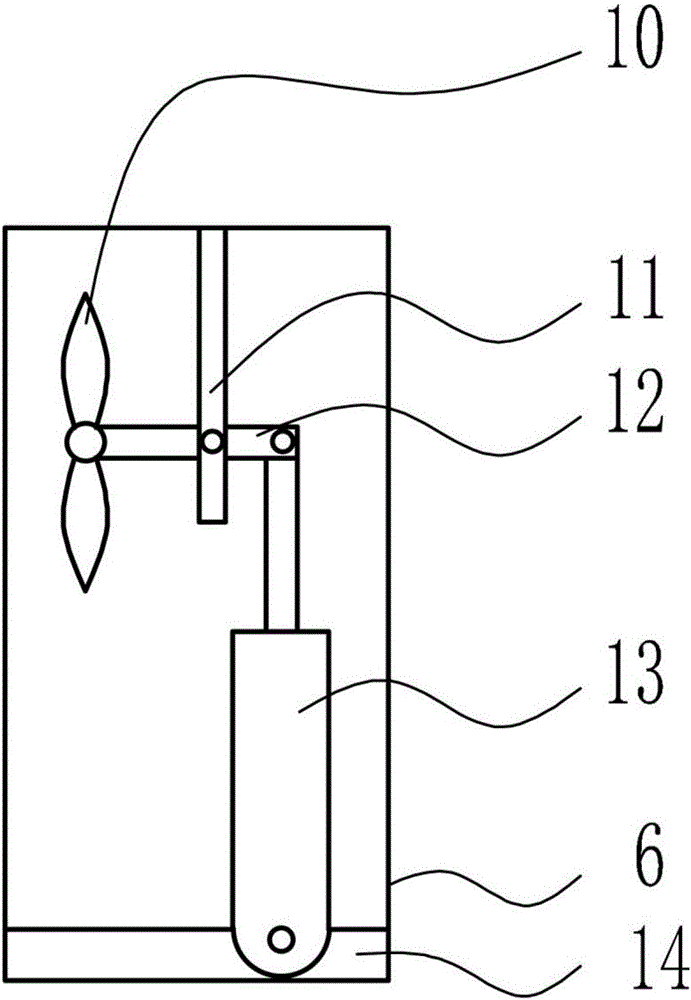

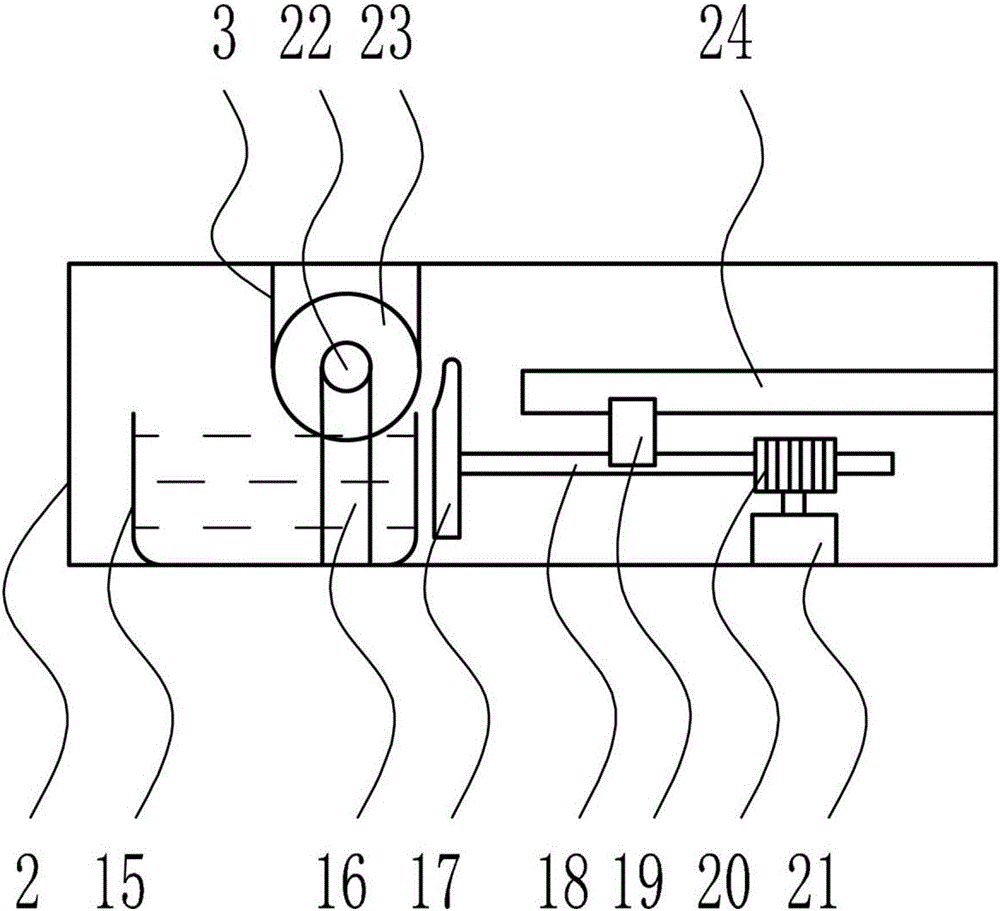

[0034] A matte waterproof inkjet printing consumable coating machine, such as Figure 1-6 As shown, it includes a first conveying device 1, a first gluing device 2, a second gluing device 4, a support plate 5, a first drying device 6, a second hot air blower 7, a second drying device 8 and a second conveying device. Device 9, the first drying device 6 includes a first hot air blower 10, a fixed rod 11, a connecting rod 12, an electric push rod 13 and a fixed plate 14, and the first gluing device 2 includes a glue tank 15, a pole 16, Squeegee stick 17, rack 18, slide block 19, gear 20, first motor 21, second motor 22, coating roller 23 and slide rail 24; The internal structure of the first drying device 6 and the second drying device 8 are identical , the internal structure of the first gluing device 2 and the second gluing device 4 is the same, the first gluing device 2 is provided on the lower right of the first conveying device 1, and the bottom of the first gluing device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com