Transfer printing type glue dispensing method

A technology of pad printing and glue dispensing, which is applied in the direction of spraying devices, coatings, and devices for coating liquid on the surface, etc. It can solve the problems of excessive glue volume, unqualified products, semi-finished products overflowing glue, etc., and achieve the effect of uniform glue volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical content and detailed description of the present invention are described as follows in conjunction with the accompanying drawings.

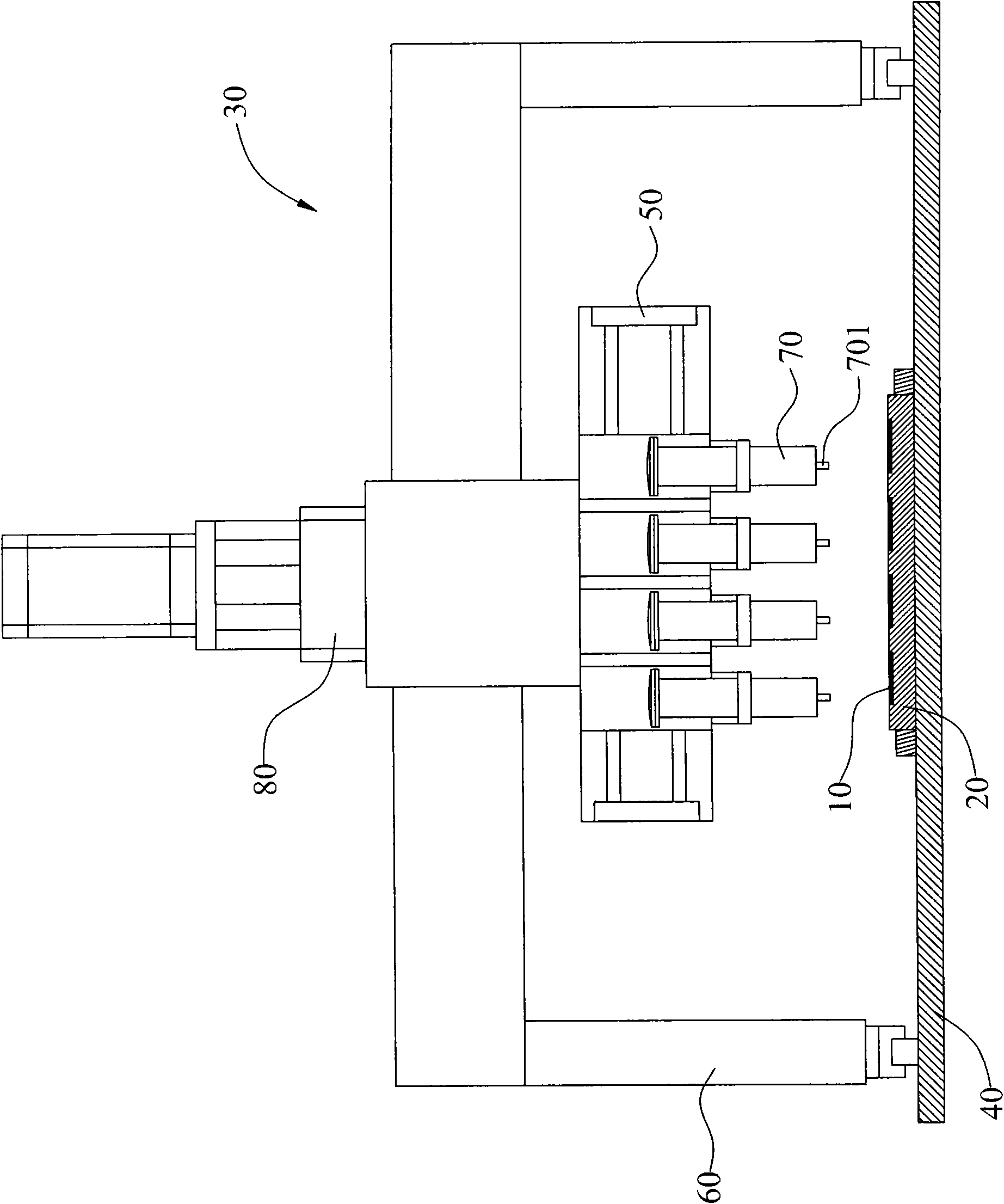

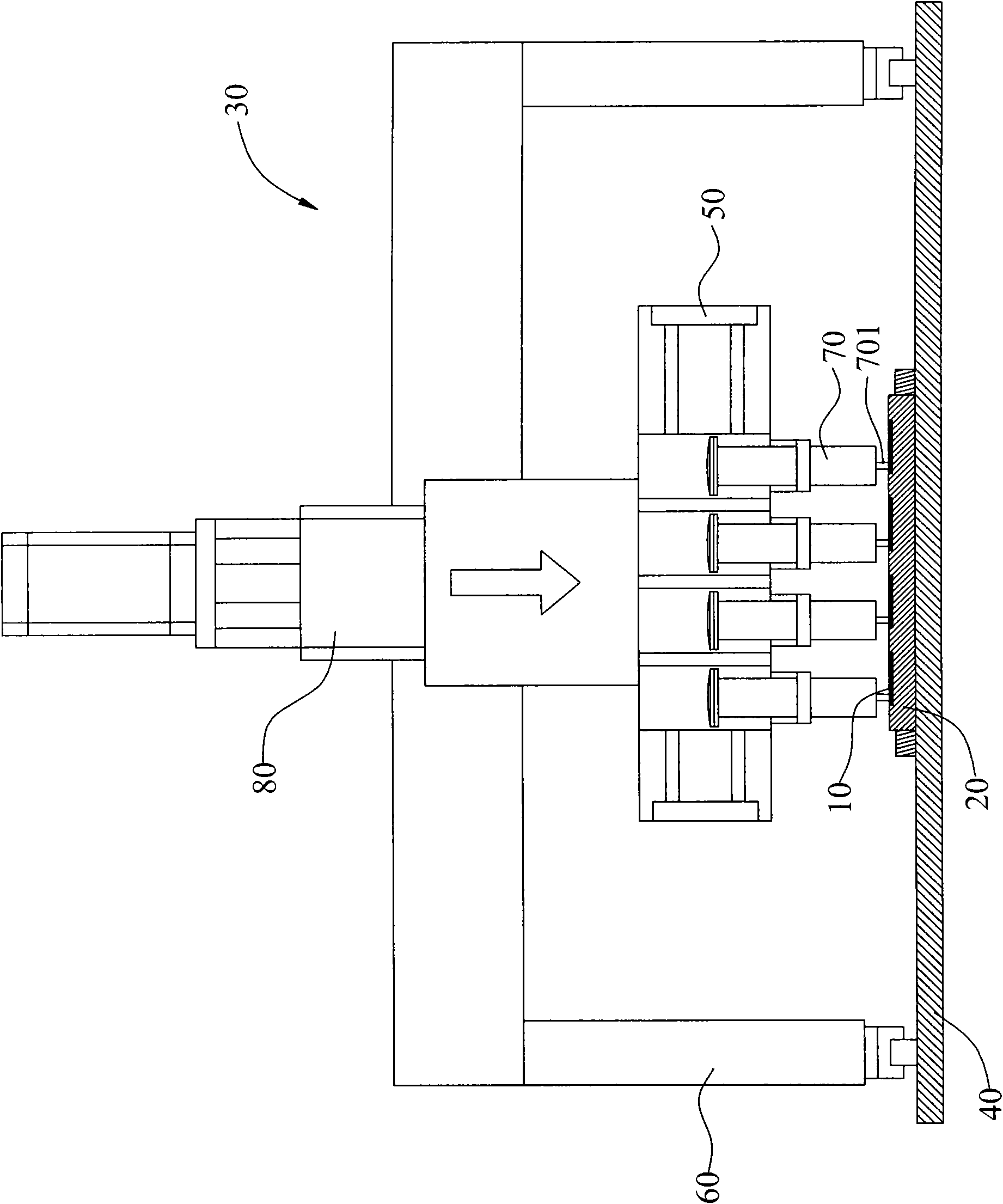

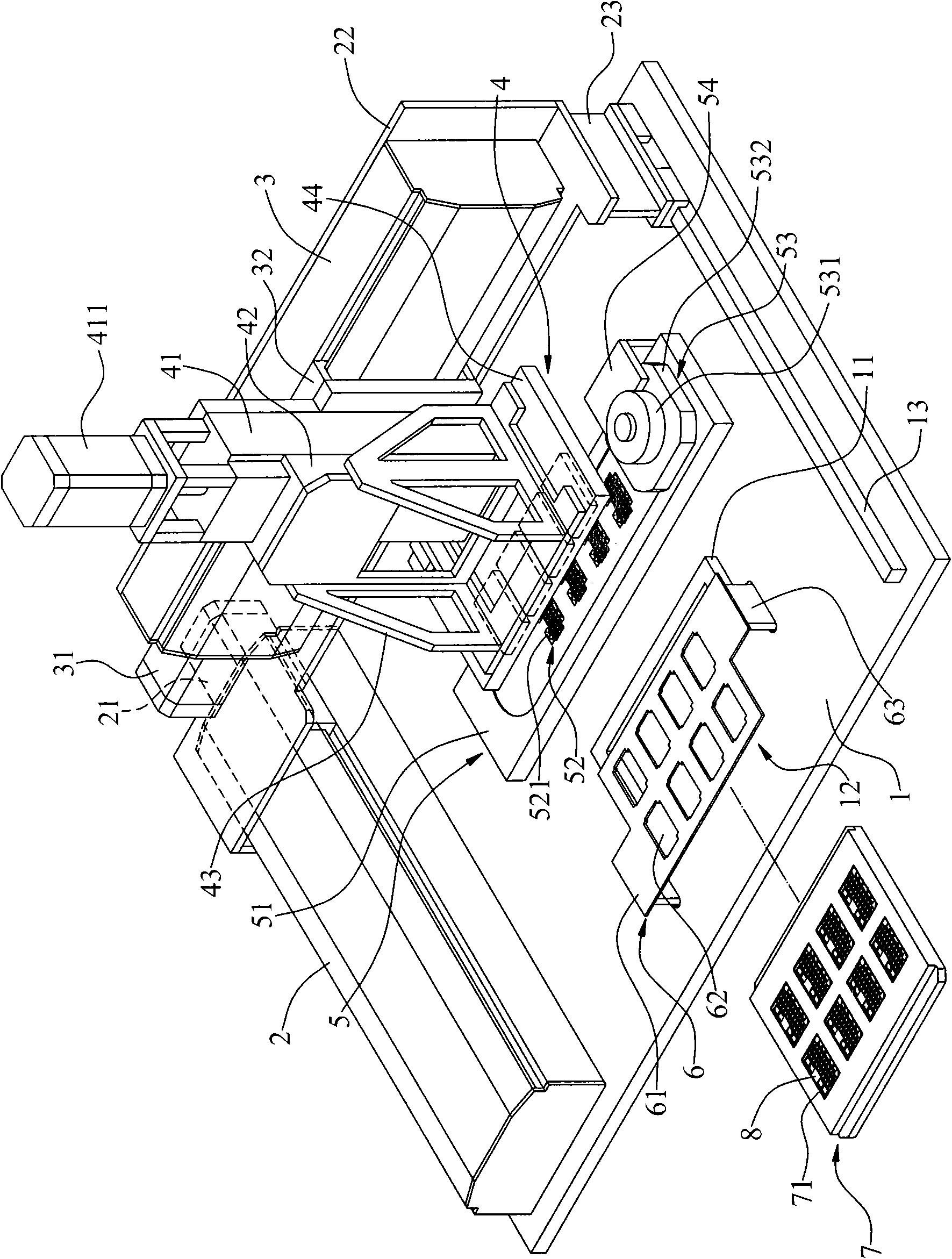

[0054] refer to Figure 2a , Figure 2b , are respectively the three-dimensional schematic diagram and the anvil block side view schematic diagram of the pad printing type glue dispenser of the present invention. Such as Figure 2a , Figure 2b Shown: the pad printing dispensing method of the present invention has a glue dispensing machine, which includes: a loading platform 1, a Y-axis moving mechanism 2, an X-axis moving mechanism 3, a pad printing module 4, a glue storage mechanism 5, The pressing mechanism 6 and the clamp plate 7.

[0055] The carrying platform 1 is arranged on the glue dispenser, and has a flat-bottomed inverted U-shaped convex strip 11 on it, and the convex strip 11 encloses a placement area 12 for placing the fixture disc 7 . In addition, a slide rail 13 is provided on the convex line 11 side.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com