Detachable type linear sliding rail dustproof belt

A technology of linear slide rails and dust-proof belts, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problems of easy warping of dust-proof belts and limited application scope of dust-proof belts, and increase the scope of application. , Good dustproof effect, strong connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

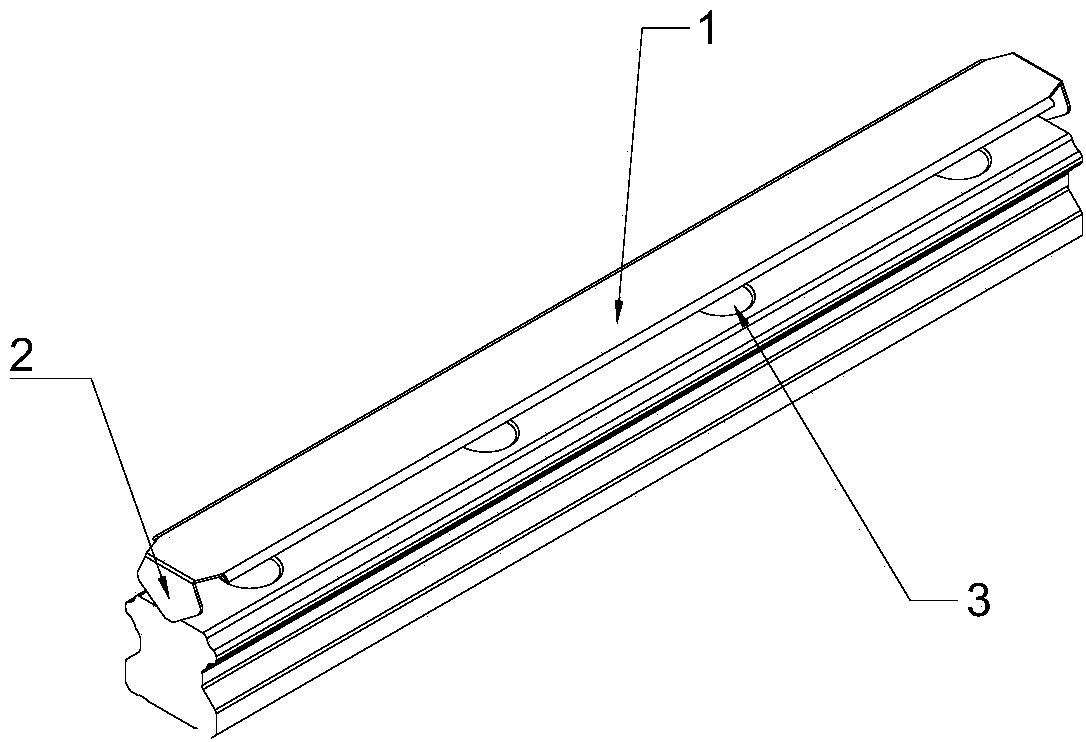

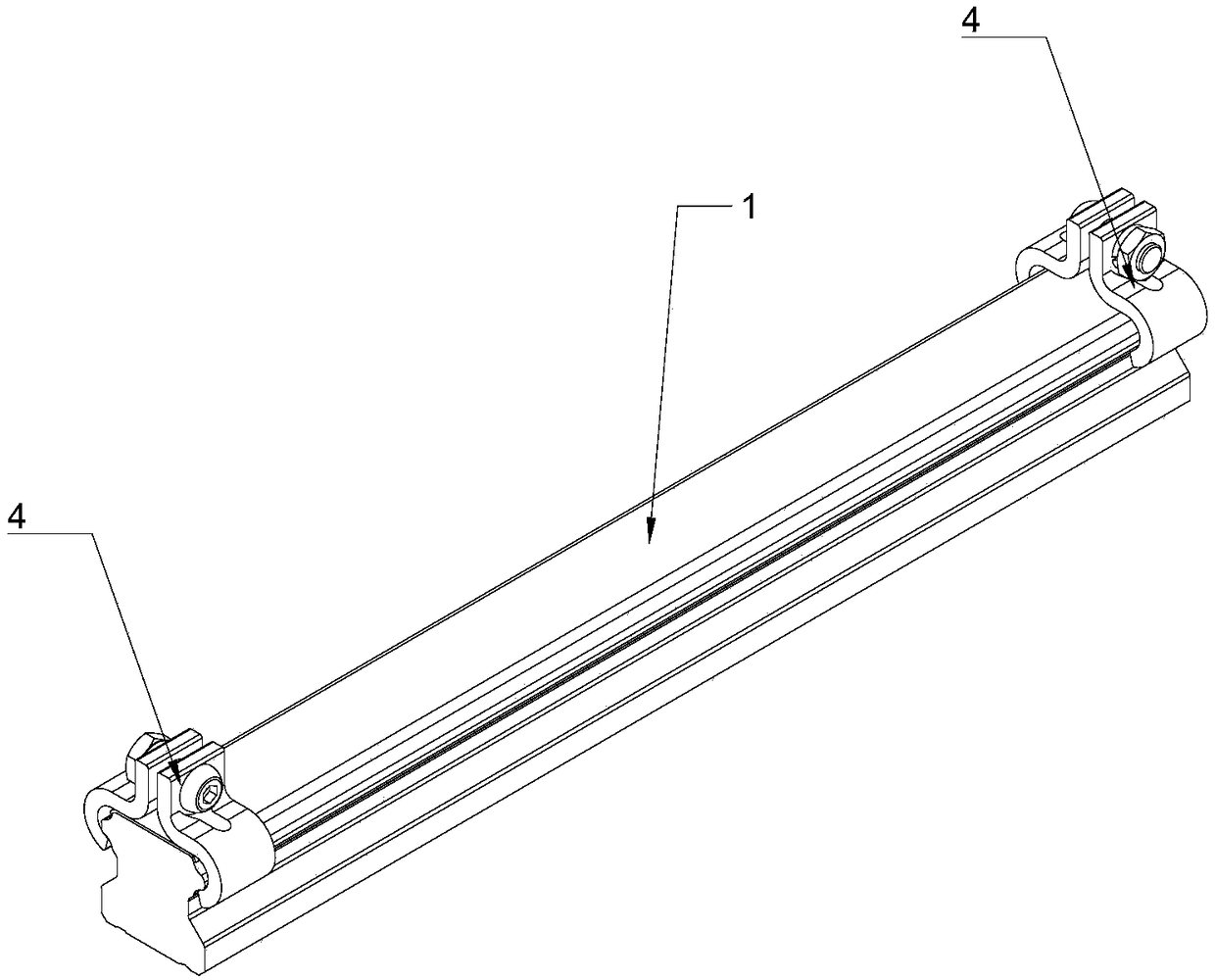

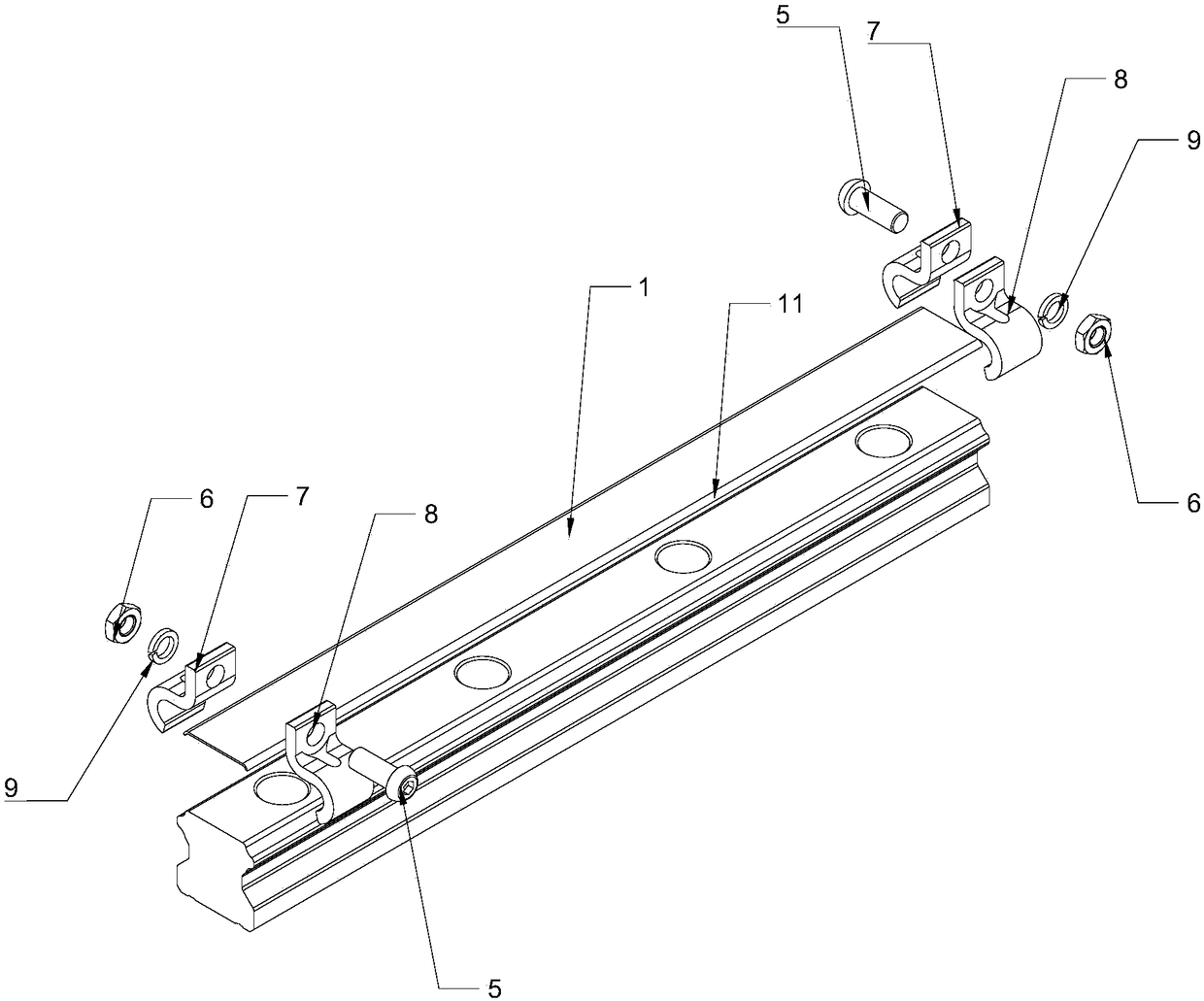

[0021] figure 2 It is a structural schematic diagram of an embodiment of the detachable linear slide rail dust belt of the present application, image 3 for figure 2 The exploded view of the structure of the detachable linear slide rail dust strip, combined with figure 2 and image 3 As shown, the detachable linear slide rail dust-proof belt includes a belt body and fixing components located at both ends of the belt body, wherein the belt body 1 covers the track surface (hereinafter referred to as the track surface) provided with screw fixing holes 3, and the belt body The size of 1 matches the size of the track surface that is provided with screw fixing holes 3. The belt body 1 covers the track surface, covers the screw fixing hole 3 on the track surface, and prevents foreign matter such as dust from entering the screw fixing hole 3, thereby preventing foreign matter such as dust from entering the moving area of the rolling element.

[0022] The size of the belt body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com