Wind-powered main shaft forging method

A wind power spindle and flange technology, applied in the field of forging production, can solve the problems of low forging precision, complicated process, high energy consumption, etc., and achieve the effect of improving forging quality, improving work efficiency and saving forging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Forging process of 1.5MW wind power main shaft, including steps:

[0033] a. The selected steel ingot must be the raw material of the steel ingot smelted by electric furnace smelting + LF (outside furnace refining) + VD (vacuum degassing) smelting process. The selected material is 34CrNiMo6, which conforms to DIN EN 10083-3, and guarantees that S≦0.15%, P≦0.20%, where [H]≦2.0ppm; [O]≦25ppm. For raw material steel ingots, the steelmaking plant conducts hot delivery of hot steel ingots according to the "Steel Ingot Hot Transport Regulations".

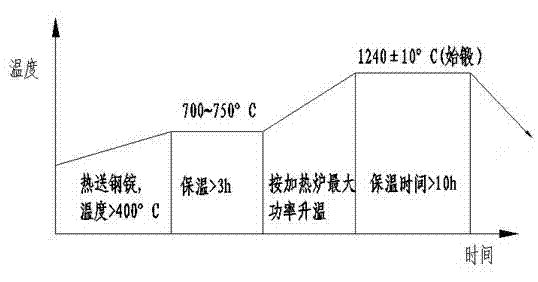

[0034] b, according to figure 2 , using hot steel ingots with a surface temperature greater than 400°C delivered by hot delivery from the steelmaking plant. The heating process is as follows: heat preservation at a furnace temperature of 700°C to 750°C for more than 3 hours, and then raise the temperature to 1240°C according to the maximum power of the heating furnace. ±10°C, keep warm for more than 10 hours;

[0035] c, accord...

Embodiment 2

[0043] The forging method of 2MW wind power main shaft, including steps:

[0044] a. The selected steel ingot must be the raw material of the steel ingot smelted by electric furnace smelting + LF (outside furnace refining) + VD (vacuum degassing) smelting process. The selected material is 42CrMo4, according to the requirements of the standard SEW550-1976, 0.40%≤C≤0.45%, Si≤0.40%, 0.60%≤Mn≤0.80%, S≤0.15%, P≤0.20%, 1.00%≤Cr≤1.20 %, 0.45%≤Ni≤0.60%, 0.18%≤Mo≤0.30%, where [H]≤2.0ppm; [O]≤25ppm.

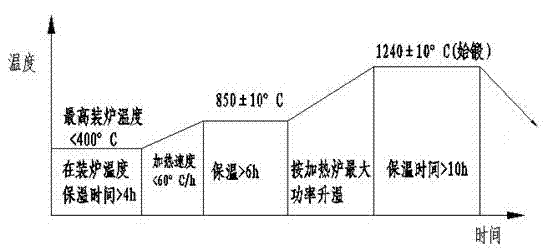

[0045] b, according to figure 1 For cold steel ingots, the cold steel ingot heating process will be adopted: put steel ingots with a surface temperature of less than 400°C into a hot furnace with a maximum charging furnace temperature lower than 400°C, keep them at the charging temperature for more than 4 hours, and then heat to 850±10°C, the temperature increase per hour is less than 60°C, and then keep warm for more than 6 hours, then raise the temperature to 1240±10°C according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com