Angle cutting machine

A technology of oblique cutting machine and cutter, which is applied in metal processing and other directions, can solve the problems of affecting product appearance and quality, low work efficiency, and many surface lines, and achieve the effect of improving appearance and quality, improving work efficiency, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

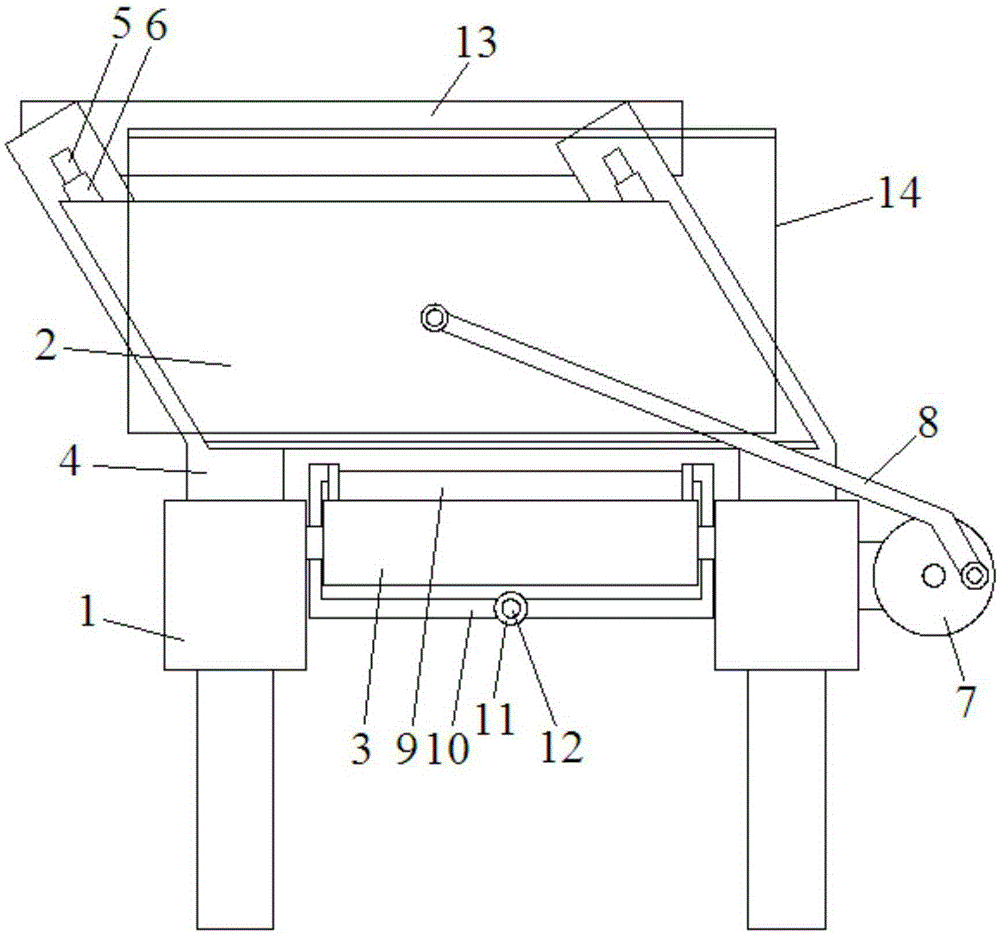

[0014] see figure 1 , a kind of oblique cutting machine, comprises frame 1, cutter 2 and workbench 3, and the both sides of frame 1 are respectively fixedly connected with left and right pillar 4 inclined to the same side, and the fronts of left and right pillar 4 are respectively There are left and right guide pillars 5 fixedly connected, and left and right guide bushes 6 are fixedly connected to both sides of the back of the cutter 2 respectively, and the left and right guide bushes 6 are correspondingly set on the left and right guide pillars 5 respectively, and respectively correspond to the The left and right guide columns 5 move up and down; one side of the frame 1 is rotated with a runner 7, and the eccentric position of the runner 7 and the front of the cutter 2 are rotated and connected with a connecting rod 8; The push plate 9 sliding along its surface, the two sides of the push plate 9 are respectively fixedly connected with the left and right connecting rods 10 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com