Bending piece detection equipment

A technology for testing equipment and bending parts, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of equipment detection efficiency reduction, achieve high automation, improve work efficiency, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

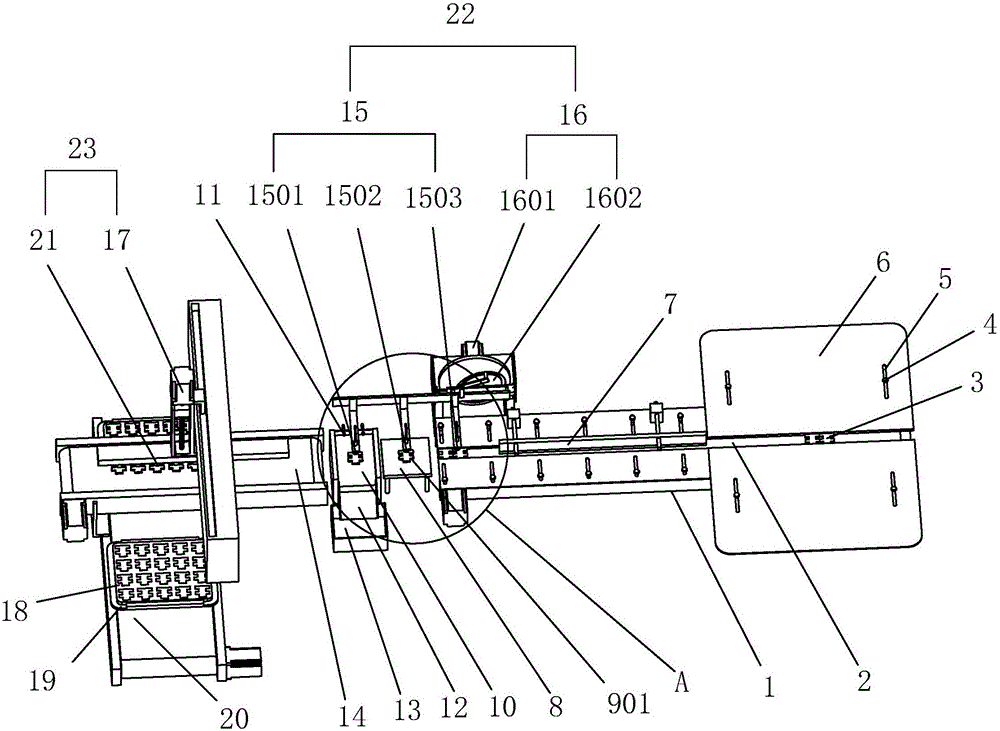

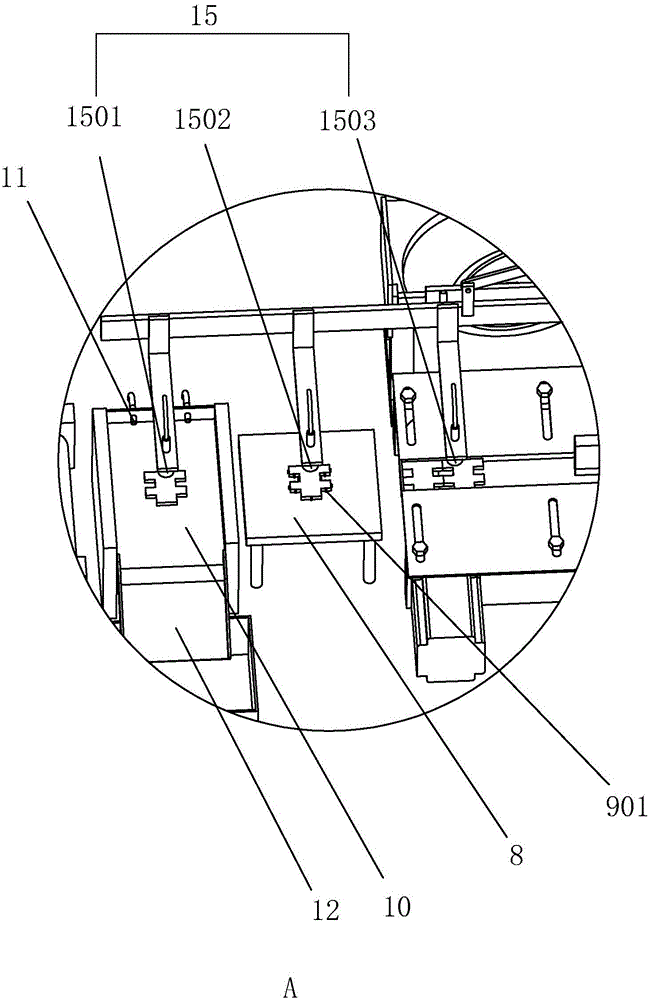

[0033] Embodiment 1: A kind of bending piece detection equipment, such as figure 1 and figure 2Shown, comprise frame 1, be provided with the feeding mechanism that is used for workpiece 3 feeding on frame 1, feed mechanism includes feed conveyer belt 2 and the drive motor that drives feed conveyer belt 2 to convey workpiece 3 (not shown in the figure ), drive the motor to work, and transfer the workpiece 3 on the feed conveyor belt 2 from one end of the feed conveyor belt 2 to the other end. The number is two and arranged oppositely, the opposite sides of the two limiting plates 6 are in contact with the front and rear sides of the workpiece 3, and a passage for the workpiece 3 to be conveyed on the feed conveyor belt 2 is formed between the two limiting plates 6, The workpiece 3 moves under the limit guide of the limit plate 6;

[0034] The two limiting plates 6 slide relative to each other or facing away from each other on the frame 1. During the relative sliding, the dis...

Embodiment 2

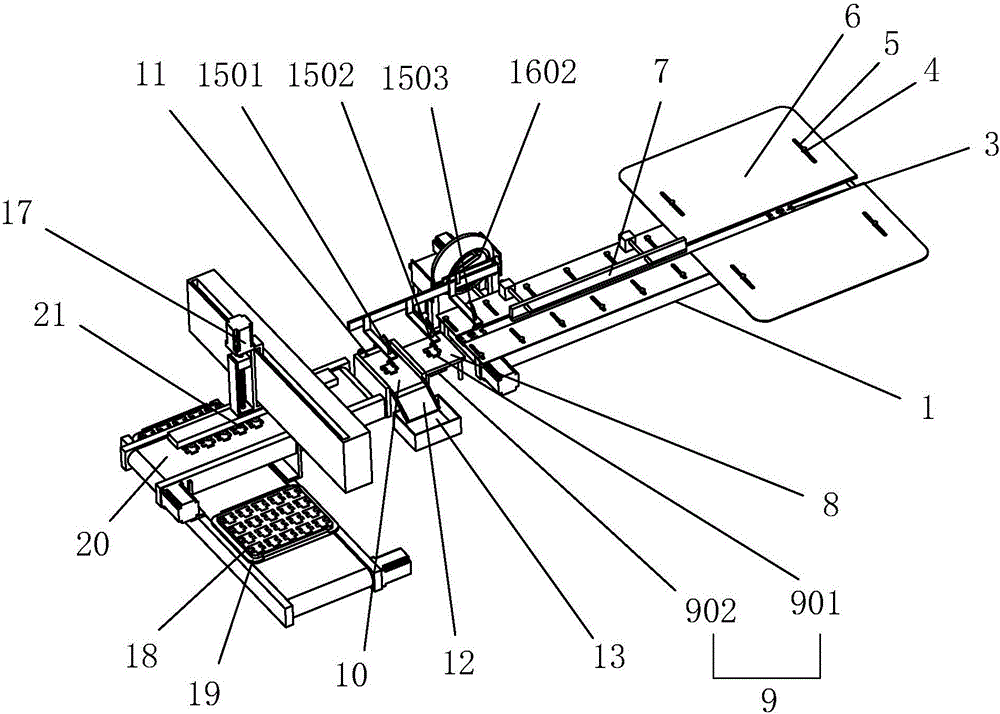

[0040] Embodiment 2: A kind of bending piece detection equipment, such as figure 1 As shown, the difference from Embodiment 1 is that the number of placement tables 19 is two, which are respectively located on the front and rear sides of the discharge conveyor belt 2. Correspondingly, the number of sliding plates 20 is two, and two swing plates Putting platform 19 is oppositely arranged, and when two sliding plates 20 slide relative or back-to-back on frame 1, can drive two placing platforms 19 to approach or stay away from, and the second carrying mechanism 23 can move the discharge conveyer belt 2 The workpieces 3 on the top are transported to two placement tables 19 in turn, which increases the placement efficiency of the equipment. After placing the container 18 on one of the placement tables 19, the placement on the other placement table 19 can be done. Put container 18 and put, increased the capacity of putting.

Embodiment 3

[0041] Embodiment 3: A kind of bending piece inspection equipment, such as image 3 As shown, the difference with Embodiment 1 is that, on the basis of Embodiment 1, a height-limiting plate 7 that restricts the workpiece 3 on the feed conveyor belt 2 from tilting upward is provided on the frame 1, and the height-limiting plate 7 is located at Directly above the workpiece 3 on the feeding conveyor belt 2, the workpiece 3 passes below the height limiting plate 7. During the conveying process of the feeding conveyor belt 2, the workpiece 3 is prone to tilt upwards in contact with the limiting plate 6. The high plate 7 abuts against the workpiece 3 to limit the upward tilt of the workpiece 3, so that the workpiece 3 can be stably transmitted on the feeding conveyor belt 2; the lower end surface of the height limiting plate 7 is provided with a wiping cushion, which is laid by sponge pad or gauze Formed, the wiping cushion layer is in contact with the upper surface of the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com