Automatic production complete plant for Maofeng tea

A complete set of equipment, the technology of Maofeng tea, applied in the field of automatic production of Maofeng tea complete sets of equipment, can solve the problems of waste of equipment resources, uneven quality, scattered processing, etc., to ensure flatness, good flatness, and difficult mesh belt distorted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

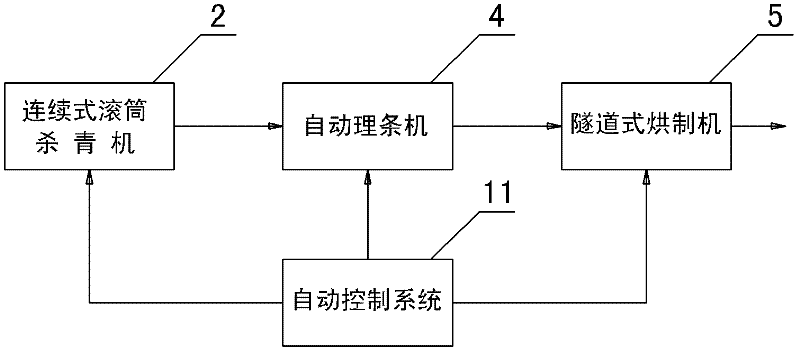

[0030] in figure 1 In the shown embodiment 1, a complete set of equipment for the automatic production of Maofeng tea, including the finishing, stripping and baking equipment of Maofeng tea. The finishing of Maofeng tea adopts a continuous roller finishing machine 2, and a continuous roller finishing machine. Connect the automatic organizer 4 (see Figure 5 ), the automatic sorting machine is connected to the tunnel drying machine 5 (see Image 6 ), the tunnel drying machine includes a frame 6 and a drying tunnel 7 with a closed structure on both sides of the frame. A heating device is provided on the top of the drying tunnel, and the heating device is a hot air device, including a belt There are infrared heating tubes 14 and a fan 15 with fins. The infrared heating tubes are arranged on the same level. The fans are arranged above the infrared heating tubes. A partition 19 is arranged below the infrared heating tubes. There are two ventilation holes; the top of the baking tunnel...

Embodiment 2

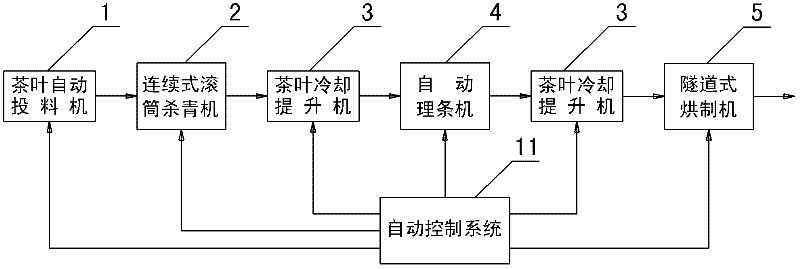

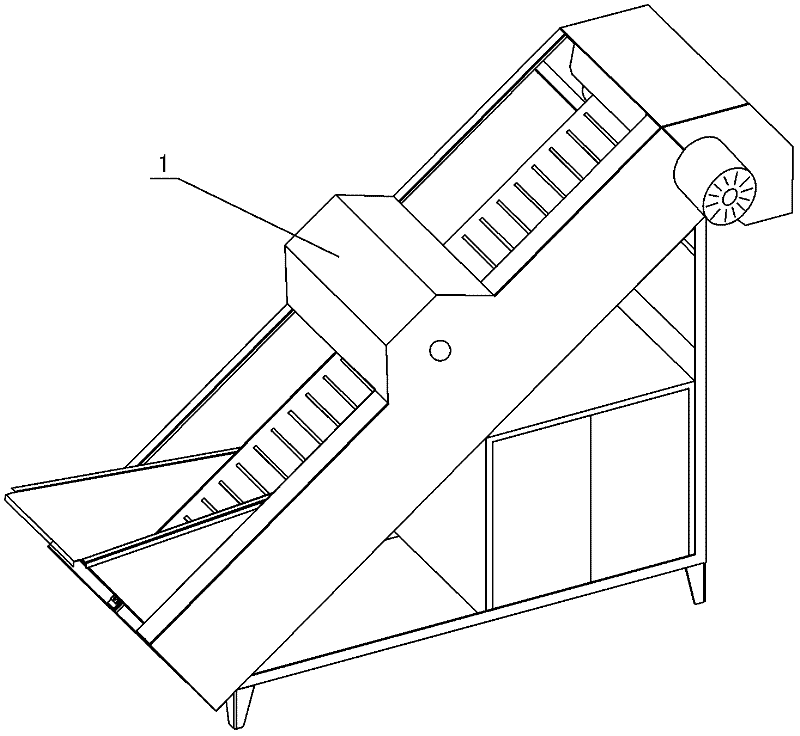

[0032] in figure 2 In the shown embodiment 2, an automatic tea feeder 1 (see image 3 ), there is a tea cooling elevator 3 between the continuous roller finishing machine and the automatic sorting machine, the automatic sorting machine and the tunnel drying machine (see Figure 4 ), the rest is the same as in Example 1.

Embodiment 3

[0034] In the Maofeng tea automated production equipment of Example 3, the front section of the support plate of the tunnel-type baking machine is a slowly rising inclined structure in the moving direction of the tea conveyor belt, and the rear section of the support plate is in a horizontal state and is in line with the front section of the support plate. Smooth connection, the length ratio between the front section of the support plate and the rear section of the support plate is 3.6 to 1, and the angle between the front section of the support plate and the horizontal plane is 3.5 degrees (see Figure 7 ), the rest is the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com