Device for suppressing pulsated impact of slurry flow in concrete pump vehicle

A concrete pump truck, pulsating impact technology, applied in the direction of unloading device, gas/liquid distribution and storage, pipeline system, etc., can solve the problems of damage to the boom mechanism, low natural frequency of the system, strong vibration of the boom, etc., to achieve convenient Maintenance, simple and compact structure, and the effect of suppressing boom vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

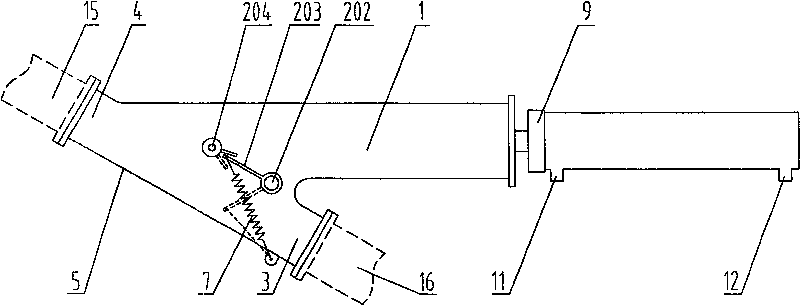

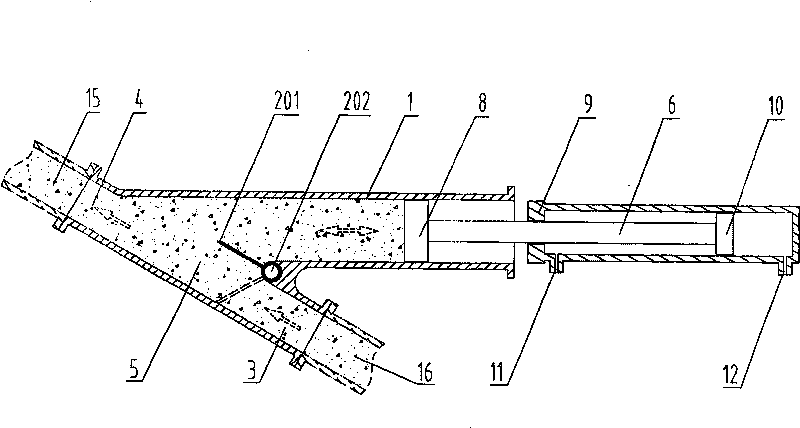

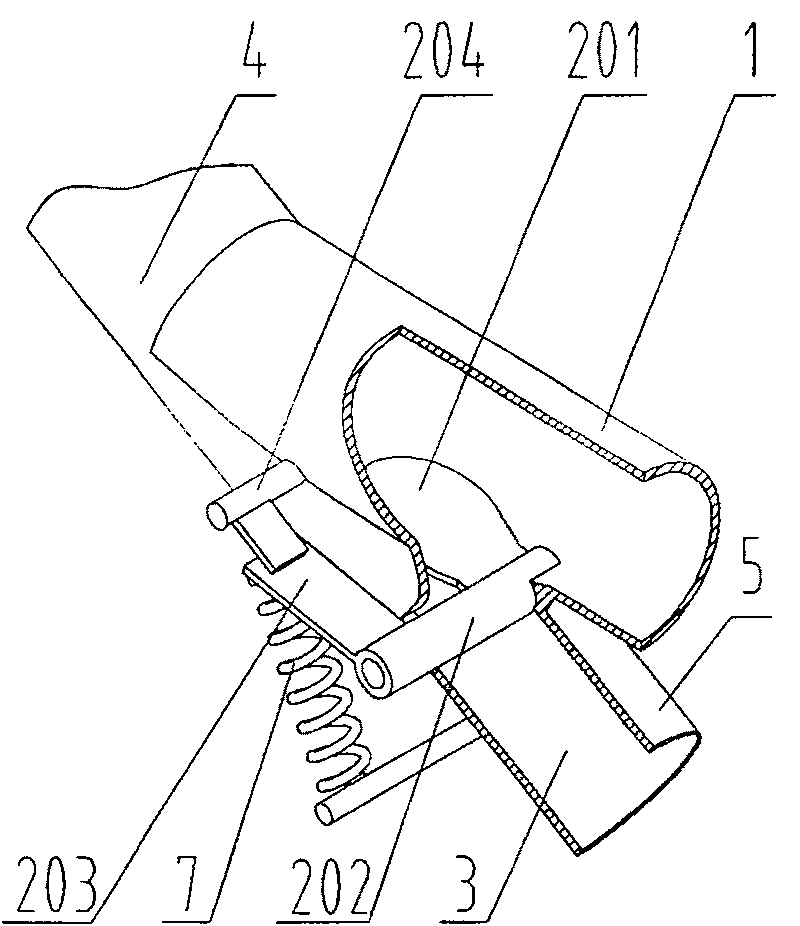

[0051] Embodiment 1: as figure 1 , figure 2 and image 3As shown, the present invention is used for suppressing the device of the pulsation impact of mixing fluid in the concrete pump truck, and it comprises feeding passage 5, feeding cylinder 1 and control mechanism, feeding cylinder 1 is kept in communication with feeding passage 5, feeding cylinder 1 is provided with a feeding piston 8 and a feeding piston rod 6, the feeding piston rod 6 is connected with the control mechanism, and there is a valve between the feeding cylinder 1 and the feeding port 3 of the feeding channel 5 to prevent the backflow of the mixed slurry fluid. On-off valve. The inner diameter of feeding cylinder 1 is different from the inner diameter of feeding port 3 and discharging port 4, so as to ensure that the feeding cylinder 1 can not be closed when the on-off valve is overturned. The feeding channel 5 and the feeding port 3 are connected with the lower feeding pipe 16 at the hopper end of the c...

Embodiment 2

[0054] Embodiment 2: The structure of this embodiment is roughly the same as that of Embodiment 1, except that the on-off valve is a rotary valve located in the delivery passage 5, and the rotary valve includes a rotary valve body 205 and a rotary shaft 206, which rotate The shaft 206 is installed on the material delivery channel 5, and the rotary valve body 205 is installed on the rotary shaft 206. The rotary valve body 205 can rotate with the rotary shaft 206 to complete the opening and closing of the material delivery channel 5. see Figure 6 and Figure 7 As shown, the rotary valve body 205 is hemispherical or spherical. When the feed port 3 feeds and the feeding piston 8 absorbs the material, the rotary valve body 205 rotates under the drive of the rotating shaft 206, and the material delivery channel 5 is opened to feed the material. An accommodating portion for a rotary valve body 205 can be provided on the inner side wall of the channel 5; when the feeding port 4 stop...

Embodiment 3

[0055] Embodiment 3: The structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that the on-off valve is a flat valve 208, a chute 51 is provided on the delivery channel 5, and the flat valve 208 is inserted in the chute 51 . see Figure 9 and Figure 10 As shown, the flat valve 208 is provided with a communication hole 207, and the flat valve 208 can slide freely in the chute 51 on the feeding channel 5. The connecting hole 207 on the top is kept in communication with the feeding channel 5. When the feeding port 3 stops feeding and the feeding piston 8 sucks the material, the flat valve 208 slides in the direction shown by the arrow in the figure to close a section of the feeding port 3. Delivery channel 5. see Figure 11 As shown, the flat valve 208 can slide freely in the chute 51 on the feeding passage 5, and when the feeding port 3 feeds and the feeding piston 8 sucks the material, the flat valve 208 withdraws from the feeding pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com