Self-circulation drying device

A drying device and drying chamber technology, which is applied to drying gas arrangement, drying solid materials, non-progressive drying machine, etc. Improved drying efficiency and space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

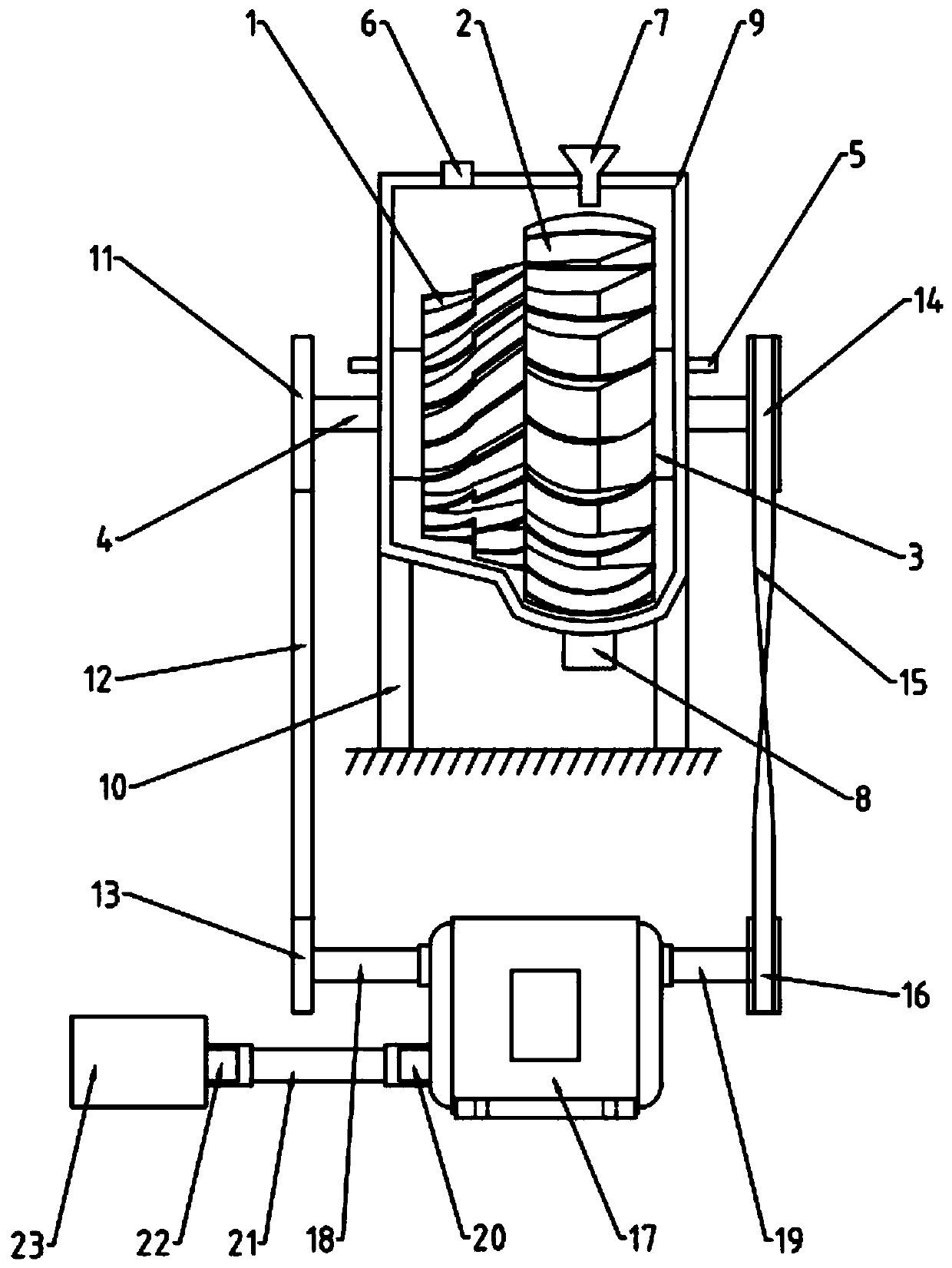

[0032] see figure 1 , figure 1 It is a self-circulating drying device of this embodiment, including a drying chamber 9 and a bracket 10, a first runner 1 and a second runner 2 are arranged in the drying chamber 9, and a material injection port 7 is arranged above the drying chamber 9 And the exhaust port 6, the air inlet 5 is provided on the side, and the discharge port 8 is provided below. When the laboratory needs to quickly dry the polymer, the material is injected into the second runner 2 in the drying chamber 9 from the injection port 7, and then the material will be carried out on the first runner 1 and the second runner 2. Twirl in a circular motion to dry.

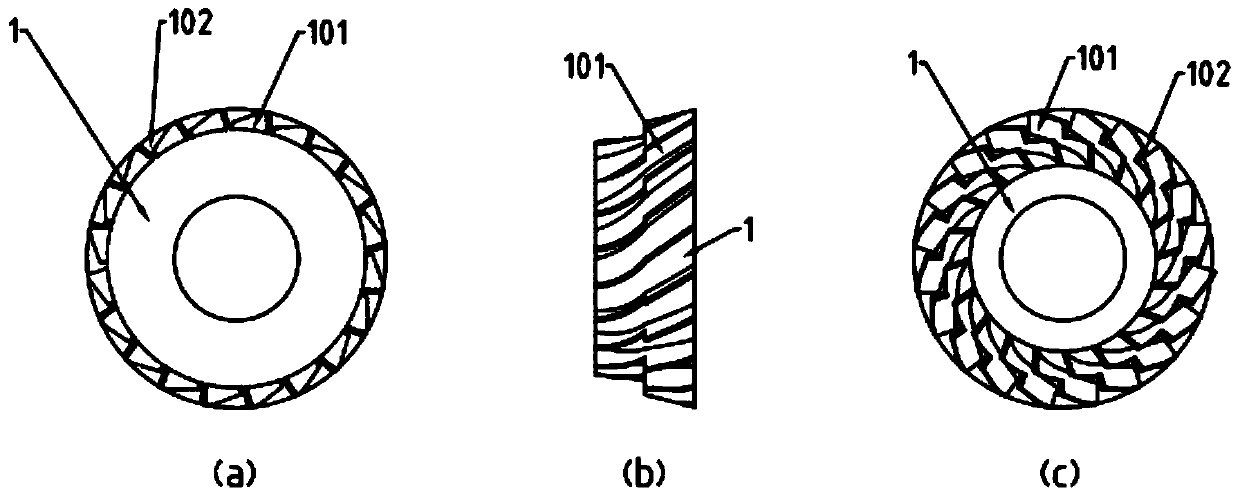

[0033] Combine below figure 2 , figure 2 It is a structural schematic diagram of the first runner 1. The diameters of the two end surfaces of the first runner 1 are different, and the whole is a conical structure. Several first baffles 101 are arranged on the outer surface of the first runner 1, adjacent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com