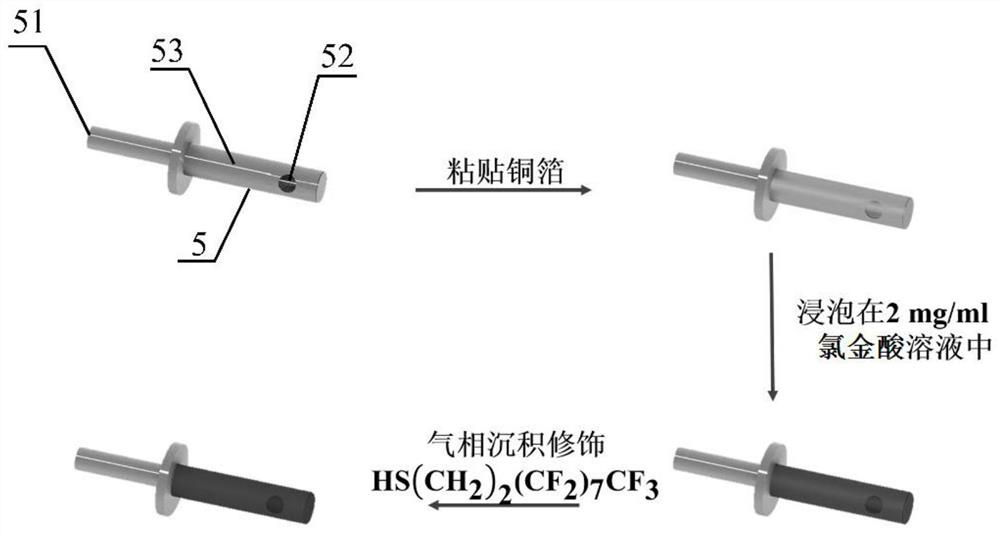

A Method for Enhancing Mixing Performance in Rotating Packed Beds Based on Liquid Distributors with Superhydrophobic Surfaces

A liquid distributor and rotating packed bed technology, applied in the field of reactors, can solve the problems of small liquid flow, insufficient mixing between liquids, and reduced liquid turbulence, so as to achieve enhanced liquid flow velocity, improved mixing effect, and improved mixing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

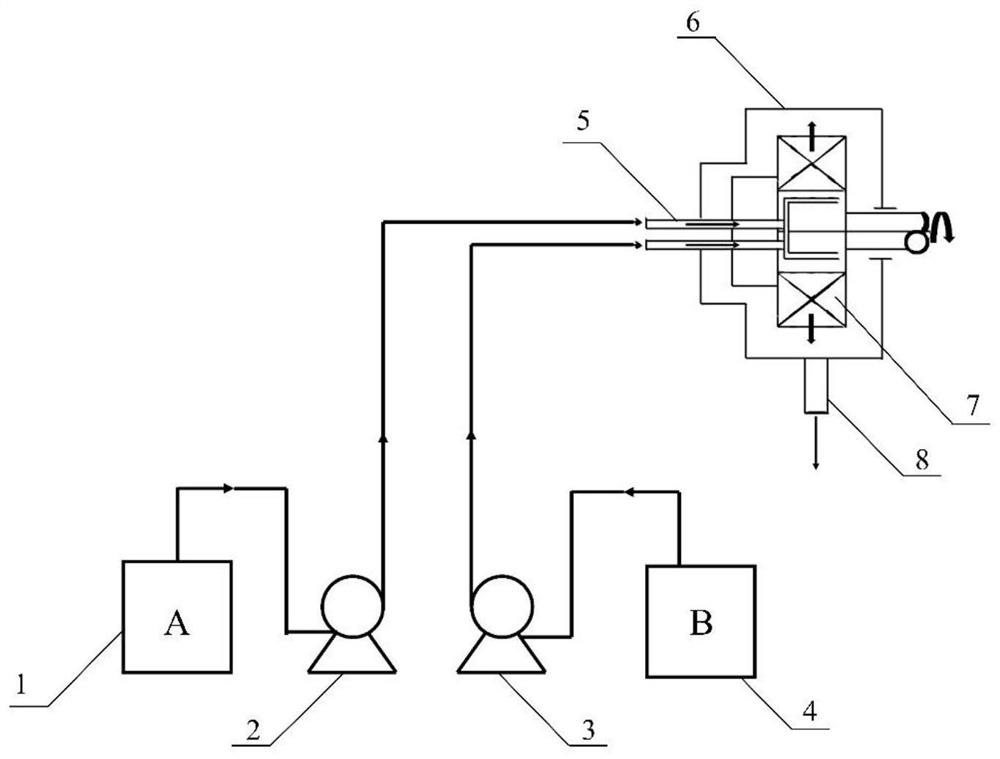

[0049] use figure 1 In the process shown, the two solutions A and B are stored in the liquid storage tanks 1 and 4 respectively, and are introduced into the liquid distributor 5 by the pumps 2 and 3, and the liquid is sprayed into the inner cavity of the rotating packed bed 6 through the liquid distributor. Under the shear action of packing 7, it finally flows out from liquid outlet 8.

[0050] Among them, solution A is sodium carbonate solution, solution B is calcium chloride solution, the concentration is 0.05M, the flow rate of the two solutions is 3.6mL / min, the volume flow ratio is 1:1, and the rotation speed is 600rpm. The influence of the liquid distributor with hydrophobic coating on the average particle size of calcium carbonate, the results are as follows Figure 5 shown.

Embodiment 2

[0056] use figure 1 As shown in the process, solution A is a mixed solution of boric acid, sodium hydroxide, potassium iodide, and potassium iodate. The concentration is 0.03M, the liquid flow rate is 3.6mL / min, the rotational speed is 600rpm, and the volume flow ratio of the two reaction solutions is 1:1.

[0057] Parallel competing reactions occur when the two solutions are mixed, and the chemical reaction equations involved are as follows:

[0058]

[0059]

[0060]

[0061] Hydrogen ion is the competing component, boric acid is the main product, and iodide triion is the by-product. Formula 1 is an acid-base neutralization reaction, which is a transient reaction, and its reaction rate constant is much greater than that of the fast reaction of Formula 2. Under ideal mixing conditions, hydrogen ions are uniformly dispersed in the solution and only react with borate to form boric acid. However, in the case of non-ideal mixing, uneven mixing will lead to too high lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com