Mobile phone module production line

A mobile phone module and production line technology, applied in conveyors, mechanical conveyors, telephone communication, etc., can solve the problems of easy fatigue of inspectors, inability to work continuously, and reduce production efficiency, so as to improve disassembly efficiency and product quality. efficiency, improve production efficiency, and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

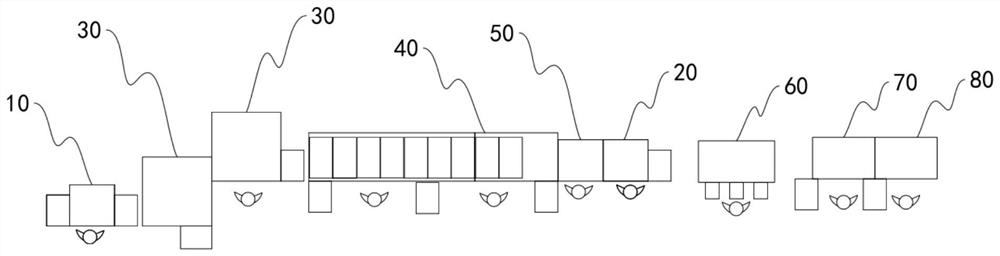

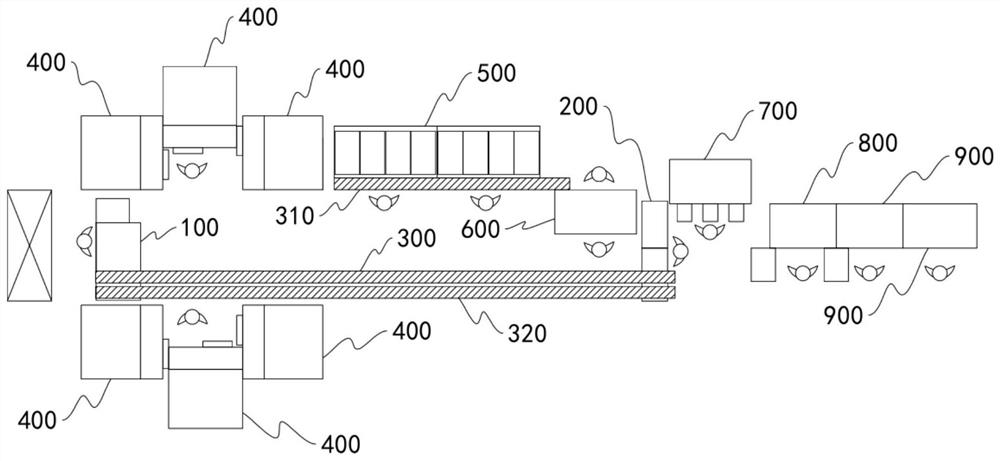

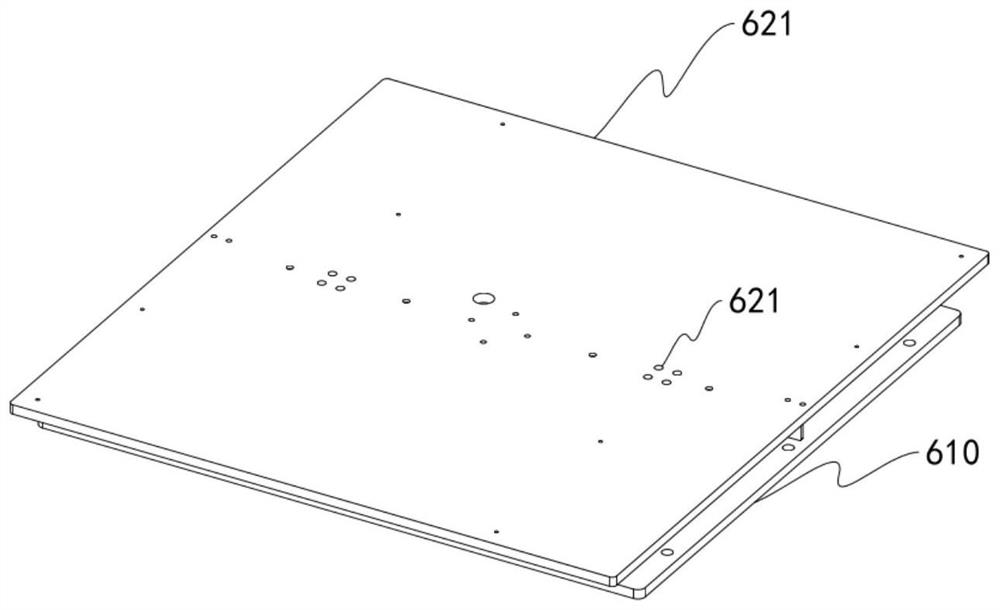

[0026] Such as figure 2 As shown, a mobile phone module production line includes a mobile phone module fixture installation station, a mobile phone module fixture disassembly station, and a first output conveyor belt connecting the mobile phone module fixture installation station and the mobile phone module fixture disassembly station. The two sides of the mobile phone module fixture installation station are respectively provided with a plurality of mobile phone module portrait test stations, and one side of the first output conveyor belt is located between the mobile phone module portrait test stations and the mobile phone module fixture dismantling station. A plurality of touch screen characteristic test stations are arranged between the positions, and a mobile phone backlight module lighting test station is arranged between the plurality of touch screen characteristic test stations and the mobile phone module fixture disassembly station, and the plurality of touch screen ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com